Soft Robotics for Advanced Handling of Delicate Fruit Products

Luan Lang

1a

, Rodrigo Antunes

1,2 b

, Martim Lima de Aguiar

1,2 c

, Nuno Pereira

1,2 d

,

Thiago Assis Dutra

1,2 e

, Yebo Lu

3f

and Pedro Dinis Gaspar

1,2 g

1

C-MAST - Centre for Mechanical and Aerospace Science and Technologies,

University of Beira Interior, Calçada Fonte do Lameiro 6, 6200-358, Covilhã, Portugal

2

Department of Electromechanical Engineering, University of Beira Interior,

Calçada Fonte do Lameiro 6, 6200-358, Covilhã, Portugal

3

College of Mechanical Engineering, Jiaxing University, Jiaxing, Zhejiang province, 314001, China

Keywords: Soft Robotic Grippers, Soft Grippers, TPU 60A, TPU 95A, Flexible Materials, Delicate Handling, Fin Ray

Effect, FRE, Robotics, Grippers.

Abstract: Soft robotic grippers can be an effective tool for handling sensitive and irregularly shaped objects, such as

horticultural products. This study evaluates three soft gripper designs—Straight, Constant Curve, and Beak—

fabricated using Thermoplastic Polyurethane (TPU) with shore hardness 60A and 95A. The grippers were

produced using a 3D printer and tested on a universal testing machine to assess mechanical performance.

Practical tests revealed that the Beak gripper made with TPU 60A exhibited superior performance, achieving

a peak force of 10.59 N at a displacement of 21.65 mm, making it suitable for delicate tasks like handling

fruits, without causing damage. In contrast, grippers made with TPU 95A, while possessing higher force

capacities, were excessively rigid and risked damaging delicate items. The study shows the importance of

material selection and gripper design in optimizing performance for specific applications. The findings validate

simulation data and indicate that TPU 60A is more appropriate for applications requiring gentle handling. Future

work includes testing with objects of varying shapes, conducting fatigue tests, and exploring multi-material

gripper designs with embedded sensing capabilities to enhance adaptability and control during use.

1 INTRODUCTION

Grippers, like robots themselves, are fundamental

elements in the modern industry, since the

manipulation of objects with various shapes is one of

the most common and complex challenges in the field

of robotics (

Youn, 2020

). To meet the tasks of

handling sensitive products or those with complex

geometries, soft grippers have been developed. They

are made from flexible materials, allowing

considerable deformation to adjust to the product

without damaging it. These grippers enable superior

results when handling sensitive and irregular objects,

a

https://orcid.org/0000-0002-2857-3092

b

https://orcid.org/0009-0002-6599-6905

c

https://orcid.org/0000-0003-0672-0378

d

https://orcid.org0000-0001-7177-751X

e

https://orcid.org/0000-0002-3576-5703

f

https://orcid.org/0000-0002-8995-370X

g

https://orcid.org/0000-0003-1691-1709

compared to grippers made from more rigid materials

(Dinakaran, 2008). With advances in technologies

such as additive manufacturing and more flexible

materials, soft grippers have become a more viable,

adaptable, and affordable solution. These advances

have allowed these grippers to be used more widely,

providing a simple, economical, and effective

approach to dealing with complex tasks such as safe

interaction with humans and handling fragile objects

(Zhai, 2023).

The fragility, sensitivity, stickiness, and

slipperiness of most food and agricultural products

have fuelled the development of soft robotic grippers

Lang, L., Antunes, R., Lima de Aguiar, M., Pereira, N., Assis Dutra, T., Lu, Y. and Gaspar, P. D.

Soft Robotics for Advanced Handling of Delicate Fruit Products.

DOI: 10.5220/0013928800003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 569-576

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

569

that are deformable, flexible, safe, low-cost, and

environmentally friendly (Liu, 2023). Thermoplastic

Polyurethane (TPU) is a thermoplastic elastomer

bridging the gap between rubbers and plastics. It

combines high flexibility and durability (Hasan,

2022), is widely available in a broad range of Shore

hardness values and exhibits excellent mechanical

strength. TPU is also readily available as a feedstock

material for Fused Filament Fabrication (FFF)

Additive Manufacturing (AM), making it suitable for

the production of soft robotic grippers.

