An Overview of the Advancements and Upgrades Made to the

Connecting Rods in the Internal Combustion Engine

M. Kathirselvam, Meiyalagan S., Raji C. and Sudhakar S.

Department of Mechanical Engineering, K.S.Rangasamy College of Technology, Tiruchengode, Namakkal, Tamil Nadu,

India

Keywords: SI Engine, Connecting Rod, Composite Materials, Optimization.

Abstract: Automotive engineering design prioritizes lowering emissions and enhancing safety features. Connecting rod

optimization, which transmit power from the piston to the crankshaft, is especially important for maximizing

engine economy and performance. The weight and design of a connecting rod in an automotive engine have

an impact on its performance. Therefore, in order to produce a connecting rod that is more affordable, robust,

and lightweight, optimization and analysis are required. This article reviews the experiments, designs, and

analyses of several researchers on the connecting rod of an engine. A detailed comparison table and graphs

are included with the evaluation. Both seasoned and inexperienced scholars in the subject of vehicle design

will find this article to be a useful resource.

1 INTRODUCTION

The connecting rod is a crucial part of IC engines,

converting the piston's alternating transverse motion

into the crankshaft's rotation. Its two eye-shaped

extremities, the big end and tiny end, are connected

by a beam-like shank. The rod's design and material

must be carefully chosen to endure high stress and

ensure smooth engine running. Due to the high-cycle

fatigue stress experienced by the connecting rod, gas

forces and inertial forces must be considered. It needs

to be sturdy enough to hold external loads,

sufficiently light to lessen inertial forces, and stiff

sufficient to permit for a suitable link with the

crankpin and Gudgeon pin. The identification of a

particular connecting rod segment as an alternating

mass can have a direct effect on the maximum value

of alternating forces. Designing connecting rods

requires special attention, and connecting rod

optimization often uses both analytical and numerical

approaches.

2 NUMERICAL ANALYSIS ON

CONNECTING ROD

An internal combustion engine's connecting rod is an

essential component. Using aluminium alloy (2024-

T361) material can help reduce weight. According to

Ebhojiaye and Eboigbe (2022), the connecting rod's

extreme end is where distortion peaks. Consequently,

the distortion will be reduced by thickening the rod's

tiny end. The values obtained for the stress

distribution was acceptable because the stress was

minimal. Maximum deformation of 0.062428mm

was recorded at the small connecting rod end, because

the material thickness was unable to support the

applied force at the rod end. The simulation results

showed that von Mises stress present in the aluminum

alloy (2024-T361) rod was less than its yield strength

indicating that there can be material saving in the

lowest stressed region.

Vinay Kumar et al. (2019) conducted a solid

modelling study on connecting rods using aluminum

alloy using CATIA V5 and ANSYS 14.0. The study

analyzed the effects of tensile and compressive loads

on the rods, focusing on normal stress and shear stress

in the x-y plane. The results showed that Ansys was

more effective than other software for identifying

minimum stresses at the piston endand crank end cap,

reducing material costs & improving material

performance. A dynamic study of the connecting rod

is necessary for additional optimisation, and finite

element analysis will yield more precise findings.

Antony et al. (2016) report that connecting rods made

of aluminium undergo higher levels of stress

induction than connecting rods made of teel. There's

224

Kathirselvam, M., S., M., C., R. and S., S.

An Overview of the Advancements and Upgrades Made to the Connecting Rods in the Internal Combustion Engine.

DOI: 10.5220/0013925600004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 5, pages

224-231

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

also a great opportunity to improve the design. For

connecting rods, steel is consequently a better

material choice.

