Design and Field Evaluation of a Robotic Cotton Harvester with

Improved Structural Balance and Suction Mechanism

Van Patiluna

1

, Joe Mari Maja

1

, Aashish Karki

2

and Edward Barnes

3

1

Center of Applied Artificial Intelligence for Sustainable Agriculture, South Carolina State University,

300 College St, Orangeburg, SC, U.S.A.

2

Department of Plant and Environmental Sciences, 171 Poole Agricultural Center, Clemson, SC, U.S.A.

3

Cotton Incorporated, 6399 Weston Parkway, Cary, NC 27513, U.S.A.

Keywords: Cotton Harvester, Robotics, Simulation.

Abstract: Mechanization in the cotton industry increased efficiency and productivity by reducing reliance on manual

labor and improving overall output. Automation and robotics have been increasingly integrated into cotton

production in the United States to address various challenges and enhance agricultural efficiency. Using

robotics and automation in agriculture is a widespread idea whose technical feasibility has already been

proven in several studies. The objective of this study is to design and implement a new robotic cotton harvester

addressing the problems encountered with the previous design. It featured a redesigned finger roller and an

optimized chassis to improve balance and structural integrity. The new design utilizes the same Amiga robotic

platform that is capable of heavy loads such as the header assembly and power generators. A field experiment

assessed harvesting efficiency under three different duty cycles corresponding to the speed of front finger

rollers. During the experiment, the new design experienced clogging of the eductor inlet hindering the

movement of cotton bolls to the collecting bin, which reduced harvesting efficiency. Although the harvesting

efficiency was lower than ideal, it was still slightly better than the previous design. Adjusting the speed of the

front finger rollers has no significant effect on the boll and trash collected, suggesting that lower speeds are

ideal. The static stress simulation of the chassis revealed a better balance and structural integrity than the

previous design. Overall, the new design of the cotton harvesting robot had better structural integrity, however,

it requires further improvements to address clogging of the eductor inlet to move the fibers from the header

assembly to the collecting bin, minimize the trash content and improve harvesting efficiency.

1 INTRODUCTION

Mechanization in the cotton industry has brought both

significant benefits and challenges by increasing

productivity by reducing reliance on manual labor but

also raised concerns about labor displacement and the

impact on traditional harvesting practices (Peterson &

Kislev, 1986). The adoption of machine harvesting

was driven largely by increased nonfarm wages and

the declining cost of mechanized harvesting,

reflecting the interplay between economic incentives

and technological advancements (Peterson & Kislev,

1986). This transition reshaped labor markets in

cotton-producing regions, with many traditional

cotton pickers shifting to other sectors such as

manufacturing (Jung, 2018).

Despite these economic gains, mechanization has

also raised environmental and sustainability

concerns. Cotton cultivation places considerable

pressure on natural resources such as land and water,

contributing to issues like soil degradation and the

overuse of pesticides (Natálio & Maria, 2018).

In response to these challenges, automation and

robotics have been increasingly integrated into U.S.

cotton production to enhance efficiency and

sustainability (Barnes et al., 2021). Recent

advancements in precision agriculture, improved

irrigation systems, and novel cotton varieties have

enabled the development of autonomous multi-

purpose robotic platforms (Maja et al., 2021). These

platforms streamline operations, optimize resource

use, and reduce the need for chemical inputs.

Currently, most cotton in the U.S. is harvested

using large, heavy mechanical pickers (EPA, 2025).

The weight of these machines causes soil compaction,

which reduces long-term soil productivity (Al-Shatib

Patiluna, V., Maja, J. M., Karki, A. and Barnes, E.

Design and Field Evaluation of a Robotic Cotton Harvester with Improved Structural Balance and Suction Mechanism.

DOI: 10.5220/0013945700003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 647-654

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

647

et al., 2021; Lagnelov et al., 2023; Antille et al.,

2016). Furthermore, the high cost of such equipment

requires large-scale operations of 600 to 800 hectares

to justify a single machine (Barnes et al., 2021).

Several robotic cotton harvesting systems have

been proposed to address these limitations. Examples

include a wet/dry vacuum cleaner-based harvester

(Fue et al., 2021), a Cartesian manipulator with a

suction-based end-effector (Maja et al., 2021), and a

three-fingered robotic end-effector using a pin tape

mechanism (Gharakhani et al., 2022). A notable

recent approach involves finger roller-based pickers,

which collect bolls in bulk rather than individually, as

demonstrated by Mail et al. (2023) at Clemson

University. This method forms the foundation for the

improved robotic harvester developed in this study.

The objective of this study is to design, build, and

evaluate an improved robotic cotton harvester that

addresses the mechanical limitations and

performance issues identified in the previous

prototype. A new prototype was developed,

incorporating a redesigned finger roller and an

optimized chassis, and was evaluated through static

stress simulations and field experiments.

