Research Advances in mRNA Vaccine Manufacturing Processes

Jianyao Sun

College of Agriculture, Yanbian University, Yanji City, Jilin, China

Keywords: mRNA Vaccines, Lipid Nanoparticles (LNPs), Manufacturing Process.

Abstract: The rapid development and deployment of mRNA vaccines have revolutionized the field of vaccinology,

particularly highlighted by their pivotal role in combating the COVID-19 pandemic. This review

systematically explores the technological advancements in mRNA vaccine production, emphasizing key

processes such as plasmid DNA (pDNA) preparation, in vitro transcription (IVT), mRNA purification, and

lipid nanoparticle (LNP) encapsulation. Innovations in nucleotide modification, codon optimization, and LNP

formulation have enhanced mRNA stability, translation efficiency, and delivery precision. Despite these

breakthroughs, challenges persist, including scalability limitations, batch variability in IVT and LNP

production, intellectual property disputes, and the need for harmonized regulatory frameworks. Emerging

delivery systems—such as polymer-based carriers, inorganic nanomaterials, and peptide derivatives—offer

promising alternatives to LNPs, potentially improving tissue targeting and reducing immunogenicity.

Furthermore, the application of mRNA technology extends beyond infectious diseases to cancer

immunotherapy and protein replacement therapies. The review underscores the importance of standardized

quality control protocols, sustainable supply chains, and global collaboration to address manufacturing

bottlenecks and ensure equitable access. By resolving these challenges, mRNA vaccines are poised to become

a cornerstone of 21st-century medicine, offering versatile solutions for evolving health crises.

1 INTRODUCTION

1.1 Type Area Introduction

The advent of mRNA vaccines represents a paradigm

shift in biomedical innovation, combining rapid

development cycles, precise antigen design, and

adaptable manufacturing processes to address global

health challenges. Since the discovery of mRNA’s

role as a protein synthesis template in the 1960s,

decades of research have focused on overcoming its

inherent instability and inefficient delivery. Early

breakthroughs, such as Wolff et al.’s 1990

demonstration of in vivo protein expression via

injected naked mRNA, highlighted its therapeutic

potential but underscored the need for robust delivery

systems (Wolff et al., 2020). The emergence of lipid

nanoparticles (LNPs) in the 2010s revolutionized

mRNA technology by enabling efficient cytoplasmic

delivery while enhancing stability and reducing

immunogenicity. These advancements paved the way

for mRNA vaccines to transition from experimental

platforms to clinical reality, exemplified by the rapid

deployment of COVID-19 vaccines like BNT162b2

and mRNA-1273 during the pandemic (Teo et

al.,2022.). Their success, however, hinged on

establishing robust manufacturing frameworks

capable of producing these genetic vaccines at

unprecedented scales.Central to mRNA vaccine

production is a multi-step process that begins with

plasmid DNA (pDNA) template preparation. pDNA,

amplified in bacterial hosts, undergoes linearization

and serves as the blueprint for in vitro transcription

(IVT). During IVT, RNA polymerase synthesizes

mRNA strands incorporating modified nucleotides

(e.g., pseudouridine) to minimize innate immune

activation. Subsequent purification steps, including

tangential flow filtration and chromatographic

methods, remove enzymatic residues and ensure

mRNA integrity. The final formulation relies on

LNPs, which encapsulate mRNA via microfluidic

mixing, optimizing particle size and encapsulation

efficiency. Each stage demands stringent quality

control, from verifying pDNA supercoiling ratios to

assessing 5’ capping efficiency and poly(A) tail

length, as outlined by regulatory bodies like the FDA

and NMPA (Verbeke et al., 2021). Despite having

these advances, challenges still remain. Scalability

458

Sun, J.

Research Advances in mRNA Vaccine Manufacturing Processes.

DOI: 10.5220/0014499200004933

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Biomedical Engineering and Food Science (BEFS 2025), pages 458-464

ISBN: 978-989-758-789-4

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

remains hindered by the lack of standardized

protocols for large-scale IVT and LNP formulation.

