Advanced ST‑SMCS Control for Efficient Power Management in

Single Inductor Multi‑Port Converters for EVS

Pydikalva Padmavathi, Rolla Tarun Teja, Karna Golla Sai Saranya, Mandala Vaishnavi,

Mandla Shalom Simon and Devarakonda Vinay Kumar

Department of Electrical and Electronics Engineering, Srinivasa Ramanujan Institute of Technology, Anantapur, Andhra

Pradesh, India

Keywords: Super Twist Mode Controller (ST‑SMCS), Super Twist Algorithm, Stability, Reliability Battery State of

Charge.

Abstract: A Single Inductor Multi-Port Power Converter gives Super Twist Mode Controller for Electric Vehicles (EVs)

The controller uses the Super Twist Algorithm to improve power conversion efficiency, stability, and

reliability in changing conditions. While navigating through thousands of simulated input-output interactions,

the system traces their behavior, adapting its parameters to the variables, thereby handling the unpredictable

changes to the energization and load of the battery. The STSMCS includes the number of losing energy and

stability under real-time, which maximizes more stability and effectiveness as effectively as more

adaptability. This technology improves efficient power transfer, contributing to sustainable transportation by

strengthening EV power systems. Such a system makes EV (electric vehicle) system effective & efficient for

power conversion to meet any operational requirement and is a tangible progression in both power conversion

& the EV system.

1 INTRODUCTION

The increasing demand for electricity as well as the

depletion of fossil fuel reserves, especially those

powered by renewable sources such as those offered

by solar photovoltaic (PV) systems, has led to a rise

in the use of electric vehicles. Solar PV covers

sunlight to electricity, and it is optimized by

Maximum Power Point Tracking (MPPT).

However, its efficiency is negatively impacted by

issues such as variation in irradiance and

discontinuous availability. Hybrid energy storage

systems (HESS) considered several secondary

batteries along with the solar PV in order to stabilize

the output power for improving the overall

performance of electric vehicles under different

conditions. By integrating the two systems, it assures

energy consistency, extending the battery life, and

enhancing the handling on extreme terrains. This

enables HESS to optimize energy management and

reduce reliance on fossil fuels by allowing for a

continuous flow of power. It also overcomes some

of the limitations associated with the variability of

solar energy and enhances sustainability. In order to

integrate different energy sources efficiently, multi

input converters are necessary as employing separate

DC to DC converters increases the complexity and

cost of the system, similar to the one in Figure 5. In

hybrid energy storage systems, multi-port converters

are commonly adopted, which can be isolated or

non-isolated. Whereas isolated converters use

highfrequency transformers to achieve voltage

matching and electrical isolation, they introduce

additional losses and size. Non-isolated multiport

converters, like H-bridge systems, provide small,

high-performance, efficient solutions with

adjustable voltage levels and high efficiency energy

transfer to EVs.

Multi-port converter designs have recently been

proposed to balance the energy flow regulation

problem with the component count. For EV and

hybrid EV applications, an economical three-port

converter with integration of fuel cell, solar cell, and

batteries. Energy is managed with advanced

techniques to optimize power distribution and

continue to reduce component size, and zero-voltage

switching DCDC converters followed for greater

efficiency. On the other hand, high step-up non-

isolated converters can improve their performance

Padmavathi, P., Teja, R. T., Saranya, K. G. S., Vaishnavi, M., Simon, M. S. and Kumar, D. V.

Advanced ST-SMCS Control for Efficient Power Management in Single Inductor Multi-Port Converters for EVS.

DOI: 10.5220/0013921800004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 5, pages

11-18

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

11

under varying conditions, and multi-output

converters can deliver stable voltage. The resulting

design is a multiport converter that satisfies the

problem with each port of the previous multiport

converters, making it a great candidate for the

modern EV industry.

2 LITERATURE SURVEY

Dhananjaya et al. (2022) introduced a new multi-

output DC-DC converter for EV applications,

dealing with cross-regulation problems in SIMO

topologies. They can control the voltage

independently, which improves the performance and

reliability of the EV power system. Its efficiency

under different conditions was validated by

MATLAB simulations and experimental results.

Athikkal et al. (2022) proposed a double input hybrid

step-up DC-DC converter used in industrial

applications with a main objective of improving the

power conversion performance of step-up DC-DC

converters by integrating dual power sources,

voltage gain optimization and reduced switching

power losses.

While the converter showed better performance

in terms of reliability and efficiency over a range of

loads, issues such as the complexity of controlling

the operation and stability under time-varying inputs

need more investigation. Alajmi et al. (2021)

proposed an efficient integration of PV systems with

a multi-port DC-DC converter. It provides better

energy management for renewable applications by

connecting both a grid and an alternative power

source to the same user/load. But issues such as

system complexity, thermal regulation, and stability

under changing solar conditions require more

optimization. Similarly, Khasim and Dhanamjayulu

(2021) summarize the selection parameters and

multi-input converter synthesis for electric vehicles

(EVs) by new demands for efficiency, power

density, and the integration of renewable energy.

