Research Progress of Pressure Sensors: Structure, Principle,

Application

Erli Zhang

a

School of Mechanical and Electrical Engineering, Guangdong University of Technology,

Guangzhou, Guangdong Province, 510000, China

Keywords: Piezoelectric Pressure Sensor, Capacitive Pressure Sensor, Piezoresistive Pressure Sensors.

Abstract: With the advancement of technology, the application of pressure sensors has gradually become more

widespread. Flexible pressure sensors have attracted people's attention because they can adapt to more

complex and changeable characteristics. The article reviews the structure, principle and application of

piezoelectric pressure sensors, capacitive pressure sensors and piezoresistive pressure sensors, and the article

provides researchers with relevant research materials for developing and improving flexible pressure sensors.

In addition, this article briefly discusses the development challenges that will be faced in the transition from

traditional rigid sensors to flexible pressure sensors in terms of future applications of pressure sensors. For

example, materials will be selected based on the application environment and accuracy requirements of future

sensors. The popularization and application of flexible sensors is bound to be the general trend. Therefore,

studying novel flexible pressure sensors sensing mechanisms and finding new multifunctional materials to

meet more application needs are major issues and challenges for future research.

1 INTRODUCTION

With the rapid innovation of the Internet of Things

(IoT), artificial intelligence (AI), and the continuous

development of the concept of intelligent

manufacturing (Duan et al,2022). Pressure sensors

are gradually being widely used in many fields. At the

same time, with the diversification of application

fields, the types of pressure sensors are gradually

increasing to suit different tasks. Since traditional

rigid pressure sensors cannot be applied to more

complex environments, flexible sensors have become

an important research field in recent years. Flexible

sensors can be stretched, compressed, and folded,

allowing them to change into different shapes to fit

onto irregular surfaces, greatly expanding their

application areas (Liu et al,2023).

Although flexible pressure sensors have made a

lot of progress and development, they still face many

challenges. One of the challenges is that as the

pressure increases and exceeds a certain limit, the

sensitivity of the flexible pressure sensor decreases.

Under high pressure, the sensor material will affect

sensitivity due to hyperelasticity and boundary

a

https://orcid.org/0009-0001-6999-3990

limitations. In order to solve the problems are

mentioned above, researchers need to constantly

optimize the micro-geometry of the sensor and the

elasticity, dielectric properties and other properties of

the material (Yuan et al,2024).

The article will list the structure, principle and

application of piezoelectric pressure sensors,

capacitive pressure sensors and piezoresistive

pressure sensors. Meanwhile, this article can provide

research data and give some optimization suggestions

for future pressure sensors for researchers who study

pressure sensors mentioned above.

2 THE STRUCTURE, PRINCIPLE

AND APPLICATION OF

PRESSURE SENSORS

2.1 Piezoelectric Pressure Sensor

Piezoelectric sensors are composed of piezoelectric

materials, and they are active sensors that do not need

external

energy

to

obtain

output

signals

(Gautschi,

Zhang, E.

Research Progress of Pressure Sensors: Str ucture, Principle, Application.

DOI: 10.5220/0014320700004718

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Engineering Management, Information Technology and Intelligence (EMITI 2025), pages 79-83