Patent disputes over critical components, such as

ionizable lipids, further complicate global

accessibility. Additionally, long-term stability studies

and harmonized regulatory frameworks for

intermediate products are urgently needed to ensure

batch consistency. Innovations in alternative delivery

systems—such as polymer-based carriers or

inorganic nanoparticles—and advancements in codon

optimization algorithms promise to address these

gaps. Beyond infectious diseases, mRNA platforms

are being repurposed for cancer immunotherapy and

protein replacement therapies, underscoring their

versatility. This review examines the technological

milestones in mRNA vaccine production, analyzes

current bottlenecks, and explores future directions to

enhance manufacturability, safety, and therapeutic

scope.

2 mRNA VACCINES

2.1 Introduction to the Background of

mRNA Vaccines

In 1961, research revealed that mRNA could serve as

a direct template guiding protein biosynthesis

(BRENNER et al.,1961, SMULL et al.,1962) In 1963,

Isaacs et al. (ISAACS et al., 1963.) discovered that

mRNA could induce the production of interferon.

mRNA can induce the production of interferon;

however, due to its inherent instability, it was not

until 1969 that Lockard and Lingrel successfully

synthesized proteins using isolated mRNA in vitro

(Lockard et al.,1969). In 1990, Wolff et al. (Wolff et

al., 1990) injected naked mRNA obtained through in

vitro transcription directly into the skeletal muscle of

mice, leading to the successful expression of the

corresponding protein in the mice and the generation

of an immune response. This groundbreaking

experiment laid the foundation for further research

into the therapeutic potential of mRNA.

2.1.1 Classification of mRNA Vaccines

mRNA can be classified into two categories based on

genetic characteristics: non-replicating mRNA and

self-amplifying mRNA (saRNA).

Non-replicating mRNA, in addition to containing

a 5' cap structure, a 5' untranslated region (5'-UTR), a

3' untranslated region (3'-UTR), and a Poly(A) tail,

solely encodes the target antigen.(Furuichi et

al.,1975)mRNA technology primarily encompasses

sequence design, delivery system construction, in

vitro transcription (IVT), and formulation

development. The complete molecular structure of

mRNA includes an open reading frame (ORF) that

encodes the target protein, flanked by 5'UTR and

3'UTR regions, a 5' cap structure (or its substitute),

and a 3' sequence [such as a poly(A) tail].Each

component has its own function, and the components

can work in an organic and coordinated manner to

jointly regulate the translation efficiency, stability,

and immunogenicity of mRNA within the body (Zong

et al.,2023, Sahin et al.,2014, Lu et al.,2024).

2.2 The Production Process of mRNA

Vaccines

The production of mRNA active pharmaceutical

ingredients (APIs) primarily involves two

fundamental steps: upstream enzymatic processes

and downstream chromatographic and ultrafiltration

purification. The upstream enzymatic processes

mainly include three enzymatic reactions: plasmid

DNA linearization, mRNA in vitro transcription, and

template DNA digestion. The downstream process

begins with the collection of in vitro transcription

(IVT) reaction products and primarily includes

dilution with nuclease-free water, chromatographic

purification, ultrafiltration diafiltration concentration,

filtration, and filling. The production of mRNA

formulations mainly involves the preparation and

encapsulation of lipid nanoparticles (LNPs), followed

by sterile filtration and formulation filling (Teo et al.,

2022). The specific production process for mRNA

vaccines can be divided into five steps: ①

Preparation of plasmid DNA (pDNA), which includes

the production and purification of pDNA. ② IVT and

modification. First, linearize the pDNA, then use the

linearized plasmid DNA as a template to transcribe

and synthesize mRNA in a cell-free system.

