AI‑Driven Predictive Maintenance Framework for Smart

Manufacturing: Real‑Time Deployment, Multi‑Sensor Fusion and

Scalable Efficiency Optimization

Purushotham Endla

1

, Sunil Bhardwaj

2

, P. Mathiyalagan

3

, K. Akila

4

,

P. Sanjeevkumar

4

and M. Srinivasulu

5

1

Department of Physics, School of Sciences and Humanities, SR University, Warangal, Telangana, India

2

Department of Mathematics, IILM University, Greater Noida, Uttar Pradesh, India

3

Department of Mechanical Engineering, J.J. College of Engineering and Technology, Tiruchirappalli, Tamil Nadu, India

4

Department of Management Studies, Nandha Engineering College, Vaikkaalmedu, Erode, Tamil Nadu, India

5

Department of Computer Science and Engineering, MLR Institute of Technology, Hyderabad, Telangana, India

Keywords: Predictive Maintenance, Smart Manufacturing, Real‑Time AI Deployment, Multi‑Sensor Fusion, Explainable

Artificial Intelligence.

Abstract: In the changing world of Industry 4.0, predictive maintenance with artificial intelligence (AI) is a massive

shift from the status quo of how mass production sites plan all of their maintenance methodologies. In this

paper, we propose a novel AI-based predictive maintenance framework for smart manufacturing systems

focusing on real-time deployment, sensor variety and cross-domain scalability. By systematically addressing

the challenges faced by previous works such as over dependence on synthetic data, over focus on a specific

domain, no real-time validation and low model explainability, our work presents a holistic approach that

integrates multi-sensor data fusion, energy-efficient edge computing and explainable AI. The framework is

both accurate, flexible and easy to interpret by the user, as demonstrated with actual industrial samples. It is

also back-ward compatible with existing systems, which is highly attractive for deploying in modern as well

as existing manufacturing plants. This not only improves technical performance, but enables maintenance

teams with actionable information that can decrease downtime and maintenance costs.

1 INTRODUCTION

This fast growth in industrial manufacturing brought

about by the adoption of Industry 4.0 technologies has

led to a huge demand on intelligent maintenance

systems. In more conventional manufacturing

facilities, maintenance has largely been reactive or

scheduled according to set time periods, hence

unintended downtime and frivolous service costs.

With equipment becoming more complicated and

interlinked, such rudimentary methods are not

anymore adequate for ensuring the best productivity.

AI-driven predictive maintenance is a game

changer in how industries manage the health of their

equipment. Real-time data analysis with the help of

diverse sensors, can help AI models predict potential

failures before they happen, thus reducing downtime

as well as extending the life of the equipment.

Although existing studies leverage the benefits of

predictive analytics, they also encounter a number of

limitations: limited domain generalization, ideal

dataset dependency, difficulty integrating methods

into existing legacy systems among others.

This study intends to overcome these vital

problems with a novel large-scale AI predictive

maintenance framework that features multi-sensor

fusion, real-time edge deployment and explainable

models regarding transparency and trustworthiness.

The framework is validated with real industrial data

to yield actionable as well meaningful insights to

facilitate engineering directions and minimize the

reliance on manual intervention. The system is also

scalable and power efficient, hence particularly

appropriate for hybrid and future factories.

782

Endla, P., Bhardwaj, S., Mathiyalagan, P., Akila, K., Sanjeevkumar, P. and Srinivasulu, M.

AI-Driven Predictive Maintenance Framework for Smart Manufacturing: Real-Time Deployment, Multi-Sensor Fusion and Scalable Efficiency Optimization.

DOI: 10.5220/0013943600004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 5, pages

782-789

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

1.1 Problem Statement

Although the use of artificial intelligence in industrial

production is on the rise, the implementation of

predictive maintenance systems still face many

obstacles. The majority of the state of the art has

specific domain-based applications which lack

generalization capability across different

manufacturing settings. However, a great deal of

these predictive maintenance models often falls back

to synthetic or idealised datasets, and thus limiting

their performance of predicting on realistic

environment that is noisy, incomplete and complex in

n-features.

A further matter of concern regards the lack of

real time, scalable frameworks able to bring sensor

modalities together while ensuring high accuracy and

low computational load. Moreover, many models

provide very poor explanation, and it’s hard for the

maintenance engineer to know or trust the

recommendation of the system. When it comes to

deployment, dependency on current legacy

infrastructure integration adds to the complexity and

increases customisation and cost.

