IoT-Enhanced Vision for Hydroponic Farm Management

E. S Selva Priya, Hariharan M, Elizabeth Ann Ninan and Durga Devi V

Department of Electronics and Communication Engineering, KCG College,

KCG College Rd, Karapakkam, Chennai, Tamil Nadu, India

Keywords: Hydroponic Farming, Internet of Things (IoT), Smart Agriculture, Automated Irrigation, Sensor-based

Monitoring, Precision Farming.

Abstract: Agriculture is very important for the economy of many developing countries, including India. However,

traditional farming methods face challenges such as small farm sizes, overuse of pesticides, and inefficient

use of resources. To address these issues, hydroponic farming offers a new way to grow crops in water with

added nutrients, without the need for soil. The proposed IoT-enhanced vision system aims to improve plant

growth by using real-time data and automation. This system continuously monitors important factors like

nutrient levels, pH, humidity, and light levels, ensuring the best conditions for plant growth. By integrating

IoT technology, the system allows for precise control over resources, leading to better efficiency, less waste,

and increased crop production with our experiment dated day 1 to day 8 the total height of our plants was

measured with the help of a scale where coriander is 1.2cm, amaranths is 4.1 cm and the height of the

spinach is 3.2cm.

1 INTRODUCTION

The increasing global demand for food and the rapid

loss of arable land, it is essential to adopt new

agricultural methods that promote sustainability (D.

Zeeuw and H. Drechsel 2015). Traditional soil-

based farming has several drawbacks, including high

water consumption, unreliable weather conditions,

and soil-related diseases. Hydroponics, where plants

are cultivated in a nutrient-rich water solution, has

been identified as a promising alternative (H. Norn

et al., 2004).

The integration of IoT technology with

hydroponics enables real-time monitoring and

automation, reducing the need for manual

intervention. Sensors are essential in maintaining

optimal growing conditions by constantly

monitoring temperature, humidity, pH levels, and

light intensity (S. Suakanto et al., 2016). The data

obtained from these sensors is then communicated to

an IoT-based dashboard, giving farmers the

capability to make better decisions based on real-

time information.

Despite its numerous advantages, hydroponic

agriculture has limitations, particularly in the types

of crops that can be successfully grown. Hydroponic

farming is best suited for leafy greens like lettuce,

spinach, and kale, and also herbs like basil and mint.

Some fruiting crops, like strawberries, tomatoes, and

bell peppers, can also be grown in hydroponic

systems, provided their environmental requirements

are met. However, root vegetables like potatoes and

carrots, which require soil support, are not suitable

for hydroponic production (K. E. Lakshmiprabha

and C. Govindaraju 2019).

The following sections describe an IoT-based

hydroponic agriculture system designed to improve

agricultural efficiency. By incorporating smart

sensors and automated systems, this system reduces

resource waste, increases productivity, and offers a

scalable solution for modern agriculture (Willig and

H. Karl et al.,2005). Hydroponic farming involves

growing plants without soil, using a water solution

enriched with nutrients. This method allows for

better control over growing conditions, reduces

water usage, and eliminates soil-borne diseases

(Krishna et al., 2019). Nevertheless, traditional

hydroponic systems require constant manual

adjustment and monitoring, which can be time and

energy-intensive (M. Rukhiran and P. Netinant

2020).

By integrating IoT technology, hydroponic farms

can be automated to consistently provide optimal

growing conditions (T. Munasinghe, E. W. Patton,

282

Priya, E. S. S., M., H., Ninan, E. A. and V., D. D.

IoT-Enhanced Vision for Hydroponic Farm Management.

DOI: 10.5220/0013927100004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 5, pages

282-293

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

and O. Seneviratne 2019). Sensors collect real-time

data on environmental conditions, and an automated

control system adjusts irrigation, lighting, and

nutrient supply accordingly (S. Sarkar et al., 2018).

The system also provides recommendations to

farmers through a dashboard to ensure crop health.

This paper presents the design and advantages of an

IoT-based hydroponic farming system.

2 RELATED WORKS

Several studies have explored the integration of IoT

and automation in agriculture to improve efficiency

and productivity. These studies highlight the

effectiveness of IoT-based automation in agriculture.

However, many existing systems lack an integrated

approach that combines multiple environmental

parameters with real-time decision-making, also

many existing systems still rely on partial automation

or manual interventions. Our proposed system aims

to fill this gap by developing a comprehensive IoT-

based hydroponic management system. The

following paper as per researched and referred states:

Automated Hydroponic System using IoT for

Indoor Farming as this study explores automation in

hydroponics using real-time monitoring and AI-

based optimizations.

An IoT-Based Automated Hydroponics Farming

System includes that this research develops a vertical

farming hydroponic system with a focus on

efficiency and productivity.

Solar-Smart Hydroponics with IoT discusses a

renewable-energy-driven hydroponic system with

AI-powered control mechanisms.

The Role of Automation and Robotics in

Transforming Hydroponics and Aquaponics which

highlights advancements in smart farming through

automation and robotics in hydroponics and

aquaponics.

Design and Development of a Modular

Hydroponic Tower with Integrated IoT Technology

mainly focuses on a modular hydroponic system that

uses IoT for remote monitoring and efficiency

improvements.

Development of Hydroponic IoT-Based

Monitoring System and Automatic Nutrition Control

Using KNN introduces machine learning for

optimizing hydroponic farming by automating

nutrient adjustments.