They emphasized the importance of optimized

switching strategies and control mechanisms to

enhance system performance. Challenges like

component cost, thermal management, and system

complexity need more research. Faridpak et al.

(2020) developed a super-lift Luo-converter in series

with pop-up buck converters for EV applications to

improve the voltage gain and efficiency of the

converter and achieve a small construction. Their

work demonstrated a stellar power conversion

efficiency and voltage stability compared to

conventional converters. Nevertheless, issues such as

circuit complexity, thermal control and practical

deployment.

3 METHODOLOGY

3.1 Modelling of PV Array

When it comes to Electric Vehicles (EVs),

understanding how a Single Inductor Multiple Output

(SIMO) Converter works is key to managing power

efficiently. Full circuit simulation of the SIMPC

integrated with battery and multiple sources, and

equivalent circuit analysis of I-V; P-V characteristic

as well as load profile and dynamic operating

conditions.

The SIMPC efficiently manages power flow from

different sources, including the battery, regenerative

braking, and external power inputs, ensuring optimal

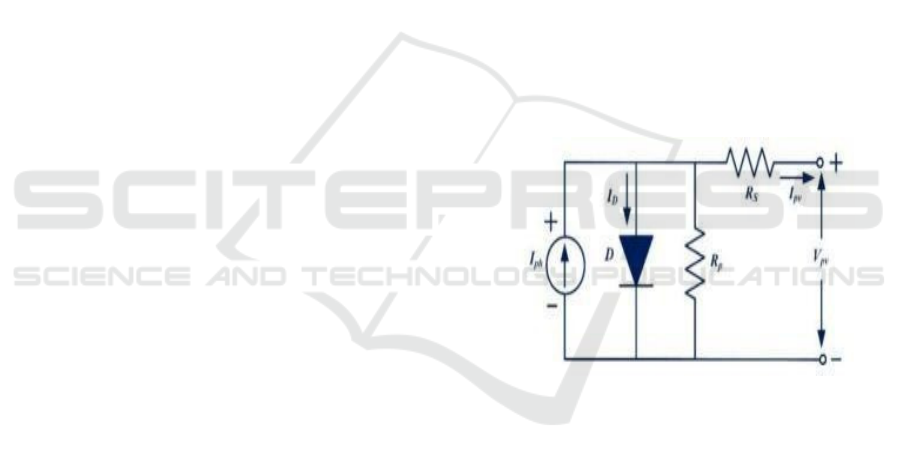

energy utilization. The analogous circuit of a solar

cell is shown in figure 1, incorporating the resistance

when connected in a series configuration (R

s

) and

resistance by connected in parallel (R

p

) alongside a

diode to model its electrical behaviour.

Figure 1: Solar cell analogous circuit representation.