(He, 2023) developed a rigid‑soft coupled robotic

gripper for adaptable grasping. The experimental

results showed that the proposed gripper can adapt to

objects with different properties (shape, size, weight,

and softness) and hold them steadily. The feasibility

of the design procedure was confirmed, as well as the

compliant and dexterous grasping capabilities of the

developed gripper. (Zapciu, 2017) developed an

adaptive robotic end effector-that used 3D printed Fin

Ray Effect (FRE) Soft Robotic Gripper Fingers

(SRGF) with embedded conductive 3D-printed

sensing circuits, which gave the end-effector

capacitive touch sensing and bend sensing

capabilities for manipulation of sensitive objects such

as fruits and vegetables.

The development of a robotic gripper for

agricultural robots must consider several factors, such

as the type of crop and its physical characteristics,

such as the shape, size, and sensitivity of the fruit or

vegetable. For example, the grippers need to be

adaptable enough to handle fragile items without

damaging them, which is critical in crops such as

tomatoes, apples and peaches. In addition, grippers

must be designed to operate in unstructured

agricultural environments, where variability in size

and shape, as well as the presence of leaves and

branches, can complicate the harvesting process.

Technologies such as sensors and artificial

intelligence algorithms can help the control of the

gripping and handling tasks to optimise harvesting

(Han, 2024), (Vrochidou, 2022).

In the case of flexible grippers, they have a

significant capacity for deformation within the elastic

regime. This ensures safe interaction with the

environment and minimises the risk of damaging

delicate objects. For this reason, these manipulators

are often chosen as end effectors in agricultural robots

for harvesting and sorting produce (Elfferich, 2022),

(Wang, 2023) and (Williams, 2019).

Soft grippers that rely on the FRE present a simple

economically viable approach to grasping objects of

various shapes (Yao, 2024). The biomimetic structure

eliminates the need for inbuilt actuation in the fingers,

thus facilitating passive adaptation to the surface of

an object upon contact. Since the introduction of the

FRE SRGF by Festo in 2016, extensive research has

inspired numerous innovative applications.

Prior work has demonstrated agricultural use

cases and flexible grasping with FRE-based soft

grippers.

However, systematic, side-by-side evaluations of

various rear-frame designs under the same materials

and test conditions are still mainly missing. Our study

fills this gap by comparing three geometries: Straight,

Constant Curve, and Beak, fabricated in TPU 60A

and TPU 95A using the identical Universal Testing

Machine (UTM) process and object set, and by

comparing the results with prior simulations. This

approach identifies material hardness and rear-frame

shape as the main design levers for the gentle

handling of delicate fruit.

Building on previous characterization and

computational simulation work (Lang, 2025), three

distinct FRE SRGF models were designed and

experimentally tested to evaluate the influence of two

key parameters: the Shore hardness of TPU and the

geometric shape of the finger’s rear frame side. The

tested geometric configurations included Straight,

Constant Curve, and Beak-shaped designs. The

results provide clear guidance: the TPU 60A Beak

achieves the best balance of compliance and force,

whereas TPU 95A is often too rigid for fragile

produce. We further link mechanics to outcome by

relating observed slippage/marking to the measured

force–displacement response and contact evolution,

and we show agreement with simulations,

strengthening actionable design rules for horticulture

and food-handling applications.

2 MATERIALS AND METHODS

The FRE SRGF design process was founded on a

simplified analysis of the structural elements of a

FRE SRGF, as described by Antunes (2024a) and

shown in Figure 1. This approach involved evaluating

the static force distributions across a segmented

model of the FRE SRGF, allowing a clearer

understanding of the mechanical role of each

component.

COBOTA 2025 - Special Session on Bridging the Gap in COllaborative roBOtics: from Theory to real Applications