Our proposed system addresses this gap by

developing a comprehensive IoT-based hydroponic

management system.

3 ANALYSIS OF THE EXISTING

AND PROPOSED SYSTEM

3.1 IoT Integration

Most existing systems incorporate IoT for real-time

monitoring and automation, enabling remote data

collection and farm management. While systems like

Next-Gen Aquaponic and Hydroponic System with

MQTT integrate IoT, their automation levels vary.

Our proposed system ensures full automation of the

IOT webpage with real-time adjustments present in

the environment.

3.2 Automation Level

The proposed system dynamically adjusts pH,

nutrient levels, and irrigation based on sensor

feedback, providing full automation Existing

systems such as Hydroponic System with MQTT

require manual control via a mobile app., whereas

Smart Greenhouse and Robust Smart Irrigation

implement partial automation.

3.3 Sensor Integration

Our system integrates NPK, pH, humidity,

temperature, and light intensity sensors, ensuring

precise environmental control While Smart

Greenhouse offers similar sensor coverage, Next-

Gen Aquaponic primarily focuses on humidity and

temperature (H. Norn et al., 2004).

3.4 Machine Learning Support

Currently, our system does not include ML, but

future implementation is planned. Among the

compared systems, only Robust Smart Irrigation

uses ML for data-driven irrigation adjustments,

3.5 Mobile App Monitoring

Our system relies on an IoT-based web dashboard,

whereas Hydroponic System with MQTT offers an

Android-based mobile app for remote control. Other

systems, including Smart Greenhouse, lack mobile

applications.

3.6 Environmental Control

Comprehensive environmental control is a key

feature of our system, managing humidity,

temperature, pH, and nutrient levels. While Smart

IoT-Enhanced Vision for Hydroponic Farm Management

283

Greenhouse provides similar control, Hydroponic

System with MQTT is limited to pH and lighting

adjustments.

3.7 Water Conservation

Water conservation is achieved through a nutrient

recycling system, optimizing water use. Smart

Greenhouse and Robust Smart Irrigation also

emphasize water efficiency (Krishna et al., 2019),

whereas Next-Gen Aquaponic is less optimized for

conservation (K. E. Lakshmiprabha and C.

Govindaraju 2019).

3.8 Nutrient Management

Our system automates nutrient adjustments based on

real-time sensor feedback, unlike Hydroponic

System with MQTT and Next-Gen Aquaponic,

which require manual input.

3.9 pH Control

Real-time pH monitoring and automatic correction

ensure stable nutrient availability in our system.

Smart Greenhouse offers similar automation,

whereas Hydroponic System with MQTT relies on

manual pH control via an app (M. Rukhiran and P.

Netinant 2020).

3.10 Light Control

Our system employs an LDR sensor to automate

lighting adjustments, like Smart Greenhouse.

Hydroponic System with MQTT allows manual light

control, but Next-Gen Aquaponic lacks this feature

(T. Munasinghe, E. W. Patton, and O. Seneviratne

2019).

3.11 Humidity Control

An automated misting system maintains optimal

humidity in our system, like Smart Greenhouse.

Hydroponic System with MQTT and Robust Smart

Irrigation lack automated humidity control (S.

Sarkar et al., 2018).

3.12 Scalability for Large Farms

Our system is designed for large-scale farming,

supporting multiple sensors and cloud-based

monitoring. Smart Greenhouse is optimized for

greenhouse settings, while Hydroponic System with

MQTT is more suited for small-scale applications

(H. Norn et al., 2004).

3.13 Cloud Based Data Logging &

Control

Cloud-based data storage enables remote monitoring

and historical analysis. Our system, Hydroponic

System with MQTT (H. Norn et al., 2004), and

Smart Greenhouse support cloud logging, while

other systems lack this feature (D. Zeeuw and H.

Drechsel 2015).