Nucleotide modification can be applied to enhance

the functionality of the mRNA. ③ Filtration and

purification of mRNA. This primarily involves

exchanging the buffer to remove impurities such as

enzymes and nucleotides. ④ Preparation and

encapsulation of LNPs. Currently, microfluidic

mixing technology is primarily used to precisely mix

the mRNA bulk solution with LNPs in a specific

ratio, thereby forming uniformly sized lipid

nanoparticles that encapsulate the mRNA. After steps

such as ultrafiltration and buffer exchange to remove

impurities, the intermediate product of mRNA-LNPs

formulation is ultimately prepared. ⑤ Filling of

Research Advances in mRNA Vaccine Manufacturing Processes

459

mRNA vaccines. After the intermediate product of

the mRNA-LNP formulation has passed the quality

inspection, it is aseptically filled to obtain the finished

product of the mRNA vaccine (Teo et al.,2022).

2.3 Delivery Vehicles

The main carriers for mRNA drug delivery include

lipid-based materials, polymers, protein derivatives,

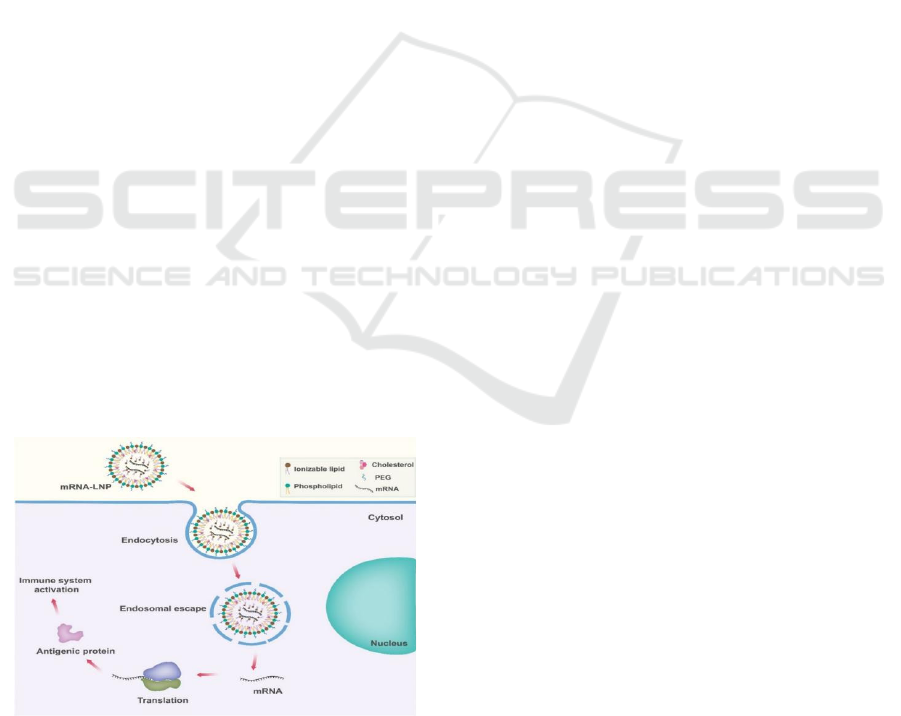

and exosomes. As shown in Figure 1, intracellular

delivery process of mRNA Vaccines (Using LNA-

mRNA Vaccine as an Example): 1. Endocytosis: the

LNA-modified mRNA vaccine, encapsulated in a

lipid nanoparticle (LNP) composed of ionizable

lipid, phospholipid, cholesterol, and PEG, is

internalized by host cells via endocytosis. The

ionizable lipid facilitates membrane interaction,

while PEG stabilizes the nanoparticle and reduces

immune recognition. 2. Endosomal Escape: within

the acidic environment of the endosome, the ionizable

lipid becomes positively charged, destabilizing the

endosomal membrane. This promotes fusion of the

LNP with the endosomal membrane, enabling the

release of the LNA-mRNA into the cytosol.3. LNA-

enhanced Stability and Translation: the incorporation

of Locked Nucleic Acid (LNA) modifications in the

mRNA backbone enhances its stability against

enzymatic degradation and improves translational

efficiency. This ensures prolonged availability of

intact mRNA in the cytosol.4. Translation of

Antigenic Protein: the released mRNA is recognized

by ribosomes, which translate it into the antigenic

protein (e.g., viral spike protein). No nuclear entry is

required, as mRNA vaccines function entirely in the

cytosol.5. Immune Activation: the antigenic protein

is processed and presented on major

histocompatibility complex (MHC) molecules,

Figure 1: This Diagram Illustrates the Mechanism of

mRNA-LNP Vaccines, Highlighting Key Steps from

Cellular Uptake to Immune Activation.