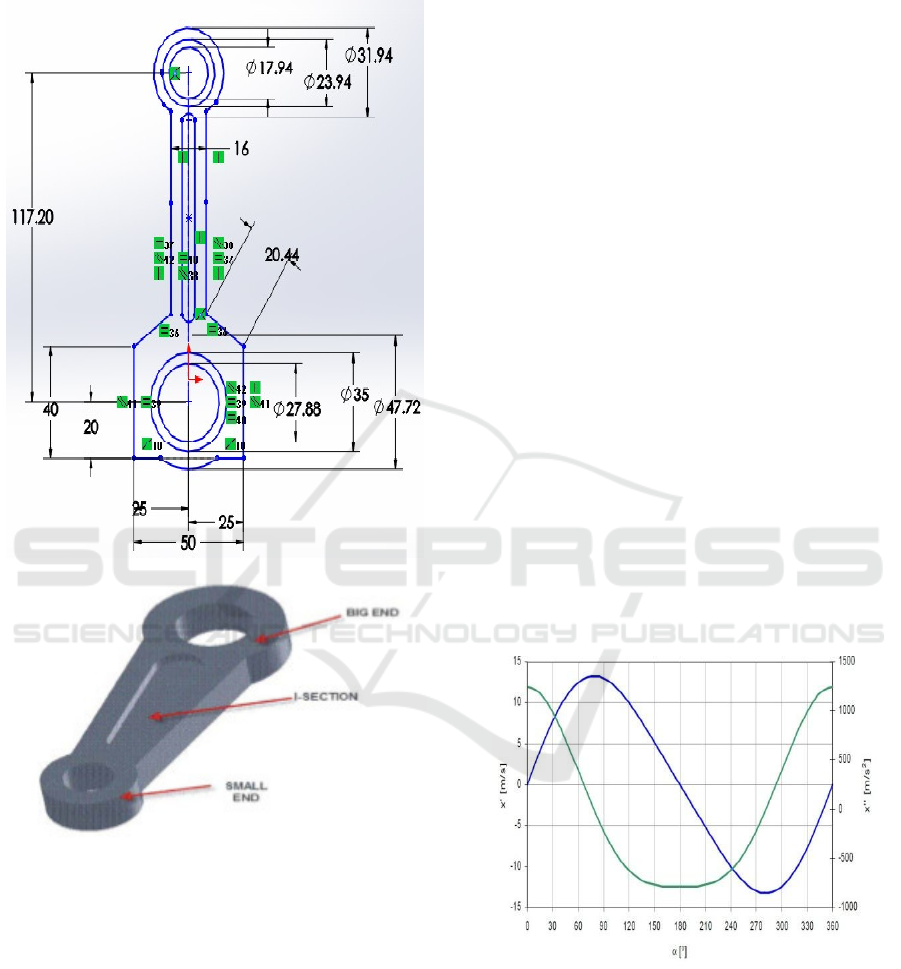

Figure 1: Schematic diagram of connecting rod.

Utilising SOLID WORK and ANSYS 15.0, Hussin et

al. (2014) used the aluminium alloys 7068 T6 and

T6511 to study solid modelling and analysis of

connecting rods. The study found that Solid Work

was effective in modelling and simulation, but Ansys

was found to be more accurate in analysis. The study

found minimum stresses at the piston end&crank end

cap, reducing material costs. A finite element analysis

will yield more accurate results than current results

and is necessary for further optimisation. A dynamic

analysis of the connecting rod is also needed. The

study highlights the need for more accurate material

optimization in connecting rod design and analysis.

Figure 1 shows the Schematic Diagram of Connecting

Rod (Abdusalam MH, Prabhat KS & Arvind SD

2014).

The connecting rod is made for maximum engine

speed and pressure, according to Murthy et al. (2019).

The big end area, small end area, and connection to

the rod's small end all had substantial material

reductions, according to finite element analysis.

Analysis and computations suggest thinner I-sections.

In addition to titanium's superior mechanical

qualities, it is lighter than steel and has lower ductility

than steel. Additionally, the new connecting rod form

weighs less than the old one.

The greatest primary stress, as determined by

Singh et al. (2015), was 411.32 MPa, which is lower

than the 530 MPa yield compressive strength. While

0.053 mm was the greatest deformation determined

by the conventional approach, 0.041 mm was the

maximum deformation determined by ANSYS

V14.0. This difference can be attributed to the

consideration of simplification hypotheses in the

classic calculation. The results were obtained at the

Inner Dead Center, indicating that the maximum

force is acting at that point. Using finite element

analysis software for stress and deformation

calculations saves time and provides results at all

nodes of the structure. The connecting rod, which is

hinged by a piston pin and a crank pin, experiences

compressive forces, resulting in a design that behaves

like a strut.

Figure 2: Acceleration and piston speed pattern dependent

on crankshaft angular displacement.

Mohsin et al. (2015) performed a connecting rod

study. They used Catia software to build the rod to

actual dimensions and conducted axi-symmetric

analysis to determine interference effects on joint

stress behavior. The research discovered increased

compressive stress in the bush, tensile stress

An Overview of the Advancements and Upgrades Made to the Connecting Rods in the Internal Combustion Engine

225

development at the tiny end, and contact pressure

development at the interface. Plots of the results were

made for the von Misses, hoop, and radial stresses.

Axial-symmetric alternatives were used to create

three-dimensional perspectives. To ascertain the

connecting rod's fatigue nature in light of load

transfer fluctuations, more investigation was done.

For the study, two load nature models, Models A and

B, with assembly and service loads, were taken into

consideration.

Figure 2 shows the Acceleration and

Piston Speed Pattern Dependent on Crankshaft

Angular Displacement (Puran Singh et al.,2015).

The study by Vinayakrao and Swami (2017)

evaluated alternative materials for connecting rods

with fewer stresses and a lighter weight. Using FEA

analysis using ANSYS 18.1 software, the study found

that the aluminum 7075-T651 connecting rod showed

nearly the same amount of stress as the existing

carbon steel connecting rod. The maximum stress

generated in case 1 was almost the same in all

materials, while in case 2, it was the same in all

materials. However, the aluminum connecting rod

had a significantly lower weight than the other two

materials. The deflection of the current connecting

rod made of CS (42CrMo4) and the connecting rod

made of aluminium (7075-T651) is equal.

Furthermore, it was discovered that the connecting

rod made of aluminium, model number 7075-T651,

weighed around 35% less.

Kushwah et al. (2021) conducted research on

improving connecting rod material through ANSYS

software analysis They discovered that the

connecting rod's bulk and power may be decreased. If

the wire is not attached, the design, material quality,

or both parameters can be improved. The connecting

rod's performance can be improved by changing the

material composition. They also found that alloying

materials can obtain desired properties by combining

various materials with different qualities.