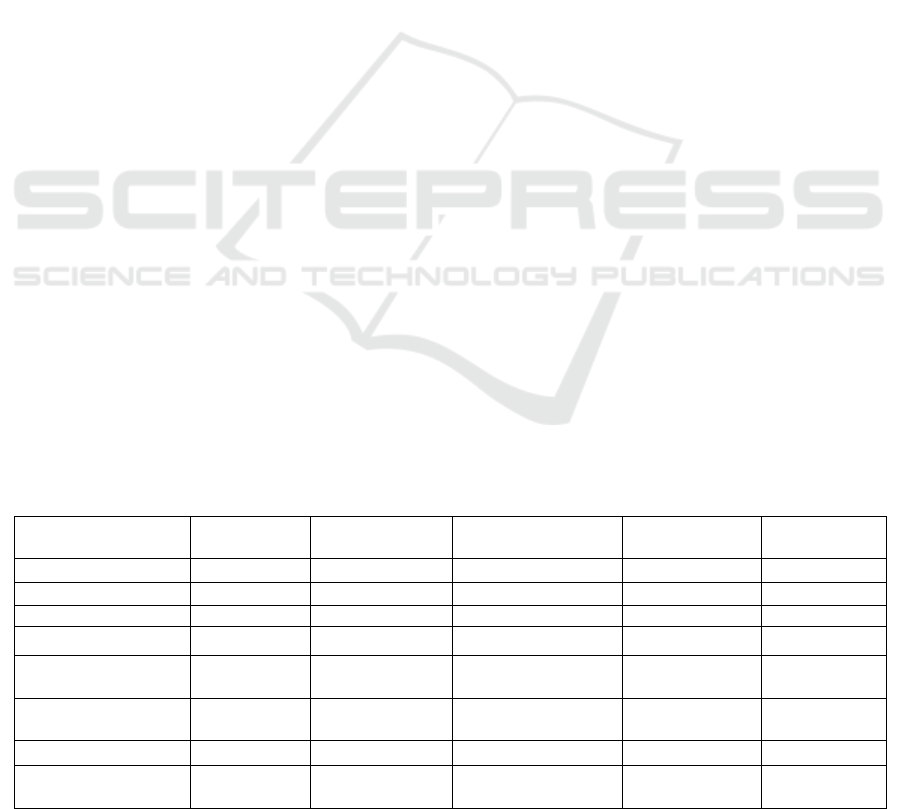

3.14 Comparative Analysis Table and

Graph

To summarize the comparison, Table 1 presents an

overview of key features in our proposed system

versus existing solutions. Additionally, Figure 1

provides a visual representation of the system

comparison based on key features. To summarize

the comparison, Table 1 presents an overview of key

features in our proposed system versus existing

solutions.

Table 1: Feature Implementations across different systems.

Feature

Proposed

System

Next-Gen

Aquaponic

Hydroponic System

with MQTT

Robust Smart

Irrigation

Smart

Greenhouse

IoT Integration Yes Yes Yes Yes Yes

Automation Level Yes Yes Yes Yes Yes

Sensor Integration Yes Yes Yes Yes Yes

Machine Learning No No No Yes No

Mobile App

Monitoring

No No Yes No No

Environmental

Control

Yes Yes Yes Yes Yes

Water Conservation Yes Yes Yes Yes Yes

Nutrient

Mana

g

ement

Yes Yes Yes No Yes

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

284

pH Control Yes No Yes No Yes

Light Control Yes No Yes No Yes

Humidity Control Yes Yes No Yes Yes

Scalability for Large

Farms

Yes Yes Yes Yes Yes

Cloud-Based

Lo

gg

in

g

No No Yes No Yes

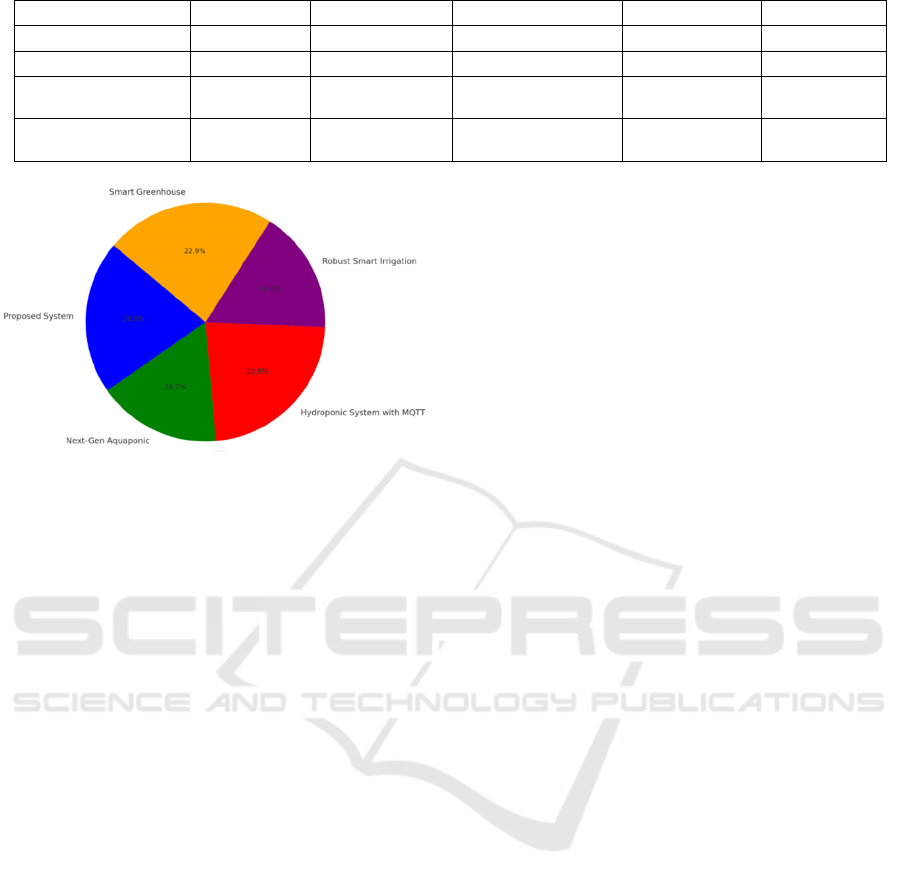

Figure 1: The pie chart illustrates the comparative analysis

of automation levels, sensor integration, machine learning

capabilities, mobile app monitoring, and environmental

control across different systems.

4 METHODOLOGY

This system consists of both hardware and software

components that work together to achieve automation

and remote monitoring. The hardware includes

microcontrollers, sensors, pumps, and displays, while

the software comprises the IoT dashboard,

communication protocols, and data processing

frameworks. Below is a detailed explanation of each

component in the system architecture.

4.1 Hardware

The proposed IoT-based hydroponic farm

management system enhances traditional

hydroponics by integrating sensors and automation

for real-time monitoring and control. This system

ensures efficient resource utilization, optimal plant

growth, and minimal manual intervention. Below is

a concise overview of its key components.