570

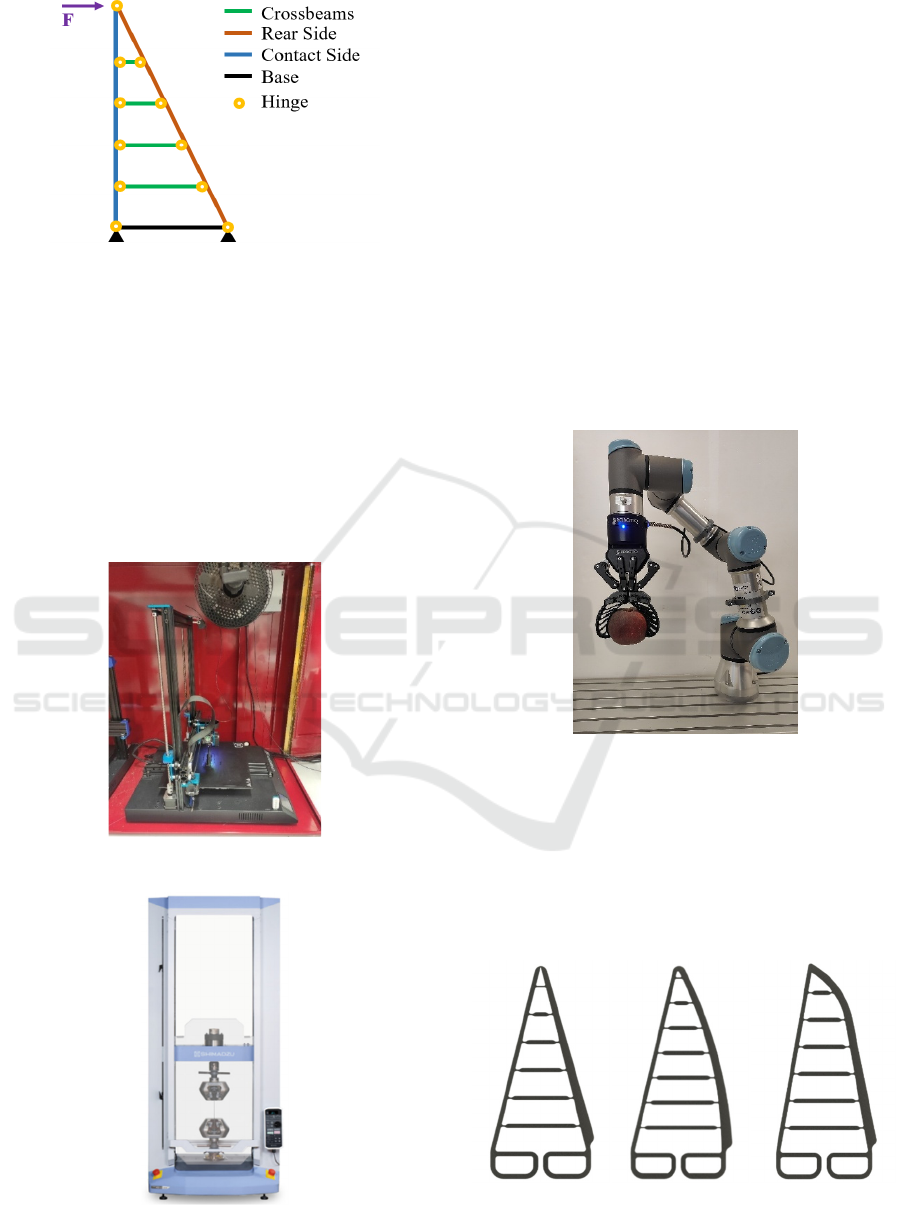

Figure 1: Simplified representation of an FRE SRF with a

grasping force at the tip of the finger.

The material selected for this study was Filaflex TPU

in both 60A and 95A Shore hardnesses, produced by

Recreus Industries S.L. The chosen 3D printer was

the Artillery Sidewinder X1, shown in Figure 2,

because it was validated and recommended by the

filament manufacturer for printing these TPU

filaments (Recreus Industries S.L., 2024). This

contributed to achieving consistent print quality,

given the challenges associated with FFF AM of

highly flexible materials.

Figure 2: 3D printer Artillery Sidewinder X1.

Figure 3: Shimadzu Autograph AGS-X-50 kN (Shimadzu

Corporation, 2023).

The Precision Universal Tester Autograph AGS-

X-50 kN (Shimadzu Corporation, 2023) is shown in

Figure 3 and was used to carry out the tensile tests. It

features a reading resolution of 0.001 mm and a

sampling rate up to 1000 Hz (1ms). It is equipped

with TRAPEZIUM LITE X software to control tests

in real time and generate reports. (Shimadzu

Corporation, 2023).

The UR3e collaborative robot, shown in Figure 4,

is widely used for small-scale assembly tasks and

handling small objects (Universal Robots, 2024). The

use of this model, together with the actuator Robotiq

2F-85 Adaptive Gripper (Robotiq, 2020) was used,

and it allows enough customizability to adapt and

attach different types of gripper fingers. This flexibility

enabled testing with various SRGF, focusing on

handling delicate products, such as fruit, to assess their

suitability in gentle handling applications.

Figure 4: Cobot UR3e gripping a peach with the developed

FRE SRGF.

The three FRE SRGF models were designed using

Computer-Aided Design (CAD) based on the design

developed by Antunes (2024a) and Antunes (2024b),

as shown in Figure 5 were printed in TPU 60A and

95A. The printing orientation followed the procedure

based on (Lang, 2025).

(a) (b) (c)

Figure 5: Three FRE SRGF CADs: (a) Straight. (b)

Constant Curve. (c) Beak.