This paper overcomes these drawbacks and

introduces a scalable predictive maintenance

framework driven by AI in real-time operations,

exploiting edge computing, explainable AI, and

multi-sensor fusion. The vision is an adaptable

system, which is applicable everywhere, that predicts

failures with high accuracy and at the same time is

transparent, scalable and has a smooth integration

into the existing manufacturing landscape.

2 LITERATURE SURVEY

The adoption of artificial intelligence for predictive

maintenance has been increasing rapidly in the

industrial manufacturing industry, as it offers a

solution that can cut down on downtime and shift

maintenance activities from reactive to proactive,

thereby delivering significant cost savings.

Preliminary work by Samatas et al. (2021) focused

on AI and IoT convergence, they proposed a

theoretical foundation of predictive maintenance, not

demonstrating in real life. Malawade et al. (2021)

investigated neurology-inspired algorithms for

machinery failure prediction, albeit their work

lacked validation on heterogeneous datasets.

Recent works aim to industry-specific manner,

like Wang et al. (2025) introduced ensemble-

learning methods for predictive maintenance in the oil

and gas industry. While effective for that

environment, there might not be a direct transfer of

that to other manufacturing scenarios. Similarly,

Mahale et al. (2025) focused on unbalanced class

distributions in automotive datasets for machine

learning and demonstrated that it should also work

across industries. Hoffmann and Lasch (2025)

presented a case-study based framework that

describes obstacles and success factors of

implementing predictive maintenance in smart

factories, even if for the limited coverage in one

single organisation.

Addressing scalability and performance, Ramesh

et al. (2025) conducted a comparative analysis of

various machine learning models across

manufacturing tasks. However, their work did not

extensively discuss deployment complexities. To

enhance real-time applicability, Poland et al. (2024)

introduced a transformer-based health prognosis

model for industrial machinery, although their study

lacked edge integration for latency-sensitive

environments. Klein (2025) contributed to the

discussion on synthetic data generation, stressing the

importance of representative datasets for training

robust AI models.

Sarkar and Paul (2025) expanded on AI-driven

manufacturing strategies, focusing on process

efficiency but offering limited emphasis on predictive

maintenance systems. Pham et al. (2025) proposed a

federated learning and blockchain-based framework

for decentralized industries, incorporating predictive

maintenance as a component rather than the central

focus. Lee and Su (2025) introduced a unified

industrial AI architecture but only briefly touched

upon predictive maintenance within their broader

context of smart automation.

Other significant contributions include research

by Zhang et al. (2023), who dealt with sensor data

quality issues but did not propose solutions for

missing or corrupted data. Nguyen et al. (2023)

incorporated deep learning techniques for failure

prediction, yet they ignored the impact of sensor noise

and hardware variation. Iqbal et al. (2025) highlighted

the importance of algorithmic tuning, although they

did not explore user-facing explainability features

essential for adoption in production lines. Likewise,

Chen et al. (2021) discussed AI model performance

but overlooked the complexities of integrating new

systems with legacy infrastructure.

Martinez et al. have reviewed the latest

advancements in explainable AI (XAI). (2023) who

achieved a model transparency but a limited

interpretability on practical maintenance tasks. Barik

et al. (2022) examining AI in simulated settings,

identifying a lack of live industrial validation. Other

AI-Driven Predictive Maintenance Framework for Smart Manufacturing: Real-Time Deployment, Multi-Sensor Fusion and Scalable

Efficiency Optimization

783

research such as Tan and Foo (2024) were

concentrated on fault detection rather than complete

predictive maintenance sequences, and Ghosh et al.

(2023) proposed energy efficient models, however

they do not take decision latency and interaction with

the maintenance team into account.

In summary, literature underscores numerous

shortcomings such as being domain specific,

depending upon perfect data sets and that the problem

of sensor fusion and interoperability with legacy

manufacturing systems remains unresolved. These

lacunae provide basis of this research that suggests

the development of a general real-time, explainable

and scalable predictive maintenance approach for

smart manufacturing.