activating adaptive immune responses (T cells and B

cells). This primes the immune system to recognize

and neutralize future pathogen exposure.

2.3.1 Liposomes and Lipid Complexes

Lipid nanoparticles (LNPs) are commonly used

advanced mRNA delivery carriers. Their emergence

is a key factor in advancing the approval of mRNA

vaccines and has also provided a direction for other

mRNA therapeutic fields (Kimura et al., 2020).

Although mRNA-based therapies possess the a

forementioned advantages, mRNA also faces

challenges such as poor stability and difficulty in

entering the cytoplasm to exert its function

(Kubiatowicz et al., 2022). Therefore, an appropriate

delivery carrier is crucial for mRNA therapy. Lipid

nanoparticles (LNPs) are the most widely used

carriers for nucleic acid drugs in clinical applications.

It can deliver mRNA to the cytoplasm to express

target proteins. Compared to other delivery carriers,

LNP has many advantages such as high encapsulation

efficiency, high transfection efficiency, simple

preparation, stable structure, and good safety (Cullis

et al., 2017, Eygeris et al., 2022). LNPs comprise four

lipids: ionizable, helper, cholesterol, and

PEGylated—each vital for stability, transfection, and

safety (Zong et al., 2023). Ionizable lipids (primary

component) are neutral at physiological pH but

protonate in acidic conditions, enabling electrostatic

mRNA encapsulation during self-assembly (Hald

Albertsen et al., 2022). In serum (neutral pH),

uncharged LNPs avoid protein binding, reducing

macrophage uptake and prolonging circulation. This

pH-responsive charge lowers toxicity versus

permanent cationic lipids. In endosomes, acid-

induced positivity enhances endosomal membrane

interaction, driving mRNA cytoplasmic release and

boosting transfection efficiency (Samaridou et al.,

2020). Helper lipids (primarily phospholipids)

stabilize LNPs and promote endosomal membrane

fusion for mRNA release. Common phospholipids

include DSPC (high phase transition temperature,

enhancing stability) and DOPE (cone-shaped

structure, driving hexagonal phase formation to boost

mRNA transfection efficiency) (Ahmed et al.,

2019). Cholesterol, the second most abundant LNP

component, localizes in the outer shell. It improves

stability, prolongs blood circulation, and increases

membrane fluidity/permeability to facilitate mRNA

release (Sebastiani et al., 2021).

BEFS 2025 - International Conference on Biomedical Engineering and Food Science

460

2.3.2 High Molecular Weight Polymers

Polymer carriers themselves are easy to prepare, and

fine-tuning their surface properties can achieve the

desired effects, promoting cross-presentation of

antigens. Modifying the surface of polymeric

nano/microspheres can mediate targeted delivery to

immune cells, enhancing antigen utilization and

activating the immune system with lower antigen

doses (Malla et al., 2024). Polymer nanocarrier

materials can be categorized into synthetic

macromolecular polymers and natural polymers.

Synthetic polymers are polymer materials

synthesized through chemical methods, which can be

custom-designed according to specific requirements.

Common synthetic macromolecular polymers include

polyethylene, polypropylene, and polystyrene,

among others. These materials are characterized by

their ease of synthesis, low cost, and lack of

immunogenicity (Charbe et al., 2020).