Soft Robotics for Advanced Handling of Delicate Fruit Products

571

To carry out the practical tests, a mechanism

developed in Antunes (2024a) and Antunes (2024b),

shown in Figure 6, was used. This allowed attaching

the SRGF to the Shimadzu Autograph AGS-X-50 kN,

and the control of the gripping width for grasping the

object shown in Figure 7.

Figure 6: Mechanism for the base and being able to carry

out practical tests.

Figure 7: Cylinder for carrying out the practical test.

3 RESULTS AND DISCUSSIONS

Practical tests were performed on a UTM with a built-

in load cell while the crosshead imposed a prescribed

finger-spacing trajectory. Each trial mounted two

identical fingers on the parallel mechanism and

grasped a rigid cylinder centred between them. The

measured force is the total normal gripping force

transmitted through the cylinder; under symmetric

contact, the per-finger force ≈ total force/2. Force–

displacement curves Figures 11, 12 and 13 were

derived directly from the UTM signal, using the same

displacement limit as in the simulations.

8 tests were carried out with each SRGF design, 5

of which were valid. For each test, each gripper model

was mounted on the mechanism developed to carry

out the tests, and the cylinder was aligned in the

centre so that both grips had the contact face area as

close as possible. Figure 8 shows the process of

carrying out the first valid test on the Straight model,

where (a) is the start of the test, (b) is the point where

the maximum force occurs and (c) is the end of the

test, the same occurs for Constant Curve in Figure 9,

and for Beak in Figure 10.

(

a

)

(

b

)

(

c

)

Figure 8: First Practical Test – Straight: (a) Beginning, (b)

Maximum Force; (c) End.

(a) (b) (c)

Figure 9: First Practical Test – Constant Curve: (a)

Beginning, (b) Maximum Force; (c) End.

(

a

)

(

b

)

(

c

)

Figure 10: First Practical Test – Constant Curve: (a)

Beginning, (b) Maximum Force; (c) End.

In the case of the Straight SRGF design, it can be seen

in Figure 11 that the maximum forces reached were

between 5.87 N and 6.69 N, with an average of 6.3 N

and a standard deviation of 0.82. All cases were

considered until 50 mm of displacement was reached,

as occurred in the computer simulations.

Figure 11: Valid Practical Tests - Straight.

