Empirical Analysis of AI‑Based Hotspot Detection in Photovoltaic

Panels Using Thermal Images

K. Subha

1

and S. Sharanya

2

1

Department of CSE, SRM IST, Kattankulathur, Chennai, Tamil Nadu, India

2

Department of DSBS, SRM IST, Kattankulathur, Chennai, Tamil Nadu, India

Keywords: Photovoltaic Panels, Hotspot, Fault Detection, Fault Classification, Thermal Image, Empirical Analysis,

Machine Learning.

Abstract: The abundant heat energy exhaled from the sun can be used for diverse applications using modern technology,

which is known as solar energy. Photoelectric cell converts sunlight energy into electrical energy directly by

using a photovoltaic effect. Long-term exposure of PV panels to malicious conditions increases their risk of

cell damage which causes hot-spot and can reduce the efficiency of electricity production, perhaps resulting

in fires. Surface fault detection (FD) is a key strategy to enhance PV panel reliability and performance and

improve energy management. This study presents an empirical analysis of hotspot detection in PV panels

using thermal images through different machine learning (ML) and deep learning (DL) algorithms including

Vision Transformer (ViT) that were assessed for fault detection in solar cells. A dataset consisting of thermal

images, derived from the solar plant, was utilized in this study, consisting of 3 classes: cell, hot spot and multi

hot spot for experiment fault classification in solar panels. To evaluate performance a comprehensive

comparison of accuracy, precision, f1-score, recall, mAP (Mean Average Precision) parameters of the model

were used. The result showed that the model based on the vision transformer exhibited better performance in

hotspot fault detection problems in PV modules. In fact, transformer models were found to be efficient for

fault detection with good accuracy (98%). Through empirical analysis it was found that Transformer based

techniques have outperformed well based on ML, DL-based approaches.

1 INTRODUCTION

Energy that originates from natural resources and is

regenerated within a human timescale is known as

renewable energy. These resources are crucial for

transitioning to a cleaner and more sustainable energy

future, as they are typically abundant and

environmentally beneficial. Renewable energy

consists mainly of solar, wind, hydropower, biomass,

and geothermal sources. Solar energy and wind

energy systems will meet 88% of global energy

demand and of all energy sources by 2050 (Ram,

Manish, et al. 2019) Solar energy is an alternative and

more pollution free electric energy while compared to

thermal energy.

The Earth absorbs solar radiation at a pace that is

about ten times higher than the rate at which people

use energy. Solar panels or PV panels are complex

structures made up of various numbers of PV cells for

producing solar energy. To keep this PV working

more efficiently and reliably over time with different

climate conditions they should be strictly monitored,

protected and inspected. However, a motley of

fault issues could appear while solar panel modules are

accomplishing due to variations in the external

environment (Alajmi, Masoud, et al, 2019)

Hotspots, cracks, open circuits, shadows and short

circuits are examples for common defects. Solar

panels that are left out in the elements for an extended

period of time are vulnerable to damage and cracking

from thunderstorms, ultra violet rays, and thermal

cycling. Hot-spot failure will arise from localized

heating of the solar panels caused by over irradiation.

Hot spots release heat and reduce the efficiency of

power generation by consuming power produced in

other parts of the panel. Solder joints on the panels

may melt when the temperature rises, harming them

and perhaps starting a fire. There are two main

avenues of study for hot-spot fault detection of solar

panels: one uses the electrical properties of the panels,

and the other uses the infrared image characteristics

of the panels (Dhimish, Mahmoud, and Ghadeer

400

Subha, K. and Sharanya, S.

Empirical Analysis of AI-Based Hotspot Detection in Photovoltaic Panels Using Thermal Images.

DOI: 10.5220/0013930500004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 5, pages

400-407

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

Badran, 2019), (Yang, Weihua,2022)

In order to use photovoltaic panel electrical

characteristics such as voltage and current for hot-

spot fault detection, these characteristics must first be

obtained and then input into an analytical

mathematical-statistical model of intelligent

algorithms. Another common method involves using

temperature and pixel data from images of infrared

photovoltaic panels. Non-contact detection

contributes to maintaining solar panel performance,

extending equipment life and increasing financial

returns. This can be done by using unmanned aerial

vehicles (UAVs) for extensive utilization of target

identification with low cost, high efficiency and a

significant field of vision. Additionally, this offers a

fresh approach to the tiresome and recurrent hot- spot

defect detection work faced by photovoltaic power

plants. Big data problems that are high-dimensional,

redundant and noisy can be better solved by deep

learning models. When detecting faults in PV panels

in a complex environment using thermal images taken

by UAV, the lightweight deep learning model is used

to speed up detection and reduce resource

consumption but cannot improve the robustness and

accuracy of hotspot detection.