2.3.3 Protein/Peptide Derivative-mRNA

Complex

Peptide/protein vaccines represent one of the most

common types of vaccines, offering advantages such

as well-defined antigenic sequences, low production

costs, and ease of preparation (Mai et al., 2020). Lou

et al. (Lou et al., 2019) developed a straightforward

method for peptide-functionalized mRNA polyplexes

to enhance dendritic cell presentation of mRNA

antigens, demonstrating high cellular uptake and no

cytotoxicity. Mai et al. (Mai et al., 2020) constructed

a delivery carrier based on protamine, which prevents

mRNA degradation, promotes antigen presentation

by antigen-presenting cells, and simultaneously

induces anti-tumor immune responses. Lin et al. (LIN

et al.,2022) developed a novel compound by

conjugating peptides with protoporphyrin for targeted

therapy and photodynamic therapy. Such

formulations provide a strong foundation for the

development of mRNA vaccine delivery systems.

3 mRNA VACCINE

PRODUCTION

3.1 Synthesis of mRNA Fragments

Currently, there are multiple methods for preparing

DNA transcription templates for mRNA vaccines,

such as templates produced using PCR technology or

non-linearized plasmids containing terminator

sequences. These drug templates can be amplified

and expanded in host cells, such as E. coli. However,

in all cases, each batch of DNA plasmids used for the

production of mRNA vaccines must undergo release

testing to confirm their sequence, purity, and quality

(Naveed et al.,2023). For the quality control of

transcription template plasmid DNA, specific

requirements have been outlined in the latest

guideline documents issued by China's NMPA, the

WHO, and the U.S. FDA. The pre-release testing of

plasmid DNA primarily includes five quality control

aspects: identification, concentration, purity, safety,

and others. Each aspect encompasses corresponding

testing items. Regarding the detection of the

percentage of supercoiled content for plasmid DNA

purity, the second edition of the draft guidance issued

by the USP in 2023 has included this item in the pre-

release testing of plasmid DNA. However, the NMPA

and WHO have not yet proposed requirements for this

specific test. The guideline documents from various

countries also recommend corresponding testing

methods, summarized as follows: for the

identification of plasmid DNA, methods include

direct sequencing, next-generation sequencing

(NGS), and restriction enzyme agarose gel

electrophoresis analysis; The detection methods for

the concentration and purity of plasmid DNA include

ultraviolet spectroscopy (UV), among others.The

detection methods for the superhelical percentage

content include capillary electrophoresis (CE) and

high-performance liquid chromatography (HPLC),

among others. The detection methods for host RNA

residual content include agarose gel electrophoresis

and HPLC, among others. The detection methods for

host DNA template residual content include

quantitative real-time PCR (qPCR) Baden et al.,2021,

Liu et al., 2022, Verbeke et al., 2021, Cortese et al.,

2024).

3.2 mRNA Production and

Optimization

The plasmid DNA template is enzymatically

linearized and purified, then used to synthesize

mRNA through in vitro transcription in a cell-free

system. After further purification, the mRNA stock

solution is obtained. Due to the degeneracy of the

genetic code, mRNA can be optimized in terms of

codon usage to achieve more efficient translation and

enhanced stability. Furthermore, modified

nucleotides can be utilized to reduce the

immunogenicity of mRNA, suppress innate immune

activation, and mitigate adverse effects such as

Research Advances in mRNA Vaccine Manufacturing Processes

461

inflammation (Maruggi et al., 2019). The 5' cap can

be introduced co-transcriptionally by adding a

capping reagent to the IVT (in vitro transcription)

mixture. The 3' poly(A) tail can be added

enzymatically or encoded directly within the DNA

template. Therefore, the release testing of mRNA

stock solutions should include specific assessments

such as the 5' capping efficiency and the length of the

3' poly(A) tail (US Pharmacopeia et al., 2023).

3.3 The Intermediate Product of the

Formulation

The NMPA (National Medical Products

Administration) has introduced the concept of

intermediate products in formulations and

emphasized that the definition of these intermediates,

as well as the establishment of quality standards for

them, should be based on the actual conditions of the

mRNA delivery system preparation process. These

intermediates may include products resulting from

the complexation of mRNA with positively charged

polymer materials, nanoparticle intermediates, and

others. The NMPA also pointed out that the testing of

intermediate products is part of process control.