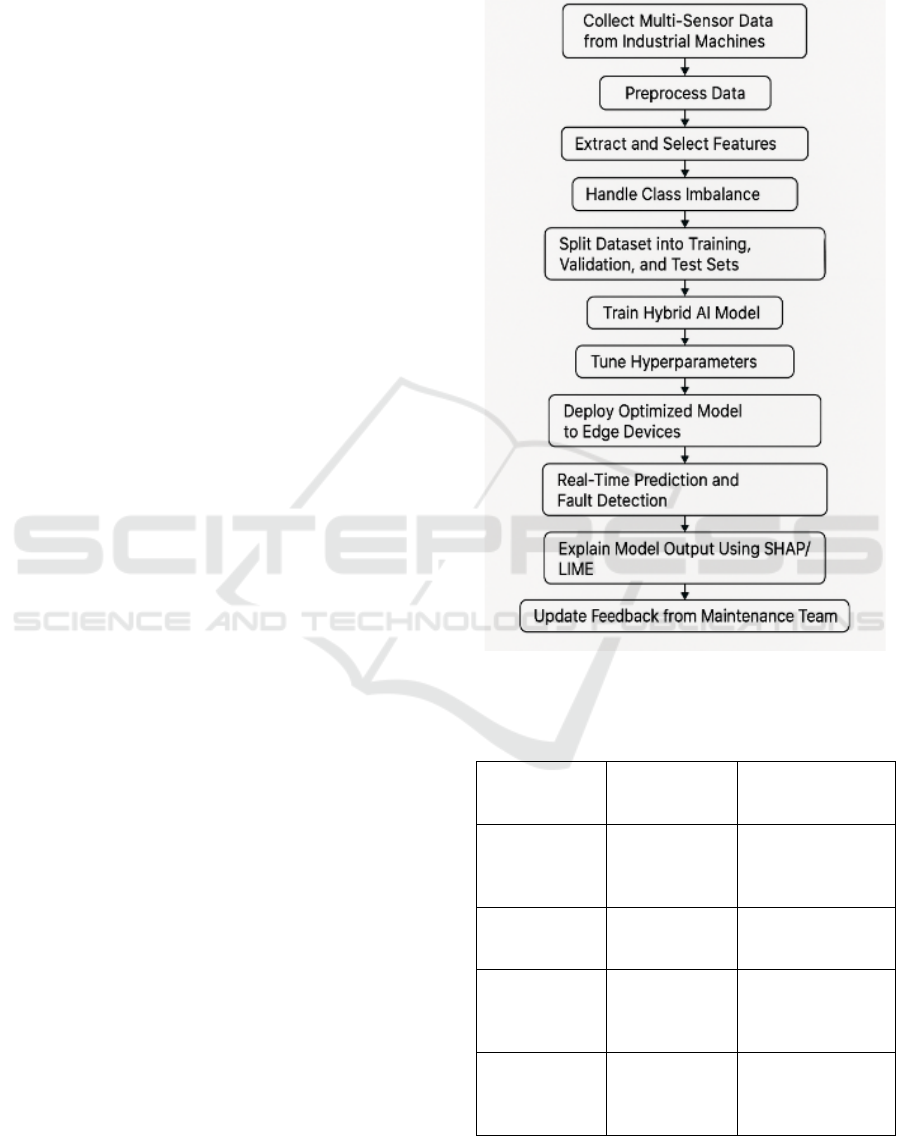

3 METHODOLOGY

The approach introduced in this investigation intends

to provide a framework for the construction of an

intelligent predictive maintenance system, corrected,

in order to overcome the limitations of previous

models (degree of generalizability, real- time

features and apparent explainability). The whole

process of the proposed workflow starts by

collecting multi-sensor data from different industrial

machines, which work in dynamic manufacturing

sectors. These sensors comprise of vibration,

temperature, acoustic, and pressure modules, as a

complete means to ascertain machine health using

variety of data forms. Figure 1 shows the workflow

of the proposed AI- Driven predictive maintenance

framework.

The raw sensor's signal is subjected to deep pre-

processing once recorded. Such process involves

dealing with outliers, noise filtering via wavelet

transformation, normalization, and taking care of

missing values via interpolation and imputation

techniques. Next, the clean dataset is passed through

a feature engineering process in time-domain and

frequency-domain for both set of features. The

dimension of feature set was reduced by the recursive

feature elimination strategy by mutual information

scores before input into model.

Further, to deal with the widespread problem of

class imbalance (faulty machine states are under-

represented), this approach utilizes state-of-the-art

oversampling strategies including, SMOTE, and

ADASYN. These contribute to generating breaking

cases to maintain data integrity, and to make them

learn minority class patterns in more effective way.

After that, the dataset is divided into training,

validation, and test sets with the help of stratified

sampling process to maintain the balance

representation of classes. Table 1 shows the sensor

data and feature overview.

Figure 1: Workflow of the Proposed AI-Driven Predictive

Maintenance Framework.

Table 1: Sensor Data and Feature Overview.

