Industrial Symbiosis Improvement with Digital Twins

Aleksandar Anastasovski

a

Faculty of Engineering, International Balkan University, Makedonsko-kosovska Brigada BB, Skopje, Macedonia

Keywords: Digital Twin, Industrial Symbiosis, System Efficiency, Energy and Mass Exchange, System Control.

Abstract: Digital twins (DTs) are dynamic digital representations of physical systems that accurately depict their

behaviour and states through virtual space over their lifetime. They are built on models and computer

programs that use real-time data from sensors or IoT devices. DTs serve as a bridge between the physical and

virtual worlds, enabling real-time tracking, data analysis, and simulation of various scenarios. They facilitate

remote management, immediate intervention, and data-driven decision-making across industries. The

implementation of DT principles in industrial symbiosis can optimize resource usage, improve collaboration,

and create more sustainable production systems. However, the lack of system integration with information

and communication technology tools and the complexity of knowledge sharing within symbiosis networks

delay its effective implementation. To establish DTs in IS, a systematic approach is required, involving the

specification of exchange processes, determination of bottlenecks, prioritization of integrated parts, and the

creation of mathematical models and simulations. The benefits of DTs in IS include reduced time to market,

reduced waste and energy consumption, improved performance monitoring, and enhanced collaboration

between teams. Future developments needed for IS include addressing the lack of big data for training ML

models, ensuring data security, establishing standards and regulations, and overcoming observability and

controllability issues.

1 INTRODUCTION

Industrial symbiosis (IS) is a mutually beneficial

interaction between different industries/companies

for the exchange of waste materials or energy to be

used as a source for other companies. That results in

the design of a production system that is more

resource-efficient and has a reduced environmental

impact (Seager et al.,2010). It is an effective strategy

for the optimization of resource usage and

collaboration improvement in the context of Industry

4.0 (Scafà et al., 2020).

Is also strengthens synergies between humans and

machines (Scafà et al., 2020). It encompasses the

exchange of waste materials and waste energy

between industrial units. Its design could be

facilitated by tools based on information and

communication technology (ICT) (Grant et al., 2010;

Kosmol, 2019) . The implementation of IS can lead

to the development of eco-industrial parks (EIPs),

where more industries collaborate to create a more

sustainable and circular production system (Al-

a

https://orcid.org/0000-0002-6159-5920

Quradaghi et al., 2020). Therefore, IS is a key

component of the circular economy. It promotes the

increasing resource efficiency, waste reduction, and

environmental sustainability. IS is a shift from the

traditional linear economic model to a more circular

approach (Feiferytė-Skirienė & Stasiškienė, 2021).

One of the main challenges in the development of

IS networks is the lack of system integration by the

use of ICT tools. Although the trend of using

semantic web technologies to share information and

knowledge is constantly increasing. These tools are

often not fully incorporated into broader IP activities

(Kosmol, 2019). This gap hinders the effective

implementation and sustainability of IP business

models.

Another major gap lies in the complexity of

knowledge sharing within IS networks. Despite being

considered as crucial in the implementation and

maintenance of IP business models. Knowledge

sharing is rarely explored or implemented in depth

(Kosmol, 2019). This lack of understanding can delay

the development of robust IS networks and limit their

potential benefits.

38

Anastasovski, A.

Industrial Symbiosis Improvement with Digital Twins.

DOI: 10.5220/0014292100004848

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences (ICEEECS 2025), pages 38-47

ISBN: 978-989-758-783-2

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

The design of EIPs for specific industries reveals

gaps in the early stages of development. While there

are frameworks to guide decision-makers, there is a

need for better integration with design software to

predict product recycling and its production

optimization (Al-Quradaghi et al., 2020). Addressing

these gaps could significantly improve the efficiency

and sustainability of IS initiatives.

Digital twins (DT) are dynamic digital

representations of physical systems. That means a

digital representation of devices or processes that

accurately represent their current and predicted future

states (Gómez-Berbís & Amescua-Seco, 2019). They

depict the behaviour and states of real-life objects

through virtual space over their lifetime (Verdouw et

al., 2021). These virtual replicas are built on a series

of models and computer programs that use real-time

data from sensors or Internet of Things (IoT) devices

(Kaur et al., 2019; X. Zhang et al., 2023) . Moreover,

it can be taken that DT is a digital shadow, digital

replica or digital mirror of physical systems (Lyu,

2024).

DTs are not just conventional data models or

simulations. They make forecasting and optimization

by simulating digital models of systems. DTs do this

by constantly updating and evolving in response to

changes in properties of physical factors (Kang et al.,

2021). All parts that are integrated into DT can be

visually seen in Figure 1. This dynamic nature

differentiates them from static digital models. DTs

serve as a bridge between the physical and virtual

worlds, allowing for real-time tracking, data analysis,

and simulation of various scenarios (Ferrigno &

Barsola, 2023). They facilitate remote management,

immediate intervention, and data-driven decision-

making across industries. These include

manufacturing, health care, transportation, and smart

agriculture (Kaur et al., 2019; Verdouw et al., 2021).

By integrating technologies such as IoT, artificial

intelligence, and machine learning, DTs can offer a

comprehensive understanding of system behavior,

and can foster improved efficiency, optimization, and

information selection in cyber-physical systems

(Awouda et al., 2024; Fuller et al., 2019).

Figure 1: The four forces that make DT.