Whether to define a product as an intermediate and

the corresponding testing requirements should

consider the following factors. ①Whether this stage

is the most sensitive phase for the corresponding

testing items. ②Whether subsequent production

processes and formulation compositions have an

impact on the active components, such as whether

lyophilization is performed.③Whether subsequent

process steps require testing at this stage, such as

using the content of active ingredients to guide

formulation preparation (Baden et al., 2021).

3.4 mRNA Vaccine Final Product

After precise mixing of mRNA original solution and

lipid nanoparticles (LNPs) and other delivery systems

in a certain proportion through jet impact mixing

method, microfluidic mixing method and other

technologies, nanoliposomes encapsulating mRNA

with uniform particle size are formed. After that,

through steps such as ultrafiltration and buffer

exchange to remove impurities, and then adding

buffer, sugars, and dispersants, followed by quality

inspection, aseptic filling is carried out to obtain the

final product of mRNA vaccine (Naveed et al.,2023).

4 APPLICATIONS OF mRNA

VACCINES

The COVID-19 pandemic, caused by the SARS-

CoV-2 virus, continues to persist, exerting a

significant impact on human health and the global

economy. Vaccines represent the primary approach to

combating the COVID-19 pandemic. According to

data released by the World Health Organization on

January 24, 2023, there are over 300 COVID-19

vaccine candidates globally, with 176 of them having

entered the clinical trial phase. Leveraging the

advantages of mRNA vaccines in preventing

infectious diseases, COVID-19 mRNA vaccines were

rapidly developed and iterated during the pandemic,

making significant contributions to the fight against

COVID-19. The Biologics License Application

(BLA) was also approved in the US in August 2021,

making it the first mRNA vaccine to be launched

globally. Moderna’s mRNA-1273 (Spikevax) was

granted an Emergency Use Authorization (EUA) in

the US in December 2020, with its Biologics License

Application (BLA) being approved in the US on

February 1, 2022, becoming the second mRNA

vaccine to be launched globally. AWcorna, co-

developed by the Academy of Military Medical

Sciences, Suzhou Abio Biology, and Yunnan Walvax

Biology, was granted an EUA in Indonesia in

September 2022, marking the first EUA obtained by

China overseas. SYS6006 from China

Pharmaceutical Group was granted an EUA in China

in March 2023, becoming the first of its kind in the

country (Cheng et al., 2020).

5 CHALLENGES AND

PROSPECTS IN mRNA

VACCINE PRODUCTION

With the advancement of technology, researchers

have developed some new quality control methods

and strategies. For instance, Packer et al., created a

kinetic model for predicting the shelf life of mRNA

vaccines and utilized this model to estimate the

expiration period of mRNA vaccines (Packer et al.,

2021). BioNTech has developed a ribozyme-based

method combined with denaturing polyacrylamide

gel electrophoresis or liquid chromatography and

mass spectrometry to quantitatively analyze and

detect the capping efficiency of in vitro transcribed

mRNA (Vlatkovic et al., 2022). The production

BEFS 2025 - International Conference on Biomedical Engineering and Food Science

462

of mRNA vaccines, from plasmid templates to final

filling, lacks standardized scale-up and quality

control, posing challenges in manufacturing. In

China, mRNA vaccine development focuses on

COVID-19, with expansion into vaccines for other

infectious diseases (e.g., RSV, influenza) and cancer.

Patent limitations in sequence design and delivery

systems, along with the need for localized raw

materials and equipment, hinder progress. Despite

these challenges, mRNA vaccines show promise in

infectious disease prevention, cancer vaccines, and

protein replacement therapies. In summary, mRNA

vaccines have significant potential in

immunotherapy, relying on stable synthesis,

immunogenicity regulation, and effective delivery

systems. They enhance our ability to combat

infectious diseases and offer new approaches in

cancer treatment by optimizing existing therapies

(Packer et al., 2021). However, addressing ethical,

regulatory, and societal acceptance issues is crucial to

ensure their safe and responsible contribution to

human health and scientific progress.