In a static structural study, Abhishek Kumar and

Pankaj Panday (2019) compared the comparable

elastic strains and von Mises stresses for structural

steel and aluminum alloy. They discovered that,

under some loading circumstances, aluminum alloy

had more stresses and strength than structural steel. In

order to maintain the necessary pressure produced

within the cylinder, they optimized AA7068

aluminum alloy connecting rods, which needed less

material and lower dimensions. Compared to the

other materials employed in the investigation, the

optimized material was shown to have a superior

nature.

According to study, Atharuddin et al. (2019)

found that using aluminum alloys instead of forged

steel to replace a damaged connecting rod can lighten

it and extend its lifespan. The study involved

analyzing the force applied to the piston head and the

effect of these forces on the connecting rod. The

automotive industry is increasingly demanding

components with high techno-economic

performance, with the connecting rod being a key

component in automobiles. The study explains the

stresses to consider when designing the connecting

rod and compares the results of the dissimilar

materials used. The findings can be applied to

designing any connecting rod in an automobile,

aiming for weight and cost reduction as well as

increasing the rod's life. The lighter weight and

increased strength of the connecting rod can be

achieved compared to the original design.

According to Ramani et al. (2014), there are two

topics covered in their study: optimising for weight

reduction and analysing the load and stress on the

connecting rod. Compressive load is one extreme

load, and tensile load is one of two load ranges in

which the connecting rod may be constructed and

improved. In addition, it is possible to optimise the

current connecting rod and replace it with a new one

that weighs 15% less.

Samal et al. (2015) used CATIA-V5 and a

machine drawing textbook to create a 3D CAD

model. They used MATLAB to compute piston

forces at crucial crank angles and Radioss and Altair

Hypermesh for finite element modelling. In the

second load example, when the connecting rod was

exposed to 37.3 bar of cylinder pressure at a 300-

degree crank angle, the highest stress created was

227.3 MPa. The connecting rod was redesigned to be

11.3% lighter and have a maximum stress of 274.2

MPa, which is also below the material's yield strength

because this stress was lower than the material's yield

strength.

A study of the literature on connecting rods under

various load situations and stress experiments was

done by Gorane et al. (2023). They carried out

optimisation research and analysis to create a more

effective connecting rod design process. For the

purpose of evaluating the connecting rod

specifications, they used forged steel material, and

they also chose I cross-sections. Weight optimisation

followed topology optimisation, which considered

the optimal material and cross-section. The

optimisation of geometry was then carried out using

the topology and FEA data. Following optimisation,

the connecting rod was put through several load

scenarios for testing, and the outcomes were

consistent with the findings drawn and the existing

design.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

226

Chougale (2014) designed a two-wheeler

connecting rod using analytical methods and FEA

analysis. A physical model was created using CATIA

V5, and stresses were calculated using ANSYS

Workbench 14.5. Thermal analysis was performed on

different materials. Results showed a significant

reduction in weight, equivalent and maximum shear

stress, and longer life cycles for new connecting rods

compared to steel rods. The Al-360 connecting rod

had a higher total heat flux of 32.765 W/𝑚𝑚2, which

is higher than structural steel's total heat flux. The

results were compared based on various performance

factors.

3 HYBRID AND COMPOSITE

MATERIAL WORKS ON

CONNECTING ROD

Velliyangiri and Vinothkumar (2022) discovered that

the minimum deformation, stress, and strain occur at

a ratio of 2 boron carbide to 10% of the alumina oxide

matrix of ordinary Al-1100. This ratio is better for

deformation and displacement. With their superior

mechanical qualities over traditional materials,

composite materials in particular, aluminium 1100

boron carbide and aluminium oxide composites find

use in a wide range of industries, including the

automotive sector. After analysing the mechanical

characteristics of the Al1100 metal matrix, the study

discovered that the good tensile and compressive

strengths were improved by the boron carbide

reinforcement. Alumina oxide has a lower impact

strength than pure 1100. While alumina oxide's metal

matrix had a higher impact strength, boron carbide

demonstrated superior compressive and tensile

strengths. The FEA analysis revealed that the

minimum strain and maximum von Mises stress occur

at a ratio of 2 Boron Carbide to 10%, while the

alumina oxide matrix of ordinary Al1100 is higher.

Prakash and Bagade's study from 2021 make

recommendations for changes to the connecting rod's

design, material, and production method. In

comparison to forging and sintering steel, advanced

materials such as micro-alloyed steel and C70

(crackable) steel provide more strength and stiffness.

Heat treatment can reduce residual strains, whereas

shot peening extends fatigue life and strengthens

fatigue. Compared to traditional materials,

MMC’ssuch as Al-15% Al2O3 and Al-10% SiC are

lighter and more rigid. Small holes can be drilled at

appropriate locations to reduce stress in the shank

section. The modified model reduces maximum Von-

Mises stress by 3.395%, resulting in more uniform

stress distribution and improving overall performance

and durability.