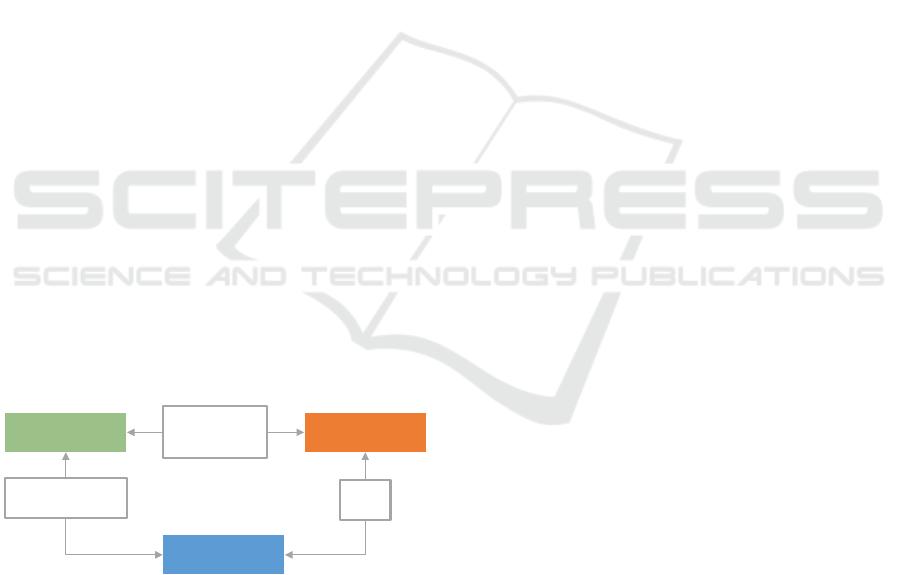

Sources for analysis of literature were Elsevier

data basis. For the searching term “Digital twins for

design of industrial symbiosis” appeared 540 raw

articles. Related to energy (used filter) are 81. Other

searching results for (“Digital twins” AND

“industrial symbiosis”) can be found 121 articles

(Fig.2).

Figure 2: Results shown by searching the Elsevier database

for expression — “Digital twins” for design of “industrial

symbiosis”

But, anyway, all those articles are not directly

connected to the use of digital twins (DTs) in IS or

EIP.

2 DIGITAL TWINS

DTs are available in several types. Asset

Administration Shell (AAS) DTs are becoming more

popular in Industry 4.0, within three different types

(J. Zhang et al., 2025). These types of AAS contribute

to the systematic engineering of specific components

in DTs. Moreover, in manufacturing, DTs can be

identified based on the relationship and data flow

between the physical object and its digital equivalent.

These types are evolving with corporate digital

transformation processes, including external data

sources such as social media and artificial intelligence

solutions. The agricultural sector emerging DTs with

levels of complexity. Type classification is based on

DIGITAL TWIN

Type of digitalization

(what functions should be digitalized)

System boundary

(what is needed to be twinned)

Types of entities twinned

(what entities)

Excellence of digitalization

(the level of digitalization)

Industrial Symbiosis Improvement with Digital Twins

39

the sophistication of the twin’s capabilities

(Pylianidis et al., 2021; Verdouw et al., 2021).

Verdóuw et al. (2021) classified different types of

DTs with the proposed conceptual framework for

their design and implementation in smart agriculture.

This framework consists of a control model based on

a general system approach and an implementation

model based on the Internet of Things Architecture

(IoT-A).

DTs can be ranged between simple data-driven

models and designed complex simulations enhanced

by artificial intelligence. The classification of DTs

often depends on their level of sophistication, the

degree of their integration with physical systems, and

the specific industry where they are used.

DTs are emerged as a key technology in Industry

4.0 and 5.0. They are widely used in equipment and

assets in creating virtual representations of physical

machines and devices in smart factories. DTs enable

real-time monitoring, predictive maintenance, and

process optimization (Lampropoulos & Siakas,

2023). IoT devices in smart factories can be

connected to DTs for dynamic representation of a

physical system through its lifecycle (sensor) data

(Catarci et al., 2019). The DTs of systems is modelled

the overall production or overall complex systems.

They provide real-time automated analysis of data

from connected machines, accelerate error detection

and make correction. This type of DTs improves

overall efficiency and reducing costs in industrial

production.

Some research finds the potential of human DTs

in the context of human-robot collaboration and

augmented reality interfaces in Industry 5.0 ((Zafar et

al., 2023)). As Industry 5.0 continues to evolve, DTs

would play an increasingly important role in

achieving smart, sustainable, and human-cantered

manufacturing (Zafar et al., 2023) .

DTs enable real-time visualization, monitoring,

and control of workflows. They simulate process

parameters (Wang et al., 2024). DTs are integrated

with local systems in real-time. This allows the

prediction of the status of production and to perform

effectiveness analysis of human resources (Ruppert &

Abonyi, 2020). They can also be used for predictive

maintenance. Integration of artificial intelligence

enables them to monitor, diagnose, and optimize

different systems (Kerkeni et al., 2025).

DTs are one of the key players in the

transformation of manufacturing towards Industry 4.0

and 5.0. They are used for product design, production

planning, ergonomics, maintenance, and the entire

product lifecycle (Cinar et al., 2020). The integration

of advanced technologies like Vision Transformers

and DTs can make manufacturing sustainable,

stronger, and more personalized (Industry 5.0 goals)

(Fantozzi et al., 2025).