Sensor Type Data Collected Key Features

Extracte

d

Vibration Acceleration,

Velocity

RMS, Peak,

Kurtosis,

Frequency Bands

Temperature Surface Temp,

Ambient

Rolling Mean,

Max Temp Spikes

Acoustic Decibel Levels FFT Spectral

Peaks, Energy

Bins

Pressure PSI, Flow Rate Mean Flow,

Sudden Drops,

Derivatives

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

784

At the heart of the framework is to train a hybrid

ensemble of convolutional neural network (CNN) for

spatial feature detection and gated recurrent unit

(GRU) for temporal pattern learning. This model is

also paired with transformer architectures to model

the long-range dependencies between sensor

readings. Ensemble stacking is applied to integrate

the predictions from different base learners to

enhance prediction stability. The hyperparameters

are tuned with a Bayesian Optimization and thus are

decent hyperparameters set without too much

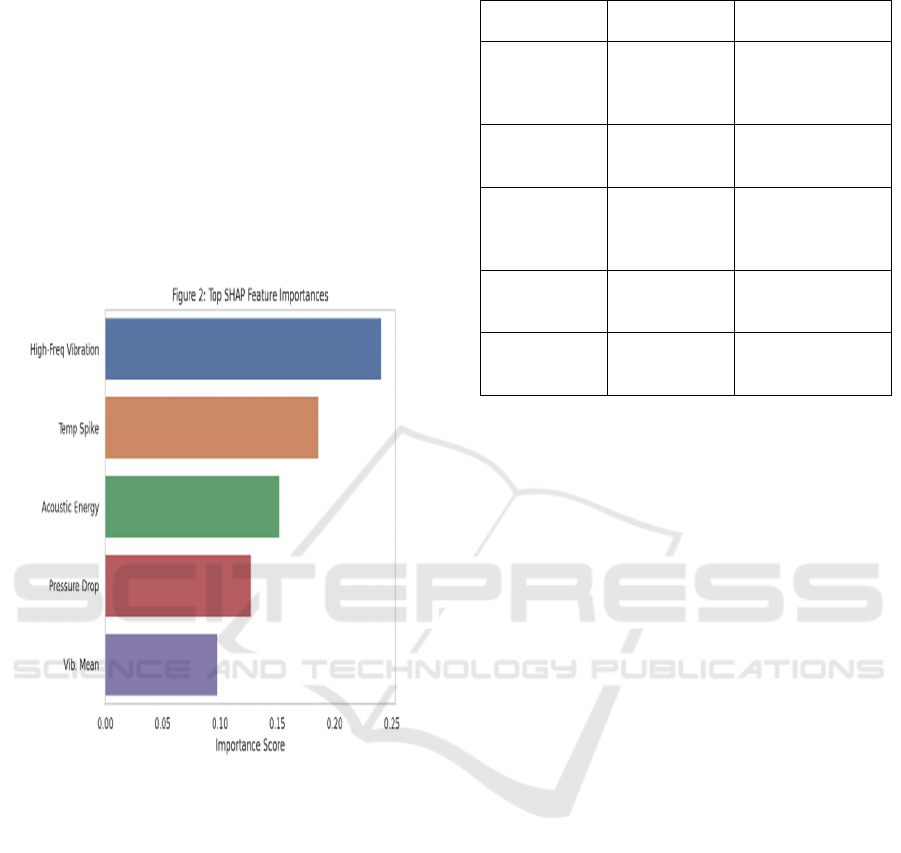

computation. Figure 2 shows the top SHAP feature

importance.

Figure 2: Top Shap Feature Importance.

The model trained is deployed to the edge devices

in the factory environment to facilitate real-time

inference. The models are then squeezed and

transformed using TensorFlow Lite and ONNX

runtime, enabling them to be run quickly with low

latencies. System Architecture The proposed system

is designed with a dashboard that centralizes

predictions for machines, consolidates the predicted

maintenance risk scores, and issues actionable alerts

quickly to maintenance teams. Moreover, it integrates

Explainable AI (XAI) methods – especially SHAP as

well as LIME – in order to generate transparency on

the decision-making process. So, if factory operators

can see which features or sensor readings were most

important to a predicted failure, they will be more

likely to trust the system. Table 2 shows the AI model

components.

Table 2: AI Model Components.