2 MATERIALS AND METHODS

2.1 Harvester Design

A new cotton harvester prototype was designed based

on the findings from the previous prototype built. It

maintained the same mechanism for collecting the

cotton bolls that is using finger rollers to pluck the

cotton bolls and an eductor system to move the bolls

to the collecting bin. It also used the same robotic

platform Amiga developed by Farm-NG

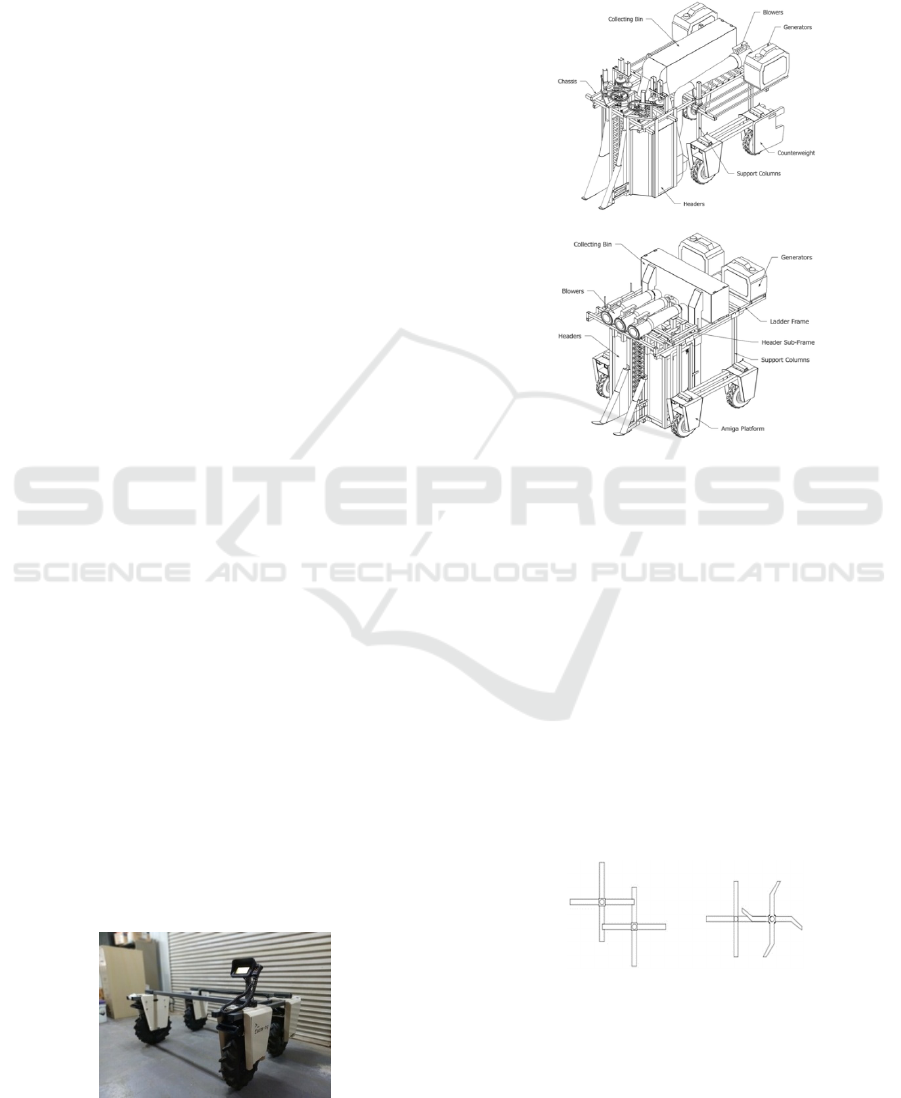

(Watsonville, CA, USA) as shown in Figure 1.

Instead of using belts and pulleys to drive the

finger rollers, an angled gearbox was used with 1:1

gear ratio used for the front rollers and 1:2 for the rear

rollers. To produce the vacuum at the eductor, an 800

CFM leaf blower was utilized. A third blower was

added to create to positive air pressure to blow the

cotton bolls accumulating in the eductor inlet.

Figure 1: Amiga robotic platform with bare chassis.

Two 2200-Watt generators were used to power the

blowers, motors and electronics system of the

harvester. The Amiga platform was powered by its

own battery pack. Figure 2 shows the sketch of the

previous design (a) and new design (b).

(a)

(b)

Figure 2: Sketches of the previous design (a) and the new

design (b).

The rollers were driven by a 100 rpm and 320 rpm

planetary gear motors for the front and rear rollers

respectively. The speed of the front rollers can be

adjusted to three duty cycles: 25%, 50% and 100%.

The shaft speed of the rear rollers was fixed at 320

rpm enough to pluck the cotton bolls from the fruiting

branch. Powering the motors were 2x15A and 2x30A

RoboClaw (BasicMicro, Temecula, CA, USA) motor

controllers. The configuration of the front finger

roller was modified as shown in Figure 3. In the

previous design, the front and rear rollers were offset

at an angle of about 54 degrees (Figure 3a). In the

revised design, the rollers are aligned side-by-side

(Figure 3b).

(a) (b)

Figure 3: Finger roller orientation of the previous design (a)

and new design (b).

The offset in the original design aimed to narrow the

header but reduced the rear roller's effectiveness,

TISAS 2025 - Special Session on Trustworthy and Intelligent Smart Agriculture Systems: AI, Blockchain, and IoT Convergence

648

since it only hit cotton bolls pulled deep enough by

the front roller. By aligning the rollers side-by-side,

cotton bolls do not have to be pulled deep enough to

be reached by the rear finger rollers (Maja et. al.,

2024). The fingers were made of aluminum, laser cut

to have 15-degree bend (Figure 3b).

