Analysis of Power Quality in Industrial Environments Using

Synchronous Machines: A Case Study

George-Andrei Marin

a

and Marian Gaiceanu

b

Department of Electrical Engineering and Energy Conversion Systems, Faculty of Automation, Computers, Electrical and

Electronics Engineering, “Dunarea de Jos” University of Galati, Romania

Keywords: Power Quality, Synchronous Machine, Power Factor, Reactive Power, PQ Monitoring.

Abstract: This paper investigates the impact of synchronous machines on power quality in industrial environments.

Synchronous machines, widely used in high-power applications, can improve various power quality issues

such as reactive power imbalance, low power factor, and harmonic distortion. This study is focused on the

power quality analysis in a heavy steel industry. As a solution to power quality issues analyses on the 4.2

MW/10 kV synchronous motor operation in a hot strip rolling mill is performed, under variable load

conditions. The main necessary waveforms have been captured over several days, including voltage, current

waveforms, power factor variations, and reactive power levels. To assess total harmonic distortion (THD),

power factor performance, and overall power quality, the collected data has been analyzed. In order to

maintain power quality within acceptable limits, the experimental obtained results show that the reactive

power compensation and power factor correction acts as key points. The paper highlights the need for

continuous monitoring and intelligent control strategies in facilities operating with synchronous machines.

This case study serves as a practical example of how industrial systems can assess and mitigate the adverse

effects of power quality disturbances.

1 INTRODUCTION

Power quality (PQ) is a critical issue in modern

electrical engineering, particularly in industrial

environments where large power demands, complex

machinery, and continuous processes impose

significant challenges on electrical infrastructure.

Power quality (PQ) refers to maintaining voltage,

current, and frequency within prescribed limits to

ensure the reliable operation of electrical equipment.

In industrial environments, power quality is a critical

issue due to the presence of high-power loads, non-

linear devices, and sensitive equipment. Poor power

quality can lead to increased losses, unexpected

equipment shutdowns, inaccurate measurements,

overheating of transformers and cables, and

ultimately, financial loss and reduced productivity

(Bollen, 2000). For energy-intensive industries, such

as steel manufacturing, chemical processing, or

mining, maintaining acceptable PQ levels is essential

a

https://orcid.org/ 0009-0006-5205-132X

b

https://orcid.org/

0000-0003-0582-5709

not only for internal efficiency but also for complying

with international standards and grid codes.

One of the most significant contributors to power

quality issues in industrial systems is the presence of

rotating electrical machines, particularly synchronous

machines. Synchronous Generators provide stable

voltage and frequency when properly regulated; can

supply or absorb reactive power by adjusting

excitation; are sensitive to load changes — transient

behavior can impact PQ. Synchronous machines are

widely used in heavy industries for power generation

in motor regimes due to their ability to regulate

voltage and maintain power factor through excitation

control. However, under certain conditions,

especially in processes with fast load changes or

torque variations, synchronous machines can act as

sources of power disturbances such as voltage sags,

harmonic distortion, flicker, and low power factor

(Akagi, 2005).

Marin, G.-A. and Gaiceanu, M.

Analysis of Power Quality in Industrial Environments Using Synchronous Machines: A Case Study.

DOI: 10.5220/0014368600004848

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences (ICEEECS 2025), pages 219-228

ISBN: 978-989-758-783-2

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

219

Role of Synchronous Machines in Power Quality:

-Synchronous Generators provide stable

voltage and frequency when properly regulated; can

supply or absorb reactive power by adjusting

excitation; are sensitive to load changes — transient

behavior can impact PQ.

- Synchronous motors, often used in high-power

applications (e.g., compressors, crushers), can be

over-excited to act as synchronous condensers,

improving power factor; help stabilize voltage by

injecting reactive power into the system.

- Synchronous condensers operate as standalone

over-excited synchronous machines without

mechanical load; used specifically for voltage

regulation and reactive power compensation;

improve power factor and stabilize weak grids.

Common power quality issues in Industrial

environments could be mentioned as follows: voltage

sags and swells – due to motor starting, faults, or large

load switching; harmonics – from variable frequency

drives (VFDs), arc furnaces, or other non-linear

loads; flicker – from rapidly changing loads;

unbalance – from uneven distribution of single-phase

loads; frequency variations – in isolated industrial

power systems; power factor issues – leading to

inefficiencies and penalties.

This paper focuses on the analysis of power

quality in an industrial setting, centered around a 4.2

MW synchronous machine operating at 10 kV in a hot

strip rolling mill. The steel rolling process is one of

the most energy-intensive and dynamically variable

industrial applications. Sudden mechanical stress,

frequent start/stop cycles, and fluctuating loads

impose transient conditions on the synchronous

motor, often leading to variations in reactive power

demand and harmonic emissions. These disturbances

propagate through the electrical system, influencing

the stability and efficiency of both the local and

upstream network (Ghosh and Ledwich, 2002).

The motivation behind this work is threefold:

• To understand and quantify the contribution

of a large synchronous machine to overall

PQ degradation;

• To assess how current international

standards apply to such installations;

• To propose technical and operational

improvements using modern analysis

techniques and reactive power management

strategies.