DTs can be integrated within real-time

localization systems (RTLS). That can predict

production status and monitor performances, as well

as analyse the effectiveness of human resources

(Ruppert & Abonyi, 2020). DTs can serve as

independent cloud computing services. That enables

scalability and will control simulations through a

model DT-as-a-Service (DTaaS) (Borodulin et al.,

2017). This showed the importance of cloud

platforms for the concept of DTs in smart factories.

Moreover, the integration can be done with the

IoT and artificial intelligence. That creates precise

digital replicas of production systems. It enables

process optimization, the reduction of downtime, and

the improvement of maintenance strategies (Fantozzi

et al., 2025). The integration of DTs into the industry

requires a combination of hardware and software

components with high performances. That

combination makes a comprehensive virtual

presentation of physical objects and processes.

Many authors gave the basic content of DT in

different ways. Alam and Sadik (2017) reported that

DTs are based on two modules. Those are physical

modules (process and communication systems) and

digital modules (virtual system—computer models

and decision-making). Rodič et al. (2017) divided

systems into digital shadows (physical systems) and

digital masters (computer models that capture the

shadow). Moreover, Lyu (2024) explained

differences between expressions digital model, digital

shadow and DT. Based on him, the digital model is

the presentation of the physical systems without the

automatic exchange of data (system simulation).

Digital shadow has a single connection with the

physical system. It only receives the change of the

state of the physical system. Contrary, DT has

bidirectional communication between digital and

physical systems with changes in both in real-time.

DT can represent part of the physical system

(reactor, separation system, or product), or it can

represent the whole system.

The main hardware for DTs are sensors, IoT

devices, and communication systems to collect real-

time data from physical parts (Costantini et al., 2022;

Khalyasmaa et al., 2023). Sensors collect information

for parameter values like temperature, vibration, and

performance metrics (Okpala Charles Chikwendu et

al., 2025).

The software, which is used creates advanced

computational models. It can contain different

simulation tools and artificial intelligence algorithms

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

40

to process and analyse the collected data (Okpala

Charles Chikwendu et al., 2025).

There are several types of software tools for

establishing DTs in the manufacturing industry. Each

of those types of software has a different purpose or

different role in the creation of DTs.

1. Unity3D—This is a tool for real-time 3D

system development. It can be chosen because its

cross-platform capability and simplified modelling of

industrial systems (González-Herbón et al., 2024;

Rassolkin et al., 2020). It is used for physical

simulations and visualization of DTs (Rassolkin et al.,

2020). Similar commercial software are: AspenONE,

CATIA®, SolidWorks®, and AutoCAD® for visual

representation and FlexSim®, Tecnomatrix®,

AnyLogic®, Simio®, Arena®, 3DVIA Composer®,

Matlab, ANSYS, Thermoflow, COMSOL, Modelica,

etc.

2. The Vuforia SDK as a software development

kit is used to simplify augmented reality integration

in DTs (González-Herbón et al., 2024).

3. Node-RED is a system integration option for

DTs (González-Herbón et al., 2024).

4. The MQTT protocol is used for communication

in DT systems (González-Herbón et al., 2024).

5. Object-Z notation is a formal language for

realizing the concept of DTs (Barbie & Hasselbring,

2024).

6. A Unified Modelling Language (UML) is used

to visualize relationships between DT concepts such

as class diagrams (Barbie & Hasselbring, 2024).

Generally speaking, there is no standardized set of

software for implementing DTs. Which software will

be used depends on the specific requirements of the

DT implementation project and the industry in which

it is applied.

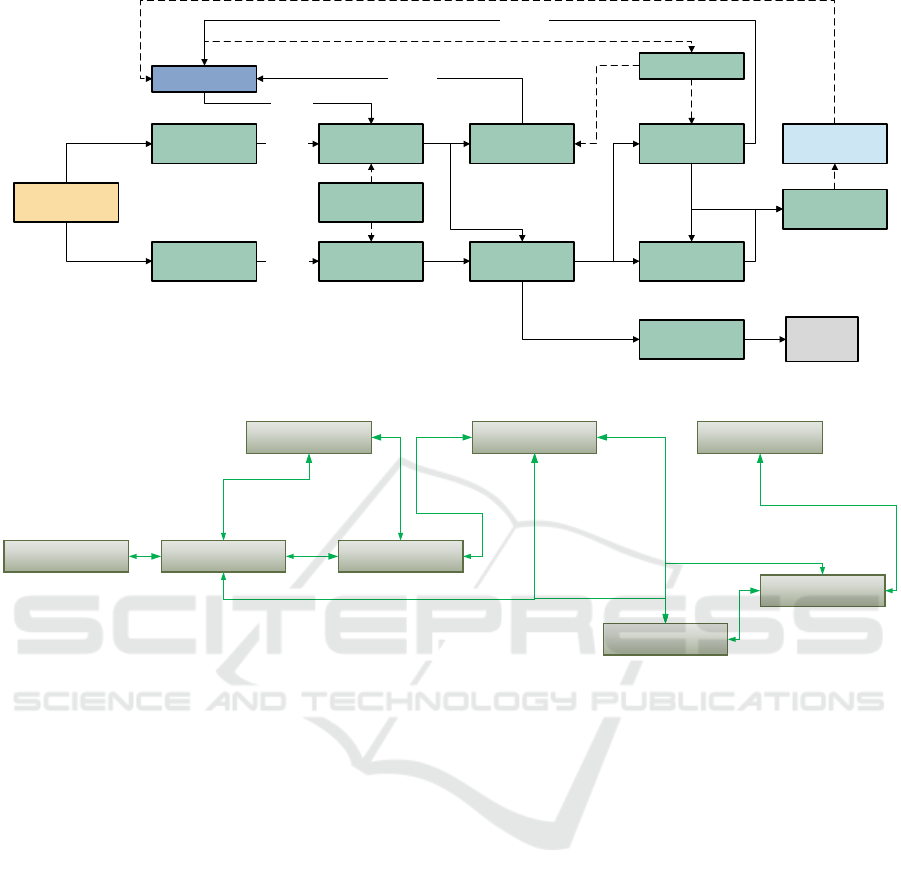

Figure 3: Architecture of DTs.

