Advanced Integrated Damage Detection System for Bulletproof

Materials Using Ultrasonic and X‑Ray Sensors with AI Algorithms

P. Sreedevi, A. Sabina Parveen, S. Diva, S. Subasanjeev, D. Pranavika and V. Rakshitha

Department of Computer Science and Engineering, V.S.B College of Engineering Technical campus, Kinathukadavu,

Coimbatore, Tamil Nadu, India

Keywords: Damage Detection, Bulletproof Materials, Integrated System, Ultrasonic Sensors, X‑Ray Sensors, Artificial

Intelligence (AI), High Risk Situations.

Abstract: A new integrated damage detection system for bullet proofing materials during high complicated situation

such as war in the border. Two sensors are combined by conventional inspection method in sensitivity in

identifying minor damage in the bulletproof material. We have developed a novel system that combine X-

Ray sensor and ultrasonic sensors to meet the need of bulletproof material damage. The ultrasonic sensors

were developed to reveal the flaws in the outside of the bulletproof material and the X-Ray sensors detect the

flaws in the internal structure of the bullet proof material using AI algorithms. The ai algorithm are trained to

detect complex patterns with damage and enable the system to detect even the smallest imperfection in the

bulletproof material. This integrated system not only speed ups the inspection and also enhance the efficiency

of the inspection compared to the conventional technique. This is a fully automatic process which mainly

avoids the human error and reduction of time and provides an accurate result. this project enables us to get

the overall safety of the bulletproof materials that are used in the high-risk environment. This project is a

stepping stone idea for the inspection and maintenance of the bulletproof materials.

1 INTRODUCTION

1.1 Background

The people who working in high-risk environments

like Military bases, police and protecting the most

important and valuable buildings and things wants the

high priority in integrity of bulletproof materials.

Such materials are manufactured to protect from the

penetration of the war materials like bullets from the

rifles. Any mistakes are small damage in these

materials have the high chance of putting the people

in the risk of death.

1.2 Problem Statement

The old and traditional methods for testing the

bulletproof materials are ineffective for detecting the

small and internal faults in the materials. These are

time-consuming, requires many labours and having

high risk of human errors. Also, here it is impossible

to detect some hidden defects that are not visible to

our naked eye, even though it is a small hidden defect

it leads to reduce the quality of the material.

1.3 Project Objective

This project creates a new system that combines

Artificial intelligence (AI) and cutting-edge sensors

to create solution for this issue. By providing fully

automatic, more accuracy, more effective solution,

this system makes fundamentally alter the way of

identifying the defects in the bulletproof materials. It

will produce the result that are more and more

accurate, faster and reduce the labour count. It is the

most intelligent idea and it guarantees the lifetime and

safety of the bulletproof materials.

316

Sreedevi, P., Parveen, A. S., Diva, S., Subasanjeev, S., Pranavika, D. and Rakshitha, V.

Advanced Integrated Damage Detection System for Bulletproof Materials Using Ultrasonic and X-Ray Sensors with AI Algorithms.

DOI: 10.5220/0013927600004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 5, pages

316-320

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

2 CORE TECHNOLOGIES

2.1 Ultrasonic Sensors

2.1.1 Principle of Operation

Ultrasonic sensors are extremely efficient at

finding subsurface defects and variations in

material properties. They work by sending high-

frequency sound waves that penetrate the material

and bounce back when they come across

irregularities like cracks, delamination, or voids.

The reflected waves are then picked up and

examined to detect hidden damage that cannot be

seen by the naked eye.

2.1.2 Advantages

High Sensitivity: Ultrasonic sensors are able to

detect very small subsurface defects that typically

escape detection by visual inspection.

Non-Destructive: The inspection process will not

damage the material so can be repeated over time.

Versatility: These sensors can be utilized on a

wide range of materials, such as metals,

composites, and ceramics.

2.2 X-Ray Sensors

2.2.1 Principle of Operation

X-Ray sensors provide a high-quality image of the

internal structure of the bulletproof material by

passing the X-Rays through the material and record

the result images. This is more effective for finding

the internal defects like fractures, variation in the

packing mass of the material with high accuracy.

By using X-Ray imaging, we can get the detailed

information about the internal structure if the

materials and easily finds the damage or defects in

it.

2.2.2 Advantages

High-quality Imaging: X-Ray sensors provide the

close-up images of the internal part of the material.

So, it allows us to find the defect easily.

Non-Destructive: By passing the X-Ray sensors

repeatedly to the material for the continuous testing

it will not make any damage to the material. It just

provides the internal structure of the bulletproof

material.

3 SYSTEM INTEGRATION AND

AI

3.1 Sensor Technology Integration

3.1.1 Complementary Strengths

The system uses both ultrasonic and X-ray sensors

because they work well together and help each

other. Ultrasonic sensors are best for finding

hidden problems under the surface, and X-ray

sensors show clear picture of inside structure.

When we combine data from both sensors, the

system can find problems more accurate and

reliable than old methods.