For connecting rods constructed of aluminium

alloy 6082, Janutienė et al. (2015) developed a

thermo-mechanical method that increased

mechanical qualities, safety, durability, and reduced

production costs. Impact strength was double that of

the previous workpiece, and ultimate strength rose by

up to 25%. The hardness varied from 58 to 62 HRB,

and the fibrous microstructure inhibited brittle

fracture and component deformation.

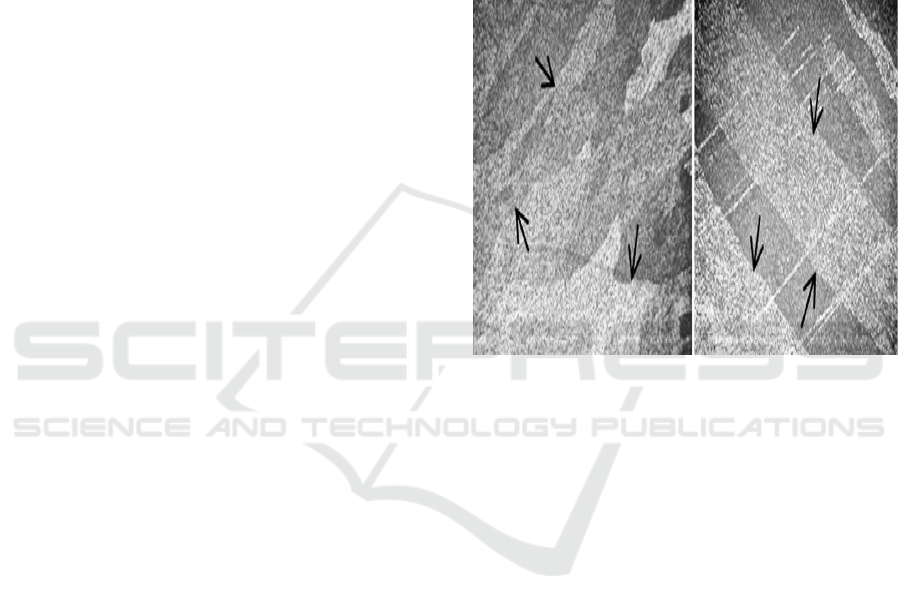

Figure 3: Regime A: Cross-cut of forging (Black arrows

mark the boundaries of coarse recrystallized grains).

Forces acting on the piston head and connecting

rod were examined by Selvakumar et al. (2021). For

displacement, von-misses stress, and strain intensity

output, they examined the pressure in the crank end

bearing & the bottom part of the connecting rod. They

found that Al6061, the material used for connecting

rods, has high deformation and low von-misses stress,

resulting in lower life and strength. However,

Al6061+SiC, with high von-misses stress, has high

strength. Aluminium 6061+SiC has greater hardness

than aluminium 6061.

Figure 3 shows the Regime A:

Cross-cut of Forging (Black Arrows Mark the

Boundaries of Coarse Recrystallized Grains) (Rasa

Kandrotaitė J. 2016).

Nitturkar et al. (2020) conducted a solid

modelling study on a connecting rod using NX 10 and

ANSYS Workbench. The study found that the

minimum stresses were found at the piston

end&crank end cap, reducing material costs. A finite

element study must come first, followed by a dynamic

analysis of the connecting rod for additional

optimisation. The connecting rod's tiny end was

where the greatest tension was discoveredIn contrast

An Overview of the Advancements and Upgrades Made to the Connecting Rods in the Internal Combustion Engine

227

to other materials, forged steel is less rigid and weighs

more, and connecting rods made of aluminium,

magnesium, and beryllium alloy exhibit more erratic

behaviour. Beryllium alloy connecting rods have the

lowest von Mises stress, lowest von Mises strain, and

maximum displacement. This study emphasizes the

requirement for more precise material optimization

outcomes.

4 EXPERIMENTAL WORKS ON

CONNECTING ROD

The stress on a connecting rod in a two-wheeler was

analysed by Khan et al. (2016) using the

photoelasticity approach and finite element analysis.

The finite element analysis results and the

experimental results showed a substantial difference,

with tensile stresses being found to be larger than

compressive stresses at both ends of the research. It

was found that the little end of the connecting rod

caused larger strains than the big end. The stress

concentration effect was found to be minimal in the

core and to exist at both ends. It was discovered that

the fillet portion on both ends was where the

connecting rod had the highest likelihood of failing.

According to the finite element study, the rod's risks

of failure were highest at the fillet portions on both

ends, where maximum stresses were also created. The

connecting rod's fillet portions need to have material

added to them in order to prevent these pressures and

failures.

Figure 4 shows the (Left) Experimental

Setup and (Right) Tensile and Compressive Loads

Acting from Both Ends.

Figure 4: (left) Experimental setup and (right) Tensile and

compressive loads acting from both ends.

Figure 5: Displays the fringes that developed at both the

compressive and tensile loads.