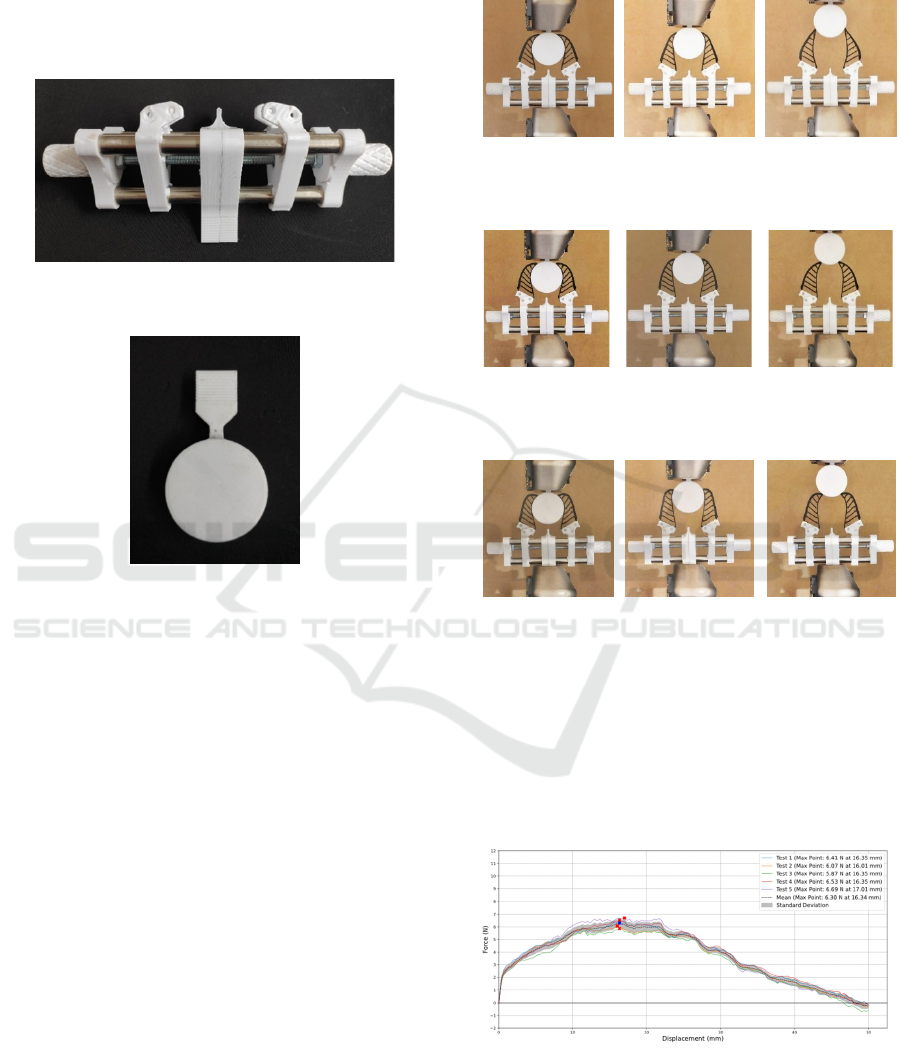

The Constant Curve SRGF design results are shown

in Figure 12, the forces ranged from 9.67 N to 11.13

N, with an average of 10.37 N. These tests also

COBOTA 2025 - Special Session on Bridging the Gap in COllaborative roBOtics: from Theory to real Applications

572

considered up to 50 mm of displacement. It should be

noted that this model has a higher standard deviation

(1.46), as the range of force values achieved was also

greater.

Figure 12: Valid Practical Tests – Constant Curve.

In the case of the results obtained for the Beak SRGF

design seen in Figure 13, the forces obtained in the

tests were between 10.48 N and 10.9 N, with a

standard deviation of 0.53 and an average of 10.59 N,

the highest of all the gripper models tested.

Figure 13: Valid Practical Tests – Beak.

Figure 14 shows the average of the Straight,

Constant Curve, and Beak SRGF designs tested. It

should be noted that the Beak SRGF design is the one

with the best result, followed by the Constant Curve

SRGF design and then the Straight SRGF design. Due

to the design developed, the Beak SRGF design, after

reaching the maximum point in terms of force, the

contact area of this design decreases, as the object is

only held at the top tips of the grippers, and therefore

ends up having an abrupt drop until the end of the test.

Analysing Figure 14, it is important to note that

all the designs showed negative forces towards the

end of the tests. This condition occurred since, when

they reached around 50

mm of displacement, the

object slipped and the grippers now under the object

were pushing it away, i.e., in compression rather than

traction. This behaviour indicates that, after a critical

point of displacement, the gripper is no longer

effective in supporting elongation, resulting in a

reversal of the applied force.

Figure 14: Average of the practical tests of the three gripper

designs.

This regime transition is particularly noticeable in the

Beak SRGF design and Constant Curve SRGF

design, which reached the highest force values but

also experienced the sharpest drop. The Straight

SRGF design, showed a lower peak force, although it

also showed relative stability in its behaviour until the

end of the test.

3.1 Comparison of Practical Grip

Results Between TPU 60A and TPU

95A

Testing and comparing the results of the SRGF

designs made from TPU 60A and TPU 95A in

practical tests allows for the practical understanding

of the mechanical behaviour of these materials in

their applications, such as handling fruit or delicate

objects. According to Antunes (2024a) and Antunes

(2024b), TPU 95A was chosen due to its favourable

balance of flexibility and mechanical strength.