A number of standards and regulatory

frameworks govern power quality performance in

industrial and public networks. IEEE 519 (2014)

provides recommended limits for harmonic distortion

(both voltage and current) at the point of common

coupling (PCC), based on system voltage and short-

circuit capacity. The European standard EN 50160

specifies acceptable variations in voltage magnitude,

frequency, flicker, unbalance, and harmonics for

public distribution systems (CENELEC, 2010).

Additionally, IEC 61000-4-30 outlines methods for

measuring power quality parameters in Class A

compliance monitoring systems. In this study,

compliance with these standards serves as a

benchmark for evaluating the observed data.

Beyond regulatory constraints, industries have an

operational incentive to monitor and manage power

quality proactively. Poor PQ can cause excessive

wear on equipment, reduce the lifetime of power

electronics, trip sensitive control systems, and

interfere with communication networks. From an

economic perspective, inefficient use of reactive

power leads to increased energy bills and potential

penalties from utility companies, especially in

countries where reactive energy is billed separately

(IEA, 2019). For a 4.2 MW motor operating

continuously under suboptimal conditions, the

additional energy losses alone can reach tens of

thousands of euros per year.

The technical complexity of managing PQ in

synchronous machine-driven systems lies in the dual

nature of the machine: as both a consumer and

potential source of reactive power, its behaviour

varies depending on excitation level, load torque, and

process dynamics. Under overexcitation, the machine

injects reactive power into the system, potentially

raising voltage beyond acceptable levels. Under

excitation, it consumes reactive power, increasing the

burden on compensation equipment. This requires

tight coordination with capacitor banks,

STATCOMs, or other power electronic devices to

avoid system instability (Arrillaga and Watson,

2003).

One of the modern approaches for PQ

improvement involves advanced monitoring systems

capable of detecting and analysing fast transient

events. Equipment compliant with IEC 61000-4-30

Class A standards allows high-resolution data

logging, real-time harmonic analysis (via FFT), and

event-triggered waveform capture. These features are

essential in rolling mill applications, where load

changes can occur in milliseconds. In this study, a

Class A analyser was installed at the motor terminal,

collecting data over a period of several days during

normal operation and planned stress-testing events.

The data acquisition included measurements of:

• Phase voltages and currents (RMS and

instantaneous),

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

220

• Active (P), reactive (Q), and apparent (S)

power,

• Power factor and displacement power factor,

• Voltage and current THD and individual

harmonic orders,

• Frequency deviations,

• Event logs (sags, swells, transients).

Collected data revealed periods of significant

deviation from IEEE 519 limits, particularly under

load transitions. Power factor fluctuated below 0.85

during start-up, while harmonic distortion of current

reached values above 10% at times—exceeding the

5% limit imposed for systems at 10 kV. Reactive

power fluctuations were also observed, indicating an

unoptimized excitation system. These findings

underline the need for dynamic reactive power

compensation and smarter excitation control

algorithms.

In addition to field measurements, the study

includes a simulation-based analysis using a detailed

model of the synchronous machine and associated

network components. This enables comparative

evaluation of measured and predicted behaviours,

identification of resonances, and testing of mitigation

techniques such as active filters and excitation

controllers. Simulation results confirm the critical

role of machine dynamics in influencing system PQ,

particularly under step changes in mechanical load

and during synchronization sequences.

With the rise of Industry 4.0 and digital twin

technologies, the concept of integrating PQ

monitoring with process control is gaining traction. In

modern industrial plants, the electrical system is no

longer isolated from production objectives—it must

adapt dynamically to load demands, system

configurations, and energy efficiency goals. This

integration requires reliable data, scalable analytics,

and intelligent decision-making frameworks. In this

context, synchronous machines—despite their robust

nature—must be carefully integrated using digital

control systems that account for their PQ impact.

By providing a detailed analysis based on both

field data and simulation, this study contributes to the

growing body of work on power quality in heavy

industry and offers practical recommendations for

engineers, energy managers, and automation

specialists working with high-power rotating

machines. Be advised that papers in a technically

unsuitable form will be returned for retyping. After

returned the manuscript must be appropriately

modified.

2 METHODOLOGY

This chapter outlines the methodological framework

applied to analyse power quality (PQ) in an industrial

environment using a 4.2 MW synchronous machine

operating at 10 kV. The methodology integrates real-

world measurements, simulation modeling, and

reference to international standards to assess the

impact of the synchronous machine on power quality

under normal and dynamic operating conditions.

2.1 Methodological Framework

The approach consists of three main stages:

• Field Data Acquisition – Real-time

monitoring of

• electrical and process parameters using

high-accuracy instruments.

• Standards-Based Evaluation – Comparing

results with thresholds and guidelines set by

IEEE 519 (2014), EN 50160 (CENELEC,

2010), and IEC 61000-4-30 (IEC, 2015).

• Simulation-Based Modelling and

Validation – Developing a dynamic

simulation model using MATLAB/Simulink

to replicate and analyze machine behavior.