Li et al. (2017) investigated the emissions,

performance, and combustion of a SI engine running

on a combination of gasoline and butanol. In

comparison to G100, they discovered that B10 and

B30 had enhanced combustion phasing, shorter flame

generation times, and longer main combustion

durations. Butanol lowered BTE, while B30 reduced

CO, UHC, and NOX emissions while producing

better results with equivalent BTE. M30, E30, and

B30 alcohol alternative fuels showed similar

combustion phasing. When fuelling with butanol-

gasoline blends, the research suggests postponing the

timing of sparking since B30 engine performance and

emissions beat G100.

Figure 5 shows the Displays the

Fringes that Developed at Both the Compressive and

Tensile Loads.

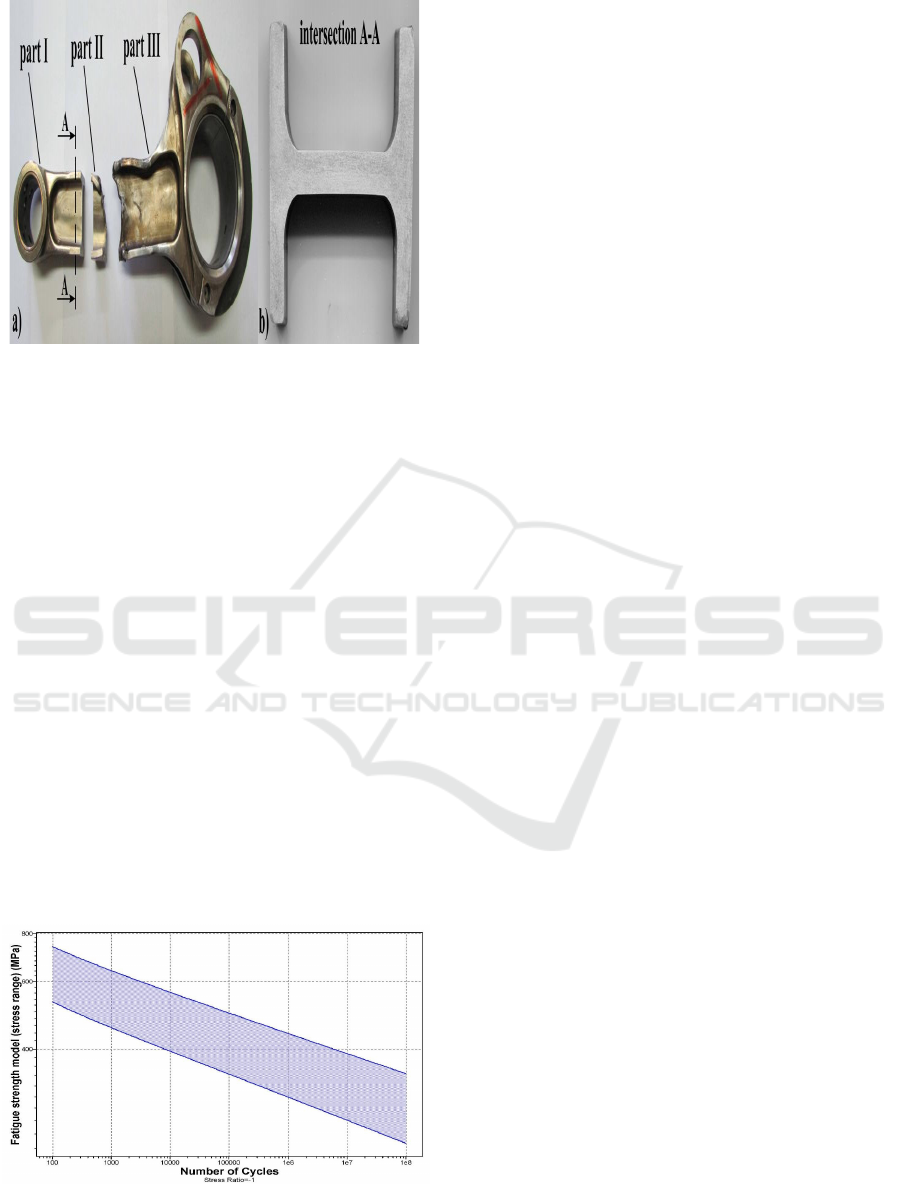

Rakić et al. (2016) identified stress and surface

roughness as the majorreasons of connecting rod

fractures. The engine's prolonged use at full load had

an impact on the breakage as well. In order to avoid

rod breakage in the forthcoming, it is suggested to

raise the radius of rounding in areas where stress

concentration is higher, schedule polishing during

final machining, and enhance control over engine

components during serial manufacturing. The study

suggests that increasing the radius of rounding and

scheduling polishing within the final machining

process can help reduce stress on the connecting rod

and prevent future rod breakage.

Figure 6 shows the

(а) The Fractured Connecting Rod (b) The

Metallographic Specimen Utilised for Macro-

Structural Examination (Intersection A-A) (Roger

Rabb 1995).

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

228

Figure 6: (а) The fractured connecting rod (b) The

metallographic specimen utilised for macro-structural

examination (Intersection A-A).