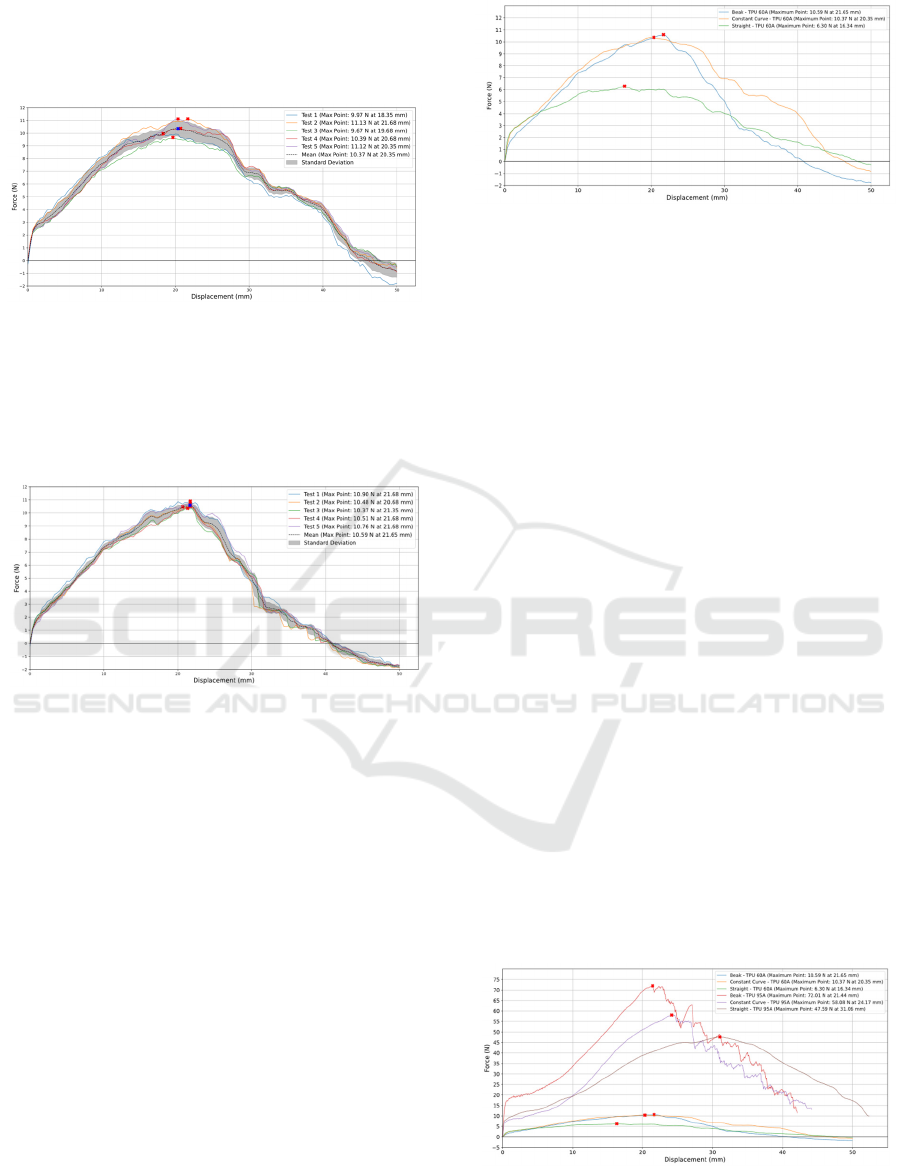

Analysing Figure 15 and Table 1, the grippers

made with TPU95A can in fact apply a higher

maximum force before the object slips compared to

those made with TPU60A, reaching 72

N for the Beak

gripper, 58

N for the Constant Curve and almost 48 N

for the Straight gripper. These values are very high,

but this rigidity can be excessive for applications that

require a softer handling, such as fruit handling.

Figure 15: Grippers made of TPU 60A vs. TPU95A.

Soft Robotics for Advanced Handling of Delicate Fruit Products

573

Table 1: Comparison of maximum force values before

slipping between grippers produced with TPU60A and

TPU95A.

Grippers

Maximum Force

(TPU 60A) [N]

Maximum Force

(TPU 95A) [N]

Bea

k

10.59 72.01

Constant Curve 10.37 58.08

Straigh

t

6.30 47.59

(a) (b)

(

c

)

(

d

)

(e) (f)

(g)

(

h

)

(i) (j)

Figure 16: Beak gripper when picking up different objects:

(a) TPU60A- Nectarine. (b) TPU95A- Nectarine. (c)

TPU60A- Peach. (d) TPU95A- Peach. (e) TPU60A-

Orange. (f) TPU95A- Orange. (g) TPU60A- Soft Football.

(h) TPU95A- Soft Football. (i) TPU60A- Flexible Ball. (j)

TPU95A- Flexible Ball.

For this reason, although TPU 60A exhibits lower

resistance to deformation and a reduced maximum

gripping force before slippage, its greater flexibility

results in improved force distribution over the surface

of the grasped fruits (peaches, oranges, and apples)

with an average weight of 185

g. Given the relatively

low weight of these fruits, the maximum gripping

forces provided by TPU 60A remain sufficient for

reliable manipulation, ensuring gentle handling

without causing damage, while still providing

adequate durability for continuous use.

This condition can be seen in Figure 16 (a), (c),

(e), (g), and (i), where the Beak gripper printed with

TPU60A was tested by gripping a series of objects.

Figure 16 (b), (d), (f), (h), and (j) are for the same

objects, but the test was carried out with the Beak

gripper printed with TPU 95A. These figures test the

best-performing SRGF developed in a laboratory

environment when handling a variety of objects, with

a focus on fruit or fruit-like shapes.

Figure 17 (a), (b), (c), and (d) show the effect of

gripping the Beak grippers printed on TPU 60A and

TPU 95A. The gripper made with TPU 95A is more

rigid and stiff, leaving visible marks on the fruit. In

contrast, the fruit gripped with the gripper printed on

TPU 60A showed no visible damage, demonstrating

a softer grip suitable for delicate handling.