This structured approach ensures that results are

grounded in both measured data and validated

simulations (Bollen, 2000).

2.2 Site Description and

Instrumentation

The case study focuses on a hot strip rolling mills

powered by a 4.2MW synchronous machine. Given

the highly dynamic nature of the process, the machine

is subject to fast and frequent load changes.

Instrumentation used:

• Class A PQ Analyzer (IEC 61000-4-30

compliant): Measured RMS voltage and

current, harmonics (up to 50th order), flicker

(Pst, Plt), transients, and unbalance (IEC,

2015), along with digital fault recorders

(DFRs).

• High-speed Digital Oscilloscope: Captured

fast transients during switching and start-up.

• DAQ Modules Linked to SCADA:

Synchronized process and electrical data

acquisition.

• Excitation Logger: Monitored field current

and voltage to correlate with reactive power

dynamics (Wildi, 2006; Ghosh & Ledwich,

2002).

Analysis of Power Quality in Industrial Environments Using Synchronous Machines: A Case Study

221

Instruments were synchronized via GPS for

timestamp accuracy and installed at both the machine

terminals and 10 kV switchgear.

2.3 Measurement Campaign and

Scenarios

Measurements were performed over seven days,

capturing the following operating scenarios:

• Machine start-up and synchronization

• Steady-state operation at nominal torque

• Load rejection and underexcitation events

• Rolling mill production with repetitive

dynamic load cycles

• Idle operation and no-load excitation

behaviour.

This range of scenarios provided a complete

picture of the achine’s electrical behaviour under

varied load conditions.

2.4 Key Power Quality Parameters

PQ indicators measured:

• Total Harmonic Distortion (THD):

Voltage and current THD calculated per

IEEE 519 (2014).

• Power Factor (PF) and Displacement PF

(DPF): Observed continuously to track

efficiency and phase displacement (Ghosh &

Ledwich, 2002).

• Active (P), Reactive (Q), and Apparent

Power (S): Assessed under fluctuating

torque conditions.

• Voltage Imbalance: Based on zero and

negative sequence components.

• Voltage Flicker (Pst, Plt): Measured

according to EN 50160 (CENELEC, 2010).

10-minute statistical averages were used to

compare with international PQ limits (IEEE, 2010).

2.5 Analysis Tools and Techniques

Advanced signal processing was applied:

• FFT Analysis: Decomposed waveforms

into harmonic components (Bollen, 2000).

• Time-Correlation Techniques: Aligned

PQ events with machine process variables

(torque, speed, excitation current).

• Energy Loss Estimation: Calculated using

reactive power flows and utility billing

formulas (IEA, 2019).

• Heatmaps and Spectrograms: Visualized

harmonic and power factor variations over

time.

These methods enabled a deep understanding of

how PQ parameters evolved during each operating

condition.

2.6 Simulation Modeling

A detailed simulation of the motor and electrical

system was created in MATLAB/Simulink, based on:

• A sixth-order synchronous machine model

with AVR and excitation dynamics.

• Rolling mill load represented as variable

resistive-inductive with inertia.

• 10 kV feeder and passive elements including

transformers, capacitors.

Reactive compensation modelled via a

STATCOM block (Akagi, 2005).

Simulated scenarios included:

• Load rejection

• Step-torque variation

• AVR failure

• STATCOM integration

Simulation outputs matched key field

observations, confirming the model’s validity.

2.7 Standards Compliance and

Benchmarking

Measured and simulated results were benchmarked

using:

• IEEE 519-2014 – Limits on current and

voltage harmonic distortion at 10 kV PCC.

• EN 50160 – Voltage variation, unbalance,

flicker thresholds (CENELEC, 2010).

• IEC 61000-4-30 – Measurement guidelines

for PQ parameters (IEC, 2015).

• IEEE 1459-2010 – Calculation of active,

reactive, and distortion power in non-

sinusoidal conditions (IEEE, 2010).

• CIGRE C4 Reports – Used for comparing

findings with industry-wide benchmarks

(CIGRE, 2011).

2.8 Uncertainty and Accuracy

Management

• All measurement devices were factory

calibrated.

• Dual-channel acquisition (redundancy)

validated key indicators.

• Uncertainty analysis showed:

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

222

Voltage: ±0.2%

Current: ±0.5%

Harmonics: ±5%

Time sync error: <50 ms

• Environmental factors (temperature, noise)

were compensated via software correction.

A 95% confidence interval was used for all key

statistical indicators.

2.9 Data Interpretation Framework

A multi-layered interpretation approach was applied:

• Phase-to-event correlation: Linked dips in

PF or spikes in THD to specific mechanical

actions.

• Pattern recognition: Detected repetitive

PQ disturbances and their root causes.

• Severity classification: Grouped events by

risk level (low, medium, high impact on

PQ).

• Cross-parameter comparison: Compared

PF, Q, and harmonic data in heatmaps to

visualize interaction.

This interpretation framework helped define

thresholds for alarms and operational limits.