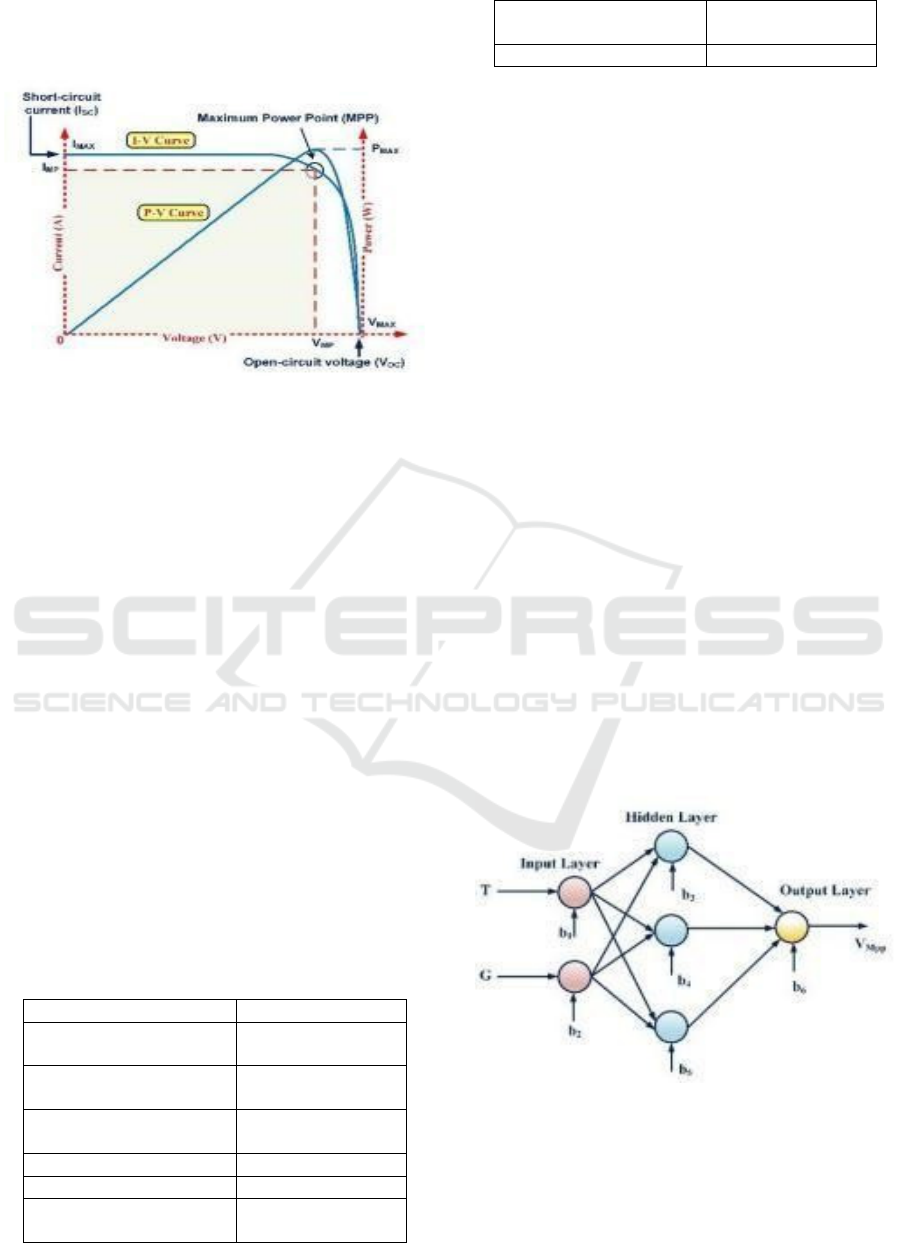

The graphical representation highlights the inherent

instability of a solar PV system’s operating point,

which constantly shifts between zero as well as the

voltage measured under open-circuit conditions. The

specific point where the solar module produces

maximum power, based on its design parameters

under varying temperatures and irradiance levels, is

called the maximum power point (MPP).

A PV array's output voltage and current depend

on factors such as temperature, irradiance, and the

series parallel configuration of its strings. Selecting

an appropriate solar panel requires careful

evaluation. This method considers a Soltech 1STH-

215-P panel with two parallel strings, each

containing two series connected modules. MATLAB

data is used for panel selection. Table 1 presents the

characteristics and measurements of a single series

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

12

module and a parallel-connected string at 1000 W/m²

irradiance and 77°F. Figure 2 shows the Solar Cell I-

V Characteristics.

Figure 2: Solar Cell I-V characteristics.

3.2 MPPT Controller

Environmental factors, such as temperature and

solar irradiance, are key in determining the power

output capability of a solar module. Real time MPPT

Implementation with efficient energy transformation

in EV power systems since solar energy generation

will depend on weather. There are three major

categories of MPPT techniques, which include AI

based methods, direct search algorithms, and indirect

estimations. Continuously tracking the mpp, direct

MPPT techniques (or real-time search-based

methods) adjust the operating point of the PV array.

These include Incremental Conductance (INC),

Perturb and Observe (P&O), and Hill Climbing

(HC) based approaches. Where P&O algorithm

observes the MPP by analyzing the variations of the

output voltage and the HC techniques maintain the

duty cycle of the converter. These methods, while

simple and widely used, are more efficient for low-

power systems because of their steady-state

behavior.

Table 1: Specifications of a 215W Solar Panel.

Parameter Value

Open circuit voltage

(Voc)

36.3V

The voltage at maximum

power point (VMPP)

34V

The voltage at maximum

power point (VMPP)

35V

Short circuit current (Isc) 7.84A

Maximum power 213.15W

Diode saturation current

(I0)

2.9259 × 10^-10 A

Current at maximum

power point (IMPP)

7.35A

Diode ideality factor 0.98117

The most widely used schemes is the incremental

conductance method for reducing steady state

oscillations at MPP. In this regard indirect methods

and artificial neural networks have been around to

improve the efficiency and responsiveness of the

MPPT. By taking into account the non-linear

dynamics of PV arrays, AI-based approaches are

quick but can be expensive computationally.

Indirect methods instead estimate the MPP based on

the output characteristics of the system.

This work make use of ANN for MPP tracking in

a Photovoltaic Solar Energy System. As shown in

Figure 3 is a three-layer ANN structure for MPP

identification. The ANN parameters cover

temperature and irradiance as input features, and its

output is the value of its MPP voltage (Vmpp). To

ensure accurate training, a dataset comprising input

variables and corresponding output values is

collected, allowing for the optimization of neuron

weights at various layers. For data acquisition and

programming, MATLAB is utilized to process solar

PV system data. Among the different training

techniques available for ANNs, thi study implements

the backpropagation algorithm to minimize errors

and enhance tracking accuracy. After training the

ANN, the neuron weight’s must be assigned. For

instance, the ANN generates V

mpp

as an output based

on the input parameters T and G. Using the modeled

PV system’s V-I characteristics, the corresponding

MPPT current (I

mpp

) can then be calculated.