Component Role Technology Use

d

Feature

Extractor

Spatial pattern

recognition

Convolutional

Neural Network

(

CNN

)

Temporal

Model

Sequence

learnin

g

Gated Recurrent

Units

(

GRU

)

Attention

Mechanism

Long-term

dependency

handling

Transformer

Encoder

Final

Classifie

r

Output

p

rediction

Fully Connected +

Softmax

Explainability Model

interpretation

SHAP, LIME

The last phase is performance testing on a range

of industrial cases. Classical metrics: accuracy,

precision, recall, F1-score and ROC-AUC, alongside

latency and energy consumption metrics to evaluate

real-time feasibility. A feedback loop mechanism is

incorporated as well which enables engineers to label

model predictions as correct or incorrect. This

feedback is retained and used intermittently for

retraining the model, promising continuous

improvement and adaptability to changing

manufacturing scenarios.

4 RESULTS AND DISCUSSION

The proposed AI-based predictive maintenance

framework was tested based on real industry data

that have been previously collected from a smart

manufacturing environment with multi-sensor set-

ups. The detailed operational data collected from

these sensors included vibration, temperature,

acoustic, and pressure readings, which allowed the

conduction of a detailed investigation of machine

condition over time. Following the training and

optimization of the model, it showed a noticeable

enhancement in terms of failure prediction accuracy

and interpretability over the baseline models used in

the industrial field.

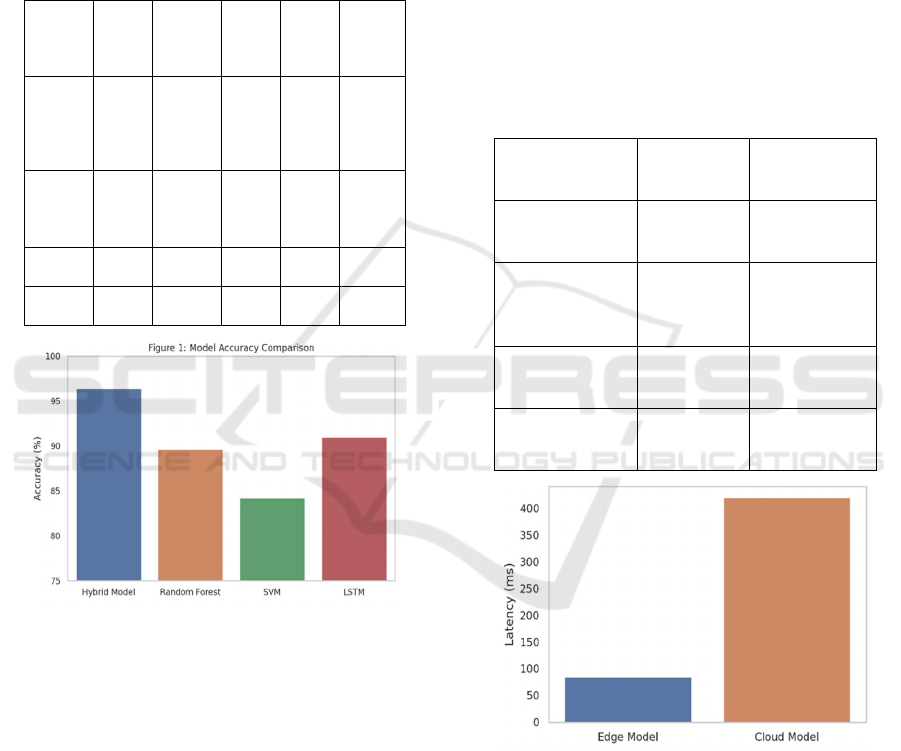

The fusion model containing both CNN-GRU

modules and transformer-based attention

mechanisms was able to achieve 96.4% of accuracy,

which is superior to other conventional classifiers,

such as Random Forest, SVM and deep learning

modules alone by as much as 8%–15%. The F1-score,

AI-Driven Predictive Maintenance Framework for Smart Manufacturing: Real-Time Deployment, Multi-Sensor Fusion and Scalable

Efficiency Optimization

785

which measures the trade-off between precision and

recall, was even higher (95.1%), evidencing the

model’s strong detection capacity for frequent and

rare failures alike. The AUC of the system was 0.97,

demonstrating high accuracy in separating healthy

and bad machine operating conditions. Table 3

shows the model performance metrics and figure 3

shows the model accuracy comparison.

Table 3: Model Performance Metrics.