After one million fatigue cycles, as shown in

Figure 7, Bari et al. (2017) investigated the fatigue-

related failure of a connecting rod in a car owing to

street usage design and discovered that a stronger

chassis was required for the Global GT1 engine. It is

anticipated that the material has a safe service life of

at least ninety minutes at 11,000 RPM. Scale

accumulation in the steel caused microcracks to

develop, which spread under fatigue stress and

eventually caused the item to fail unexpectedly. Due

to improper refurbishment or sulfurized oil, the

fracture surface displayed brittle inclusions that were

sulfurized. The connecting rod broke towards the

conclusion of the exhaust stroke, mostly as a result of

fatigue loading, and the engine management system

heard noises prior to failure. Based on estimates, the

maximum bending stress at the shank centre would be

equivalent to 25% of the maximum stress after a

single engine cycle. The highest stress found at the

large end of the FE simulation corresponds with the

real fracture location.

Figure 7: Probable fatigue strength vs fatigue cycle of low

alloy steel AISI 4140.

Cervelin et al. (2019) introduced a novel method

for signal conditioning force measurements in crank-

slider systems. Utilising data processing methods, by

using this method, the connecting rod force is less

affected by interference and noise. The immediate

IMEP approach serves as its foundation. The method

was tested on a small-sized sintered connecting rod,

which reacted linearly to static axial forces. Dynamic

tests were performed to confirm that the approach is

applicable. The anticipated outcomes of the static and

dynamic testing showed that, at least in low-

frequency situations, glueing a tee rosette to the

midspan of a connecting rod can convert it into a force

transducer. Since the friction forces within the slider

crank are usually larger than the 6 N taken into

consideration in the study, consistent connecting rod

outcomes are anticipated to be superior. The same

SNR may be maintained by using a low-pass filter

with a smaller pass band. As a result of the suggested

measuring method, the results may be directly tested

in reciprocating machine applications, which makes

them pertinent to the research of mechanisms and

mechanical compound design. An improved

representation of real behaviour is made possible by

the dynamic connecting rod stresses, which can

record friction forces, motor torque, instantaneous

pressure, and other data immediately inside the

machine. Further tests are needed to ensure the

method provides coherent results at higher speeds.

5 CONCLUSIONS

In piston engines, the connecting rod plays a critical

role in transferring loads from the piston to the

crankshaft. Diesel engines with high torque at low

rotation rates put a lot of stress on the crankshafts,

pistons, and other engine parts. The fatigue strength

of the rod is limited by several factors, including

mistakes in material composition, technical

malfunctions, and poor design. This study employs

both computational and experimental investigation of

the failure of a connecting rod using advanced stress

analysis utilizing the finite element method (FEM).

The results exhibited that the main cause of failure

in connecting rods was excessive bending stress,

leading to cracks and ultimately fractures.

Additionally, the study highlighted the importance of

proper material selection and design considerations in

improving the fatigue strength of connecting rods in

piston engines.

The surface finish and heat treatment processes

play a crucial role in enhancing the durability of

connecting rods.

An Overview of the Advancements and Upgrades Made to the Connecting Rods in the Internal Combustion Engine

229

Overall, a holistic approach that considers all

these factors is essential for preventing failures and

improving the performance of connecting rods in

piston engines. Furthermore, regular inspection and

maintenance of connecting rods can help identify

potential issues before they lead to catastrophic

failures. By implementing these measures, engine

manufacturers can ensure the reliability and longevity

of their products.

REFERENCES

Abdusalam MH, Prabhat KS & Arvind SD “Design and

Analysis of Connecting Rod Using Aluminium Alloy

7068 T6, T6511”, International Journal of Mechanical

Engineering and Technology (IJMET), 2014, Vol 05,

pp: 57-69.

Abhishek Kumar &. Pankaj Panday “Comparative Study of

Connecting Rod Materials Using NumericTechnique”,

International Journal of Innovative Trends in

Engineering (IJITE), 2019, Vol 08, pp: 19-26.

Akbar Khan H, Dhananjay RD & Mirza MM

“Experimental Stress Analysis ofTwo-Wheeler

Connecting Rod Using Photoelasticity”, IJARIIE,

2016, Vol 02, pp: 1141-1150.

Ambrish Tiwari, Jeetendra Kumar Tiwari & Sharad Kumar

Chandrakar “Fatigue Analysis of Connecting Rod

Using Finite Element Analysis to Explore Weight and

Cost Reduction Opportunities for a Production of

Forged Steel Connecting Rod”, International Journal of

Advanced Mechanical Engineering, 2014, Vol 04, pp:

782-802.

Andoko& Nanang Eko Saputro “Strength analysis of

connecting rods with pistons using finite element

method”, MATEC Web of Conferences 204, 2018.

AndokoAndoko, Imam Muda Nauri, Paryono Paryono,

Pradhana Kurniawan, Dhanang Reza Pradica,

Raymond Philander Jeadi, RiduwanPrasetya, and

TurnadLenggo Ginta “Failure Analysis of Connecting

Rod”, AIP Conference Proceedings 2262, 2020.

Antony S, Arjun A &Shinos TK “Design and Analysis of a

Connecting Rod”, International Journal of Engineering

Research & Technology (IJERT), 2016, Vol 05, pp:

188-192.