Figure 3: Neural network-based framework for maximum

power point tracking (MPPT).

As a result, the maximum power

(P

max

)idetermined by multiplying V

mpp

and I

mpp

. The

PV system and MPPT tracker, illustrated in Figure 4,

include an ANN-based control unit and a converter.

Advanced ST-SMCS Control for Efficient Power Management in Single Inductor Multi-Port Converters for EVS

13

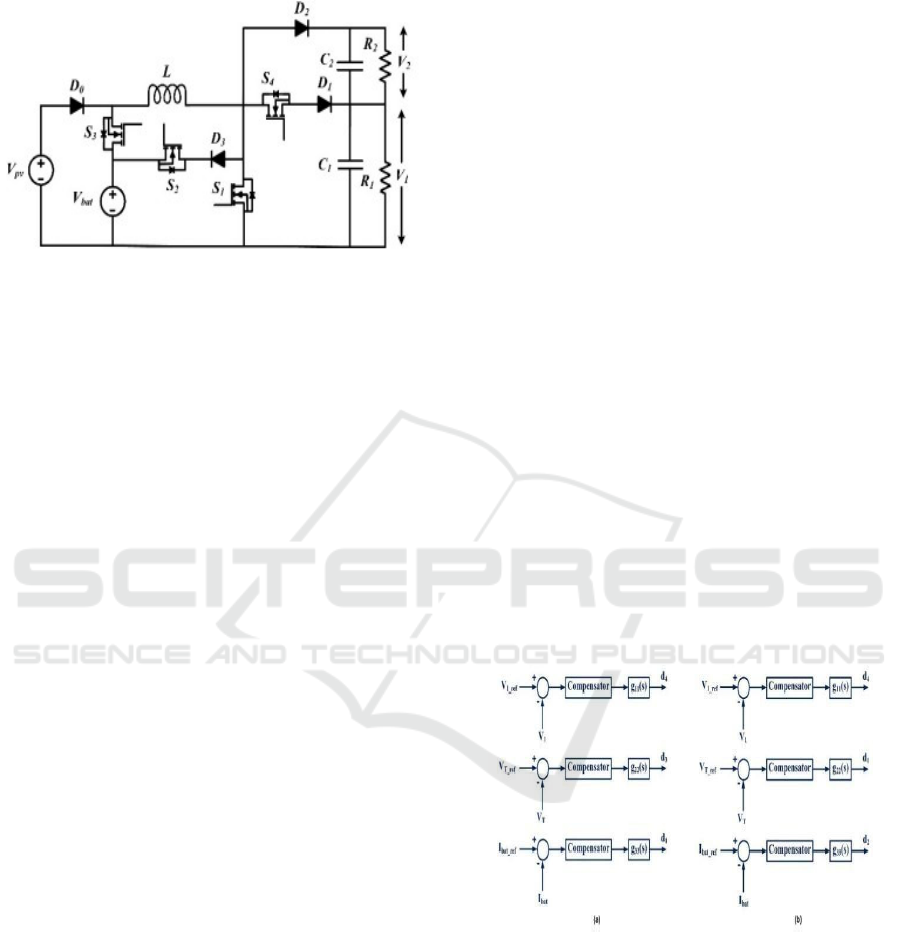

3.3 Proposed DC-DC Converter

Figure 4: Novel dual-input dual-output multi-port converter

architecture.

Figure 4 illustrates the two-input, two-output

configuration of the converter that is proposed. The

energy distribution from dual sources at the input is

analyzed using load resistances R

1

and R

2

. To

enhance the switching efficiency of the converter, the

power flow between sources and load resistances is

controlled by modulating voltages at the input.

Additionally, voltages at the output could be

modified based on voltages at the input of the

multilayer inverter, ensuring efficient power

management. Because of its sturdy construction, this

converter is ideal for combining a battery with a solar

photovoltaic system. Using the designated circuit

components, illustrates how power moves from the

energy sources to the load. The load resistances (R1

and R2) can be represented in terms of the motor's

equivalent resistance and the input voltages of the

multilayer inverter. Moreover, the proposed

controller may also be interfaced with a variety of

multilevel inverters which truly makes it a versatile

solution for energy management in electric car

applications.

The asymmetrical voltage source requirements of

multilevel inverters can all be met by the proposed

controller. Four switches are considered to control

energy transmission from voltages across input to

those across output in the stacked inverter which

increase voltage adaptability and control through the

use of multilayer inverter.

In an EV power system, a new method, especially

for the Super Twisting Sliding Mode Control System

(ST-SMCS) is introduced to control the flow of

power between battery (Vbat) and solar PV (Vpv).

Vbat can't power Vpv but Vpv powers Vbat so

energy is used more wisely. In EV applications,

batteries are usually charged via solar PV or external

sources since solar PV is not rechargeable by the

battery. Battery charge-based controller the

controller operates in different modes depending

upon the charge Available in battery and the load

Demand. When the demand is very high, only the

energy sources will provide power, while S1, S3, and

S4 are connected, and S2 is off. Also when demand

is low Vpv charges Vbat and load is served by Vpv

as S1, S2 and S4 are ON and S3 is OFF. In order to

operate both stable and efficient, the system will

balance the power accordingly and minimizes ripple

current, allowing the entire system to work as best

suited to the EV.