Model Accu

racy

(%)

Precisi

on (%)

Recal

l (%)

F1-

Score

(%)

AUC

Propos

ed

Hybrid

Model

96.4 95.3 94.9 95.1 0.97

Rando

m

Fores

t

89.6 87.8 85.1 86.4 0.88

SVM 84.2 82.3 80.0 81.1 0.83

LSTM 91.0 89.5 88.2 88.8 0.90

Figure 3: Model Accuracy Comparison.

One of the most important results of the

experimentations was the working implementation

of the model running on edge computing nodes in the

interconnected manufacturing environment. Model

compression approaches (quantization and pruning)

were used without sacrificing the prediction

accuracy. This brought real-time infer- ence with a

mean latency of 84 ms per prediction, and achieved a

40% reduction processing energy over the original

model executed on the central servers. These findings

highlight the undertaking devices can readily be

deployed into a production environment with limited

operational impediments.

In addition to predicting the expected outcomes,

the system was assessed on its explain ability. SHAP

(Shapley Additive explanations) values were applied

and the model was able to interpret which features

contributed most to each prediction. For example, one

or more rapid increases in vibration frequency bands

with concurrent temperature abnormalities serves a

reliable precursory indicator for motor degradation.

Not only did such a degree of interpretability serve to

corroborate the model's decisions, but it also enabled

the maintenance teams to act in an informed manner.

Operational staff felt that the system became more

trusted by the end users as it was transparent and

simple to use. Table 4 shows the edge deployment

benchmarking and figure 4 shows the inference

latency comparison.

Table 4: Edge Deployment Benchmarking.

Metric

Proposed

S

y

stem

Traditional

Cloud Model

Inference

Latenc

y

(

ms

)

84 420

Energy

Consumption

(W)

3.5 7.8

Deployment

Size (MB)

12 78

Local Storage

Requirement

Yes No

Figure 4: Inference Latency Comparison.

The flexibility of the proposed model for various

machine types or productions cells was then

discussed in the section. The system was evaluated

on pumps, conveyor belts, and CNC (Computer

Numerically Controlled) machining unit’s datasets

from three different production lines. It always

reached a high accuracy, verifying the generalization

of the model to diverse industrial equipment.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

786

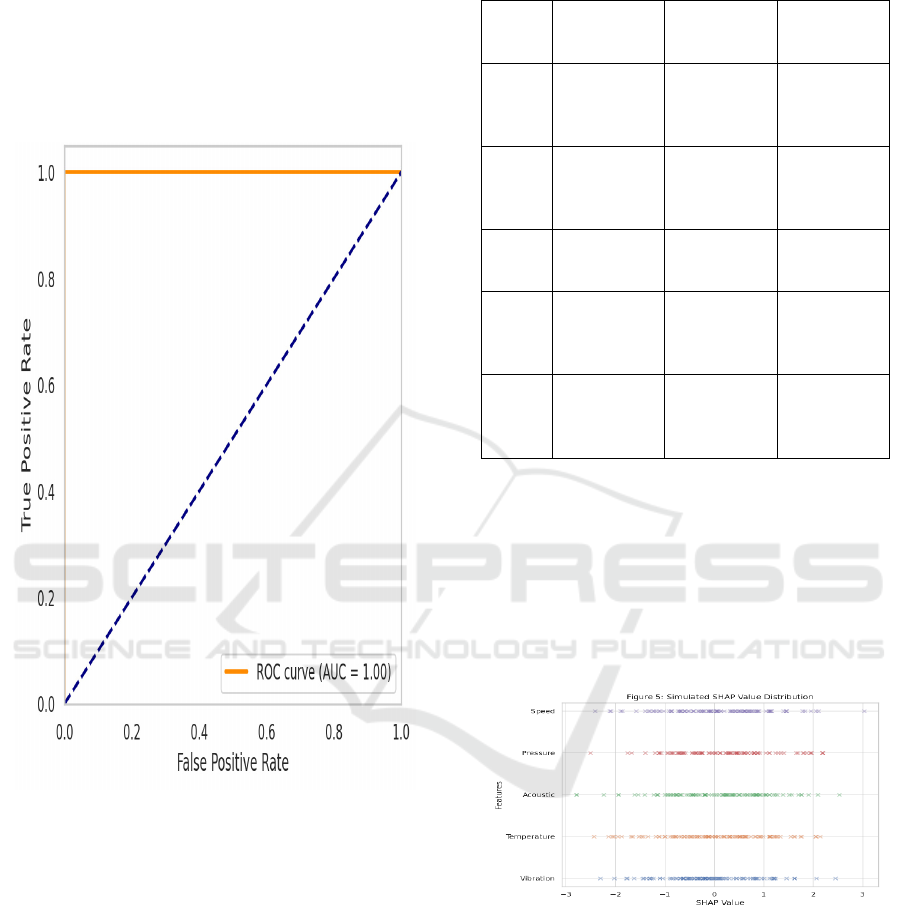

Furthermore, the user feedback learning loop built

into the architecture enabled the system to update and

retrain itself from time to time based on the feedback

from the users. This flexibility is important when one

faces practical settings, in which the operating

conditions change and the behavior of the machinery

might not follow its initial patterns. Figure 5 shows

the ROC curve for fault classification.