This survey begins by detailing the external

factors that lead to failures in PV modules, discussing

their impact on both the physical components and

overall performance. Consequently, an examination

of the various types and modes of failure is conducted,

identifying hotspots as the most significant issue. In

conclusion, strategies for reducing these failures are

suggested.

Figure 1: From a solar cell to a PV-system.

Figure 1 outlines a PV system's components, from

solar cells to panels, inverters, meters, and optional

batteries, illustrating how sunlight is converted into

electricity for home or grid use.

2 LITERATURE SURVEY

(Qian et al. 2023) mentioned about Hotspot Defect

Detection (HDD) in photovoltaic (PV) modules with

infrared images (IFIs) is a challenging task due to the

size and morphology variations of individual hotspots

and the lack of an effective detection method to find

all hotspots. HF protective measures such as

segmentation of IFIs and implementation of state-of-

the-art YOLOv5s in the training of background noise

data up to October 2023 that is not befitting of the FI

will improve the identification of FI hotspots leading

to tailored HF supplier screening and reduced

transmission rates of FI.

(Alajmi et al. 2019) did a research on incredibly

cooling efficiency which exhibits the deficiency of

conventional defect localization methods in PV

arrays. This promotes a new approach for fault

hotspot detection based on infrared thermal imaging;

going forward, they plan to build models that allow

for the quick detection of open-circuit and short-

circuit faults.

(Dhimish and Badran. 2019) Presented a fuzzy

logic-based approach for detection of faults in

photovoltaic modules. Input parameters used in

model: three input parameters were proposed in their

model: open circuit voltage (Voc), short-circuit current

(Isc), and Power Loss Percentage (PPL). One major

drawback of their method is that the hot spots are not

identified under high partial shading conditions.

(Yang et al, 2022) reviewed a number of CNN-

based surface defect detection methods. This study

emphasizes the significance of artificial intelligence

in enhancing defect recognition in photovoltaic

modules based on machine vision. (Dhimish, Mather,

and Holmes et al, 2019) characterize eight

horticultural types of hotspots based on PV

degradation rate and PPL. They use cumulative

density function (CDF) modeling to achieve 80%

accuracy in hotspot impact prediction. It indicates

that hybridization of models with CDF will

significantly improve the predictive capability.

(Liu et al. 2024) presented a Machine Learning

based Stacking Classifier (MLSC) as a solution for

solar panel hotspot fault diagnosis. It compares the

physical methods of detection, threshold methods and

AI methods of detection. The results obtained with

this method can serve as a basis to present whether

MLSC is useful for accurate detection; in this case,

fault detection is achieved based on irradiance,

Empirical Analysis of AI-Based Hotspot Detection in Photovoltaic Panels Using Thermal Images

401

temperature, current, and power parameters.

The proposal for accurate PV string diagnosis

suggests a stacking classifier (MLSC) model to

accomplish accurate classification automatically and

remotely. The MLSC for PV string accurate fault

diagnosis is inspired and based on the physical fault

detection methods known as artificial intelligence.

PV fault diagnosis techniques incorporate physical

detection methods, threshold methodologies and

machine learning methods of detection. Additionally,

physical techniques tackle the identification and

position of the fault through the use of measuring

instruments to capture and scrutinize the performance

features of the PV defect. Threshold techniques apply

the I- V technique based on the position of inverter

current scans to generate I-V curves under normal and

faulty conditions.

3 RESEARCH METHODOLOGY

It describes strategies for analyzing data with the

intent of anticipating hotspot faults in PV systems. By

Performing Empirical analysis, we can identify

appropriate ML and DL algorithms for fault

detection. Algorithms like Support Vector Machine

(SVM), Logistic Regression, Decision Tree,

XGBoost, Naive Bayes, and Convolutional Neural

Networks (CNN) were analyzed in this work.