3.1.2 Data Fusion Techniques

One of the big challenges in making this system is

combining data from ultrasonic and X-ray sensors

without any missing parts. These sensors work

differently and give different types of data, so their

outputs need to be merged using smart data fusion

techniques. The project solves this problem by

creating algorithms that can sync data from both

sensors and give a single view of the material's

condition. This combined data is then fed into AI

algorithms for analysis, allowing a detailed check

of the material's strength and condition.

3.2 AI Algorithms for Data Analysis

3.2.1 Training Process

Advanced AI algorithms are used to understand the

data from the sensors. The AI is trained using lots

of data from both damaged and undamaged

materials so it can learn to spot patterns linked to

damage. The training involves giving the AI huge

amounts of sensor data so it can tell the difference

between slightly damaged and undamaged

materials. Over time, the AI gets really good at

finding even small flaws, which helps it detect

damage quickly and accurately.

3.2.2 Benefits of AI

Automation: The AI automates the analysis

process, so there’s no need for humans to step in,

and it reduces chances of mistakes.

Increased Sensitivity: AI can spot very tiny

patterns, making damage detection more sensitive.

It can find flaws that normal methods might miss.

Advanced Integrated Damage Detection System for Bulletproof Materials Using Ultrasonic and X-Ray Sensors with AI Algorithms

317

Continuous Improvement: The system can keep

getting better as it gets more data. This means it

stays useful even when new types of damage or

materials show up.

4 PRACTICAL APPLICATIONS

AND BENEFITS

4.1 Real-World Application

4.1.1 Military and Law Enforcement

The system is commonly used in dangerous places

where the strong and non-vulnerable bulletproof

materials are very important. One of its main jobs

is to check the body armour used by soldiers and

police officers. By making sure the armour has no

problems or weaknesses, the system helps keep

these people safer and better prepared while they’re

on duty.

4.1.2 Critical Infrastructure

The system can also be used to check armoured

vehicles, airplanes, and other structures. If the

protective materials in these fails, it could lead to

serious disasters. By using the system to find

damage early and fix it, companies can prevent

future problems and ensure their equipment is safe

and reliable.

4.2 Benefits over Manual Methods

4.2.1 Automation

Adding AI to this system brings several big

improvements compared to traditional inspection

methods. One of the biggest advantages is that it

will automates the process. By letting AI to handle

the analysis, the system reduces the need for human

involvement and the chance of mistakes. This

speeds up inspections and ensures the results are

consistent and reliable every time.

4.2.2 Enhanced Sensitivity

Another big advantage of the system is how much

best it is at spotting tiny details. The AI can pick up

on weak patterns or signs of damage that older

methods might miss. This makes it way more

sensitive and accurate when checking for flaws.

For things like bulletproof materials used in

dangerous situations, this extra sensitivity is most

important to make sure everything stays strong and

reliable.

4.2.3 Continuous Enhancement

The system is super flexible, meaning it can keep

getting better as more data is collected. This system

will be always useful, even when dealing with new

types of damage or materials. Because it can

constantly update and improve itself, the system

adapts to new situations and keeps performing well

for a long time.

5 FUTURE IMPROVEMENTS

AND CHALLENGES

5.1 Scalability and Adaptability

5.1.1 Suitability for Various Materials

The project focuses on making the system scalable

and adaptable to different materials and

environments. Bulletproof materials come in many

forms, like ceramics, composites, and metals, each

with unique properties and ways they might fail.

The system is designed to be flexible, so it can be

customized for different materials and uses. This

adaptability ensures that it works well for a wide

range of tasks, from checking lightweight body

armour to inspecting heavy armoured vehicles.

5.2 Ethical and Safety Considerations

5.2.1 Minimizing Radiation Exposure

The project ensures the ethical and safety measures,

like minimizing radiation exposure from X-ray

sensors. Keeping the system safe for both operators

and the items being checked is a high priority. By

cutting down on radiation exposure, the project

ensures the system can be used safely in various

environments.

5.2.2 Transparency and Collaboration

This project also ensures that the AI's decision-

making is clear and trustworthy. This means users

easily can understand how the AI works and feel

confident in its choices. By building transparency and

accountability into the AI, the project ensures the

system is more reliable and gains the trust from

everyone who are all involved in it, which is key for

its success and widespread use.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

318

5.3 Cost-Effectiveness and Accessibility

5.3.1 Affordability

The system is affordable and can be used by a wide

range of people. This is achieved by using readily

available parts, efficient data processing techniques

and scalable AI models. By keeping costs low, the

project aims to make the system accessible to small

organizations, like local police departments or

developing countries and the people who might have

limited budgets.