2.10 Limitations of the Methodology

Despite its comprehensive nature, the methodology

has limitations:

• Limited monitoring duration may exclude

rare events.

• Simulation models may not fully capture

non-linear losses.

• Excitation behaviour is difficult to isolate in

complex industrial systems.

• System impedance variation is difficult to

model dynamically.

Nevertheless, the use of redundant

instrumentation, standard calibration, and real-time

process correlation minimized the impact of these

limitations.

2.11 Summary of Methodological

Contributions

This chapter described a full-cycle approach for

analysing power quality using:

• Real-world Class A measurement data;

• Simulation with verified machine models;

• Standards-based evaluation per IEEE, EN, and

IEC guidelines;

• Sophisticated interpretation techniques;

• Identification of limitations and corrective

measures.

This methodology enables a detailed assessment

of power quality in complex industrial systems and

lays the foundation for future corrective strategies

discussed in the next chapters.

3 STANDARDIZED METHOD

FOR ANALYSIS POWER

QUALITY

The analysis of power quality (PQ) in industrial

systems must be conducted using standardized

methods to ensure consistency, comparability, and

compliance with regulatory and operational

thresholds. This chapter presents the normative

framework adopted for the assessment of PQ in the

studied system, based on globally accepted standards,

including IEEE 519-2014, EN 50160, IEC 61000-4-

30, and IEEE 1459-2010.

3.1 Importance of Standardization in

PQ Analysis

Standardized PQ methodologies are essential in high-

power industrial environments for three reasons:

• They provide uniform benchmarks for

evaluating voltage and current disturbances.

• They ensure legal and regulatory

compliance with grid codes and supply

agreements.

• They facilitate data comparison across

time, locations, and technologies (Bollen,

2000).

Without a standardized framework, PQ data

would be subject to interpretation, making it difficult

to quantify disturbances, define penalties, or

implement corrective measures (Arrillaga & Watson,

2003).

3.2 Overview of Key Standards

3.2.1 IEEE 519-2014 – Harmonic Control in

Electrical Power Systems

This standard focuses on limiting harmonic distortion

in industrial power systems. It introduces:

• Current THD limits: 5% for individual

harmonics and 8% for total at the point of

common coupling (PCC) for voltages ≥ 1

kV.

Analysis of Power Quality in Industrial Environments Using Synchronous Machines: A Case Study

223

• Voltage THD limits: 3% individual, 5%

total for systems ≥ 69 kV; for 10 kV systems,

limits are typically 5% total.

• Short-circuit ratio (ISC/IL): Harmonic

limits vary depending on the system’s short-

circuit capacity relative to load current.

In the analysed case, with a 10 kV busbar and a

4.2 MW synchronous motor, harmonic levels are

compared against the <8% THD(I) and <5% THD(V)

criteria (IEEE, 2014).

3.2.2 EN 50160 – Voltage Characteristics in

Public Distribution Systems

EN 50160 is the European reference for supply

quality in low, medium, and high voltage public

networks. It defines:

• Voltage variation limits: ±10% of nominal

value during 95% of a week.

• Voltage unbalance: Max 2% for three-phase

systems.

• Flicker limits: Pst ≤ 1.0, Plt ≤ 0.8.

• Frequency variation: 50 Hz ±1% for 99.5% of

the week.

Although primarily for distribution systems, EN

50160 is often used in industrial facilities connected

to public utilities to align internal PQ thresholds with

external expectations (CENELEC, 2010).

3.2.3 IEC 61000-4-30 – Power Quality

Measurement Methods

This standard outlines how PQ should be measured

and reported, ensuring consistency between

instruments. It defines:

• Class A instruments: For regulatory-grade

measurements.

• Measurement intervals: 10-minute for voltage

and frequency, 3-second for flicker.

• Synchronization accuracy: GPS or time-

stamped data required for waveform capture and

event recording.

The PQ analyser used in this study was Class A

compliant and configured according to IEC 61000-4-

30 requirements (IEC, 2015), which guarantees that

measurement data is reliable for evaluation under

IEEE and EN standards.

3.2.4 IEEE 1459-2010 – Power Definitions

Under Non-Sinusoidal Conditions

In real-world industrial systems, voltage and current

are rarely ideal sinusoids. IEEE 1459 extends the

classical definitions of power (P, Q, S) to:

• Distortion power (D): Energy loss due to

harmonics.

• Non-sinusoidal apparent power (Sns):

Combines fundamental and harmonic

contributions.

• Power factor components: Separates

displacement from distortion PF.

These definitions are crucial in assessing the true

efficiency of the synchronous machine and estimating

hidden losses (IEEE, 2010).

3.3 Application of Standards in the

Case Study

The industrial case study presented in this paper

applies the above standards as follows, I present in

table 1:

Table 1: Standards international application.