This work employs quantitative research

methodology to analyze the use of ML and DL

techniques for hotspot fault detection in PV systems.

The methodology includes data capture, feature

engineering, data preparation, model choice, and

analysis of results with the purpose of determining the

practicality of hotspot fault methods within the

context of solar energy system reliability and

performance optimization.

Data Collection: The analysis is based on

operational data acquired from a real-world solar PV

system in Location. Data on temperature patterns, in

the form of infrared (IR) thermography imaging, are

collected from different equipment and saved in

cloud- based systems for real-time analysis of hotspot

faults in solar panels.

Data Processing: The use of higher-order statistics

(HOS) such as mean, variance, skewness, and kurtosis

in data processing to reveal subsurface defects is an

essential part of machine learning. These parameters

compress the entire thermographic sequence into one,

or very few, images that contain detailed information

about the defects.

Model Development: ML and DL techniques are

used to develop fault detection models that can

identify deterioration patterns in solar panel

infrastructure. For classification problems, logistic

regression, tree-based methods, XGBoost, Naive

Bayes, and Support Vector Machines are

examples of supervised learning methods which are

adopted.

Model Training and Validation: To predict hotspot

faults in solar Panels, training and validation data

were evaluated using a 60-40 split. Cross- validation

techniques were applied to validate the data.

Optimising model performance and improving

predicted accuracy is achieved by hyperparameter

tuning. Model validation is performed with the use of

Accuracy, Precision, Recall, and F1-score. The figure

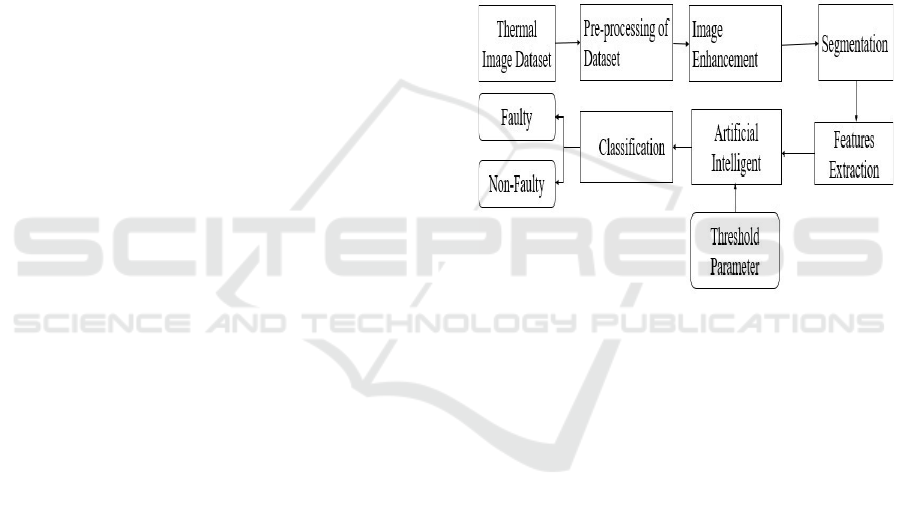

2 represents a basic architecture diagram for AI based

hotspot fault detection in PV panels.

Figure 2: The proposed AI model to detect hotspot.

Support Vector Machine (SVM): Support Vector

Machines (SVMs) are learning algorithms that use

supervised models to tackle tricky problems in

classification, regression, and spotting outliers. Two

distinct classes- health (non-faulty) and faulty

(hotspot) are created from the thermal pictures of PV

panels using SVM to detect faults. SVM's primary

goal is to find a function for training data that is as

smooth as possible with no deviations from the real

vectors. This method splits thermographic images of

PV systems into separate parts, and creates color

descriptors for each area. These color descriptors then

serve as features to train various learning algorithms.

These algorithms group PV panels into three types:

normal, hotspot, and faulty. After rigorous testing and

in-depth analysis, the results show that the learning

system has an accuracy of 92%.