The new design also focused on improving the

structural integrity of the robot chassis, addressing the

observed stresses and displacements from the field

trials of the previous design. Structural improvements

were introduced. First, ground clearance could be

adjusted through a separate sub-frame (Figure 2b). It

can be raised to adjust the ground clearance up to a

maximum travel of 100 mm. Secondly, the balance of

the entire robot can be adjusted by sliding the ladder

frame front or back. All the robots’ components

including the headers, ducts, collecting bin, blowers,

electronics and generators were mounted on the

ladder frame. This free movement of the ladder frame

allows the load to be moved along the support

columns to adjust the balance and weight distribution

as needed. A third blower was added to produce

positive air pressure to clear out stuck cotton bolls and

trash on the eductor inlet. The new design widened

the chassis by 4.3% to 1.62 m, while maintaining a

wheelbase of 0.96 m. Figure 4 shows the completed

robot.

(a) (b)

Figure 4: Front (a) and rear (b) views of the completed

assembly of the robotic cotton harvester.

Table 1: Weights of the load components.

Componen

t

Previous New

Header gross weigh

t

75.47 kg 85.79 kg

Generator dry weight 24.99 kg (245.06 N)

Static-stress simulation of the chassis of the

previous and new design was conducted to evaluate

the structural integrity of the chassis using Autodesk

Fusion (Autodesk, San Francisco, CA, USA).

Simulated loads of the heavy components such as the

header assembly and power generators were applied

to the chassis (see Table 1). Mechanical properties of

the materials used of the construction of the chassis

such as AISI 1018 and Aluminum 6061 (header

assembly) and 5052 H32 (chassis) were used applied

in the materials properties for simulation. Load was

also applied to the header assembly equivalent to the

bending force of a cotton stalk, about 63.64 N

(Khudayarov et. al., 2022; Zao et. al., 2022).

The load setup will provide the ultimate loads test

for the chassis. Once simulations were completed,

key parameters such as von Mises stress,

displacement, strain and safety factors were analyzed

using visualization tools and quantitative metrics

provided by the simulation software (Jahanbakhshi

et.al., 2019).

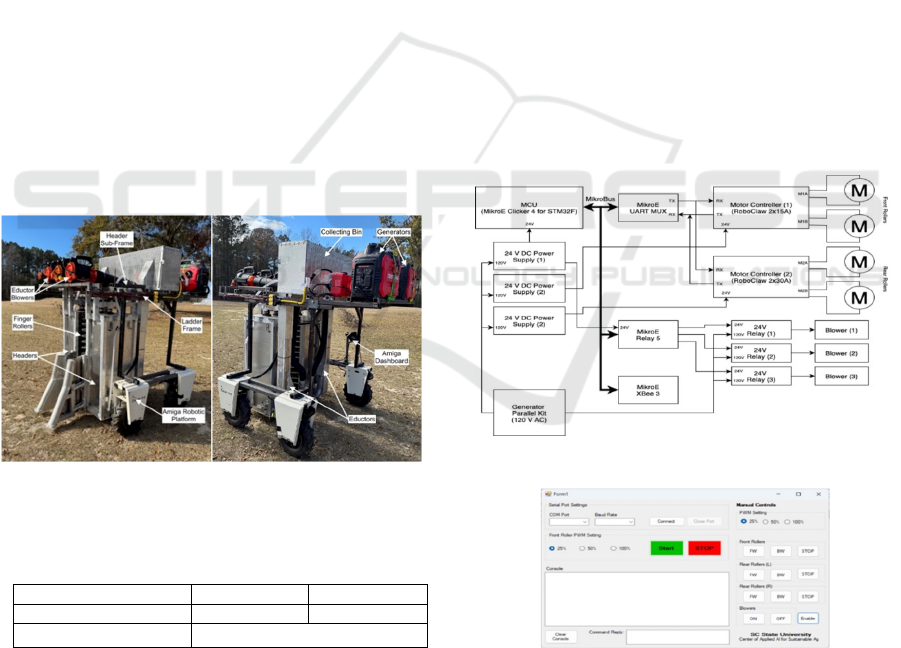

2.2 Control System

A MikroE Clicker 4 for STM32F (Belgrade, Serbia)

microcontroller board was used to control the motors,

blowers and handles wireless communication with

the base computer. Attached to the Clicker 4 board

were UART MUX 4 Click (to handle serial

communication with the motor controllers), Relay 5

Click (to control the AC power to the blowers) and

XBee 3 Click (for wireless communication). Figure 5

shows the block diagram of the control system.

Figure 5: Control system block diagram.

Figure 6: Dashboard and control software.

Three 24V DC power supply powered the

microcontroller and motor controllers. These power

supplies were also powered by a 120V AC coming

from the combined output the two generators through

a parallel kit. A dashboard software was developed to

Design and Field Evaluation of a Robotic Cotton Harvester with Improved Structural Balance and Suction Mechanism

649

control the system remotely (Figure 6). It featured an

automatic startup sequence (start button) and system-

wide shut down (stop button).

An automatic startup sequence was implemented

to manage the proper activation order of the motors

and blowers, thereby preventing power surges caused

by simultaneous current draw. The startup

configuration also enables pre-selection of the front

roller speed, which can be set to 25%, 50%, or 100%

duty cycle—corresponding to approximate shaft

speeds of 25 rpm, 50 rpm, and 100 rpm, respectively.

In addition to the automated sequence, the dashboard

software provides manual control options. An XBee

transceiver connected to the base computer facilitates

wireless communication with the controller module.

2.3 Study Site

The experiment and data collection were conducted

at the South Carolina State University Research and

Demonstration Farm in Olar, SC, USA (33.162161, -

81.136361). The cotton variety used was Deltapine

DP 2127 B3XF. The field was planted in a 1:1 skip-

row configuration to accommodate the robotic

harvester and to provide maneuvering space for the

research crew. Figure 7 shows an aerial view of the

cotton field used for the experiment.