Historically, controllers are mainly evaluated for

performance in steady-state and dynamic scenarios

to ensure the best operation in continuous conduction

mode (CCM). A reduction of the power consumption

in fuction of the electricity demand of the load is

done by the converter working in discontinuous

conduction mode (DCM) at low energy demand

when charging a battery needs very low current to

avoid energy loss. Part IV provides a detailed

examination of the various input sources by

analyzing all input sources separately, allowing for

single-input operation, to directly manage the flows

of power. This includes Modes of operation where

the converter operates primarily in battery charging

and discharging modes for horizontal, well2, and

well4-based EVs.

Figure 5 shows the Adaptive

Control Mechanism of the Proposed Converter in (a)

Discharge Phase and (b) Charge Phase.

Figure 5: Adaptive control mechanism of the proposed

converter in (a) Discharge Phase and (b) Charge Phase.

The Super Twist Sliding Mode Control (ST-SMC)

method is one of robust control methods that

establishes stability by driving the system trajectory

to a specified sliding surface and then maintain it in

this sliding mode in the face of uncertainties and

disturbances.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

14

Defining the Sliding Surface: In the first stage of

ST-SMC algorithm, we define the sliding surface

based on the desired dynamics of the system and

also the tracking errors. The sliding surface for a

single-input system is generally given

by:s(x)=x˙+λx (1)

where: x is the state variable. Λ is a positive constant

that determines the system’s behavior and

convergence rate.

3.4 ST-SMC Consists of Two Control

Steps

Step 1: Twist Control:

This step applies a discontinuous control law to drive

the system trajectory toward the sliding surface. It is

given by:

u

1

=−k

1

sign(s(x)) (2)

where k

1

>0 is a control gain. The sign function

ensures rapid correction of deviations, pulling the

system toward the sliding surface.

Step 2: Super Twist Control:

To further refine the control and reduce errors, a

second component is added that incorporates the

derivative of the sliding variable:

u2=−k2s˙(x) (3)

where k

2

>0 is another positive control gain. This term

smooths out control actions, reducing system

oscillations and improving precision.

Combining the Control Laws:

The total control input is the sum of the two

components:

u=u1+u2=−k1sign(s(x))−k2s˙(x) (4)

This composite law guarantees that the system

reaches the sliding surface and stays on it along the

desired trajectory and is not influenced by outside

disturbances.

4 STABILITY AND ROBUSTNESS

It provides for guaranteed stability and stability

robustness, even for highly nonlinear or uncertain

systems, reproducing the STSMC algorithm with

guaranteed convergence under linear and nonlinear

constraints, ensuring that the trajectory can be

guaranteed to converge to the sliding surface and

then sufficiently stay on it. This methodology is

commonly adopted in control applications where

accuracy and resilience are essential.

5 SIMULATION RESULTS

5.1 Discharging Mode

A uni directional DC to DC converter with battery to

assist the virtual battery energy storage device. It

governs the energy generated by the PV panel to

satisfy the load and charge the battery when

necessary. Critical components that help control the

power flow and maintain voltage stability, include

Diodes (D0–D3), capacitors (C1, C2), and switching

devices (S1–S4). Current measurements are used to

monitor the behaviour of a battery charge and

discharge while voltage measurements (V1, V2, VT)

indicates the levels of the output. This facilitates

efficient power transferring, allowing this system to

provide energy from the battery when the PV output

is low.