4.1.1 Microcontroller (ESP32)

The ESP32 microcontroller serves as the system’s

central processing unit, collecting data from sensors

and executing control actions. It features built-in

Wi-Fi and Bluetooth, enabling real-time data

transmission to the IoT dashboard for remote

monitoring and control.

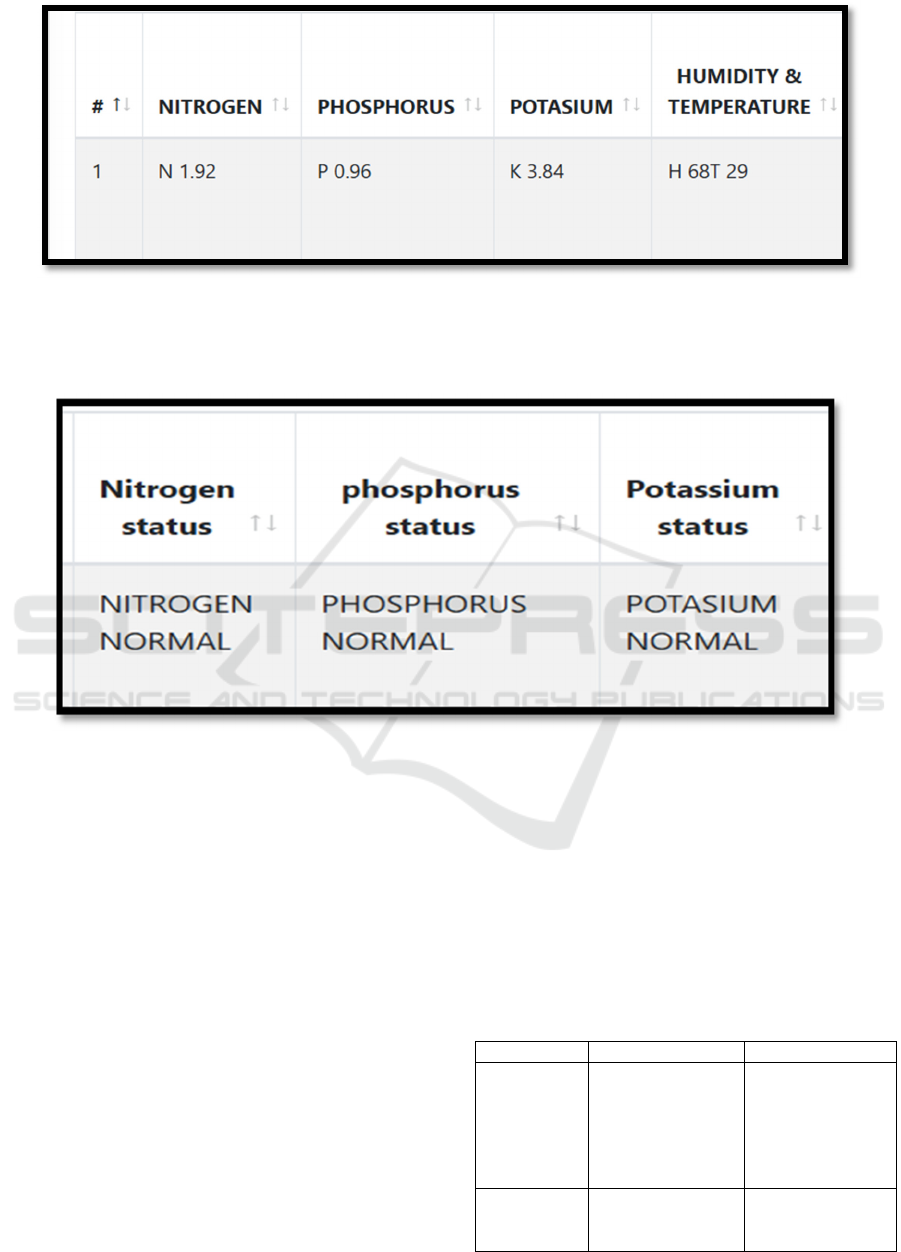

4.1.2 NPK Sensor

The NPK sensor (also known as Nitrogen,

phosphorus and potassium) measures nutrient

concentration in the water as shown in fig 2 that

ensure an optimal balance. If levels drop, the ESP32

activates nutrient pumps to maintain plant health,

preventing deficiencies or over-fertilization.

4.1.3 pH Sensor

The pH sensor continuously monitors

acidity/alkalinity. If pH deviates from the optimal

range (5.5-6.5), the ESP32 triggers corrective

mechanisms, ensuring efficient nutrient absorption.

4.1.4 LDR Sensor (Light Dependent

Resistor)

The LDR sensor measures ambient light intensity

and controls LED grow lights accordingly. This

automation optimizes photosynthesis while

conserving energy.

4.1.5 Humidity Sensor

Humidity affects plant transpiration and water

uptake. The system regulates humidity by activating

misting or ventilation as needed, preventing fungal

growth and ensuring plant health.

4.1.6 LCD Display

The LCD module provides real-time

environmental readings, allowing on-site

monitoring of key parameters such as pH levels,

temperature, lux that is light and humidity (K. E.

Lakshmiprabha and C. Govindaraju 2019).

4.1.7 IoT Dashboard

A cloud-based interface allows farmers to remotely

monitor and control farm conditions. Users can

analyze historical trends and receive alerts for

IoT-Enhanced Vision for Hydroponic Farm Management

285

deviations from optimal conditions (Krishna et al.,

2019).