6 CONCLUSION

The evolution of mRNA vaccine manufacturing has

been marked by transformative innovations, from

nucleotide modifications to LNPs, enabling

unprecedented speed and precision in vaccine

development. The COVID-19 pandemic catalyzed

the industrialization of these technologies, proving

their viability in global health crises. However,

scalability and standardization challenges—such as

inconsistent IVT yields and LNP batch variability—

highlight the need for automated, closed-loop

production systems and universal quality

benchmarks. Regulatory agencies must prioritize

harmonizing guidelines for intermediate products,

particularly mRNA-LNP complexes, to streamline

commercialization. Future progress hinges on

diversifying delivery platforms, such as peptide-

based carriers or stimuli-responsive nanomaterials, to

improve tissue targeting and reduce off-target effects.

Equally critical is addressing intellectual property

barriers and fostering open-access collaborations to

democratize mRNA technology. Investments in

sustainable raw material supply chains and localized

manufacturing infrastructure will enhance global

equity, particularly for low-resource regions. As

mRNA platforms expand into oncology and genetic

disorders, rigorous long-term safety assessments and

public education initiatives are essential to build trust.

In summary, mRNA vaccines epitomize the

convergence of molecular biology and

bioengineering, offering a dynamic toolset against

evolving pathogens and complex diseases. By

resolving existing technical and logistical hurdles,

this technology can fulfill its promise as a cornerstone

of 21st-century medicine.

REFERENCES

Ahmed, K. S. 2019. Liposome: composition,

characterisation, preparation, and recent innovation in

clinical applications. Journal of drug targeting, 27(7),

742–761.

Baden, L. R. 2021. Efficacy and Safety of the mRNA-1273

SARS-CoV-2 Vaccine. The New England journal of

medicine, 384(5), 403–

416. https://doi.org/10.1056/NEJMoa2035389

Brenner, S. 1961. An unstable intermediate carrying

information from genes to ribosomes for protein

synthesis. Nature, 190, 576–581.

Charbe, N. B. 2020. Small interfering RNA for cancer

treatment: overcoming hurdles in delivery. Acta

pharmaceutica Sinica. B, 10(11), 2075–2109.

Cheng, Q. 2020. Selective organ targeting (SORT)

nanoparticles for tissue-specific mRNA delivery and

CRISPR-Cas gene editing. Nature nanotechnology,

15(4), 313–320.

Cortese, S. 2024. Psychopharmacology in children and

adolescents: unmet needs and opportunities. The lancet.

Psychiatry, 11(2), 143–

154. https://doi.org/10.1016/S2215-0366(23)00345-0

Cullis, P. R. 2017. Lipid Nanoparticle Systems for Enabling

Gene Therapies. Molecular therapy, 25(7), 1467–1475.

Eygeris, Y. 2022. Chemistry of Lipid Nanoparticles for

RNA Delivery. Accounts of chemical research, 55(1),

2–12.

Furuichi, Y. 1975. A blocked structure at the 5' terminus of

mRNA from cytoplasmic polyhedrosis virus. Nature,

253(5490), 374–375.

Hald Albertsen, C. 2022. The role of lipid components in

lipid nanoparticles for vaccines and gene therapy.

Advanced drug delivery reviews, 188, 114416.

Isaacs, A., & Cox, R. A. 1963. Foreign nucleic acids as the

stimulus to make interferon. Lancet, 2(7299), 113–116.

Kimura, N. 2020. Development of a Microfluidic-Based

Post-Treatment Process for Size-Controlled Lipid

Nanoparticles and Application to siRNA Delivery.

ACS applied materials & interfaces, 12(30), 34011–

34020.

Kubiatowicz, L. J. 2022. mRNA nanomedicine: Design and

recent applications. Exploration, 2(6), 20210217.