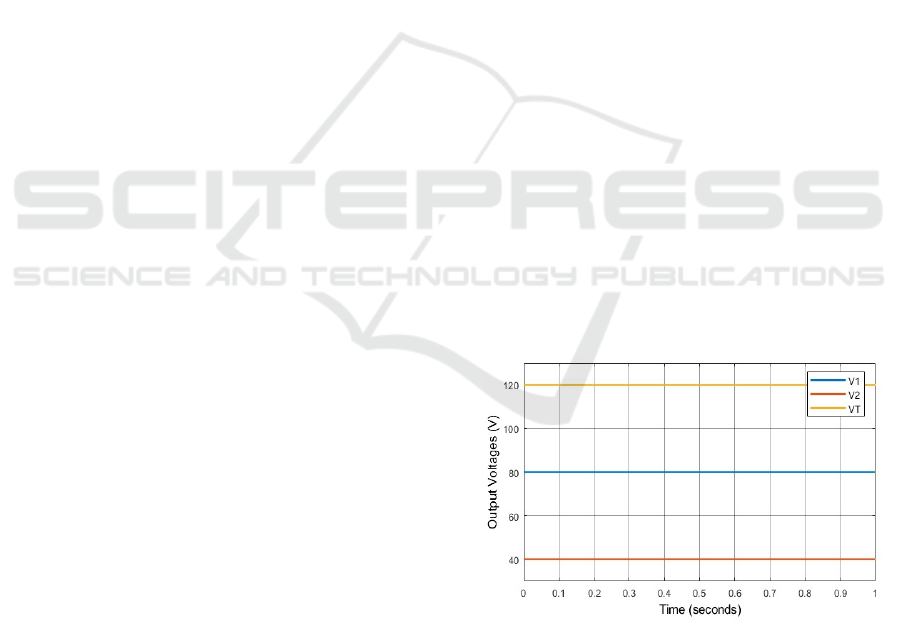

The voltages at the output nodes (V1, V2, and

VT) during battery discharge mode (through the

inductor) are plotted for one second in Fig 8. The

voltages with V1 40V, V2 80V, and VT ~120V does

not change indicating good DC to DC converter

regulation. The constant voltage levels imply that the

battery is successfully and consistently powering the

load. This attests to the system's capacity to sustain a

consistent power output throughout the discharging

stage.

Figure 6: Voltage response during battery discharge.

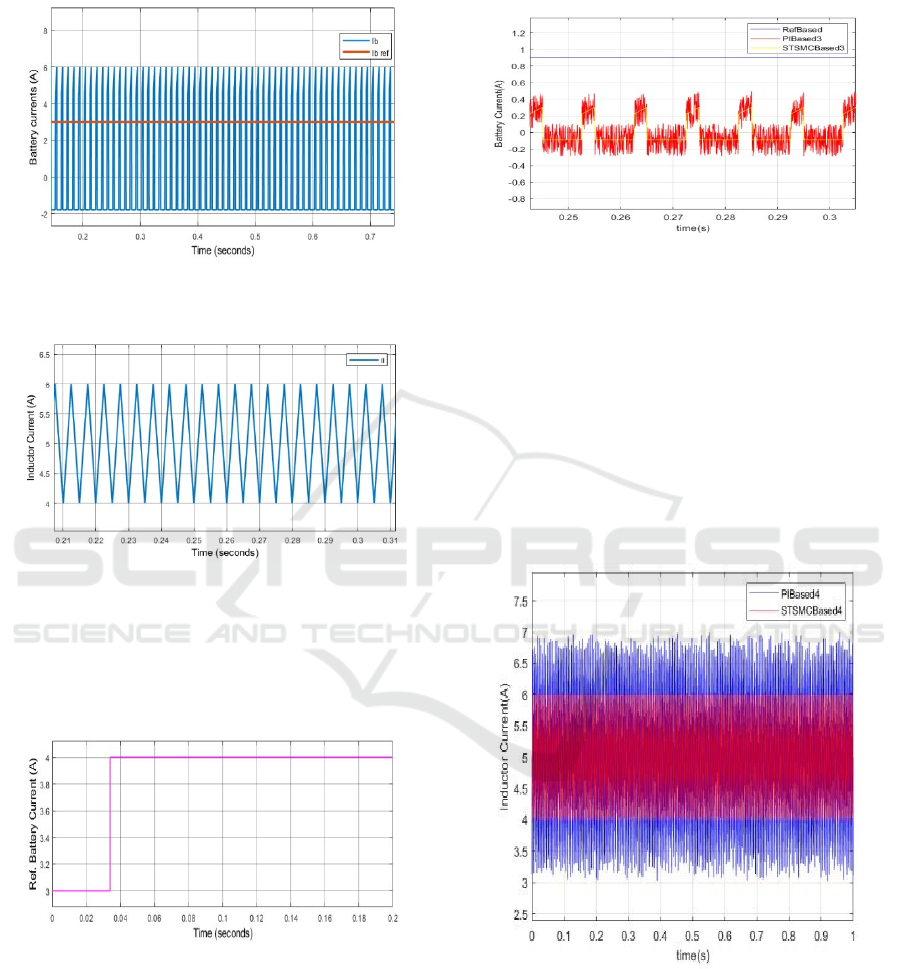

The Target Current Value remains steady at

approximately 3.5A, ensuring controlled power

delivery to the load, while the actual battery current

(I

b

) fluctuates slightly due to the DC-DC converter's

switching action. Figures 6, 7 and 8 depict the

Advanced ST-SMCS Control for Efficient Power Management in Single Inductor Multi-Port Converters for EVS

15

Battery Current, Reference Battery Current, and I

C

in

Discharging Mode, respectively.

Figure 7: Comparison of battery current and control

reference current during discharge mode.

Figure 8: Inductor current in discharging mode.

The photo voltalic panel generates electricity, the

battery stores extra energy and supplies it when

needed, and the converter regulates voltage and

current for a stable output. Figure 9 illustrates the

variation in battery reference current.

Figure 9: Change in battery reference current.