ISBN: 978-989-758-792-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

79

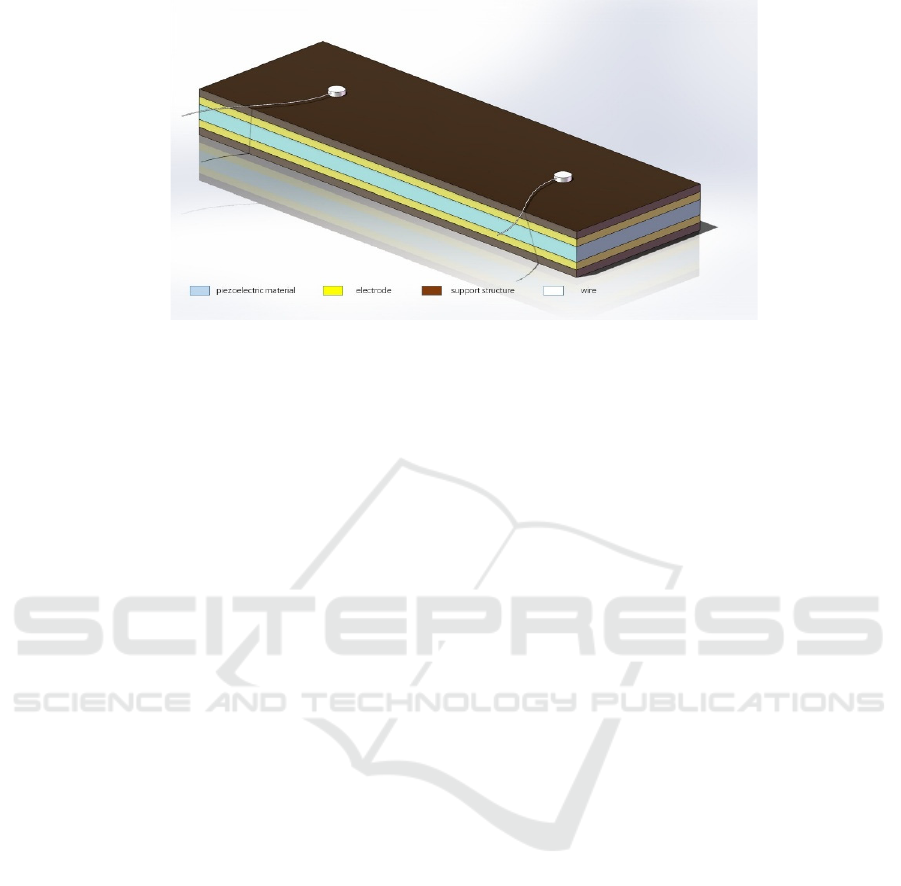

Figure 1: Piezoelectric pressure sensor device structure (Picture credit : Original).

2002). Flexible piezoelectric pressure sensors usually

consist of four parts: piezoelectric material, electrode,

support structure, and wire, as shown in Figure 1. The

piezoelectric effect produced by piezoelectric

materials is the working basis of piezoelectric sensors.

Electrodes are the medium through which the sensor

transfers charge. The support structure is the

packaging protection structure of the sensor. It has a

suitable Young's modulus and can provide a flexible

environment. In addition, the support structure is

usually made of some polymers, such as polyimide

(PI), polydimethylsiloxane (PDMS), polyethylene

terephthalate (PET), etc. Therefore, the supporting

structure usually has the characteristics of insulation,

stretchability and corrosion resistance, which makes

the packaging structure better protect other

components in the sensor. The wire is used to connect

the piezoelectric pressure sensor to external

instruments and transmit electrical signals (Ma,2024).

Due to their exceptional stretchability and other

characteristics that extend their service life, flexible

piezoelectric pressure sensors are frequently utilized.

The working principle of the piezoelectric

pressure sensor is the piezoelectric effect. The

piezoelectric effect is that when a piezoelectric

material is subjected to external pressure, alternating

charges are generated on the surfaces of both ends of

the piezoelectric material, thereby forming a voltage

at both ends of the piezoelectric material (Wang et al,

2010). The voltage signal generated by the

piezoelectric material will be exported by the

electrode, and will be amplified, filtered, and

processed by the signal conditioning circuit and

transformed into a standard electrical signal output.

The processed standard electrical signal is

proportional to the externally applied pressure, so the

pressure can be calculated by measuring the size of

the standard electrical signal.

Piezoelectric pressure sensors have wide

frequency and high dynamic performance, so they

have significant advantages in measuring transient

dynamic parameters (Tan et al,2006). The values that

show how the system reacts and evolves in response

to quickly shifting external stimuli are known as

transient dynamic parameters. The parameter is very

important when used to analyze and design the

dynamic performance of the system to guarantee that

the system is able to react steadily and quickly under

transient conditions. Piezoelectric pressure sensors

also have the characteristics of good stability.