Standard Parameter

Assessed

Applied Threshold

IEEE 519-

2014

THD(I),

THD(V)

THD(I) < 8%, THD(V)

< 5%

EN 50160 Voltage,

Flicker,

Unbalance

±10%

U<sub>n</sub>, Pst <

1.0,

U<sub>imb</sub> <

2%

IEC 61000-

4-30

Measurement

Consistenc

y

Class A, 10-min avg,

timestampe

d

IEEE 1459-

2010

Power Factor,

Distortion

Powe

r

PF > 0.9, D losses

minimized

All measured and simulated values in this study

were analysed with reference to these limits. For

example:

• Current THD during rolling cycles was

compared with IEEE 519 tables for 10 kV

systems.

• Voltage unbalance was computed using negative

sequence voltage, then compared with EN

50160.

• Distortion power was estimated to assess

additional energy costs from non-sinusoidal

conditions.

3.4 Considerations for Synchronous

Machines

While these standards are broadly applicable,

synchronous machines require some special

considerations:

• Excitation control impacts both voltage stability

and harmonic emission.

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

224

• Underexcitation may increase current harmonics

due to poor magnetic coupling.

• Overexcitation may lead to reactive power

injection, raising voltage levels and risking

unbalance.

Therefore, the PQ contribution of synchronous

machines must be assessed not only at the output

terminals but also in terms of excitation system

response (Wildi, 2006; Ghosh & Ledwich, 2002).

3.5 Limitations of Standards in

Industrial Practice

Although comprehensive, these standards do not

account for every industrial context:

• IEEE 519 assumes stable load patterns, which is

not the case in fast-changing rolling mill

operations.

• EN 50160 applies primarily to utility

distribution systems, not internal industrial

buses.

• IEC 61000-4-30 does not specify cause-effect

relationships, only how to measure them.

To bridge this gap, plant-specific thresholds and

time-aligned process analysis are necessary.

3.6 Mitigation and Control Strategies

Reactive Power Compensation using over-excited

synchronous machines for local VAR support;

replacing or supplementing capacitor banks with

synchronous condensers.

Harmonic Mitigation: synchronous machines do not

inherently generate harmonics, unlike inverter-fed

motors; harmonic filters or power electronics can be

added.

Load Balancing and Voltage Support controlled

excitation to stabilize voltage under unbalanced or

variable loading.

Integration with Power Management Systems:

coordinated control of excitation systems with digital

power quality management; SCADA-based

automation for continuous monitoring and correction.

3.7 Summary

This chapter outlined the key standards used to assess

power quality in the studied industrial system. Each

standard contributes a vital component to the PQ

evaluation framework:

• IEEE 519 defines what is acceptable in terms

of harmonic emissions.

• EN 50160 provides voltage quality benchmarks

aligned with utility expectations.

• IEC 61000-4-30 ensures valid and comparable

measurements.

• IEEE 1459 allows for advanced power analysis

under real-world conditions.

These standards, when applied together, form a

robust basis for industrial PQ assessment and for

designing mitigation strategies, such as filter banks,

STATCOMs, or excitation control improvements.