Figure 7: Aerial shot of the cotton farm at SC State

Research and Demonstration farm.

Due to planting delays, cotton was sown on June 14,

2024. Chemical defoliants were applied on November

27, 2024, and the harvesting experiments were

conducted approximately one month later, on

December 23, 2024.

The experimental design followed a completely

randomized design (CRD) with three (3) treatments

and three (3) replications per treatment. The objective

was to evaluate the effect of front finger roller speed

on the number of cotton bolls and the amount of trash

collected during harvesting. Details of each treatment

are provided in Table 2.

Table 2: Experiment Treatment Details.

Treatment A Front finger rollers at 50% duty cycle.

Treatment B Front finger rollers at 25% duty cycle.

Treatment C Front finger rollers at 100% duty cycle.

A total of nine rows were selected and prepared

for the study. Each row measured 3 meters in length,

with a minimum buffer zone of 1.5 meters between

rows to prevent cross-contamination and allow robot

maneuverability. The layout and locations of the

treatment rows are shown in Figure 8. To minimize

the time and effort required to reposition the robot

between rows, an optimized experimental sequence

was developed.

(a)

(b)

Figure 8: Selected treatment rows with buffer zones: (a)

Treatments A3, C3, B3 and C1; (b) Treatments A1, A2, B1,

B2 and C2. C1-1 was replaced by C1-2 as treatment C1.

Instead of running treatments in a strict numerical

order, the robot followed a path that allowed for the

most efficient traversal across the field. The sequence

was as follows: A1-B1-C1-B2-A2-C2-B3-C3-A3.

The robot was configured with the appropriate

duty cycle setting for the front finger rollers, based on

the treatment assignment. The startup sequence was

executed using the developed dashboard software to

ensure that the motors for both the front and rear

rollers started in the correct order. The robot was

positioned at the center of the selected row (Figure 9)

and driven forward at a constant speed of

approximately 0.2 m/s.

Figure 9: Harvester robot positioned to harvest cotton bolls

from the treatment row.

Cotton bolls were collected from four distinct

locations: (1) inside the collecting bin, (2) within the

TISAS 2025 - Special Session on Trustworthy and Intelligent Smart Agriculture Systems: AI, Blockchain, and IoT Convergence

650

eductor duct, (3) on the ground, and (4) remaining

unharvested on the plant. The collected bolls were

placed into separate, labeled paper bags for each

treatment. After the experiment, cotton fibers were

separated from foreign materials such as leaves and

stalk fragments that were inadvertently collected

during harvesting. The cleaned cotton fiber and

associated trash were then weighed separately.

Due to the mechanical damage inflicted by the

harvesting process, most bolls were too mangled to be

counted individually. To estimate the number of

cotton bolls collected from each source (bin, header,

ground, and plant), the total fiber weight was divided

by 5.3 grams—the average weight of a single

Deltapine DP 2127 B3XF cotton boll. The average

boll weight was determined by sampling and

weighing intact bolls from the same experimental

field. After the number of cotton bolls were

determined, the harvesting efficiency of the robotic

cotton harvester was calculated using Equation (1).

𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦

𝑜𝑢𝑡𝑝𝑢𝑡

𝑖𝑛𝑝𝑢𝑡

𝑥100%

(1)

where:

output – number bolls collected in the bin

input – total number of cotton bolls collected

The input data included the estimated number of

cotton bolls collected from four locations: the

collecting bin, header assembly, ground, and

remaining on the plant. Trash content, consisting

primarily of leaves, stems, and other debris, were

quantified by its weight relative to the total harvested

material.

To calculate the percentage of trash collected in the

bin and header assemblies, Equation (2) below was

used.

% 𝑡𝑟𝑎𝑠ℎ

𝑡𝑟𝑎𝑠ℎ 𝑤𝑒𝑖𝑔ℎ𝑡

𝑡𝑟𝑎𝑠ℎ

𝑓

𝑖𝑏𝑒𝑟 𝑤𝑒𝑖𝑔ℎ𝑡

𝑥100%

(2)

Trash found on the ground and on the plant were

excluded from analysis, as it was not mechanically

collected during the experiment and therefore not

attributable to the harvester's performance.