The connection between physical and virtual

systems is done with a communication interface. Its

role is connection and conversion of data through

sensors, switches, routers, firewalls, hosts, links,

databases, intelligent devices and management

systems (Fig. 3). That is a two-way street.

Communication solutions are IoT, big data, and cloud

technologies (Shin et al., 2018).

DTs can have different levels of autonomy in

response to physical systems, and they can have

different levels of integration of physical systems.

Autonomy is directly connected to responses in real-

time.

3 DIGITAL TWINS AS AN

IMPORTANT TOOL FOR

INDUSTRIAL SYMBIOSIS

The implementation of DT principles in industry or

systems created by IS can be done only on previously

designed models. Lyu (2024) gave differentiation

between models created with various methodologies

as first principle models (models based on numerical

solutions and optimization), statistical models

(machine learning based on historical state and

behaviour data, neural networks), rule-based and

multiagent system based decision-making models,

computer-aided engineering (CAE), deep learning

models, industrial DT applications (for PALM), IoT,

AI-based operational energy-DT (EDT), Data-driven

EDT, power industry EDT, generic EDT, etc.

Software that will be used in any of these types of

models should provide the following: synchronization

rules and template implementation for temporal data,

their synchronization, their aggregation, obtain data

from sensors and other sources in the physical

systems,

data conversion, use of behavioural models

of DT, implementing visual models, creating multi-

images of physical systems (PS), DT data processing

and analysis, results visualization, ensure data

confidentiality, and DT data storage. All these digital

processes with their relations are presented in Fig. 4.

Digital platforms for the implementation of DTs

are IoT, Business process Management platforms,

analytics & data platforms, and application platforms

(Nath, 2021). Moreover, there can be used public

clouds like Microsoft Azure, Amazon Web Services

(AWS), Google Cloud Platform (GCP), Alibaba

Cloud, Oracle Cloud Infrastructure (OCI), IBM

Cloud, and Tencent Cloud.

In manufacturing, the collaboration DT is divided

into the physical world (shop floor and management

floor participants) and the cyber world (DT layers,

industrial technology layers and application layers).

The shop floor participants are factories machines,

workers, monitoring devices, sensors, robotic devices,

etc. The management floor participants are people

who use operational data such

as decision-makers,

management department employees, HR, security,

and all other human supported departments in

administration).

Production process

Sensors,

smart devices,

Databases,

Management system

Physical system data

update

Physical system feedback

Virtual copies

(simulation, other

alg orithms)

Industrial Symbiosis Improvement with Digital Twins

41

Figure 4: Software system architecture for DTs.

Figure 5. Interaction between different information technologies for creating of DT in industrial symbiosis.

On the other side, in the cyber world, DT layer has

models and solutions for autonomous collaborative

industrial manufacturing. Here could be found real-

time data and predictions of potential risks that are

used by decision-makers and sent to the physical

system. The industrial technologies layer is included

in solutions for collaboration, like blockchain

networks (secure exchange of data), AI-based DT

technologies (predictive data analytics, predict

potential risks, predictive maintenance, etc.), cloud

and edge computing technologies for real-time data

analysis, and visualization tools for clear and quick

understanding of physical systems (Fig. 5). The

application layer is the usage of DT for different

systems, like the energy industry, rail industry,

logistic industry, health care industry, etc.

DTs in manufacturing creates systems at different

levels, like unit level (smallest participant/unit),

system level (system of a few participants or units

connected into a process) and system of systems

(SoS) level (connected to several systems or DT

levels).

The implementation of DT in the industry is in a

low stage. Applications of DT in industry are in

general for optimization and predictions for discrete

manufacturing; manage, predict, optimize, safety and

scheduling of batch processes; predict energy demand

and improve energy distribution; improvement and

prediction of renewable energy generation; conduct

real-time FEM analytics for assessing offshore oil

platforms’ structural integrity using weather and

ocean data; enhance recovery yields in mineral

processing and monitor mine tailings and

environmental waste in real-time and offer expert

recommendations; vehicles supply manufacturers

with usage data for design enhancements. Current

information about implemented projects of DT in the

industry showed partial implementation of specific

processes. DT is implemented in water processing for

future state of the system prediction, an air separation

process for selecting the fastest start up and shut

down, beverage processes for rescheduling based on

various disturbances, steam turbine subsystems for

online performance monitoring, and phosphorus

production for minimal energy consumption. Ma et

Physical object

Behavior data

(sensor 1, 2, 3, …. n)

Muls emedia data

(devices 1, 2, 3, …. m)

Behavior data

synchronization and

aggregation

Mulsemedia data

synchronization and

aggregation

Mathematical mode l

DT data synchronization

and a ggre gation

Behavior dat a analyzi s DT data processing

DT reproduction

Data protection

Actuators

(1, 2, 3, …. n)