Bari K, Rolfe A, Christofi A, Mazzuca C & Sudhakar KV

“Forensic Investigation of a Failed Connecting Rod

from a Motorcycle Engine”, Case studies in

engineering failure analysis, 2017.

Daramy Vandi Von Kallon & Bai Kamara “FEA of a Lab-

Scale IC Engine Connecting Rod”, Proceedings of the

2nd African International Conference on Industrial

Engineering and Operations Management Harare, 2020

DewenJiaa, Yunpeng Lia, Xiwen Denga, Jilin Leia& Wei

Dengb “Design research on forging mark of connecting

rod”, Engineering Failure analysis, 2019.

Ebhojiaye RS &Eboigbe CI “Design and Analysis of 80cc,

4-Stroke Spark Ignition Engine Connecting Rod”,

Journal of Science and Technology Research, 2022,

Vol 4, pp: 278- 288.

Fanil Desai, Kirankumar Jagtap&Abhijeet Deshpande

“Numerical and Experimental Analysis of Connecting

Rod”, International Journal of Emerging Engineering

Research and Technology, 2014, Vol 2, pp: 242-249.

Fengjun Zhang and Yi Zhang “Setting of Natural Fracture

Splitting Surface on Connecting Rod and Its Formation

Mechanism”, Metals, 2020, Vol 10.

Fuertes JP, Murillo O, Leon J, Luis C, Salcedo D, Puertas I

&Luri R “Mechanical properties analysis of an Al-Mg

alloy connecting rod with submicrometric structure”,

Procedia Engineering, 2015, Vol 132, pp:313 – 318.

Fuertes JP, Luis CJ, Luri R, Salcedo D, Leon & Puertas

“Design, simulation and manufacturing of a connecting

rod from ultra-fine-grained material and isothermal

forging”, Journal of Manufacturing Processes, 2016,

Vol 21, pp: 56–68.

Gu Z, Yang S, Zhao Y & Dai X “Fracture splitting

technology of automobile engine connecting rod”, Int J

Adv Manuf Technol ,2005, Vol 25, pp; 883-887.

Leonardo Cervelin, Carlos AF, Rodolfo CCF, Julio NS &

Cesar AP “Measurement of the friction forces between

piston and cylinder in reciprocating machines using the

connecting rod strain behavior”, Mechanical Systems

and Signal Processing, 2019, Vol 130, pp: 677-691.

Mohsin Ali MH & Mohamed Haneef “Analysis of Fatigue

Stresses on Connecting Rod Subjected to Concentrated

Loads at The Big End”, Materials Today, 2015, Vol 02,

pp: 2094 - 2103.

Momin atharuddin, sandeepkumar JA, Hussain P &

Mallikarjuna reddy P “design & analysis of a

connecting rod with Different materials”, Journal of

engineering science, 2019, Vol 10, pp: 184-196.

Murthy BSN, Adarsh Kumar K, Abdul MS, Praveen SSS

“Design and Analysis of Connecting Rod for Weight

and Stress Reduction”, International Journal of

Engineering Research & Technology (IJERT), 2019,

Vol 07.

Mustafa Guven Gok & Omer Cihan “Investigation of

Failure Mechanism of a DCI Engine Connecting Rod”,

European Journal of Technique, 2021, Vol 11, pp: 222-

22.

Nitturkar HD, Kalshetti SM &Nadaf AR “Design and

Analysis of Connecting Rod using Different Materials”,

International Research Journal of Engineering and

Technology (IRJET), 2020, Vol 07, pp: 1011-1017.

Poppy Puspitasari, Dewi IzzatusTsamroh,MochamadAchy

arsyah, Beny Bandanajaya and Dewi puspitasari

“Multistage artificial aging optimization for tensile

properties of Duralium using Response Surface Method

(RSM)”, MATEC Web of Conferences 204, 2018.

Pradeep Kumar D & Prakash Kumar P “A Review on

Analysis of Connecting Rod Using Finite Element

Method”, International Journal of Science, Engineering

and Technology, 2023.

Prasanta Kumar Samal, Murali B, Abhilash &Tajmul Pasha

“Finite Element Analysis of Connecting Rod of IC

Engine”, MATEC, 2015.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

230

Prathamesh SG, Vijay BR, Vijaykumar J, Kuldeep A,

Mahajan Sachin RK & Anil Shirgire, European

Chemical Bulletin, 2023, Vol 12, pp: 2861-2871.

Priyabrata Parida, Mausam Acharya, Ajay Purty &

Chandan Soren “Analysis of Connecting Rod Under

Different Material Condition”, International Journal of

Engineering Research & Technology (IJERT), 2021,

Vol 10, pp: 616- 628.

Puran Singh, Debashis Pramanik & Ran Vijay Singh

“Fatigue and Structural Analysis of Connecting Rod’s

Material Due to (C.I) Using FEA”, International

Journal of Automotive Engineering and Technologies,

2015, Vol 04, pp: 245-253.

Ramani JD, Sunil Shukla & Pushpendra KS “FE-Analysis

of Connecting Rod of I.C.Engine by Using Ansys for

Material Optimization”, Journal of Engineering

Research and Applications, 2014, Vol 04, pp: 216-220.