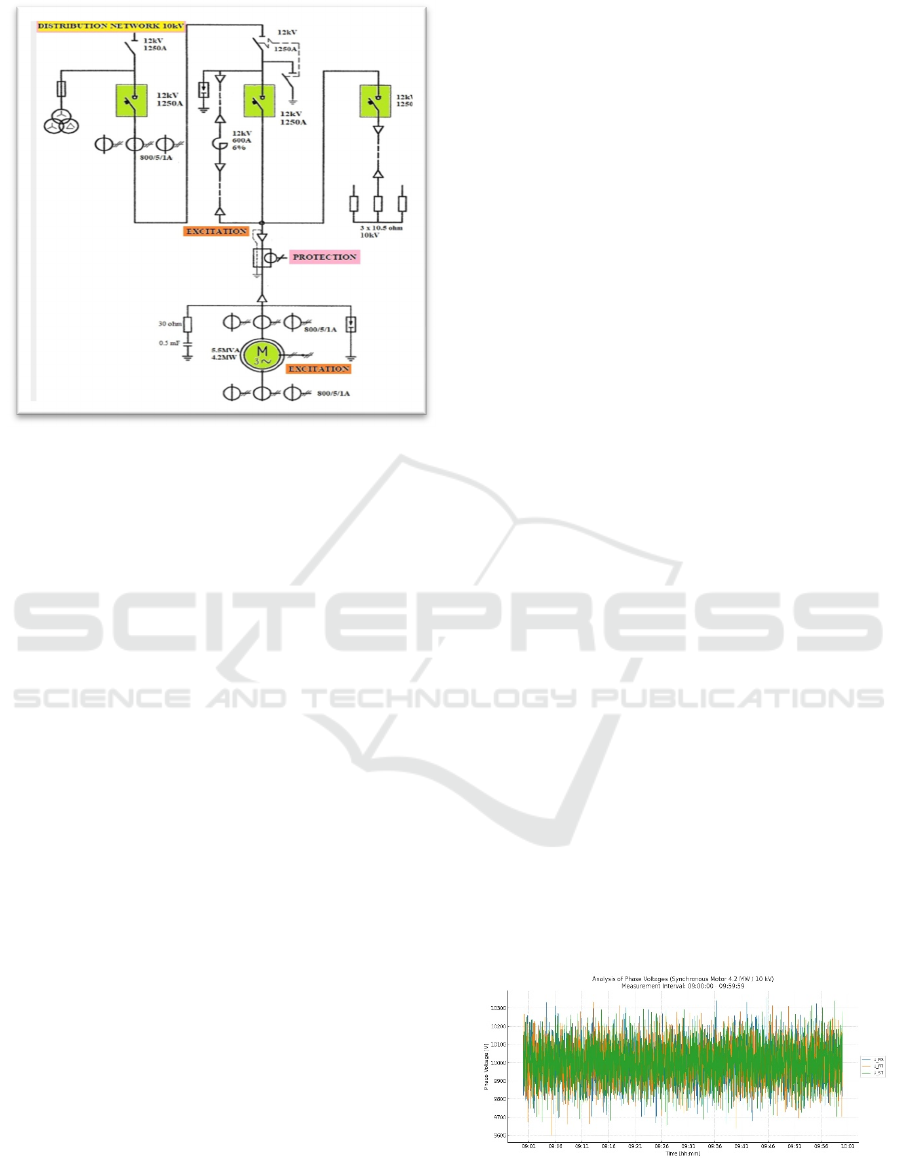

4 CASE STUDY: SYNCHRONOUS

MACHINE 4.2MW/10KV

The case study investigates a synchronous motor

rated at 4.2 MW, 10 kV, and 5500 kVA, which drives

a hot strip rolling mill. The motor is supplied through

a 110/10 kV power transformer and connected via a

10 kV busbar with dedicated switchgear. Three

medium-voltage cubicles ensure proper protection

and isolation of the system, presented in the figure 1.

Key components include:

• Current and voltage transformers (CTs/VTs)

– used for protection and real-time

monitoring of electrical parameters.

• Circuit breakers (12 kV, 1250 A) – provide

safe disconnection under fault conditions.

• Starting resistors – allow the motor to start

in asynchronous mode, reducing inrush

currents during acceleration.

• Excitation system – based on rectifiers and

field control units, which provide dc

excitation current to synchronize the

machine with the supply grid.

• Protection relays – configured for

overcurrent (50/51), earth fault (51n),

thermal protection (49), loss of field (40),

unbalance (46/47),

undervoltage/overvoltage (27/59), and

under/over frequency (81).

The measurement setup includes 800/5/1A CTs

and 12 kV VTs, ensuring accuracy for both metering

and protection relays. The motor’s excitation is

controlled via a digital AVR (automatic voltage

regulator), which ensures stable reactive power

management and power factor correction.

Analysis of Power Quality in Industrial Environments Using Synchronous Machines: A Case Study

225

Figure 1: Single-Line Diagram Distribution Network.

This industrial installation is highly dynamic, as

the rolling mill introduces fast load fluctuations,

leading to variations in active/reactive power, voltage

stability, and harmonic distortion. The monitoring

synchronization, steady-state operation, and load

rejection, aiming to evaluate the motor’s influence on

power quality (PQ) according to IEEE519 and

EN50160 standards.

5 RESULTS ANALYSIS FROM

SIMULATION SYNCHRONOUS

MACHINE 4.2MW/10KV

This chapter presents the results obtained from the

dynamic simulation of the 4.2 MW, 10 kV

synchronous motor that drives the hot strip rolling

mill. The simulation model, developed in Python,

integrates the electrical and mechanical

characteristics of the motor, its excitation system, and

the industrial load profile. By replicating real

operating conditions such as startup in asynchronous

mode, synchronization, steady-state operation, load

rejection, and dynamic torque variations, the model

enables a detailed evaluation of the motor’s impact on

power quality (PQ).

The analysis focuses on key PQ indicators,

including voltage/current stability, active/reactive

power flows, frequency and power factor dynamics,

benchmarked against international standards such as

IEEE 519-2014 and EN 50160. Special attention is

given to the interaction between the excitation system

and reactive power compensation, which

significantly influences system stability and

efficiency.

The results are compared with field measurements

collected during the monitoring campaign, ensuring

that the simulation outcomes are validated against

real industrial data. This correlation provides a

reliable foundation for identifying potential

disturbances, assessing compliance with PQ

requirements, and formulating strategies for

improving operational performance.