Lin, H. X. 2022. An acid-targeting peptide can be used as a

carrier for photodynamic therapy (PDT). Mater Today

Commun, 31, 103659.

Liu, M. A. 2022. WHO informal consultation on regulatory

considerations for evaluation of the quality, safety and

Research Advances in mRNA Vaccine Manufacturing Processes

463

efficacy of RNA-based prophylactic vaccines for

infectious diseases, 20-22 April 2021. Emerging

microbes & infections, 11(1), 384–391.

Lockard, R. E. 1969. The synthesis of mouse hemoglobin

beta-chains in a rabbit reticulocyte cell-free system

programmed with mouse reticulocyte 9S RNA.

Biochemical and biophysical research communications,

37(2), 204–212.

Lou, B. 2019. mRNA Polyplexes with Post-Conjugated

GALA Peptides Efficiently Target, Transfect, and

Activate Antigen Presenting Cells. Bioconjugate

chemistry, 30(2), 461–475.

Lu, C. 2024. Safety, Immunogenicity, and Mechanism of a

Rotavirus mRNA-LNP Vaccine in Mice. Viruses,

16(2), 211.

Mai, Y. 2020. Intranasal delivery of cationic liposome-

protamine complex mRNA vaccine elicits effective

anti-tumor immunity. Cellular immunology, 354,

104143.

Malla, R. 2024. mRNA vaccines and their delivery

strategies: A journey from infectious diseases to cancer.

Molecular therapy, 32(1), 13–31.

Maruggi, G. 2019. mRNA as a Transformative Technology

for Vaccine Development to Control Infectious

Diseases. Molecular therapy, 27(4), 757–772.

Naveed, M. 2023. A one-health approach to design an

mRNA-based vaccine candidate against the lumpy skin

disease virus as an alternative to live-attenuated

vaccines. European review for medical and

pharmacological sciences, 27(13), 6401–6413.

Packer, M. 2021. A novel mechanism for the loss of mRNA

activity in lipid nanoparticle delivery systems. Nature

communications, 12(1), 6777.

Sahin, U. 2014. mRNA-based therapeutics--developing a

new class of drugs. Nature reviews. Drug discovery,

13(10), 759–780.

Samaridou, E. 2020. Lipid nanoparticles for nucleic acid

delivery: Current perspectives. Advanced drug delivery

reviews, 154-155, 37–63.

Sebastiani, F. 2021. Apolipoprotein E Binding Drives

Structural and Compositional Rearrangement of

mRNA-Containing Lipid Nanoparticles. ACS nano,

15(4), 6709–6722.

Shi, S. 2015. VEGFR targeting leads to significantly

enhanced tumor uptake of nanographene oxide in vivo.

Biomaterials, 39, 39–46.

Smull, C. E. 1962. Enhancement of the plaque-forming

capacity of poliovirus ribonucleic acid with basic

proteins. Journal of bacteriology, 84(5), 1035–1040.

Teo, S. P. 2022. Review of COVID-19 mRNA Vaccines:

BNT162b2 and mRNA-1273. Journal of pharmacy

practice, 35(6), 947–951.

Verbeke, R. 2021. The dawn of mRNA vaccines: The

COVID-19 case. Journal of controlled release, 333,

511–520.

Vlatkovic, I. 2022. Ribozyme Assays to Quantify the

Capping Efficiency of In Vitro-Transcribed mRNA.

Pharmaceutics, 14(2), 328.

Wolff, J. A. 1990. Direct gene transfer into mouse muscle

in vivo. Science, 247(4949 Pt 1), 1465–1468.

Yang, A. 2021. Hydrogel/nanoadjuvant-mediated

combined cell vaccines for cancer immunotherapy.

Acta biomaterialia, 133, 257–267.

Zong, Y. 2023. Lipid Nanoparticle (LNP) Enables mRNA

Delivery for Cancer Therapy. Advanced materials,

35(51), e2303261.

BEFS 2025 - International Conference on Biomedical Engineering and Food Science

464