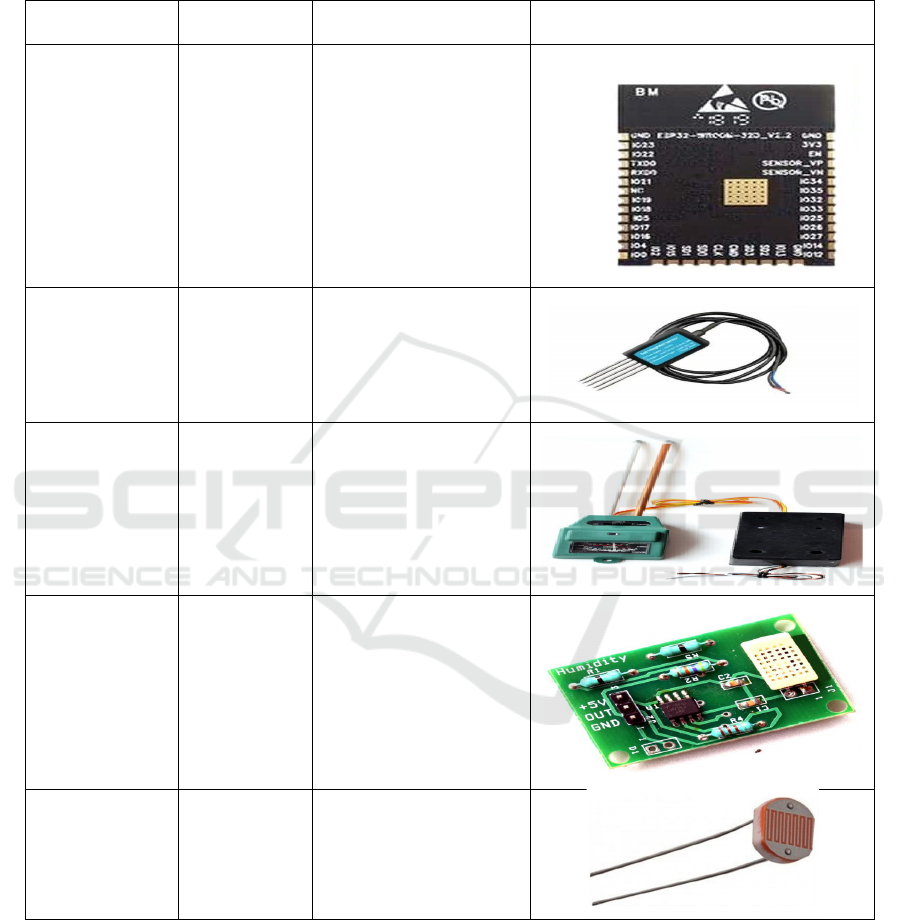

The proposed system can be better represented in

table 2 where each component is mentioned with

care and specifications along with their images.

Table 2: Proposed system hardware components.

Parameter Specification Description Images

Microcontroller ESP32

Dual-core 32-bit processor

with Wi-Fi & Bluetooth

for IoT connectivity

NPK Sensor

0-1999 mg/kg,

±2% accuracy

Measures soil nutrient

levels (Nitrogen,

Phosphorus, Potassium)

pH Sensor

0-14 pH,

±0.5%

accuracy

Monitors pH level of

nutrient solution for plant

health

Humidity Sensor

DHT11, 0-

100% RH,

±1% accuracy

Measures humidity in the

hydroponic environment

LDR Sensor

5V output,

High light

sensitivity

Detects light intensity to

optimize plant growth

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

286

Relay Module

12V DC,

ULN2003A

driver

Controls switching of

pump and light based on

sensor readings

LCD Display

16x2

Alphanumeric

Display

Displays real-time sensor

data and system status

(LCD Display setting with

the values of pH-6.76,

Lux-0, Temp-29. and

humidity-64)

Power Supply

12V DC

Adapter, 1A

output

Provides stable power to

all system components

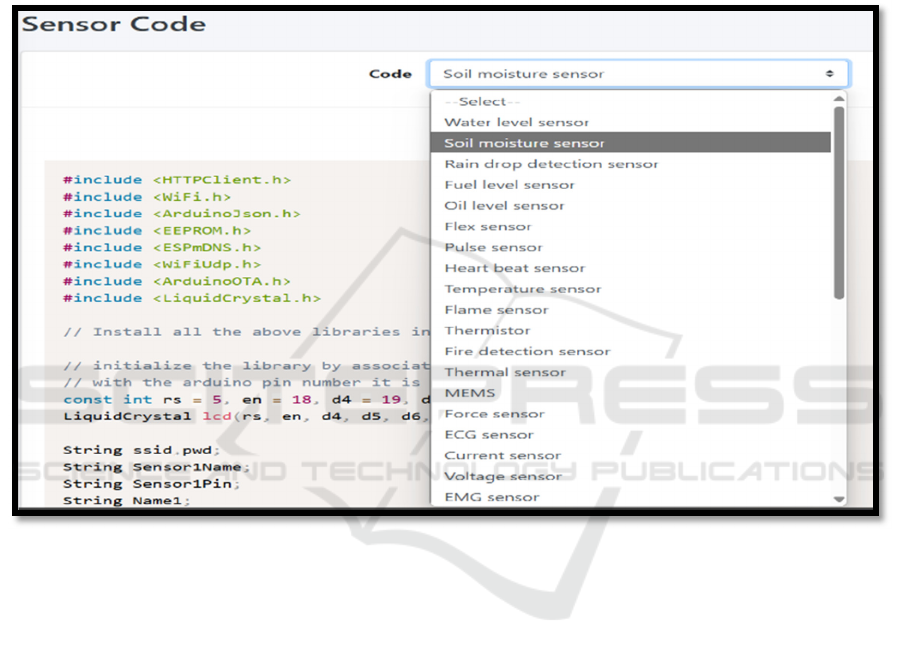

4.2 Software Implementations

Figure 2: IoT Dashboard Displaying Real-Time Sensor Data.