Decision Trees: Decision trees are great approach

for hotspot analysis in solar PV system. Very simple

to deploy with good performance for both numerical

and categorical data. This method helps narrow down

the conditions that can predict hotspots considering

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

402

many factors such as temperature and irradiance and

current and voltage. The input data for solar power

plants consists of power generation and weather, and

the process of pre-processing data until training the

model using the proposed DT-LGB (Decision Trees

with Light Gradient Boosting) algorithm to predict

errors. After training, the model learns to identify

patterns and anomalies in the input data, whether

these are major flaws or smaller discrepancies. Most

of these findings require follow-up for appropriate

treatment or diagnosis. According to the study's

results, the model attained an efficiency rate of 81%.

Logistic regression: Logistic regression, a

statistical tool used mostly in binary classification,

can be used for thermal image classification where

image pixels are considered features and predicted

with the use of a sigmoid function. It is most

appropriate for binary classification problems, for

which one needs to predict two possible outcomes.

Sigmoid functions convert any real number input to

a value between 0 and 1; it is a chance of belonging

to that specific class. According to the study results,

the model achieved an efficiency rate of 89 percent.

Naive Bayes: Naive bayes is a probabilistic

classifier based on Bayes' theorem for hotspot

analysis in solar PV systems with strong(naive)

independence assumptions between the features. This

algorithm is used to detect visual flaws in

photovoltaic modules based on data extracted from

deep learning model. The findings imply that deep

learning feature extraction combined with naive

bayes offers a strong technique for PV module

condition monitoring, providing a dependable means

of problem detection and system efficiency

maintenance.

CNN: The CNN was trainee dusting a data set of

labeled thermal images where hotspots were

manually annotated, allowing the system to learn the

distinguishing features of hotspot patterns. The

system achieved an impressive 95% detection rate,

demonstrating its effectiveness in accurately

identifying hotspots.

Random Forest: Random forest extracted features

according to the calculated feature importance by

forming the feature subspace. It selected the decision

trees for construction according to the similarity and

classification accuracy of different decisions. After

performing the rigorous testing, it provides 85 percent

accuracy.

ViT: Vision Transformers, or ViT for short, is a

fascinating architecture that leverages self-attention

mechanisms to analyze images. The whole setup is

built around a sequence of transformer blocks. Each

of these blocks is made up of two key components: a

multi-head self- attention layer and a feed-forward

layer. This model attained an efficiency rate of 98

percent.

4 EMPIRICAL ANALYSIS

An empirical analysis involves collecting and

analysing data to test hypotheses based on machine

learning algorithms with different classification

metrics. The focus of this subsection is to show the

results achieved with various supervised

classification algorithms and their corresponding

metrics like Accuracy, Precision, Recall, F1-score,

and mean Average Precision (mAP).

INDICATOR AND PROMINENCE: Indicators are

essential tools used in machine learning and deep

learning algorithms to provide information about

specific conditions, performance of PV panels with

various classification metrics. It is used to establish to

what extent the model is applicable to the given

situation and to ascertain the health state of the

machine. They are of extreme relevance in

confirming the model dataset. Some of the possible

metrics in classification are discussed below.

4.1 Accuracy

Accuracy refers to the proportion of correctly

identified images versus the total number of images.

To achieve these confusion matrices are used for the

effectiveness of a classification framework. It is a

matrix table that uses four distinct combinations of

expected and actual values—TP, TN, FP and FN to

summarize how well a machine learning algorithm

performs.

I.

True Positive (TP): It is able to predict defect

columns.

II.

False Positive (FP): It is able to predict non-

defect columns as defect columns.

III.

False Negative (FN): It is able to predict

defect columns as non-defect columns.

IV.

True Negative (TN): It is able to predict non-

defect columns.

Mathematically, it is expressed as:

𝐴𝑐𝑐𝑢𝑟𝑎𝑐𝑦 =

(1)

4.2 Precision

Precision is a measure to find the accuracy of positive

predictions made by a model. Precision of image

classification is the number of correctly predicted

positive examples over all the examples which were

Empirical Analysis of AI-Based Hotspot Detection in Photovoltaic Panels Using Thermal Images

403

predicted positive. Mathematically, it is expressed as

𝑃𝑒𝑟𝑐𝑖𝑠𝑖𝑜𝑛 =

()

(2)

Figure 3: Confusion matrix of logistic regression.

Figure 4: Confusion matrix of naive bayes.