(a) Peach after being

gripped the gripper printed

with TPU 60A.

(b) Peach after being gripped

the gripper printed with TPU

95A.

(c) Orange after being

gripped the gripper printed

with TPU 60A.

(d) Orange after being

gripped the gripper printed

with TPU 95A.

Figure 17: Peach and Orange after being gripped by the

Beak gripper printed with TPU60A and TPU95A.

COBOTA 2025 - Special Session on Bridging the Gap in COllaborative roBOtics: from Theory to real Applications

574

4 CONCLUSIONS

Besides the practical tests used a rigid cylinder and a

small set of fruits. Tests were quasi-static with a

specific printer/material brand and printing

orientation, which was already tested (Lang, 2025).

The setup assessed a parallel two-finger grasp without

closed-loop sensing/control, but do not diminish the

central finding that TPU 60A Beak provides a

favourable compliance–durability trade-off for

delicate handling.

The practical tests indicated that the Beak gripper

performed best in terms of force capacity, followed

by the Constant Curve and then the Straight grippers.

The Beak gripper achieved a maximum force before

slippage of 10.59

N at a displacement of 21.65 mm,

demonstrating superior load-bearing capability. The

Constant Curve gripper closely followed with a

maximum force before slippage of 10.37

N at

20.35 mm, suggesting that its design is nearly as

effective as the Beak gripper. In contrast, the Straight

gripper reached a lower maximum force before

slippage of all the designs with 6.30

N at 16.34 mm,

implying that its less curved design is less efficient in

supporting loads.

All grippers showed a marked decrease in force after

reaching their maximum force before slippage values.

Despite no visible signs of fractures or plastic

deformation, future work should include fatigue tests

to assess gripper durability under prolonged and

cyclic use. It is also suggested that tests be carried out

with objects of different shapes in addition to the

cylinder used, broadening the scope of the practical

evaluation and computer simulation; performing

bruise-threshold quantification on representative

produce to map allowable contact pressures; multi-

material printing and embedded/skin sensing for

closed-loop grip control; surface liners/textures and

food-grade elastomers for hygienic wash-down.

These advances have the potential to add great

value to companies by offering custom solutions at a

lower associated cost.

Comparisons with grippers made from TPU95A,

as designed by Antunes (2024a) and Antunes

(2024b), revealed that, as expected, TPU95A offers

greater resistance to deformation, its high hardness

can compromise the integrity of delicate items like

fruit during handling. Grippers made with TPU60A

provide better adaptability by conforming to the

object shapes without sacrificing durability or

causing damage to the fruit, thus allowing delicate

handling of soft and perishable products.

The experimental results offer insights into how

the design of the frame’s rear side of FRE SRGF and

material selection impact gripper efficiency during

handling tasks.

ACKNOWLEDGEMENTS

These results are within the research activities of

project “ROBOTA-SUDOE - Robotics, Automation,

and Digitalization as Drivers of Competitiveness and

Growth for SMEs” (S1/1.1/P0125), which is co-

funded by the European Union through the European

Regional Development Fund (ERDF) and national

funds, under the territorial cooperation Interreg

Europe Programme 2021–2027 (eSUDOE 2021-

2027). This research was partially funded by the

Portuguese Foundation for Science and Technology,

I.P. (FCT, I.P.) FCT/MCTES through national funds

(PIDDAC), under the R&D Unit C-MAST/Center for

Mechanical and Aerospace Science and

Technologies, reference: Projects UIDB/ 00151/2020

(https://doi.org/10.54499/UIDB/00151/2020) and

UIDP/00151/2020 (https://doi.org/10.54499/UIDP/0

0151/2020)

REFERENCES

Antunes, R., Lang, L. M. C., de Aguiar, M. L., Dutra, T. A.,

& Gaspar, P. D. (2024a, August 4–6). Enhancing the

performance of Fin Ray effect soft robotic finger via

computational design and simulation. Paper presented

at the 20th ASME/IEEE International Conference on

Mechatronic and Embedded Systems and Applications

(MESA 2024), Genoa, Italy.

Antunes, R., Lang, L. M. C., de Aguiar, M. L., Dutra, T. A.,

& Gaspar, P. D. (2024b, August 4–6). Design of Fin

Ray effect soft robotic gripper for improved mechanical

performance and adaptability: Numerical simulations

and experimental validation. Paper presented at the

IEEE/ASME MESA 2024 Conference, Genoa, Italy.