VIRTUAL MODEL

- Data

- Ti me st amps

- Data

- Ti me st amps

RESEARCH

- Data

- Ti me st amps

Research results

RESEARCH OBJECTIVES

Research results

- Cloud storage

- Local storage

- Remote users

DATA

(weather, economics, market)

SUPPLY CHAIN

ERP, manufacture, customer,

human capital, management

system

Energy trading system

IoT/intelligent apps

Business apps

CLOUD

(DT apps, IoT platform)

Service managemnet

ENERGY GENERATION

(wind, solar, hydro, other)

ELECTRICITY GRID

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

42

al. (2022) reported about DT implementation in the

ceramic industry in China. Implementation in Pharma

can lead by DT connections with cognitive sensors

and simulations. Based on that, DT is directed to

visualization. Visualization is done with smart data

management and integration. It uses data

visualization, data persistence and processing, and

data integration. Integrated data are shown in MES,

SCADA, PLC and IBA (Salis et al., 2023).

Logistics is very important in supply chains for

industrial processes or in systems like IS. DT can be

used in “Logistics 4.0” as part of Industry 4.0. This

helps in tracking the movement of goods.

Moreover, control, energy generation and fault

diagnostics of wind turbines can be supported by DT.

Iyer et al. (Iyer et al., 2024) showed the system of

IS based on the framework of digitalization within

Industry 4.0. They connect existing “industrial

technologies” based on products and information that

are supplied by industry in symbiotic systems. All

these information must be sent to the work centre of

DT (Park et al., 2020). On the other side, the

sustainable smart manufacturing framework suggests

using intelligent design, intelligent production,

intelligent maintenance and service, and intelligent

recovery (Ren et al., 2019).

Determination and creation of DT are done by two

teams: business & operations team, and the IT &

development team (Nath, 2021). The implementation

steps for DT in IS are following:

1. There must have already established IS or

EIP.

2. Specification of all processes that connect

units in IS or EIP. Determination exchange

processes for energy, materials, goods, and

services. The whole system is divided into

subsystems based on the business model that

will be used. (separate system for electricity

generation and distribution, separate heat

generation and distribution, separate

systems for sharing materials, etc.).

3. Determination of bottlenecks and negative

factors. Preparing of high-digital DT

references.

4. Prioritization of integrated parts and data

validation.

5. Creating mathematical models and

simulation.

6. Selecting the best model with simulation

validation.

7. Determination of the connection points for

sensors and all other equipment that is

required. Making a list of equipment for

further projects.

8. Determination of benefits (added value,

economic and quality benefits).

9. The project proposal is analysed for

economic, environmental, production and

social benefits. If there are benefits (higher

incomes), comes the next step. Based on the

type of connection, selection of

communication technology must be done. If

there are no calculated benefits, the whole

process returns back to the basics modelling

and simulation.

10. Determination of complete business process

and operation plan. Decision-making for

investment for the DT project.

11. When all processes and connections are

determined, the digital (virtual) system is

designed.

12. Installation of required equipment (sensors,

flowmeters, ethernet, etc.) and establishing

two-way connection between physical and

digital systems.

13. The first results for the function of created

DT. Testing and improvement.

14. Used Business model will lead to creating

sub-control centres. Those sub-control

centres are control systems of separate

companies that are in charge of the supply or

distribution of utilities, materials or services.

15. All sub-control centres are connected to the

main control centre of IS where the

management of IS can be controlled,

monitored and take action with decision-

making for all units that consist of the IS or

EIP.

In case when IS management is responsible for all

exchange processes in IS, and no other companies are

in charge of specific types of distribution or services,

there is only one control centre.

Establishing DTs in the industry, but also in IS

must be based on key factors for approving that kind

of project. Objective criteria must be set based on the

DT’s target to ensure it adds business value. Business

values and outcomes broadly include improved life of

the asset, process efficiency gains, operational

optimization or lower operating costs, new digital

revenues, competitive advantages, improvement and

customer satisfaction (production units in IS),

improved safety, and social goodness, like the

reduction of the carbon footprint (Nath, 2021).

Moreover, the part of business processes is sending

alerts. Yellow (lower importance) and red (high

importance) alert for the probability of existing

problems in the system. Many monitored parameters

Industrial Symbiosis Improvement with Digital Twins

43

are related to the key performance indicators

determined for the system.

Senna et al. (2020) determined pillars of energy-

DT. The four pillars are factory driver IO, human-

machine interaction, energy data modelling &

standardization, and data-driven services. As

supporting IOT technologies are selected factory

driver IO, big data & cloud computing, industrial

internet of things (IIoT), AI, DT modelling and

simulation, and augmented reality. Major objectives

for establishing are energy savings, environmental

footprint reduction, and life cycle cost reduction.

IS contain production processes as all processes

of exchange and transformation of materials and

energy quality; there are storage, recyclability,

services, etc. Integration of all these additional

segments in DT could be made with specified DTs of

storage/warehouses, DT of shipping, DT of recycle

system, and DT of specific services based on KPIs

related to those services.