4.3 Recall (R)

Remember that recall, sensitivity, or true positive rate

measures the skill of a classification model to capture

all relevant data points within a given dataset. As far

as image classification is concerned, recall measures

the ratio of true positive cases (images belonging to a

certain class) which the model recognizes to the total

number of positive cases. Mathematically, it is

expressed as:

𝑅𝑒𝑐𝑎𝑙𝑙 =

()

(3)

4.4 F1-Score

The performance of image classification models

relies on many metrics, one being F1-Score, which

captures both precision and recall in a single measure

that balances the trade-off. The model can be utilized

in various aspects of classification accuracy and is a

good add-on to models that integrate other form of AI

tasks. Mathematically, it is expressed as:

𝐹1−𝑆𝑐𝑜𝑟𝑒=2∗

(∗)

()

(4)

Figure 5: Confusion matrix of decision tree.

Figure 6: Confusion matrix of random forest.

Multi-class image classification comes hand in

hand with object detection, and object detection

comes with its own F1-Score based metrics named

Mean Average Precision (mAP). AP is commonly

known for capturing the precision-recall trade-off but

for a targeted class. Mathematically, it is expressed

as:

𝐴𝑃 = ∑

(

𝑅

𝑅

)

𝑃

(5)

𝑚𝐴𝑃 =

∑

𝐴𝑃

(6)

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

404

Table 1: Algorithm comparison.

Algorithm

Accur

ac

y

Preci

sion

Recall

F1-

Score

mA

P

LR

89 87 86 86 85

Naive Bayes 83 81 82 81 79

Decision

Trees

81 79 83 81 78

Random

Forest

85 90 92 91 86

SVM 92 91 90 90 89

CN

N

95 94 95 95 93

ViT 97 96 97 96 95

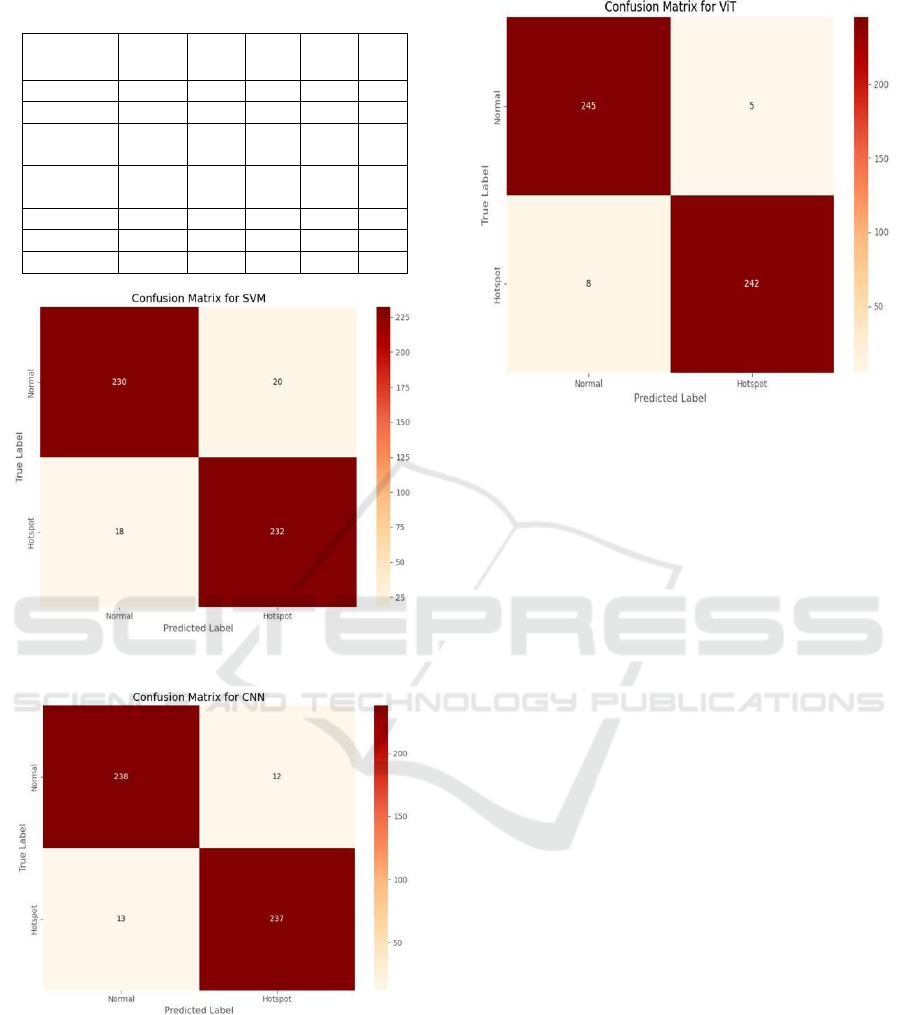

Figure 7: Confusion matrix of SVM.