The Arduino IDE is used for programming the

ESP32 microcontroller, providing a user-friendly

environment to write, compile, and upload code. It

supports Embedded C, the primary programming

language for this system, enabling seamless

integration of sensors and automation logic. The

code is designed to collect real-time data from

various sensors, process it, and control actuators

based on predefined conditions. To enhance remote

monitoring and control, the system utilizes an IoT

IoT-Enhanced Vision for Hydroponic Farm Management

287

platform where sensor data is uploaded to a cloud-

based dashboard. Platforms such as Thing Speak,

Blynk, or a custom web server are used to visualize

real-time parameters like temperature, humidity,

light intensity, pH levels, and nutrient concentrations

(K. E. Lakshmiprabha and C. Govindaraju 2019).

Users can access this data from anywhere, analyse

trends, and make informed decisions about

irrigation, fertilization, and lighting adjustments. By

combining Arduino IDE for programming,

Embedded C for automation logic, and IoT

integration for remote monitoring, the system

ensures efficient and automated smart farming

operations, enhancing resource management and

crop productivity. Figure 2 displays the IoT

dashboard interface used for real-time monitoring of

sensor data (Krishna et al., 2019).

Figure 3: Microcontroller interacts with sensors.

4.3 System Workflow

The system operates by continuously collecting real-

time data through various sensors, which measure

essential environmental parameters such as nutrient

levels, pH, humidity, temperature, and light intensity

(M. Rukhiran and P. Netinant 2020). These sensors

send their readings to the ESP32 microcontroller,

which serves as the central processing unit of the

system. Once the ESP32 receives the data, it

analyses and processes the information to determine

if any environmental adjustments are necessary. It

compares the sensor readings with predefined

threshold values to ensure optimal growing

conditions for plants. If the detected conditions

deviate from the ideal range, the microcontroller

takes corrective action. For example, if soil moisture

is too low, the water pump is turned on for irrigation

(T. Munasinghe, E. W. Patton, and O. Seneviratne

2019). If light intensity is insufficient, LED grow

lights are activated to provide additional

illumination. Similarly, if nutrient levels drop below

the required threshold, fertilization adjustments can

be made accordingly. All sensor readings and

system activities are uploaded to an IoT platform

such as Thing Speak, Blynk, or a custom web server

for real-time monitoring and analytics (S. Sarkar et

al., 2018). Users can remotely access this data, track

environmental trends, and make informed decisions

to optimize plant health. This combination of sensor-

driven automation, IoT connectivity, and real-time

monitoring makes the system highly efficient and

ideal for smart agriculture applications. Figure 4

illustrates an example of the automated response

system activated when sensor values exceed

thresholds (K. E. Lakshmiprabha and C.

Govindaraju 2019).

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

288

Figure 4: Automated Response to Sensor Readings.

Further figure 5, includes a \detailed data analytics

views, will be integrated accordingly based on their

relevance

Figure 5: Status window of the NPK level also known as data analytic view.

5 OPTIMAL PARAMETERS

Hydroponics is a modern farming method that

allows plants to grow in a controlled, soil-free

environment. The system relies on the precise

regulation of water, nutrients, and environmental

factors like pH, temperature, and humidity (H. Norn

et al., 2004). These implementations based on the

observed table 3 came below where the proper and

observed parameters were mentioned to ensure a

healthy and fruitful vegetation. This tables also helps

in keeping the plants in an optimized state for proper

growth. This enables the proper standard where the

management can distinguish between what is the

problem with the farm plants.

5.1 Mathematical Analysis

5.1.1 System Parameters

Mathematically, plant growth in hydroponic farming

can be modelled as:

𝐺(𝑡) = 𝑓(𝑁,𝑃,𝐾,𝑝

,𝐻,𝑇,𝐿) (D. Zeeuw and H.

Drechsel 2015)

Table 3: Hydroponic System Parameters.

Paramete

r

O

p

timal Ran

g

e Descri

p

tion

NPK Levels

Nitrogen: 100-500

mg/kg |

Phosphorus: 30-

100 mg/kg |

Potassium: 100-

400 mg/kg

Essential

nutrients for plant

growth

pH Level 5.5 - 6.5

Ideal range for

nutrient

absor

p

tion

IoT-Enhanced Vision for Hydroponic Farm Management

289

Humidity 50% - 80% RH

Maintains plant

moisture and

reduces water

loss

Light

Intensit

y

200 - 800 lux

Ensures optimal

p

hotosynthesis

Water

Temperature

18°C - 24°C

Prevents root

stress and ensures

nutrient uptake

where:

• G(t) represents the plant growth function

over time,

• N, P, K are the concentrations of nitrogen,

phosphorus, and potassium (in ppm),

• pH is the acidity level of the nutrient

solution,

• H is the humidity level (%)

• T is the temperature (°C),

• L is the light intensity (lux).