3 RESULTS

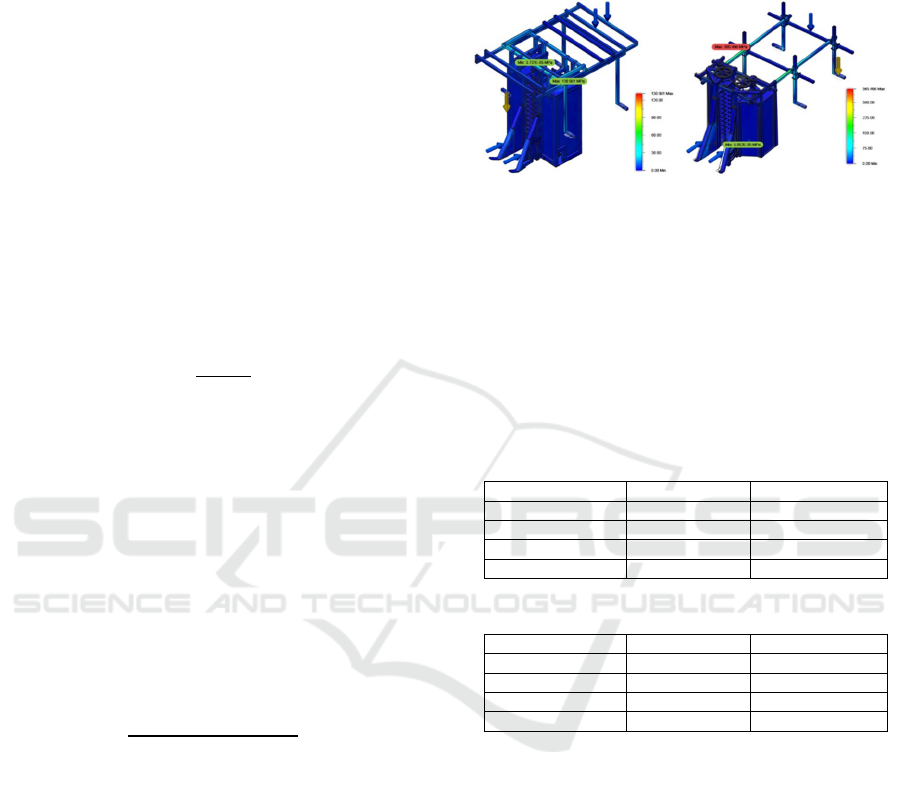

3.1 Static Stress Analysis of the Chassis

After the simulation, the results revealed a

concentration of stress in the cantilever structure of

the previous design (Figure 10b). In contrast, the new

design exhibited moderate stress localized on one of

the crossbars of the header sub-frame (Figure 10a).

The elevated stress observed in the previous

design was attributed to the header assembly being

supported solely by the front columns of the chassis,

creating a cantilevered overhang effect.

(a) (b)

Figure 10: Stress visualization of the integrated stress

analysis for the (a) previous design and (b) new design

showing von Mises stress.

In the redesigned system, the headers were supported

on all four sides, allowing the load to be distributed

more evenly across the sub-frame. Quantitative

simulation data comparing the two designs is

summarized in Table 3.

Table 3a: Static stress simulation data for the previous

design.

Data Min Max

Stress (von Mises) 5.025E-05 MPa 365.496 MPa

Displacement 0.00 mm 49.383 mm

Strain 4.240E-10 0.003

Safety Facto

r

0.566 15.00

Table 3b: Static stress simulation data for the new design.

Data Min Max

Stress (von Mises) 3.731E-05 MPa 130.981 MPa

Displacement 0.00 mm 3.223 mm

Strain 1.938E-10 0.001

Safety Facto

r

1.58 15.00

The previous design exhibited a significantly

higher von Mises stress of 365.496 MPa, compared to

130.981 MPa observed in the new design. In the

previous design, stress was primarily concentrated at

the frame joints between the cantilever and the

support columns. Both designs experienced strain in

the same high-stress regions, with the previous design

showing a peak strain of 0.003, while the new design

showed a lower value of 0.001. As expected, the

maximum displacement was also greater in the

previous design, measured at 49.38 mm at the stalk

lifter. The simulation did not fully account for

dynamic displacement in the cantilever structure, but

further inspection of the integrated model revealed a

pronounced increase in displacement at the cantilever

section, as illustrated in Figure 11.

Design and Field Evaluation of a Robotic Cotton Harvester with Improved Structural Balance and Suction Mechanism

651

Figure 11: Displacement of the chassis of the previous

design.

The high stress concentration observed in the

previous design resulted in a safety factor of only

0.57, indicating a high risk of permanent deformation

or even material failure under operational loads. This

value fell below both the yield and ultimate tensile

strengths of the material, suggesting structural

inadequacy. In contrast, the new design achieved a

64.18% reduction in von Mises stress compared to the

previous version and exhibited substantially lower

displacement with no bending or deformation.