Figure 8: Confusion matrix of CNN.

Figure 9: Confusion matrix of vision transform.

The empirical analysis of seven machine learning

models Logistic Regression, Naive Bayes, Decision

Trees, Random Forest, SVM, CNN, and Vision

Transformer (ViT) demonstrates the superiority of

deep learning approaches for anomaly detection in

photovoltaic system thermography (figure 3-9).

Traditional models like Logistic Regression (89%

accuracy) and Naïve Bayes (83% accuracy) showed

reasonable performance but suffered from higher

misclassification rates, as observed in their confusion

matrices, where a significant number of false

positives and false negatives were recorded. Decision

Trees (81%) and Random Forest (85%) improved in

recall but lacked overall precision, indicating

inconsistencies in classification. SVM (92%)

provided a more balanced performance with fewer

misclassifications, showing its ability to handle non-

linearly separable data effectively. However, CNN

(95%) and ViT (97%) outperformed all traditional

models, with ViT achieving the highest precision

(96%) and recall (97%), signifying its superior ability

to capture complex spatial patterns in thermal images.

The confusion matrix for ViT exhibited the lowest

number of false classifications, demonstrating its

robustness. The

results

confirm

that

deep

learning-based

models, especially ViT, are the most

effective for analyzing photovoltaic thermographic

data, offering higher accuracy and reliability in

detecting hotspots and anomalies, which is crucial for

early fault detection and maintenance in solar energy

systems.

Empirical Analysis of AI-Based Hotspot Detection in Photovoltaic Panels Using Thermal Images