Rasa Kandrotaitė J “Behaviour of Truck’s Compressor’s

Connecting Rods Made of Aluminium Alloy under

Different Manufacturing Conditions”, Transport, 2016,

Vol 31, pp: 41-46.

Rianti Dewi Sulamet-Ariobimo, Muhammad Fadhlan,

Yoska Oktaviano, Tono Sukarnoto, YusepMujalis&

Amal Witonohadi “The effects of I-Beam thickness to

microstructure and compression load of thin wall

ductile iron connecting rod”, International Journal of

Lightweight Materials and Manufacture, 2023, Vol 06,

pp: 392-404.

Roger Rabb “Fatigue Failure of a Connecting Rod”,

Wartsila Diesel International Ltd, 1995, pp: 97-112.

Saharash Khare, Singh OP, Bapanna Dora K &Sasun C

“Spalling investigation of connecting rod”Engineering

Failure Analysis, 2012, Vol 19, pp: 77-86.

Satish Sanjeev Marathe & Prayag Satish Patil “Modelling

and Analysis of Connecting Rod for Multicylinder

Engine by FEA Approach”, Indian Journal of Applied

Research, 2020, Vol 10.

Selvakumar S, Abhinand P, Ajai Baranidaran, Aswin

Paroli& Mebin Thomas “Analysis and Evaluation of

connecting rod using composite materials (Al+SiC)”,

International Journal of Advances in Engineering and

Management (IJAEM), 2021, Vol 03, pp: 01-11.

Shaik Rafi & Amara Nageswara Rao “Design and

Numerical Analysis of Connecting Rod with Different

Materials”, International Journal of Research

Publication and Reviews, 2023, Vol 04, pp: 2133-2142.

Shubham Chougale “Thermal and Structural Analysis of

Connecting Rod of An Ic Engine”, Journal of Emerging

Technologies and Innovative Research (JETIR), Vol

04, pp: 209-215.

Slavko Rakic, UgljesaBugaric, Igor Radisavljevic& Zeljko

Bulatovic “Failure analysis of a special vehicle engine

connecting rod”, Engineering Failures Analysis, 2016.

Strozzi A, Baldini A, Giacopini M, Bertocchi E &

Mantovani S “A Repertoire of Failures in Connecting

Rods for Internal Combustion Engines, And Indications

on Traditional and Advanced DESIGN METHODS”,

Engineering Failures Analysis, 2015.

Sudheer Singh K, Amit Agrawal & Koli CS “A Review

Study on Simulation Analysis of Connecting Rod of

Engine”, International Journal of Science, Engineering

and Technology, 2021.

Tanya Buddi & Rana RS “Fabrication and finite element

analysis of two-wheeler connecting rod using

reinforced aluminum matrix composites Al7068 and

Si3N4”, Materials Today: Proceedings, 2021, Vol 44,

pp: 2471–2477.

Veda Prakash V “Connecting Rod Testing for Improvement

of Engine Performance with Nano Composite Material

Approch”, International Journal of Mechanical

Engineering, 2021, Vol 06, pp: 4344- 4352.

Velliyangiri B & Vinothkumar S “Design Analysis and

Comparative Mechanical Properties of Al -Metal

Matrix S.I Engine Connecting Rod”, International

Research Journal of Modernization in Engineering

Technology and Science, 2022, Vol 04, pp: 5995- 6000.

Vinay Kumar K, Mahesh M, Sharan P, Gopi J & Venkatesh

J “Design and Analysis of a Connecting Rod”,

International Journal of Research in Engineering,

Science and Management, 2019, Vol 02, pp: 401- 405.

Vinayakrao BA & Swami MC “Analysis and Optimization

of Connecting Rod used in Heavy Commercial

Vehicles”, International Journal of Engineering

Development and Research, 2017, Vol 05, pp: 684-707.

Yoo YM, Haug EJ & KK Choi “Shape Optimal Design of

an Engine Connecting Rod”, Journal of Mechanisms,

Transmissions, and Automation in Design, 1984, Vol

106, pp: 415-419.

Yu Li, Jinke Gong, Wenhua Yuan, Jun Fu, Bin Zhang and

Yuqiang Li “Experimental investigationoncombustion,

performance, and emissions characteristics of butanol

as an oxygenate in a spark ignition engine”, Advances

in Mechanical Engineering, 2017, Vol 09.

Zhongjian Pan & Yi Zhang “Numerical investigation into

high cycle fatigue of aero kerosene piston engine

connecting rod”, Engineering Failure Analysis, 2020.

Zhou Shi &Shuqing Kou “Inverse Reconstruction of

Fracture Splitting Connecting Rod and its Strength and

Fatigue Life”, J Fail. Anal. and Preven, 2018.

Zhu Jun-chao, Zhu Han-hua, Fan Shi-dong, Xue Liang-

jun& Li You-feng “A Study on the influence of Oil film

lubrication to the Strength of Engine Connecting Rod

Components”, Engineering Failures Analysis, 2015.

An Overview of the Advancements and Upgrades Made to the Connecting Rods in the Internal Combustion Engine

231