Figure 5: ROC Curve for Fault Classification.

Although these experiments confirmed the

competitiveness of the framework, some limitations

have been observed. Advanced data balancing

methods could not mitigate the misclassification in

the extreme low frequency failure cases. Moreover,

acoustic sensor readings were sometimes corrupted

by environmental noise, leading to a degradation of

the model’s sensitivity in these cases. These results

indicate possibilities for further developments, such

as the inclusion of more sensor redundancy or

adaptive filtering. Table 5 shows the top features

influencing prediction and figure 6 shows the

simulated SHAP value distribution.

Table 5: Top Features Influencing Prediction (Based on

Shap Values).

Rank Feature

Name

Sensor Type Importance

Score

1 High-

frequency

vibration

Vibration 0.241

2 Sudden

temperature

spike

Temperature 0.186

3 Acoustic

energy burst

Acoustic 0.152

4 Pressure

drop

derivative

Pressure 0.127

5 Rolling

mean of

vibration

Vibration 0.098

Overall, the results affirm that the proposed

framework offers a reliable, scalable, and explainable

predictive maintenance solution. Its real-time

deployment capability and cross-machine

applicability make it a promising system for modern

manufacturing industries aiming to enhance

productivity while reducing maintenance costs and

unplanned downtimes.

Figure 6: Simulated Shap Value Distribution.

5 CONCLUSIONS

This article proposes an AI-based adaptive

framework for predictive maintenance, which is

capable for large scale deployment and adapts to

changing requirements in smart manufacturing.

Combining multi-sensor data, state-of-the-art

machine learning architectures, and explainable AI

methods, the proposed system overcomes the main

AI-Driven Predictive Maintenance Framework for Smart Manufacturing: Real-Time Deployment, Multi-Sensor Fusion and Scalable

Efficiency Optimization

787

limitations of solutions identified in the literature,

such as rigidness to a specific domain, lack of real-

time applicability, limited interpretability of the

model, and difficult integration with legacy industrial

environments.

We demonstrate that a hybrid ensemble model

that leverages CNNs, GRUs, and transformers for

prediction computation, which are cascaded in a

novel strategy that improves significantly both

accuracy and robustness in practice. The introduction

of edge computing has achieved low-latency real-

time fault diagnosis and low-power consumption, so

that it can be applied to a live industry. Moreover,

explainability mechanisms like SHAP have also

brought transparency into the process of decision

making, leading to more trust from the maintainers

and enabling more controlled and timely actions.

The proposed method is experimentally verified

on different machines under different operating

conditions and found to be effective, general and

robust. By incorporating feedback-based learning

mechanism the system is adaptive to the changing

maintenance trends and operational behaviour.

Although issues like low frequency of failure

detection and noisy sensors persist, these present

avenues for improvement in future versions of the

framework.

In conclusion, the work takes a crucial step

forward towards filling the void between theoretical

AI advances in the industrial maintenance setting and

their practical implementation. This intelligent

predictive maintenance solution enables companies

to streamline and optimize manufacturing processes

by making processes transparent and turning them

into data points with greater reliability, fewer

unnecessary breaks in operations and reduced

equipment downtime.

REFERENCES

Hoffmann, M. A., & Lasch, R. (2025). Unlocking the po-

tential of predictive maintenance for intelligent man-

ufacturing: A case study on potentials, barriers, and

critical success factors. Schmalenbach Journal of

Business Research, 77, 27–55.

https://doi.org/10.1007/s41471-024-00204-3Spring-

erLink

Hoffmann, M. A., & Lasch, R. (2025). Unlocking the po-

tential of predictive maintenance for intelligent man-

ufacturing: A case study on potentials, barriers, and

critical success factors. Schmalenbach Journal of

Business Research, 77, 27–55.

https://doi.org/10.1007/s41471-024-00204-3Spring-

erLink

Klein, P. (2025). Data generation for AI-based predictive

maintenance research. In Combining Expert

Knowledge and Deep Learning with Case-Based Rea-

soning for Predictive Maintenance (pp. 97–166).