405

5 RESULT AND DISCUSSIONS

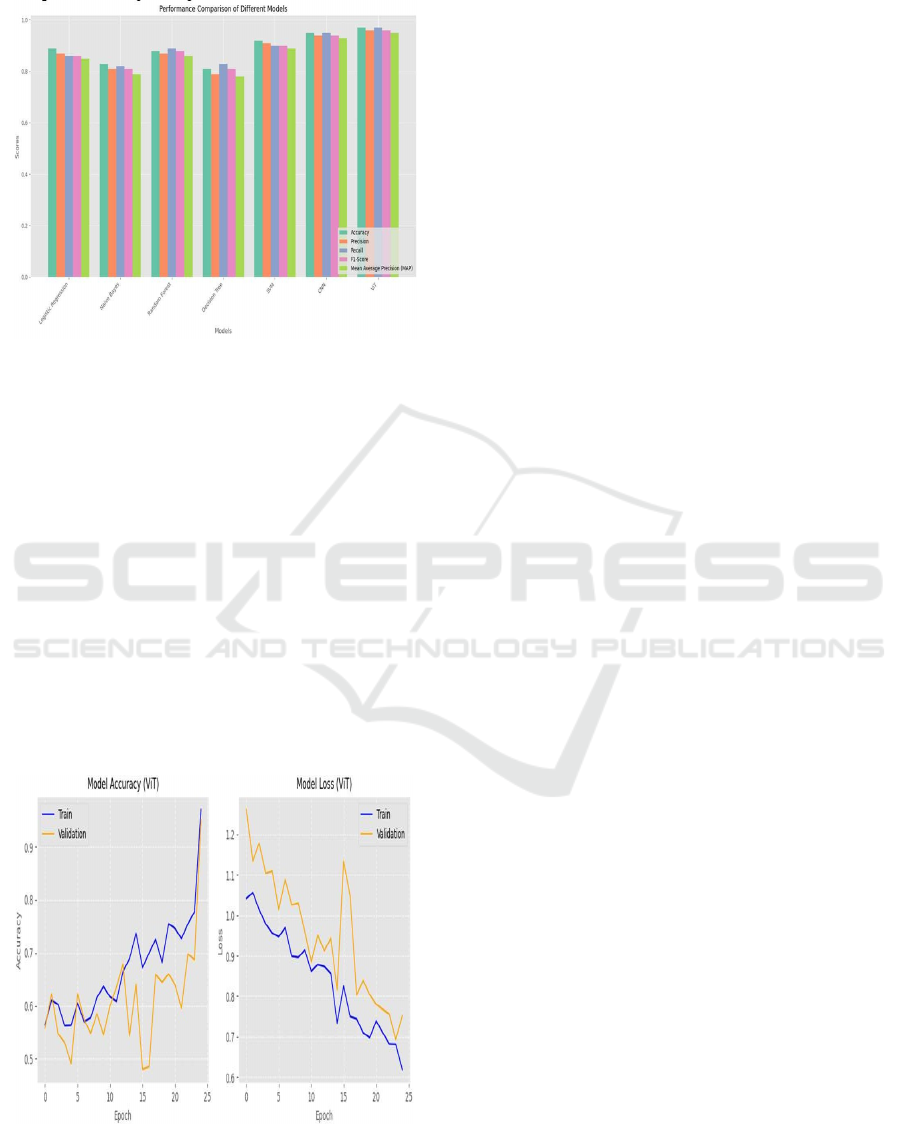

Figure 10: Performs comparison.

By comparing seven diverse classification

algorithm such as Logistic Regression, Naïve Bayes,

Decision Trees, Random Forest, SVM, CNN, and

Vision Transforms (ViT) to evaluate performance of

fault detection in PV panel using thermal image.

Based on Accuracy, Precision, Recall, and F1-score

and mAP, ViT algorithm illustrated the most

excellent outcomes with the most elevated precision

and the slightest misclassification blunders. CNN and

SVM moreover performed well but had marginally

lower accuracy compared to ViT. Conventional

machine learning models appeared generally lower in

execution, showing that profound learning

approaches, particularly ViT, are more compelling

for accomplishing superior classification. Figure 10

shows the comparison among the algorithms.

Figure 11: ViT accuracy and performance validation.

The analysis of the effectiveness of various

machine learning models integrated with photovoltaic

framework thermography shows that Vision

Transformer (ViT) outperforms the others by a

considerable performance metrics. ViT achieved the

most elevated accuracy (97%) with prevalent

precision (96%), recall (97%), and F1-score (96%),

demonstrating its robustness in classification tasks

(figure 11). The confusion matrix for ViT appears to

have negligible misclassifications, with only few

False Positives and False Negatives, making it the

most reliable. CNN takes after closely with a

precision of 95%, whereas SVM moreover performs

well at 92%, but both show somewhat higher

misclassification rates. Conventional models like

Calculated Relapse, Naïve Bayes, Choice Trees, and

Irregular Woodland appear lower precision,

extending from 81% to 89%, with expanded

misclassification blunders. The experimental

examination affirms that profound learning

approaches, especially ViT, viably capture spatial and

relevant data, making them the optimal choice for

identifying warm peculiarities in photovoltaic

frameworks.

6 CONCLUSIONS

This analysis compiles a comparative study of

different classification techniques conducted to

determine the best algorithm for PV system hotspot

fault detection. The result indicates that models

developed on deep learning, and Vision Transforms

(ViT) in particular, outperformed all other

conventional machine learning algorithms in terms of

accuracy, precision, recall, F1 score and mAP. ViT

recorded the highest accuracy of 97%, and hence it is

the best choice when the correct detection of defects

in PV panels. CNN and SVM were also doing

exceptionally well, and other conventional models

like Logistic Regression, Naive Bayes, Decision

Trees and Random Forest recorded much lower

accuracy and reliability.Based on these findings, it is

evident that advanced deep learning techniques

provide superior results, making them well-suited for

enhancing the efficiency of photovoltaic system

monitoring and fault detection.

REFERENCES

Alajmi, Masoud, et al. "IR thermal image analysis: An

efficient algorithm for accurate hot-spot fault detection

and localization in solar photovoltaic systems." 2019

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

406

IEEE International Conference on Electro Information

Technology (EIT). IEEE, 2019.