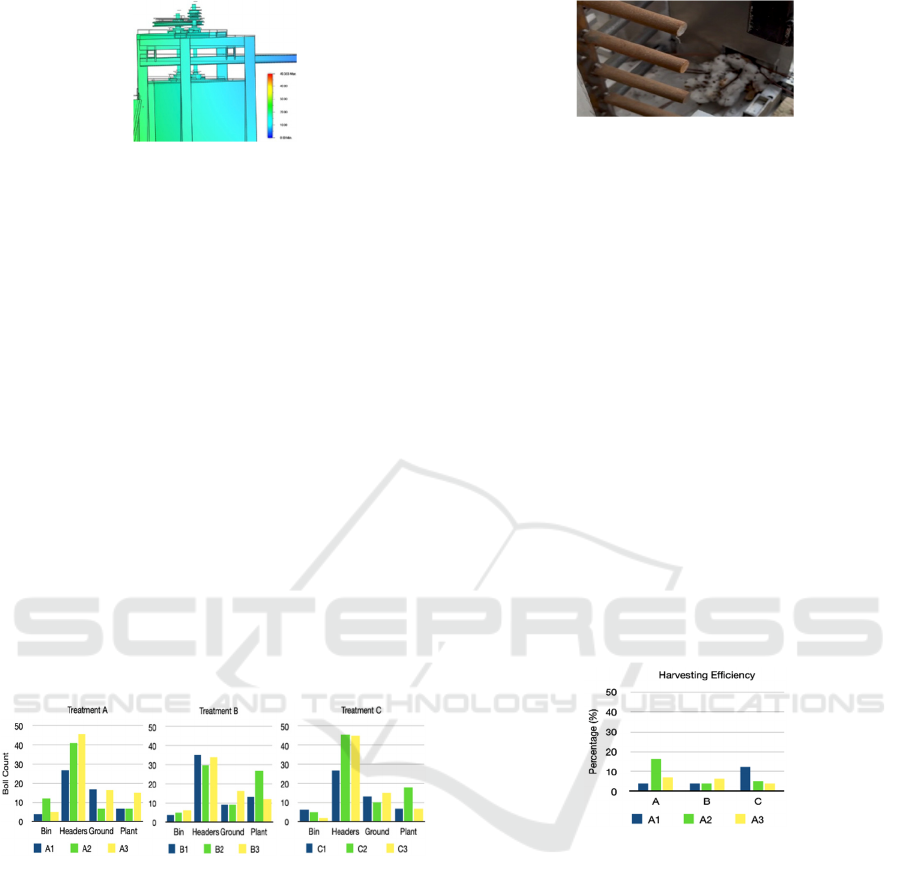

3.2 Cotton Boll Harvesting

After weighing the collected cotton fibers, the

approximate number of cotton bolls from each

collection point—the collecting bin, inside the

headers, on the ground, and remaining on the plant—

was estimated by dividing the fiber weight by the

average weight of a single boll (5.3 grams).The

estimated distribution of cotton bolls across these

collection points is illustrated in Figure 12.

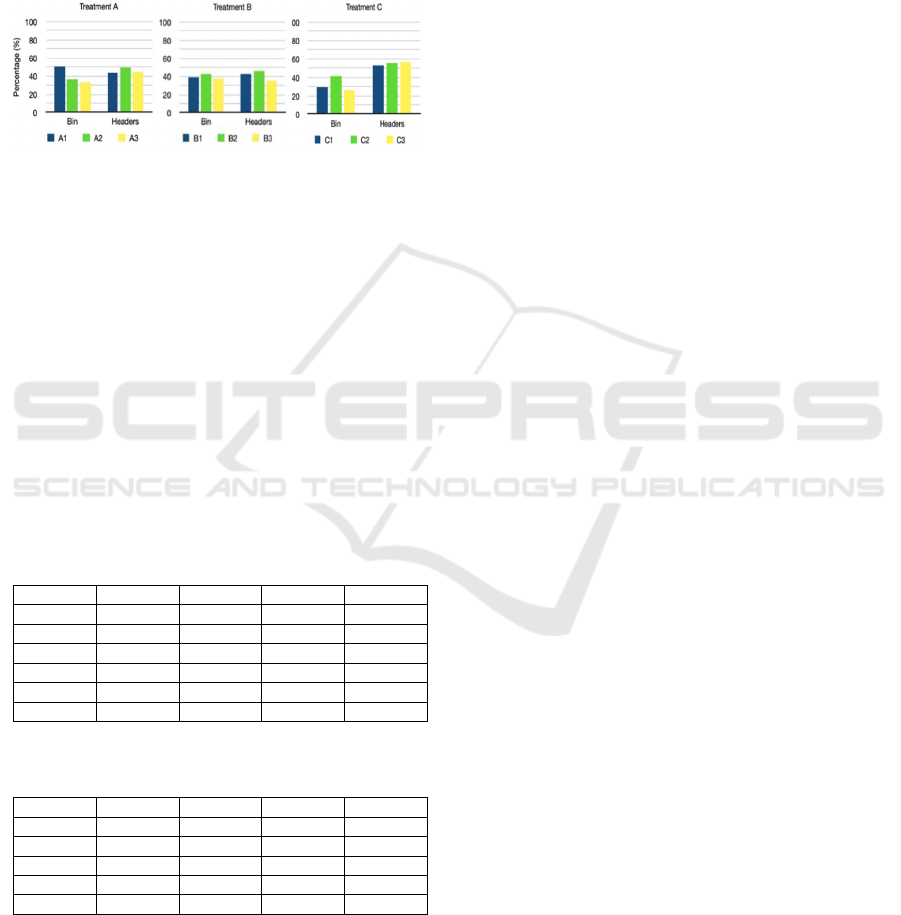

(a) (b) (c)

Figure 12: Cotton boll count collected from the bin,

headers, ground and plant from (a) Treatment A, (b)

Treatment B, and (c) Treatment C.

The data revealed that most cotton bolls were

collected from within the header assembly (near the

eductor inlet), while the smallest quantity was

recovered from the collecting bin. This indicated that

many bolls were unable to move from the header to

the bin, suggesting a failure in the boll transfer

process. Upon inspection, it was confirmed that

cotton bolls and plant debris had clogged the eductor

inlet (Figure 13), thereby restricting the vacuum

airflow needed to move the material.

Figure 13: Cotton bolls and trash accumulating on the

eductor inlet.

This blockage was likely exacerbated by the long

delay between defoliation and harvesting, during

which colder temperatures caused the plants to

become brittle. Consequently, broken branches and

stalk fragments accumulated at the inlet, further

impeding airflow. The positive air pressure generated

by the third blower, approximately 20 psi, was

insufficient to effectively clear the obstruction.

According to the spindle-type harvester in-season

procedures (Cotton Inc.), it would take around 125 psi

to effectively remove lint build up (cotton fiber) and

trash. Among the treatments, Treatment A yielded the

highest number of cotton bolls transferred to the

collecting bin, while Treatment C had the highest

accumulation within the header.