The goal of this system is to optimize G(t) by

dynamically adjusting nutrient and environmental

parameters using an IoT-based automation

framework.

5.1.2 Maintaining the Integrity of the

Specifications

The essential nutrients supplied to plants in a

hydroponic system follow the equation:

N final = N initial + N added − N consumed

(K. E. Lakshmiprabha and C. Govindaraju 2019)

• N final is the final nutrient concentration,

• N initial is the initial concentration in the

solution,

• N added is the nutrient added externally,

• N consumed is the amount absorbed by

plants.

The system ensures real-time monitoring of nutrients

by using an NPK sensor, which provides data to

maintain the optimal range:

𝑁 𝑜𝑝𝑡, 𝑃 𝑜𝑝𝑡, 𝐾 𝑜𝑝𝑡 = 100 − 200 𝑝𝑝𝑚

(Krishna et al., 2019)

If the sensor detects a drop below N opt, the system

automatically adds nutrients through a controlled

relay mechanism. (M. Rukhiran and P. Netinant

2020)

5.1.3 pH Regulations

Plant growth is significantly affected by the pH level

of the nutrient solution. The pH control system

follows an adaptive correction model:

𝑝

𝑛𝑒𝑤 = 𝑝

𝑐𝑢𝑟𝑟𝑒𝑛𝑡 + ∆𝑝

(T.

Munasinghe, E. W. Patton, and O. Seneviratne 2019)

where Δ pH is adjusted based on the difference from

the optimal range (pH opts = 5.5 − 6.5) (S. Sarkar et

al., 2018).

The system activates an alkaline or acidic solution

pump when:

∣ pH current – pH opts ∣ > 0.5 (Willig and H. Karl

et al.,2005)

5.1.4 IoT Data Update Model

The real-time data update follows a time-dependent

model:

𝐷(𝑡) = 𝑆(𝑡) + 𝐴(𝑡) (E.S. Selvapriya

and L. Suganthi 2023)

Tables 4: Difference between traditional and IoT

based.

where:

• D(t) = Data sent to cloud at time t

• S(t) = Sensor data at time t

• A(t) = Adjustments made by the system

6 RESULTS AND EVALUATION

The system was tested in a controlled environment.

The key findings include:

• Nutrient Optimization: The NPK sensor

ensured precise nutrient delivery.

• Water Conservation: Automated irrigation

reduced water usage by 40%.

• pH Stability: The pH sensor maintained an

optimal range of 5.5–6.5 for plant growth.

• Remote Monitoring: Farmers could access

real-time data through an IoT dashboard.

The system parameters as given in the table 4

represent the difference between traditional and IoT

based plantations. This ensures a growth of plants

irrespective of the initial based difference.

Tables 4: Difference between traditional and IoT based.

Parameter

Traditional

H

y

dro

p

onics

IoT-Based

H

y

dro

p

onics

Water Usage High

Low (40%

less)

Monitoring Manual Automated

pH Control

Periodic

Adjustment

Real-time

Adjustment

Cost

Efficienc

y

Moderate

High (Long-

term savings)

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

290

6.1 Statistical Evaluation

Figure 6 represents the growth of the plants with

respect to the experimental procedure that we

conducted with the help of vegetables like

Amaranthus, Spinach, and coriander.

The day-to-day growth of the plants based on the

observation of 1 to 7 days.

Figure 6: Line graph representation of the growth of the

plant.

6.2 Experimental Observation

During the span of eight days, we have noticed a

drastic growth of the plants that bloomed to have

structure, leaves and stability in the hydroponic

farming. The plants used were coriander, amaranths,

and spinach. Each grew under the same

circumstances and with the help of the Hardware

and the NPK solution. The following Figures 7,8

and 9 shows the growth of the plants with regards to

their day-to-day growth. In this experiment we

regarded no fundamentals of planting but the

simplicity of the plantation and by the help of our

proposed system we were able to determine what the

plant wanted at that time with regards to the

different timeline. The solution of NPK increased as

shown in the graph. This indicates that as the plants

grow the solution and maintenance of the plants also

increases for a fruitful harvest. With the help of our

proposed system grow thing the plants felt like they

were telling us what they needed daily. This also

improved our understanding of the farm and the

management need. The plants started showing their

leaves at day 3 and increased in size progressively.

Figure 7: coriander, amaranths and spinach at day 2 of

plantation.

The following fig 8 describes the plants after 4

consecutive days of monitoring. Clarifying the

progression of the plants in a hydroponic system.

Figure 8: growth of the plants on day 4.

By day 8 they were measured and where coriander

was 1.2cm, amaranths was 4.1 cm and the height of

the spinach was 3.2cm. as shown in fig 9 below:

Figure 9: the growth of the plants (coriander, Amaranthus

and spinach) by day 8.

1234567

pH Level

6.8 6.5 6.3 6.2 6.1 6 5.9

Nutrient

Level

(ppm)

120 140 160 180 190 200 210

0

50

100

150

200

250

NUTRIENTS & PH LEVEL

DAYS

GROWTH OF PLANT

IN 7 DAYS

IoT-Enhanced Vision for Hydroponic Farm Management

291

7 DISCUSSIONS

To ensure optimal plant growth, key environmental

parameters must be maintained within specific

ranges. The proposed IoT-enhanced hydroponic

system effectively regulates factors such as nutrient

levels, pH balance, humidity, and light intensity. The

NPK sensor maintains optimal nutrient

concentrations, while pH sensors ensure an

appropriate acidity range for plant growth. Humidity

control prevents excessive moisture loss, and the

IoT-enabled dashboard allows real-time monitoring

and remote decision-making. The system’s

automation significantly reduces water and nutrient

wastage while improving overall plant yield.