The graph represents battery current (A) over

time (s) for three different control methods:

RefBased4 (blue), PIBased3 (red), and

STSMCBased3 (yellow). The STSMC-based control

demonstrates higher fluctuations while keeping the

current within a specific range, whereas the PI-based

approach shows comparatively lower variations. The

reference current remains steady, acting as a standard

for evaluating performance. Figure 10 illustrates the

Comparison of Battery Current Using Different

Control Strategies.

Figure 10: Comparison of Battery Current Using Different

Control Strategies.

The graph represents inductor current (A) over time

(s) for two control methods: PIBased5 (blue) and

STSMCBased5 (red). The STSMC-based approach

demonstrates smoother performance with reduced

oscillations, while the PI-based method exhibits

higher fluctuations around the set current value. This

comparison highlights the effectiveness of STSMC

in maintaining stable inductor current Figure 11

illustrates the Inductor Current Comparison for PI-

Based and STSMC-Based Control.

Figure 11: Inductor current comparison for PI-Based and

STSMC-Based control.

5.2 Charging Mode

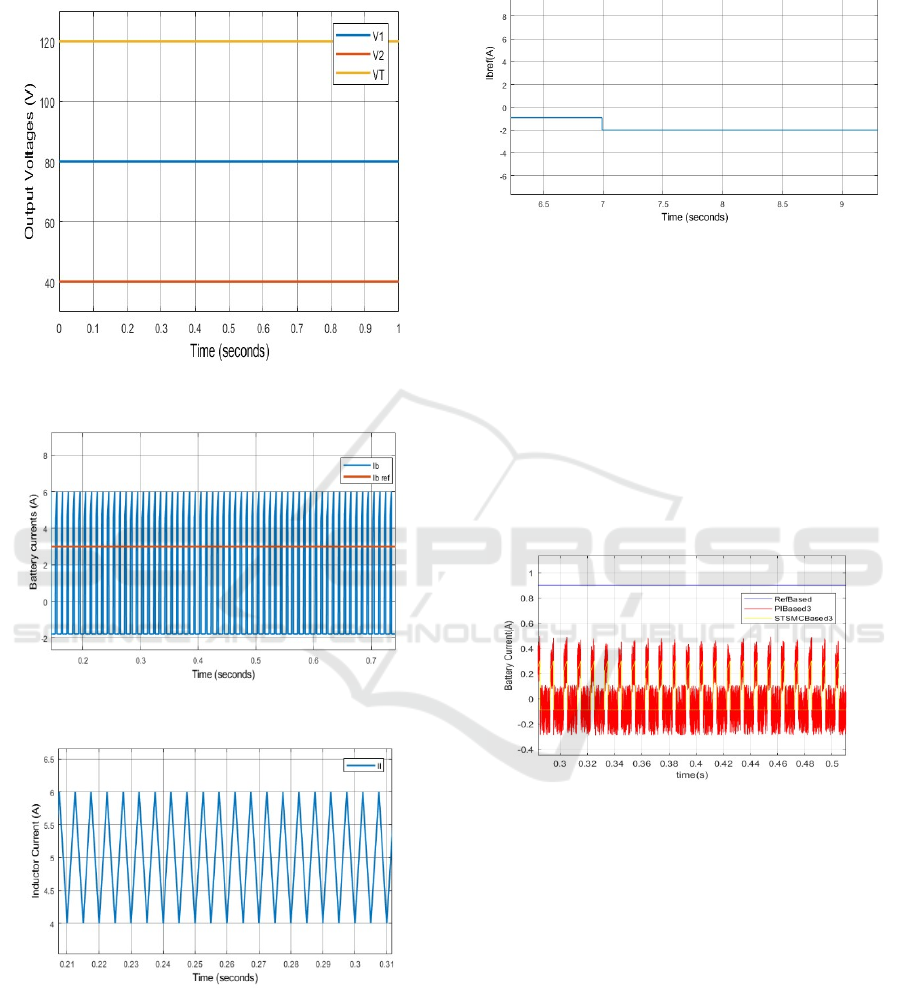

To maintain stable power delivery and enable real-

time voltage and current monitoring, the photo

voltalic panel generates electricity, the battery stores

surplus power for future use, and the converter

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

16

dynamically regulates voltage and current. The

resultant voltage, battery power, and inductor current

are depicted in Figure 12, 13, and 14, respectively

Figure 12: Output voltages in charging mode.

Figure 13: Battery current and reference battery current.

Figure 14: Inductor current in charging mode.

The converter regulates energy flow, with the PV

panel supplying power while the battery charges or

discharges based on changes in the reference current.

This mechanism ensures stable voltage and current

delivery to the load while enabling real-time system

monitoring. The graph illustrating the different in

battery current is presented in Figure 15.

Figure 15: Change in reference battery current.

The graph illustrates battery current (A) over time

(s) for three control strategies: RefBased (blue),

PIBased3 (red), and STSMCBased3 (yellow). The

reference current remains steady, while the PI-based

and STSMC-based methods show oscillations, with

STSMC exhibiting slightly higher fluctuations. This

shows the performance comparison and differences

between traditional PI and advanced STSMC

controller techniques. Schematic representation of

the Battery Current Response for Various Control

Strategies is shown in Figure 16.