Because of the relatively stable nature of the

piezoelectric effect of its working principle, it has a

strong ability to resist external interference. Therefore,

piezoelectric pressure sensors are usually used in

long-term monitoring of the environment or the

automation field. Stable data results can be obtained

without frequent recalibration of the sensor.

Furthermore, piezoelectric pressure sensors have a

long service life because they use a design

mechanism without moving parts, which greatly

reduces the negative effects of mechanical wear or

component fatigue. In some industrial environments

and aerospace fields, piezoelectric pressure sensors

have become their first choice due to the harsh

application environment of sensors and the inability

to frequently replace sensors. In addition,

piezoelectric pressure sensors are universally utilized

in mechanical mechanisms of industrial production

and even in medical equipment such as ventilators.

2.2 Capacitive Pressure Sensor

Capacitive pressure sensors are typically consist of a

dielectric layer and parallel plates with electrodes on

both ends of the dielectric layer. Usually one of the

two parallel plates will be fixed, and the other parallel

EMITI 2025 - International Conference on Engineering Management, Information Technology and Intelligence

80

Figure 2: Capacitive pressure sensor device structure (Picture credit: Original).

plate will have the ability of mechanical sensing, as

shown in Figure 2 (Mishra et al,2021). In the

production and manufacturing of traditional

capacitive pressure sensors, metal materials such as

copper and silver are often selected as the

manufacturing materials of electrodes. The electrodes

of the flexible capacitive pressure sensor are required

for good conformability so that the flexible sensor can

bend, stretch and have other properties (Mishra et

al,2021). With the advancement of science, it has

become easier to manufacture electrodes that meet the

performance requirements of soft sensors. Electrodes

made of carbon nanotubes (CNTs) are flexible,

stretchable and transparent (Mishra et al,2021). In

addition, the electrode material can also choose some

composite materials to satisfy the diverse needs of

applications in practice.

The capacitive pressure sensor can be regarded as

a parallel plate capacitor, and the data of sensor's

detection is reflected by the capacitance change of the

parallel plate capacitor. The value of capacitance

depends mainly on the relative distance between the

two parallel electrode plates and the dielectric

constant. The relative distance between the two

parallel plates changes with the external pressure, and

the two are inversely proportional. The dielectric

constant is usually associated with the material in the

dielectric layer and the temperature.

Capacitive pressure sensors have excellent

sensitivity and can remain stable to changes in

ambient temperature. Therefore, capacitive pressure

sensors are often used in the medical field. In the last

few years, cuff electrodes have been frequently

utilized to monitor neural signals. However, the

radius of the nerve is much larger than that of the cuff

electrode, so the cuff electrode may cause excessive

pressure on the nerve tissue. Therefore, an elliptical

electrode with the ability to flatten the nerve trunk and

increase the contact zone between the nerve trunk and

the electrode was proposed. Therefore, the capacitive

pressure sensor with elliptical electrodes can better

detect the pressure between the nerve stem and the

electrodes, thereby detecting people's nerve health

(Chiang et al,2007). The application of capacitive

pressure sensors in the medical field often requires

changing the material, shape and other characteristics

of the electrode according to the situation to cope with

different environments. Capacitive pressure sensors

can be integrated into most medical devices because

they can be made very small. During surgical

operations, piezoelectric pressure sensors are

integrated into minimally invasive catheter surgeries

to monitor patients’ blood pressure and other

conditions. In addition, capacitive pressure sensors

are used in environments that are in direct contact

with medical drugs, such as infusion pumps and

ventilators, because of their strong corrosion

resistance. Many features of capacitive pressure

sensors can satisfy their use in the medical field, and

the development of flexible capacitive pressure

sensors can further expand their application range.