Compared to traditional hydroponic farming, the

IoT-based system minimizes manual intervention

and increases efficiency. The observed plant growth

during the experiment supports the claim that IoT

integration leads to better environmental control and

optimized farming conditions.

8 CONCLUSIONS

The proposed IoT-based hydroponic farm

management system successfully integrates

automation, real-time monitoring, and IoT based

data processing to enhance agricultural efficiency.

By leveraging sensors and IoT connectivity, the

system optimizes resource utilization and ensures

stable environmental conditions, leading to

improved plant health and yield. Experimental

results validate its effectiveness in maintaining an

ideal growth environment while minimizing manual

effort. Future enhancements may include AI-based

predictive analytics, mobile app integration, and

machine learning for data-driven decision-making.

Including the addition of suitable security measures

that enhances the IoT webpage user experience that

includes the variation and protection of the IoT

system. The system serves as a scalable and

adaptable model for modern precision agriculture,

providing a sustainable solution to food production

challenges in urban and resource-limited

environments.

REFERENCES

A. Willig and H. Karl, Protocols and the Architectures for

Wireless Sensor Networks, John Wiley & Sons, The

Atrium, Southern Gate, Chichester, West Sussex,

England, 2005.

S. Suakanto, V. J. L. Engel, M. Hutagalung, and D. Angela,

“Sensor Networks Data Acquisition and Task

Management for Decision Support of Smart Farming,”

Proceedings of the 2016 International Conference on

Information Technology Systems and Innovation

(ICITSI), Bandung – Bali, Indonesia, Oct. 24–27,

2016. Available: IEEE Xplore

H. Norn, P. Svensson, and B. Andersson, “A convenient

and versatile hydroponic cultivation system for

Arabidopsis thaliana,” Physiologia Plantarum, vol. 121,

no. 3, pp. 203–209, Jul. 2004. Available: Wiley Online

Library

D. Zeeuw and H. Drechsel, Cities and Agriculture:

Developing Resilient Urban Food Systems, Routledge,

London, UK, 2015. Available: Springer

Automated Hydroponic System using IoT for Indoor

Farming, Proceedings of the IEEE International

Conference on Smart Agriculture, 2023. Available:

IEEE Xplore

An IoT-Based Automated Hydroponics Farming and Real-

Time Crop Monitoring System, Proceedings of the

2022 IEEE International Conference on Agricultural

IoT Systems, 2022. Available: IEEE Xplore

Solar-Smart Hydroponics Farming with IoT-Based AI

Controller, Proceedings of the IEEE International

Conference on Renewable Energy and IoT

Applications, 2023. Available: IEEE Xplore

The Role of Automation and Robotics in Transforming

Hydroponics and Aquaponics, Discover Artificial

Intelligence, Springer, 2025. Available: Springer

Design and Development of a Modular Hydroponic Tower

with Integrated IoT Technology, Proceedings of the

International Conference on Smart Farming and

AgriTech, Springer, 2024. Available: Springer

Development of Hydroponic IoT-Based Monitoring

System and Automatic Nutrition Control Using KNN,

Proceedings of the IEEE International Conference on

Computational Agriculture, 2023. Available: IEEE

Xplore

K. E. Lakshmiprabha and C. Govindaraju, “Hydroponic-

based smart irrigation system using Internet of Things,”

International Journal of Communication Systems, vol.

32, no. 10, p. e4071, 2019. Available: Wiley Online

Library

A. Krishna, M. Pallec, R. Mateescu, L. Noirie, and G.

Salaun, “IoT composer: Composition and deployment

of IoT applications,” Proceedings of the IEEE/ACM

41st International Conference on Software Engineering

(ICSE), pp. 19–22, 2019. Available: IEEE Xplore

M. Rukhiran and P. Netinant, “Effect of environmental

conditions on accuracy rates of face recognition based

on IoT solution,” Journal of Current Science and

Technology, vol. 10, no. 1, pp. 21–33, 2020. Available:

Springer

T. Munasinghe, E. W. Patton, and O. Seneviratne, “IoT

Application Development Using MIT App Inventor to

Collect and Analyze Sensor Data,” Proceedings of the

2019 IEEE International Conference on Big Data

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

292

(BigData), pp. 6157–6159, 2019. Available: IEEE

Xplore

S. Sarkar, S. Gayen, and S. Bilgaiyan, “Android Based

Home Security Systems Using IoT and Firebase,”

Proceedings of the International Conference on

Inventive Research in Computing Applications

(ICIRCA), pp. 102–105, 2018. Available: IEEE

Xplore.

E.S. Selvapriya and L. Suganthi. 2023. Design and

implementation of low power Advanced Encryption

Standard cryptocore utilizing dynamic pipelined

asynchronous model. Integr. VLSI J. 93, C (Nov 2023).

https://doi.org/10.1016/j.vlsi.2023.102057

L.Suganthi, R.Anandha Praba , E.S.Selva Priya. “Enhanced

Arrhythmia Detection Through Wavelet Scattering and

Deep Learning Techniques”, Journal of University of

Shanghai for Science and Technology,ISSN: 1007-673

IoT-Enhanced Vision for Hydroponic Farm Management

293