4 HOW DT CAN IMPROVE IS

The benefits for the industry gotten by usage of DT

are many. Reduced time to design and to market (DT

utilize digital models to simulate product

performance, potentially reducing or eliminating the

need for field trials. This is because simulations can

identify likely failure scenarios, enabling designers to

make necessary product adjustments before

production.), Reduced waste during manufacturing

(determining optimal manufacturing parameters can

reduce waste and rejects, leading to a greener and

more advanced production process.), Reduced energy

consumption (DT enables first-time right production,

reducing energy consumption per part. It can also

identify products with suboptimal energy

performance for replacement.), Reduced raw

material consumption (operating optimally with

minimal defects reduces raw material consumption,

promoting greener operation.), and Improved

performance monitoring (High-fidelity 3D models

enhance augmented reality, improving product

tracking and problem-solving. IoT technologies also

offer the advantage of remote monitoring.),

Introduction of numerous virtual sensors (digital

models in DTs allow engineers to measure physical

quantities, like temperature and pressure, at locations

unsuitable for physical sensors.), Maintaining

optimal operation (two-way communication between

a DT and its physical twin, like a production machine,

allows for parameter adjustments in the DT to be

applied to the physical counterpart, ensuring optimal

operation.), Reduced cost of maintenance of

machinery and elimination of downtime (By

predicting future states using predictive analytics, a

DT can anticipate maintenance issues, allowing for

preventive maintenance and avoiding costly

shutdowns. Optimizing asset operations also reduces

maintenance costs.), Improved warehousing/shipping

of finished products (A DT mirroring warehousing

and shipping optimizes operations, further reducing

the facility’s carbon footprint.), Improved

collaboration between teams (Digital models linked

by a common digital thread improve factory team

collaboration by providing a “single source of truth”.

This minimizes errors and enhances synergies in

manufacturing optimization.), Improved safety (DT-

controlled augmented reality can train staff in

hazardous trades safely).

5 FUTURE DEVELOPMENTS

NEEDED FOR IS

DTs are not so well presented to the industrial

symbiotic systems. There is not enough knowledge in

management or engineers that are employed in

production plants.

There is a lack of big data for training ML models

in DTs of manufacturing processes. ML models are

crucial in DTs for autonomous decision-making.

They need large, representative data sets, which are

scarce in manufacturing due to its heterogeneous

nature, unlike uniform consumer industries. Each

manufacturing method requires unique data, making

it time-consuming and resource-intensive to build

large data sets. Challenges include finding, accessing,

and transforming data from various sources, along

with issues of poor data quality and translation loss.

Data security in DTs is crucial in a connected IIoT

environment to protect intellectual property,

requiring a focus on privacy, confidentiality,

transparency, and data ownership, particularly in

business collaborations.

The lack of standards, regulations, and

governance in data handling hinders data-centric

technologies like DTs. For effective data sharing,

interoperability standards are vital, especially

between DTs from different organizations. Issues

may also occur when DTs at various levels produce

different data types without correct conversion.

Reluctance to share strategic knowledge: data is

now a key asset, not just a business by-product.

Therefore, companies may keep data confidential to

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

44

maintain their competitive edge, hindering

collaboration between organizations’ DTs.

Observability and controllability issues: a DT’s

control system requires processes to be observable

and controllable. Sensors need to capture critical

quantities effectively, while actuators must execute

the DT’s commands. Suitable hardware is essential

for DT success.

Creating physics-informed ML models enhances

accuracy by identifying and removing data outliers,

but their complex multi-physics and multiscale nature

complicate high-fidelity model development.

Lifecycle mismatch: products like aircraft and

cars often last longer than the software used to design,

simulate, or analyze them. Unsupported software can

render the virtual twin obsolete before its physical

version.

Upfront capital outlay: creating reliable DTs

requires significant resources affordable only by large

corporations. Without resource pooling by industry

bodies, DTs may remain inaccessible to smaller

businesses for years.

Conventional engineers must learn new ML and

AI methods and be assured of their effectiveness to

adopt DTs in the factory.

6 CONCLUSIONS

DTs are built on mathematical models and simulation

software that use real-time data from sensors or IoT

devices. The implementation of DT principles in IS

can optimize resource usage, improve collaboration,

and create more sustainable production systems.

However, the lack of system integration with ICT

tools and the complexity of knowledge sharing within

symbiosis networks delay its effective

implementation. To establish DTs in IS, a systematic

approach is required, involving the specification of

exchange processes, determination of bottlenecks,

prioritization of integrated parts, and the creation of

mathematical models and simulations. The benefits of

DTs in IS include reduced time to market, reduced

waste and energy consumption, improved

performance monitoring, and enhanced collaboration

between teams. Future developments needed for IS

include addressing the lack of big data for training

ML models, ensuring data security, establishing

standards and regulations, and overcoming

observability and controllability issues.

REFERENCES

Alam, K. M., & El Saddik, A. (2017). C2PS: A digital twin

architecture reference model for the cloud-based cyber-

physical systems. IEEE Access, 5, 2050–2062.

https://doi.org/10.1109/ACCESS.2017.2657006

Al-Quradaghi, S., Zheng, Q. P., & Elkamel, A. (2020).

Generalized Framework for the Design of Eco-

Industrial Parks: Case Study of End-of-Life Vehicles.

Sustainability, 12(16).

https://doi.org/10.3390/SU12166612

Awouda, A., Traini, E., Bruno, G., & Chiabert, P. (2024).