2.3 Piezoresistive Pressure Sensors

Piezoresistive resistors and diaphragms are the core

parts of the piezoresistive pressure sensor structure

(Tran et al,2018). The structure diagram of the

traditional piezoresistive pressure sensor is shown in

Figure 3. The most important step in the manufacture

of piezoresistive pressure sensors is the design of the

sensing diaphragm. The design area of a conventional

square flat diaphragm is typically separated into two

levels, with the upper layer being variable and the

bottom layer being fixed, as seen in Figure 4. In

addition, the edges of the diaphragm will be fixed.

Because of this double-layer sensing diaphragm

structure, the sensitivity and linearity can be

improved (Tran et al,2018). When manufacturing

piezoresistive pressure sensors, different structures

and

material choices will affect the sensitivity and

Research Progress of Pressure Sensors: Structure, Principle, Application

81

Figure 3: Piezoresistive pressure sensor device structure (Picture credit: Original).

Figure 4: Traditional square flat diaphragm structure (Picture credit: Original).

linearity of the piezoresistive pressure sensors. A

high-sensitivity pressure sensor with exceptional

linearity in the 0–54 kPa range was predicted

theoretically. It was constructed using a twin

Wheatstone bridge architecture and a diaphragm that

was 7 μm thick. In addition, a graphene-based

resistive pressure sensor has a low linearity but a very

high sensitivity across a broad pressure range (0~100

kPa) (Zhang et al,2018). Consequently, the

performance of the piezoresistive pressure sensor is

somewhat influenced by the choice of material and

structure.

The working principle of piezoresistive pressure

sensor is piezoresistive effect. The piezoresistive

effect refers to the change in resistance when

mechanical strain occurs due to external pressure

(Meti et al,2016). When the piezoresistive pressure

sensor is subjected to external pressure, the sensing

diaphragm will deform and exert bending force on the

piezoresistive resistors. For the varistor device, the

piezoresistive action will cause the resistance value to

fluctuate (Tran et al,2018). The piezoresistive effect

of semiconductor materials is significant and has high

sensitivity. Compared with semiconductor materials,

the piezoresistive effect of metal materials is weaker,

and it mainly causes changes in resistance through

geometric deformation. The piezoresistive device

connected to the upper diaphragm is connected in a

Wheatstone bridge structure. An output voltage

proportionate to the external pressure is produced

from the resistance change brought on by the

piezoresistive effect (Meti et al,2016). The method of

applying an input voltage to a Wheatstone bridge

structure and obtaining a linear output result has the

characteristic of high sensitivity because small

changes in resistance in the piezoresistive effect can

be amplified.

Because of their high sensitivity, ease of

preparation, and ability to provide linear signals,

piezoresistive pressure sensors are widely used.

Piezoresistive pressure sensors have been noticed by

people due to their affordability and ease of

preparation. Since the flexible electronic instruments

are developing rapidly, the demand for piezoresistive

pressure sensors with high sensitivity, long service

life and wide data detection range is gradually

increasing. Flexible electronic devices using

piezoresistive pressure sensors can be used to detect

a range of micro-movements such as heartbeat and

breathing (Cao et al,2021). Detecting tiny movements

requires very high sensitivity of the sensor, so the

piezoresistive pressure sensor is suitable for this

application, and its linearity characteristics can also

clearly reflect the data of tiny changes. Driven by the

rapid development of science and technology,

electronic devices are gradually being integrated into

the medical field. The possibility of using some

piezoresistive graphene sensors with special sawtooth

structures for invasive surgical procedures has been

proposed (Szczerba,2022). For the application of

piezoresistive pressure sensors in the medical field,

the flexible sensor structure can better fit the patient's

skin surface and better detect the patient's relevant

data. Thus, the trend of future sensor advancement

innovation will be the creation of flexible

piezoresistive pressure sensors.

EMITI 2025 - International Conference on Engineering Management, Information Technology and Intelligence

82

3 CONCLUSION

This article focuses on the structure, principle and

application of piezoelectric pressure sensors,

capacitive pressure sensors and piezoresistive

pressure sensors. With the development and progress

of technology, flexible mechanisms and pressure

sensors are gradually integrated. Flexible pressure

sensors have the characteristics of high sensitivity,

long service life, and can be applied to more

diversified environments. Therefore, the

development of flexible pressure sensors has become

the main trend of future sensor development.