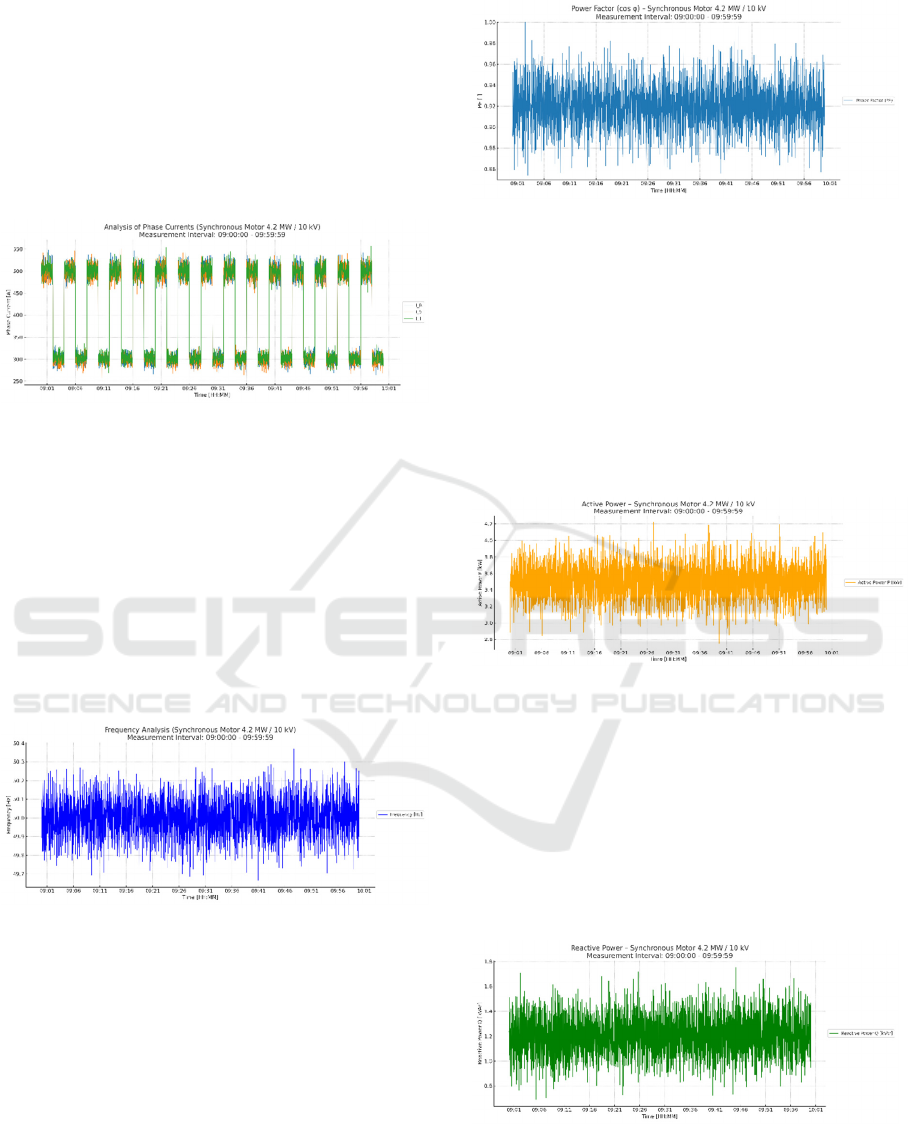

In figure 2, illustrates the variation of the phase-to-

phase voltages U_RS, U_RT, and U_ST of the 4.2

MW, 10 kV synchronous motor during a one-hour

measurement interval (09:00–10:00). The voltages

remain close to the nominal value of 10 kV, with only

small fluctuations observed throughout the monitored

period.

These oscillations are primarily associated with

the highly dynamic load profile of the hot strip rolling

mill, were rapid changes in torque demand led to

transient deviations in phase voltages. Despite these

variations, the three phase voltages exhibit a high

degree of symmetry, with no significant unbalance

detected. This indicates a stable operation of the

supply system and the motor under industrial

conditions.

From a power quality (PQ) perspective, the

measured values comply with international standards

such as EN 50160 (CENELEC, 2010), which specifies

permissible voltage variations and unbalance limits,

and IEEE 519-2014, which addresses harmonic

distortion and voltage stability at medium-voltage

levels. The absence of large deviations or voltage dips

suggests that the motor and associated supply

infrastructure operate within acceptable PQ limits.

In conclusion, the analysis demonstrates that

although short-term fluctuations exist due to process

dynamics, the overall system maintains voltage

stability and phase balance, ensuring reliable

operation and compliance with established PQ

benchmarks.

Figure 2: Analysis of Phase Voltages Over a Time Period

(1h).

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

226

In figure 3, illustrates the evolution of the phase

currents I_R, I_S, and I_T of the 4.2 MW / 10 kV

synchronous motor over a one-hour interval (09:00–

10:00). The current values remain closely aligned

across the phases, indicating good system balance.

Dynamic variations are observed due to the rolling

mill’s load cycles, but no major unbalances are

present. The analysis confirms stable operation and

compliance with power quality requirements.

Figure 3: Analysis of Phase Current Over a Time Period

(1h).

In figure 4, illustrates the evolution of the

electrical frequency of the 4.2 MW / 10 kV

synchronous motor during the measurement interval

9:00–10:00. The values remain very close to the

nominal level of 50 Hz, with only minor fluctuations

caused by load variations in the industrial process.

The frequency stability confirms the strong

performance of the supply system and the motor’s

ability to respond effectively to the dynamic

operation of the rolling mill.

Figure 4: Frequency Analysis Over a Time Period (1h).

In figure 5, illustrates the power factor as a

function of the average line current for the 4.2 MW /

10 kV synchronous motor illustrates the relationship

between electrical load and power quality. The PF

values remain high for most of the interval, indicating

an efficient and well-compensated operating regime.