IoT-Based Framework for Digital Twins in the Industry

5.0 Era. Sensors, 24(2).

https://doi.org/10.3390/S24020594

Barbie, A., & Hasselbring, W. (2024). From Digital Twins

to Digital Twin Prototypes: Concepts, Formalization,

and Applications. IEEE Access, 12, 75337–75365.

https://doi.org/10.1109/ACCESS.2024.3406510

Borodulin, K., Sokolinsky, L., Radchenko, G., Tchernykh,

A., Shestakov, A., & Prodan, R. (2017). Towards digital

twins cloud platform: Microservices and computational

workflows to rule a smart factory. UCC 2017 -

Proceedings of The10th International Conference on

Utility and Cloud Computing, 205–206.

https://doi.org/10.1145/3147213.3149234

Catarci, T., Sapio, F., Firmani, D., Mandreoli, F., Leotta, F.,

& Mecella, M. (2019). A Conceptual Architecture and

Model for Smart Manufacturing Relying on Service-

Based Digital Twins.

https://doi.org/10.1109/icws.2019.00047

Cinar, Z. M., Korhan, O., Nuhu, A. A., & Zeeshan, Q.

(2020). Digital Twins for Industry 4.0: A Review.

https://doi.org/10.1007/978-3-030-42416-9_18

Costantini, A., Antonacci, M., Nehls, D., Bellavista, P.,

Delamarre, C., Galletti, M., Martelli, B., Ahouangonou,

J. C., Di Modica, G., Cesini, D., & Duma, D. C. (2022).

IoTwins: Toward Implementation of Distributed

Digital Twins in Industry 4.0 Settings. Computers, 11.

https://doi.org/10.3390/computers11050067

Fantozzi, I. C., Loy, G., Santolamazza, A., & Schiraldi, M.

M. (2025). Digital Twins: Strategic Guide to Utilize

Digital Twins to Improve Operational Efficiency in

Industry 4.0. Future Internet, 17.

https://doi.org/10.3390/fi17010041

Feiferytė-Skirienė, A., & Stasiškienė, Ž. (2021). Seeking

Circularity: Circular Urban Metabolism in the Context

of Industrial Symbiosis. Sustainability, 13(16).

https://doi.org/10.3390/SU13169094

Ferrigno, E., & Barsola, G. A. (2023). 3D Real Time Digital

Twin. SPE Latin American and Caribbean Petroleum

Engineering Conference Proceedings, 2023-June.

https://doi.org/10.2118/213115-MS

Fuller, A., Fan, Z., Day, C., & Barlow, C. (2019). Digital

Twin: Enabling Technologies, Challenges and Open

Research. IEEE Access

, 8, 108952–108971.

https://doi.org/10.1109/ACCESS.2020.2998358

Gómez-Berbís, J. M., & Amescua-Seco, A. de. (2019).

SEDIT: Semantic Digital Twin Based on Industrial IoT

Data Management and Knowledge Graphs.

Industrial Symbiosis Improvement with Digital Twins

45

Communications in Computer and Information

Science, 1124 CCIS, 178–188.

https://doi.org/10.1007/978-3-030-34989-9_14

González-Herbón, R., González-Mateos, G., Rodríguez-

Ossorio, J. R., Domínguez, M., Alonso, S., & Fuertes,

J. J. (2024). An Approach to Develop Digital Twins in

Industry. Sensors 2024, Vol. 24, Page 998, 24(3), 998.

https://doi.org/10.3390/S24030998

Grant, G. B., Seager, T. P., Massard, G., & Nies, L. (2010).

Information and Communication Technology for

Industrial Symbiosis. Journal of Industrial Ecology,

14(5), 740–753. https://doi.org/10.1111/J.1530-

9290.2010.00273.X

Grant, Seager et al 2010 - Information and Communication

Technology. (n.d.).

Iyer, S. V, Sangwan, K. S., & Dhiraj. (2024). Development

of an Industrial Symbiosis Framework through

Digitalization in the Context of Industry 4.0. Procedia

CIRP, 122, 515–520.

https://doi.org/https://doi.org/10.1016/j.procir.2024.01.

075

Kang, J. S., Chung, K., & Hong, E. J. (2021). Multimedia

knowledge‐based bridge health monitoring using

digital twin. Multimedia Tools and Applications,

80(26–27), 34609–34624.

https://doi.org/10.1007/S11042-021-10649-X

Kaur, M. J., Mishra, V. P., & Maheshwari, P. (2019). The

Convergence of Digital Twin, IoT, and Machine

Learning: Transforming Data into Action. Internet of

Things, 3–17. https://doi.org/10.1007/978-3-030-

18732-3_1

Kerkeni, R., Mhalla, A., & Bouzrara, K. (2025).

Unsupervised Learning and Digital Twin Applied to

Predictive Maintenance for Industry 4.0. Journal of

Electrical and Computer Engineering, 2025(1),

3295799. https://doi.org/10.1155/JECE/3295799

Khalyasmaa, A. I., Eroshenko, S. A., Stepanova, A. I., &

Matrenin, P. V. (2023). Review of the Digital Twin

Technology Applications for Electrical Equipment

Lifecycle Management. Mathematics, 11.

https://doi.org/10.3390/math11061315

Kosmol, L. (2019). Sharing is Caring - Information and

Knowledge in Industrial Symbiosis: A Systematic

Review. Proceedings - 21st IEEE Conference on

Business Informatics, CBI 2019, 01, 21–30.

https://doi.org/10.1109/CBI.2019.00010

Lampropoulos, G., & Siakas, K. (2023). Enhancing and

securing cyber-physical systems and Industry 4.0

through digital twins: A critical review. Journal of

Software: Evolution and Process, 35(7), e2494.

https://doi.org/10.1002/SMR.2494

Lyu, Z. (2024). Handbook of Digital Twins. Handbook of

Digital Twins, 1–902.

https://doi.org/10.1201/9781003425724/HANDBOOK

-DIGITAL-TWINS-ZHIHAN-LYU/RIGHTS-AND-

PERMISSIONS

Ma, S., Ding, W., Liu, Y., Ren, S., & Yang, H. (2022).