There are several challenges in the way of the

advancement of flexible sensors. The flexible

structure of the flexible pressure sensor and the

selected material often affect the final performance of

the pressure sensor. Different application fields have

different requirements for sensor accuracy and

different application environments. Therefore, the

application field needs to be considered when

designing flexible mechanisms and finding new

functional materials. In addition, the production and

processing of sensors also need to keep up with the

speed of technological development. Finding new

sensing mechanisms is essential for future sensor

development. The article suggests that in the future

development of pressure sensors, attention should be

paid to finding new pressure sensor sensing

mechanisms. This can not only broaden the

application range of sensors, but also provide options

for applications that require higher accuracy, simpler

preparation and lower cost. The advancement of

pressure sensors should be associated with

applications. Further research based on application

requirements is a prerequisite for the advancement of

pressure sensors.

REFERENCES

Cao, M., Su, J., Fan, S., Qiu, H., Su, D., & Li, L. (2021).

Wearable piezoresistive pressure sensors based on 3D

graphene. Chemical Engineering Journal, 406, 126777.

Chiang, C. C., Lin, C. C. K., & Ju, M. S. (2007). An

implantable capacitive pressure sensor for biomedical

applications. Sensors and Actuators A: Physical, 134(2),

382-388.

Duan, Y., He, S., Wu, J., Su, B., & Wang, Y. (2022). Recent

progress in flexible pressure sensor arrays.

Nanomaterials, 12(14), 2495.

Gautschi, G. (2002). Piezoelectric sensors (pp. 73-91).

Springer Berlin Heidelberg.

Liu, E., Cai, Z., Ye, Y., Zhou, M., Liao, H., & Yi, Y. (2023).

An overview of flexible sensors: Development,

application, and challenges. Sensors, 23(2), 817.

Ma, R. (2024). Research on flexible piezoelectric pressure

sensor based on hybrid MAPbI3 pressure-sensitive

material, Xidian University.

Meti, S., Balavald, K. B., & Sheeparmatti, B. G. (2016).

MEMS piezoresistive pressure sensor: A survey.

International Journal of Engineering Research and

Applications, 6(4), 23-31.

Mishra, R. B., El-Atab, N., Hussain, A. M., & Hussain, M.

M. (2021). Recent progress on flexible capacitive

pressure sensors: From design and materials to

applications. Advanced Materials Technologies, 6(4),

2001023.

Szczerba, Z., Szczerba, P., & Szczerba, K. (2022).

Sensitivity of piezoresistive pressure sensors to

acceleration. Energies, 15(2), 493.

Tian, H., Lin, Q., & Li, B. (2006). Research on the

application of optical fiber transmission technology of

piezoelectric pressure sensor. Sensors and

Microsystems, 25(2), 3.

Tran, A. V., Zhang, X., & Zhu, B. (2018). Mechanical

structural design of a piezoresistive pressure sensor for

low-pressure measurement: A computational analysis

by increases in the sensor sensitivity. Sensors, 18(7),

2023.

Wang, L., Qin, L., & Li, L. (2010). Piezoelectric dynamic

pressure sensor. 2010 IEEE International Conference

on Information and Automation (pp. 906-911). IEEE.

Yuan, H., Zhang, Q., Zhou, T., Wu, W., Li, H., Yin, Z., ...

& Jiao, T. (2024). Progress and challenges in flexible

capacitive pressure sensors: Microstructure designs and

applications. Chemical Engineering Journal, 149926.

Zhang, J., Chen, J., Li, M., Ge, Y., Wang, T., Shan, P., &

Mao, X. (2018). Design, fabrication, and

implementation of an array-type MEMS piezoresistive

intelligent pressure sensor system. Micromachines, 9(3),

104.

Research Progress of Pressure Sensors: Structure, Principle, Application

83