Due to the blocked/clogged eductor inlet, it was

expected that the harvesting efficiency would be

lower. Although some treatments like A2 and C1

have more than 10% harvesting efficiency, it was

much lower than the ideal of 100%, as shown in

Figure 14.

Figure 14: Harvesting efficiency for the 3 treatment rows.

The average for treatments A, B and C was 9.25%,

4.95% and 7.02% respectively. Treatment B had the

lowest harvesting efficiency while treatment A had

the highest. The previous design has an average

harvesting efficiency of 5.77%, 5.72% and 8.1% for

treatments A, B and C respectively. The new design

has the highest efficiency at 9.25% for treatment A

(50% duty cycle) while the previous has the highest

efficiency at 8.1% for treatment C (100% duty cycle).

The results revealed that the new design has the

highest efficiency when the front finger roller is

rotating at 50 rpm while the previous design achieved

the highest efficiency at full speed of 100 rpm.

Overall, the new design has slightly better results at

50% and 100% duty cycles compared to the previous.

The percentage of trash collected from the

collecting bin, headers, ground and plants are shown

TISAS 2025 - Special Session on Trustworthy and Intelligent Smart Agriculture Systems: AI, Blockchain, and IoT Convergence

652

in Figure 15. Treatment C has the least amount of

trash at the collecting bin. It also has the most trash

collected at the headers. Treatments A and B have

below 50% trash in either collecting bin and headers.

The data also shows that almost half of the weight

collected in the collecting bin and headers were trash.

The average trash percentage at the bin were 39.96%,

39.6% and 32.58% for treatments A, B and C

respectively.

(a) (b) (c)

Figure 15: Percentage of trash collected from the collecting

bin and headers among cotton fibers for Treatments A (a),

B (b) and C (c).

Meanwhile, the average trash percentage from the

headers were 46.28%, 41.35% and 55.08% for

treatments A, B and C respectively. Unfortunately,

the data from the previous design only weighed the

branches wrapped around the finger rollers which

excluded the twigs and leaves, therefore comparison

to the current data could not be made.

The effect of the duty cycle applied to the motors

of the front finger roller to the cotton bolls and trash

collected was analyzed using one-way ANOVA.

Table 4 shows the result of the analysis.

Table 4a: Effect of PWM applied to front finger rollers on

number of bolls collected.

Treat B_Bin B_Head B_Gnd B_Plnt

A 5.23 32.50 9.95 15.11

B 3.31 27.19 9.33 15.59

C 3.13 0.19 10.82 6.74

F

0.7057342 0.6981467 0.1536920 0.6351503

p

-value

0.5305679 0.5338403 0.8608073 0.5620781

F

-Cri

t

5.1432529 5.1432529 5.1432529 5.1432529

Table 4b: Effect of PWM applied to front finger rollers on

amount of trash collected.

Treat T_Bin T_Head T_Gnd T_Plnt

A

16.78 156.00 27.25 15.08

B

8.61 101.25 19.19 28.16

C

7.97 185.18 29.27 16.55

F

1.98574193

2.3709049

8.35233882

3.64021987

p

-value

0.21785843

0.1742695

0.00757796

0.06389921

The results revealed no significant differences

between different PWM duty cycles on the number of

bolls collected in the bin (p=0.5305), headers

(p=0.5338), ground (p=0.8608) and plant (p=0.5620)

(Table 3a). This suggests that varying the shaft speed

of the front finger rollers had minimal influence on

the efficiency of harvesting. The amount of trash

collected along with the cotton fibers in the collecting

bin (p=0.2178) and headers (p=0.1742) were also

non-significant (Table 3b), suggesting that the speed

of front finger rollers did not change the trash amount.

Thus, in this scenario, it would be ideal to operate at

lower speeds to reduce energy use and lessen the wear

and tear of the motors.

4 CONCLUSIONS

The new robotic cotton harvester was successfully

designed, constructed, and tested in field conditions.

All core systems functioned as intended, with only

minimal operational issues. However, the field

experiment revealed a critical limitation: a significant

number of cotton bolls failed to reach the collecting

bin due to blockage at the eductor inlet caused by

accumulated trash and fiber. This obstruction reduced

the effectiveness of the vacuum transfer system.

The third blower, intended to generate positive air

pressure to clear the inlet, produced only about 20 psi,

way insufficient to remove blockages during

operation. As a result, most of the harvested bolls

remained within the header, limiting overall

harvesting efficiency. Although the new system

performed slightly better than the previous version at

50% and 100% duty cycles, only a small fraction of

the harvested bolls reached the collecting bin. Trash

content remained high, accounting for at least 50% of

the material collected in both the bin and header

assemblies.

Analysis showed that varying the duty cycle of the

front finger rollers (25%, 50%, 100%) had no

significant effect on the number of cotton bolls

collected or the amount of trash recovered. Therefore,

operating the rollers at the lowest speed (25% duty

cycle or 25 rpm) is recommended, as it reduces power

consumption and mechanical wear without

compromising performance.

The static stress simulation revealed a stark

contrast between the two chassis designs. The

previous version exhibited excessive von Mises stress

at the cantilever structure—6.5 times higher than the

acceptable limit—resulting in a safety factor below 1,

indicating a high risk of permanent deformation or

failure. In contrast, the new design demonstrated

improved stress distribution, minimal displacement,

and enhanced structural integrity under load. The

optimized weight distribution also reduces the load on

the front motors, lowering operating temperatures and

extending motor lifespan.