Dinakaran, V. P., Balasubramaniyan, M. P., Muthusamy,

S., & Panchal, H. (2023). Performa of SCARA based

intelligent 3 axis robotic soft gripper for enhanced

material handling. Advances in Engineering Software,

176, 103352.

Elfferich, J. F., Dodou, D., & de Santina, C. (2022). Soft

robotic grippers for crop handling or harvesting: A

review. IEEE Access, 10, 75428–75443.

Han, C., Lv, J., Dong, C., Li, J., Luo, Y., Wu, W., &

Abdeen, M. A. (2024). Classification, advanced

technologies, and typical applications of end-effector

for fruit and vegetable picking robots. Agriculture, 14,

1776.

Hasan, M. J. (2022). Design and fabrication of an adaptive

gripper with Fin-Ray effect (Course report ME-3200).

Soft Robotics for Advanced Handling of Delicate Fruit Products

575

Department of Mechanical Engineering, Khulna

University of Engineering & Technology.

He, Z., Lian, B., & Song, Y. (2023). Rigid–soft coupled

robotic gripper for adaptable grasping. Journal of

Bionic Engineering, 20, 2601–2618.

Lang, L., Antunes, R., de Aguiar, M. L., Dutra, T. A., &

Gaspar, P. D. (2025). Mechanical characterization and

computational analysis of TPU 60A: Integrating

experimental testing and simulation for performance

optimization. Materials, 18(2), 240.

Liu, Y., Hou, J., Li, C., & Wang, X. (2023). Intelligent soft

robotic grippers for agricultural and food product

handling: A brief review with a focus on design and

control. Advanced Intelligent Systems, 5, 2300066.

Recreus Industries S.L. (2024). Filaflex 60A Technical

Data Sheet and Disclaimer. Retrieved from

https://recreus.com/en/products/filaflex-60a

Robotiq. (2020). Robotiq adaptive grippers. Robotiq.

Shimadzu Corporation. (2023). Autograph AGS-X series

[Product brochure]. Shimadzu Corporation.

Universal Robots. (2024, November 5). The UR3e.

Retrieved November 5, 2024, from https://www.uni

versal-robots.com/products/ur3-robot/

Veloso, A., Ilangovan, A., Baptista, C., Espírito-Santo, C.,

Amaro, C., Canavarro, C., Pintado, C. M., Morais, D.,

Ferreira, D., Beato, H., Luz, J. P., de Andrade, L. P.,

Resende, M., & Paul. (2022). PrunusPÓS. In Inovação

no pós-colheita de pêssego e cereja (p. 47). Empresa

Diário do Porto, Lda.

Vrochidou, E., Tsakalidou, V. N., Kalathas, I., Gkrimpizis,

T., Pachidis, T., & Kaburlasos, V. G. (2022). An

overview of end effectors in agricultural robotic

harvesting systems. Agriculture, 12, 1223.

Wang, X., Kang, H., Zhou, H., Au, W., Wang, M. Y., &

Chen, C. (2023). Development and evaluation of a

robust soft robotic gripper for apple harvesting.

Computers and Electronics in Agriculture, 204,

107534.

Williams, H., Ting, C., Nejati, M., Jones, M. H., Penhall,

N., Lim, J., Seabright, M., Bell, J., Ahn, H. S., Scarfe,

A., Duke, M., & MacDonald, B. (2019). Improvements

to and large-scale evaluation of a robotic kiwifruit

harvester.

Journal of Field Robotics, 37, 187–201.

Yao, J., Fang, Y., Yang, X., Wang, P., & Li, L. (2024).

Design optimization of soft robotic fingers biologically

inspired by the Fin Ray effect with intrinsic force

sensing. Mechanism and Machine Theory, 191,

105019.

Youn, J.-H., Jeong, S. M., Hwang, G., Kim, H., Hyeon, K.,

Park, J., & Kyung, K.-U. (2020). Dielectric elastomer

actuator for soft robotics applications and challenges.

Applied Sciences, 10, 5469.

Zapciu, A., Constantin, G., & Popescu, D. (2017). Adaptive

robotic end-effector with embedded 3D-printed sensing

circuits. MATEC Web of Conferences, 121, 01006.

Zhai, Y., Yan, J., Shih, B., Faber, M., Speros, J., Gupta, R.,

& Tolley, M. T. (2023). Desktop fabrication of

monolithic soft robotic devices with embedded fluidic

control circuits. Science Robotics, 8, eabq6270.

COBOTA 2025 - Special Session on Bridging the Gap in COllaborative roBOtics: from Theory to real Applications

576