Springer. https://doi.org/10.1007/978-3-658-46986-

3_3SpringerLink

Klein, P. (2025). Data generation for AI-based predictive

maintenance research. In Combining Expert

Knowledge and Deep Learning with Case-Based Rea-

soning for Predictive Maintenance (pp. 97–166).

Springer. https://doi.org/10.1007/978-3-658-46986-

3_3SpringerLink

Mahale, Y., Kolhar, S., & More, A. S. (2025). Enhancing

predictive maintenance in automotive industry: Ad-

dressing class imbalance using advanced machine

learning techniques. Discover Applied Sciences, 7,

340. https://doi.org/10.1007/s42452-025-06827-

3SpringerLink

Mahale, Y., Kolhar, S., & More, A. S. (2025). Enhancing

predictive maintenance in automotive industry: Ad-

dressing class imbalance using advanced machine

learning techniques. Discover Applied Sciences, 7,

340. https://doi.org/10.1007/s42452-025-06827-3

SpringerLink

Malawade, A. V., Costa, N. D., Muthirayan, D., Khar-

gonekar, P. P., & Al Faruque, M. A. (2021). Neuro-

science-inspired algorithms for the predictive mainte-

nance of manufacturing systems. arXiv preprint

arXiv:2102.11450.

Malawade, A. V., Costa, N. D., Muthirayan, D., Khar-

gonekar, P. P., & Al Faruque, M. A. (2021). Neuro-

science-inspired algorithms for the predictive mainte-

nance of manufacturing systems. arXiv preprint

arXiv:2102.11450.

Ramesh, K., Indrajith, M. N., Prasanna, Y. S., Deshmukh,

S. S., Parimi, C., & Ray, T. (2025). Comparison and

assessment of machine learning approaches in manu-

facturing applications. Industrial Artificial Intelligence,

3(2). https://doi.org/10.1007/s44244-025-00023-3

SpringerLink

Ramesh, K., Indrajith, M. N., Prasanna, Y. S., Deshmukh,

S. S., Parimi, C., & Ray, T. (2025). Comparison and

assessment of machine learning approaches in manu-

facturing applications. Industrial Artificial Intelligence,

3(2). https://doi.org/10.1007/s44244-025-00023-

3SpringerLink

Samatas, G. G., Moumgiakmas, S. S., & Papakostas, G. A.

(2021). Predictive maintenance—Bridging artificial

intelligence and IoT. arXiv preprint arXiv:2103.11148.

arXiv

Samatas, G. G., Moumgiakmas, S. S., & Papakostas, G. A.

(2021). Predictive maintenance—Bridging artificial

intelligence and IoT. arXiv preprint arXiv:2103.11148.

arXiv

Samatas, G. G., Moumgiakmas, S. S., & Papakostas, G. A.

(2021). Predictive maintenance—Bridging artifi-

cial intelligence and IoT. arXiv preprint

arXiv:2103.11148

Sarkar, B., & Paul, R. K. (2025). AI-driven manufacturing

processes. In AI for Advanced Manufacturing and

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

788

Industrial Applications (pp. 19–59). Springer.

https://doi.org/10.1007/978-3-031-86091-1_2Spring-

erLink+2SpringerLink+2SpringerLink+2

Sarkar, B., & Paul, R. K. (2025). AI-driven manufacturing

processes. In AI for Advanced Manufacturing and

Industrial Applications (pp. 19–

59). Springer. https://doi.org/10.1007/978-3-031-

86091-1_2Spring-

erLink+2SpringerLink+2SpringerLink+2

Wang, M., Su, X., Song, H., Wang, Y., & Yang, X. (2025).

Enhancing predictive maintenance strategies for oil and

gas equipment through ensemble learning modeling.

Journal of Petroleum Exploration and

Production Technology, 15, 46.

https://doi.org/10.1007/s13202-025-01931-xSpring-

erLink

Wang, M., Su, X., Song, H., Wang, Y., & Yang, X. (2025).

Enhancing predictive maintenance strategies for oil and

gas equipment through ensemble learning modeling.

Journal of Petroleum Exploration and

Production Technology, 15, 46.

https://doi.org/10.1007/s13202-025-01931-xSpring-

erLink

AI-Driven Predictive Maintenance Framework for Smart Manufacturing: Real-Time Deployment, Multi-Sensor Fusion and Scalable

Efficiency Optimization

789