Ali, Muhammad Umair, et al. "Early hotspot detection in

photovoltaic modules using color image descriptors:

An infrared thermography study." International Journal

of Energy Research 46.2 (2022): 774-785.

Balasubramani, Gomathy, and Venkatesan Thangavelu.

"Thermal Image Analysis of Photovoltaic Panel for

Condition Monitoring Using Hybrid Thermal Pixel

Counting Algorithm and XGBoost Classifier." Electric

Power Components and Systems (2023): 1-14.

Dhimish, Mahmoud, and Ghadeer Badran. "Photovoltaic

hot- spots fault detection algorithm using fuzzy

systems." IEEE Transactions on Device and Materials

Reliability 19.4 (2019): 671-679.

Dhimish, Mahmoud, Peter Mather, and Violeta Holmes.

"Novel photovoltaic hot-spotting fault detection

algorithm." IEEE Transactions on Device and Materials

Reliability 19.2 (2019): 378-386.

Koester, L.; Linding, S.; Louwen, A.; Astigarraga, A.;

Manzolini, G.; Moser, D. Review of photovoltaic

module degradation, field inspection techniques and

techno-economic assessment. Renew. Sustain. Energy

Rev. 2022, 165, 112616.

Liu, Bo, et al. "Fault diagnosis of photovoltaic strings by

using machine learning‐based stacking classifier." IET

Renewable Power Generation 18.3 (2024): 384-397.

Moskovchenko, Alexey, and Michal Svantner.

"Thermographic Data Processing and Feature

Extraction Approaches for Machine Learning-Based

Defect Detection." Engineering Proceedings 51.1

(2023): 5.

Pruthviraj, Umesh, et al. "Solar photovoltaic hotspot

inspection using unmanned aerial vehicle thermal

images at a solar field in south india." Remote Sensing

15.7 (2023): 1914.

Qian, Huimin, et al. "Hotspot defect detection for

photovoltaic modules under complex backgrounds."

Multimedia Systems 29.6 (2023): 3245-3258.

Qureshi, Muhammad Salik, Shayan Umar, and Muhammad

Usman Nawaz. "Machine Learning for Predictive

Maintenance in Solar Farms." International Journal of

Advanced Engineering Technologies and Innovations

1.3 (2024): 27-49.

Ram, Manish, et al. "Global energy system based on 100%

renewable energy–power, heat, transport and

desalination sectors." Study by Lappeenranta

University of Technology and Energy Watch Group,

Lappeenranta, Berlin 10 (2019)

Sharanya, S., and Revathi Venkataraman. "Empirical

analysis of machine learning algorithms in fault

diagnosis of coolant tower in nuclear power plants."

New Trends in Computational Vision and Bio-inspired

Computing: Selected works presented at the ICCVBIC

2018, Coimbatore, India (2020): 1325-1332.

Sivagamasundari, S., and Manjula Sri Rayudu. "IoT based

solar panel fault and maintenance detection using

decision tree with light gradient boosting."

Measurement: Sensors 27 (2023): 100726.

T. Alqahtani, A. Almutared and A. Alzahrani,

"Photovoltaic Hot Spot Detection System Using Deep

Convolution Neural Networks," 2023 IEEE

International Future Energy Electronics Conference

(IFEEC), Sydney, Australia, 2023, pp. 327-330, doi:

10.1109/IFEEC58486.2023.10458570.

Umar, Shayan, Muhammad Salik Qureshi, and Muhammad

Usman Nawaz. "Thermal imaging and ai in solar panel

defect identification." International Journal of

Advanced Engineering Technologies and Innovations

1.3 (2024): 73-95.

Venkatesh, S. Naveen, et al. "A comparative study on bayes

classifier for detecting photovoltaic module visual

faults using deep learning features." Sustainable Energy

Technologies and Assessments 64 (2024): 103713.

Yang, Weihua. "A survey of surface defect detection based

on deep learning." 2022 7th International Conference

on Modern Management and Education Technology

(MMET 2022). Atlantis Press, 2022.

Zazoum, Bouchaib. "Solar photovoltaic power prediction

using different machine learning methods." Energy

Reports 8 (2022): 19-25.

Empirical Analysis of AI-Based Hotspot Detection in Photovoltaic Panels Using Thermal Images

407