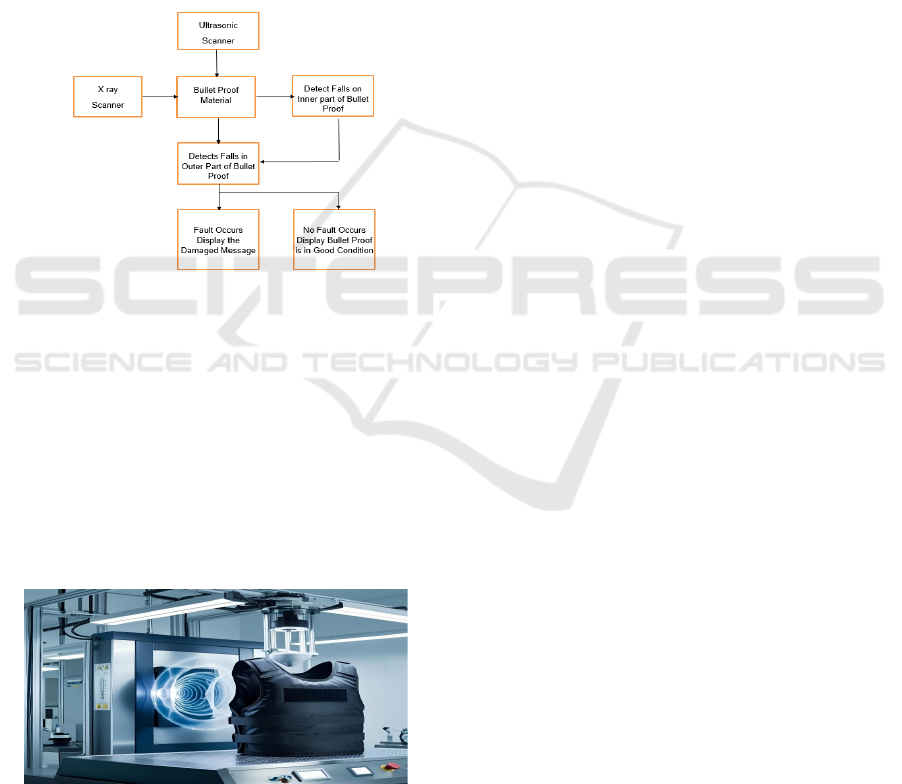

5.3.2 Practicality

Figure 1: Quality Testing of the Bullet Proof Vest.

Besides being affordable, this system is also designed

to be practical and easy to use for mostly the people.

This means it is user-friendly and does not require any

advanced technical skills. By focusing on simplicity,

the project ensures that organizations of all sizes and

skill levels can be easily adoptable and use this

system effectively.

Figure 1 shows the Quality

Testing of the Bullet Proof Vest. Figure 2 shows the

Representation of Quality Testing of the Bullet Proof

Ves t.

Figure 2: Representation of Quality Testing of the Bullet

Proof Vest.

6 CONCLUSIONS

This project is a huge step forward in technology for

detecting damage in bulletproof materials. By

combining ultrasonic and X-ray sensors with smart

AI, the system offers better accuracy, speed, and

reliability. It’s designed for high-risk situations and

focuses on being easy to use, adaptable, and

affordable, making it a valuable tool for ensuring the

safety and effectiveness of bulletproof materials.

Through ongoing testing, teamwork, and innovation,

the project aims to deliver a practical and efficient

solution that addresses a critical need in the safety and

security industry.

REFERENCES

Liu, H., & Liu, Y. (2019). "Damage detection of composite

materials using ultrasonic wave propagation." Materials

Science and Engineering A, 747, 155-165.This paper

reviews ultrasonic techniques for detecting damage in

composite materials, which could include ballistic

materials like Kevlar and ceramics.

Pérez, M. T., & Cabrera, J. F. (2017). "X-ray inspection of

composite materials used in aerospace applications."

Materials Testing Journal, 59(1), 45-52. This research

examines the application of X-ray inspection for

detecting internal damage or voids in composite

materials, which are similar to those used in bulletproof

materials.

Ting, Y., & Hsieh, C. (2015). "X-ray tomography for

nondestructive inspection of composite materials."

Journal of Materials Science, 50(22), 7435-7444.This

paper discusses X-ray tomography as a powerful tool

for non-destructive testing, including applications for

damage detection in high-performance composite

materials.

Wang, X., & Zou, J. (2020). "Ultrasonic guided wave

technology for damage detection in composite

structures." Composites Science and Technology, 185,

107885.This study covers how ultrasonic guided waves

can be utilized to detect damage in composite materials,

which is highly relevant for bulletproof materials.

Yang, J., & Lee, S. (2021). "Applications of X-ray imaging

in structural health monitoring of advanced materials."

Journal of Structural Health Monitoring, 20(4), 1368-

1379.This review provides an overview of X-ray

imaging techniques and their applications in structural

health monitoring, particularly for materials subjected

to high stress, such as bulletproof composites.

Yun, H., & Lee, Y. (2018). "Ultrasonic Nondestructive

Testing for Damage Detection of Bulletproof

Materials." Journal of Applied Acoustics, 136, 45-58.

This paper discusses the application of ultrasonic waves

for non-destructive testing (NDT) of materials,

Advanced Integrated Damage Detection System for Bulletproof Materials Using Ultrasonic and X-Ray Sensors with AI Algorithms

319

including bulletproof composites, to detect damage or

defects.

Zhang, Y., & Liu, X. (2020). "Artificial Intelligence-based

damage detection using ultrasonic and X-ray sensors."

Computers in Industry, 117, 103221.This paper

discusses how AI algorithms can process ultrasonic and

X-ray sensor data for damage detection in materials,

improving accuracy and speed.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

320