Digital twin and big data-driven sustainable smart

manufacturing based on information management

systems for energy-intensive industries. Applied

Energy, 326, 119986.

https://doi.org/10.1016/J.APENERGY.2022.119986

Nath, S. van S. P. I. D. (2021). Building Industrial Digital

Twins. Packt Publishing; Safari.

Okpala Charles Chikwendu, -, Nwankwo Constance

Obiuto, -, & Udu Chukwudi Emeka, -. (2025). Digital

twin applications for predicting and controlling

vibrations in manufacturing systems. World Journal of

Advanced Research and Reviews, 25.

https://doi.org/10.30574/wjarr.2025.25.1.3821

Park, K. T., Lee, D., & Noh, S. Do. (2020). Operation

Procedures of a Work-Center-Level Digital Twin for

Sustainable and Smart Manufacturing. International

Journal of Precision Engineering and Manufacturing -

Green Technology, 7(3), 791–814.

https://doi.org/10.1007/S40684-020-00227-

1/METRICS

Pylianidis, C., Osinga, S., & Athanasiadis, I. N. (2021).

Introducing digital twins to agriculture. Computers and

Electronics in Agriculture, 184.

https://doi.org/10.1016/j.compag.2020.105942

Rassolkin, A., Rjabtsikov, V., Vaimann, T., Kallaste, A.,

Kuts, V., & Partyshev, A. (2020). Digital Twin of an

Electrical Motor Based on Empirical Performance

Model. 2020 11th International Conference on

Electrical Power Drive Systems, ICEPDS 2020 -

Proceedings.

https://doi.org/10.1109/ICEPDS47235.2020.9249366

Ren, S., Zhang, Y., Liu, Y., Sakao, T., Huisingh, D., &

Almeida, C. M. V. B. (2019). A comprehensive review

of big data analytics throughout product lifecycle to

support sustainable smart manufacturing: A

framework, challenges and future research directions.

Journal of Cleaner Production, 210, 1343–1365.

https://doi.org/10.1016/J.JCLEPRO.2018.11.025

Rodič, B. (2017). Industry 4.0 and the New Simulation

Modelling Paradigm. Organizacija, 50(3), 193–207.

https://doi.org/10.1515/ORGA-2017-0017

Ruppert, T., & Abonyi, J. (2020). Integration of real-time

locating systems into digital twins. Journal of

Industrial Information Integration, 20.

https://doi.org/10.1016/j.jii.2020.100174

Salis, A., Marguglio, A., De Luca, G., Razzetti, S.,

Quadrini, W., & Gusmeroli, S. (2023). An Edge-Cloud

based Reference Architecture to support cognitive

solutions in Process Industry. Procedia Computer

Science, 217, 20–30.

https://doi.org/10.1016/J.PROCS.2022.12.198

Scafà, M., Marconi, M., & Germani, M. (2020). A critical

review of symbiosis approaches in the context of

Industry 4.0☆. Journal of Computational Design and

Engineering, 7(3), 269–278.

https://doi.org/10.1093/JCDE/QWAA022

Senna, P. P., Almeida, A. H., Barros, A. C., Bessa, R. J., &

Azevedo, A. L. (2020). Architecture Model for a

Holistic and Interoperable Digital Energy Management

Platform. Procedia Manufacturing, 51, 1117–1124.

https://doi.org/https://doi.org/10.1016/j.promfg.2020.1

0.157

ICEEECS 2025 - International Conference on Advances in Electrical, Electronics, Energy, and Computer Sciences

46

Shin, H. J., Cho, K. W., & Oh, C. H. (2018). SVM-Based

Dynamic Reconfiguration CPS for Manufacturing

System in Industry 4.0. Wireless Communications and

Mobile Computing, 2018(1), 5795037.

https://doi.org/10.1155/2018/5795037

Verdouw, C., Tekinerdogan, B., Beulens, A., & Wolfert, S.

(2021). Digital twins in smart farming. Agricultural

Systems, 189.

https://doi.org/10.1016/J.AGSY.2020.103046

Wang, B., Zhou, H., Li, X., Yang, G., Zheng, P., Song, C.,

Yuan, Y., Wuest, T., Yang, H., & Wang, L. (2024).

Human Digital Twin in the context of Industry 5.0.

Robotics and Computer-Integrated Manufacturing, 85,

102626. https://doi.org/10.1016/J.RCIM.2023.102626

Zafar, M. H., Sanfilippo, F., & Blazauskas, T. (2023).

Harmony Unleashed: Exploring the Ethical and

Philosophical Aspects of Machine Learning in Human-

Robot Collaboration for Industry 5.0. 2023 IEEE

Symposium Series on Computational Intelligence, SSCI

2023, 1775–1780.

https://doi.org/10.1109/SSCI52147.2023.10371798

Zhang, J., Ellwein, C., Wortmann, A., Michael, J., &

Heithoff, M. (2025). Digital twin and the asset

administration shell. Software and Systems Modeling.

https://doi.org/10.1007/s10270-024-01255-0

Zhang, X., Lin, D. K. J., & Wang, L. (2023). Digital Triplet:

A Sequential Methodology for Digital Twin Learning.

Mathematics, 11(12).

https://doi.org/10.3390/MATH11122661

Industrial Symbiosis Improvement with Digital Twins

47