Design and Field Evaluation of a Robotic Cotton Harvester with Improved Structural Balance and Suction Mechanism

653

While the new robotic harvester marks a

substantial improvement in structural design and

robustness, further enhancements are required to

address boll transfer issues and trash reduction. If

cotton bolls retained in the header were successfully

transferred to the collecting bin, harvesting efficiency

could increase by as much as 60%. Additionally,

implementing strategies to minimize trash intake will

be essential to improve fiber purity and overall

performance.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge Cotton

Incorporated for funding this project under Project

No. 24-061. Special thanks are extended to Ms.

Melissa Mitchell and Dr. Lamin Drammeh of South

Carolina State University 1890 Research & Extension

for their continued support and guidance throughout

the duration of this research.

REFERENCES

Antille, D. L.; Bennett, J. M. L.; Jensen, T. A. (2016) Soil

compaction and controlled traffic considerations in

Australian cotton-farming systems. Crop Pasture Sci.,

67, 1–28. http://dx.doi.org/10.1071/CP15097

Barnes, E.; Morgan, G.; Hake, K.; Devine, J.; Kurtz, R.;

Ibendahl, G.; Holt, G. (2021) Opportunities for Robotic

Systems and Automation in Cotton Production.

Agriengineering, 3, 339–362. https://doi.org/10.3390/

agriengineering3020023

Cotton Inc. (2025, September 11). The Spindle-Type

Cotton Harvester In-Season Procedures https://www.c

ottoninc.com/cotton-production/ag-resources/harvest-

systems/the-spindle-type-cotton-harvester/in-season-

procedures.

EPA, U.S. Environmental Protection Agency. Available

online: https://www3.epa.gov/ttn/chief/ap42/ch09

/final/c9s03-1.pdf (accessed 12 July 2025).

Fue, K.; Porter, W.; Barnes, E.; Li, C. (2020) Rains, G.

Center-articulated hydrostatic cotton harvesting rover

using visual-servoing control and a finite state machine.

Electron, 9, 1–21. https://doi.org/10.3390/electronics

9081226

Fue, K.; Porter, W.; Barnes, E.; Li, C.; Rains, G. (2020)

Evaluation of a Stereo Vision System for Cotton Row

Detection and Boll Location Estimation in Direct

Sunlight. Agronomy, 10, 1137. https://doi.org/10.3390/

agronomy10081137

Gharakhani, H., Thomasson, J.A. Lu, Y. (2022) An end-

effector for robotic cotton harvesting. Smart

Agricultural Technology, Vol. 2. https://doi.org/10.1

016/j.atech.2022.100043

Jahanbakhshi, A.; Heidarbeigi, K. (2019) Simulation and

Mechanical Stress Analysis of the Lower Link Arm of

a Tractor Using Finite Element Method. Journal of

Failure Analysis and Prevention, 19, 1666–1672.

https://doi.org/10.1007/s11668-019-00763-2

Jung, Y. (2018). The legacy of king cotton: agricultural

patterns and the quality of structural change. SocArXiv.

https://doi.org/10.31235/osf.io/trjfz

Khudayarov, B.M; Kuziev, U.T.; Sarimsakov, B.R.;

Khuydaykulov, R.F. (2022) Dependence of the bending

force on the morphology of cotton stems and on the

parameters of the stalk bender. IOP Conf. Ser.: Earth

Environ. Sci., 1076 012045. https://doi.org/10.10

88/1755-1315/1076/1/012045

Lagnelöv, O.; Larsson, G.; Larsolle, A.; Hansson, P. (2023)

Impact of lowered vehicle weight of electric

autonomous tractors in a systems perspective. Smart

Agricultural Technology, 4, 100156. https://doi.org/1

0.1016/j.atech.2022.100156

Mail, M.F., Maja, J.M., Marshall, M., Patiluna, V., Cutulle,

M., Miller, G., Bridges, W., Barnes, E. (2024)

Development of New Cotton Harvesting Robot. In

2024 Beltwide Cotton Conference, Fort Worth, TX,

USA, 3-5 January 2024, pp. 649-657.

Maja, J.M., Mail, M.F., Patiluna, V., Miller, G., Cutulle,

Marshall, M., Barnes, E. (2024) A new mobile robot

harvesting prototype for cotton production. In AgEng

2024 Conference, Athens, Greece, 1-4 July 2024, pp.

328-336.

Maja, J.; Polak, M.; Burce, M.; Barnes, E. (2021) CHAP:

Cotton-Harvesting Autonomous Platform.

Agriengineering, 3, 199–217. https://doi.org/10.3390/a

griengineering3020013

Natálio, F. and Maria, R. (2018). Structural evolution of

gossypium hirsutum fibers grown under greenhouse

and hydroponic conditions. Fibers, 6(1), 11.

https://doi.org/10.3390/fib6010011

Peterson, Willis & Kislev, Yoav. (1986). The Cotton

Harvester in Retrospect: Labor Displacement or

Replacement? The Journal of Economic History, 46(1),

199-216.

Zhao, W.; Xie, J.; Wang, Z.; Gao, Q.; Chen, M. (2022)

Investigation of mechanical properties of cotton stalk

based on multi-component analyses. Int. Agrophys., 36,

257-267. https://doi.org/10.31545/intagr/152488

TISAS 2025 - Special Session on Trustworthy and Intelligent Smart Agriculture Systems: AI, Blockchain, and IoT Convergence

654