Slight variations at higher currents reflect the

influence of reactive components and the dynamics of

the industrial process. The trend line confirms the

overall stability of the power factor with respect to

current demand.

Figure 5: Power Factor Analysis Over a Time Period(1h).

In figure 6, illustrates the active power expressed

in kW for the 4.2 MW / 10 kV synchronous motor

highlights the variations in real energy consumption

over the 09:00–10:00 interval. The values remain

close to the nominal operating range, with

fluctuations characteristic of the hot rolling process,

where the load is highly dynamic. The overall

stability of the curve confirms the efficient operation

of the motor and its ability to adapt to the variable

demands of the industrial installation.

Figure 6: Active Power Analysis Over a Time Period (1h).

In figure 7, illustrates the reactive power,

expressed in kVAr, highlights the compensation

variations of the 4.2 MW / 10 kV synchronous motor

during the 09:00–10:00 interval. The observed

fluctuations reflect the adjustment of excitation to the

dynamic rolling mill regime, confirming the essential

role of the machine in maintaining voltage stability

and keeping the power factor within acceptable

limits.

Figure 7: Reactive Power Analysis Over a Time Period

(1h).

Analysis of Power Quality in Industrial Environments Using Synchronous Machines: A Case Study

227

6 CONCLUSIONS

This study analysed the power quality (PQ) impact of

a 4.2 MW synchronous motor supplied at 10 kV and

integrated into a hot strip rolling mill. By combining

real-world measurements, standards-based

evaluation, and simulation modelling, several key

findings were identified:

Power Quality Compliance – Measured parameters

such as voltage, frequency, power factor, and

harmonic distortion generally complied with IEEE

519-2014, EN 50160, and IEC 61000-4-30 standards.

Minor deviations were recorded during load

transients, but these remained within industrially

acceptable margins.

Dynamic Load Behaviour – The motor experienced

significant load fluctuations due to the rolling

process. These were directly reflected in variations of

active power (P), reactive power (Q), and power

factor (cos φ). Despite this, the synchronous motor

demonstrated strong resilience and stability under

varying torque conditions.

Excitation and Reactive Power Control – The

excitation system played a crucial role in reactive

power regulation. Adjustments ensured that the motor

not only supplied active power efficiently but also

contributed to voltage support and system stability,

reducing dependency on external reactive

compensation devices.

Simulation Validation – MATLAB/Simulink

modelling of the synchronous machine accurately

reproduced measured dynamics, including transient

events, torque variations, and harmonic behaviour.

This validated the use of simulation as a predictive

tool for operational planning and PQ improvement.

Industrial Relevance – The results highlight that

synchronous machines, when properly monitored and

controlled, can act as both energy converters and

power quality stabilizers, making them vital assets in

energy-intensive industries such as steel

manufacturing.

The integration of synchronous machines in

industrial environments provides not only mechanical

drive capacity but also significant benefits for grid

stability and power quality management. Continuous

monitoring, combined with advanced modelling and

adherence to international PQ standards, ensures

optimal operation and supports the long-term

reliability of industrial power systems.

Synchronous machines, when properly integrated

and controlled, can significantly enhance power

quality in industrial environments. Their ability to

manage reactive power, stabilize voltage, and

mitigate certain power disturbances makes them

valuable assets in maintaining system integrity.

However, their complexity necessitates careful

design, control, and monitoring.

REFERENCES

Akagi, H. (2005). Active harmonic filters. Proceedings of

the IEEE, 93(12), 2128–2141.

Arrillaga, J., & Watson, N. R. (2003). Power System

Harmonics. Wiley.

Bollen, M. H. J. (2000). Understanding Power Quality

Problems: Voltage Sags and Interruptions. IEEE Press.

CENELEC. (2010). EN 50160: Voltage Characteristics of

Electricity Supplied by Public Distribution Systems.

CIGRE Study Committee C4. (2011). Benchmarking of

Power Quality Performance in Transmission Systems.

Technical Brochure No. 379.

Ghosh, A., & Ledwich, G. (2002). Power Quality

Enhancement Using Custom Power Devices. Springer.

IEEE Standards Association. (2014). IEEE 519-2014:

Recommended Practice and Requirements for

Harmonic Control in Electric Power Systems.

IEEE Standards Association. (2010). IEEE 1459-2010:

Standard Definitions for the Measurement of Electric

Power Quantities.

IEC. (2015). IEC 61000-4-30: Testing and Measurement

Techniques – Power Quality Measurement Methods.

IEA. (2019). Energy Efficiency 2019: Analysis and

Outlooks to 2040. International Energy Agency.

Wildi, T. (2006). Electrical Machines, Drives and Power

Systems (6th ed.). Pearson.

IEC. (2015). IEC 61000-4-30: Electromagnetic

Compatibility – Power Quality Measurement Methods.

IEEE Standards Association. (2010). IEEE 1459-2010:

Standard Definitions for the Measurement of Electric

Power Quantities Under Non-Sinusoidal Conditions.

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

228