Figure 16: Battery current response for different control

strategies.

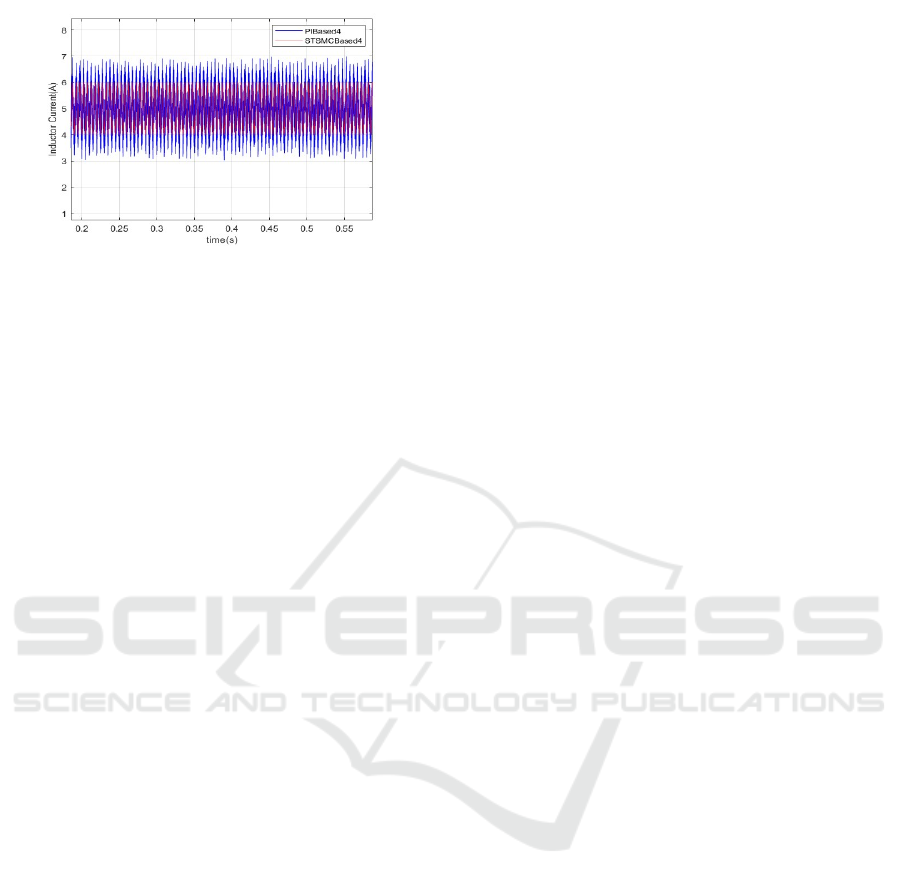

The induturing current (A) over time (s) both for

PIBased4 (blue) and STSMCBased4 (red) control

methods is depicted. The response using STSMC

method has a smoother curve and less fluctuating

performance compared to that of PI achieved

approach. Extending this analysis to the inductors

spectrum regarding their oscillatory dynamics

would provide a more sophisticated insight into how

the STSMC technique outperformed previous

results. Inductor Current Response Using PI-Based

and STSMC-Based Control as Recorded in Figure

17.

Advanced ST-SMCS Control for Efficient Power Management in Single Inductor Multi-Port Converters for EVS

17

Figure 17: Inductor current response using PI-Based and

STSMC-Based control.

6 CONCLUSIONS

To summarize, the design performance has a

significant improvement by applying the Super-

Twisting Sliding Mode Control (STSMC) for Single

Inductor Multi-Port Power Controller in EV

applications. By replacing the classical PI-based

controller by the proposed one based on STSMC,

the method succeeds in dampening chattering as well

as restoring the voltage and current distortions. This

leads to a smoother and more stable operation.

Moreover, in comparison with STSMC, the

integration of a compensator achieves better

disturbance rejection response and also provides a

quick dynamic response against changes in load

conditions.

The findings of the Simulated and Empirical

Evaluations validate the proposed advanced control

strategy, showcasing a decrease in steady-state error

and enhanced efficiency in the aggregation of

multiple energy sources, such as battery and solar

panel networks. With its data-driven power

distribution and management, this approach is

required for electric vehicles since the need for

energy is dynamic depending on driving conditions.

The proposed STSMC-based system is assessed to be

suitable for use in EV applications, highlighting its

advantages as a cost efficient and energy-effective

solution for numerous energy splits, encourages

performance improvement and diminishes

distortions.

REFERENCES

A. Ajami, H. Ardi, and A. Farakhor, ‘‘A novel high step-up

DC/DC converter based on integrating coupled

inductor and switchedcapacitor techniques for

renewable energy applications,’’ IEEE Trans. Power

Electron., vol. 30, no. 8, pp. 4255–4263, Aug. 2015,

doi: 10.1109/TPEL.2014.2360495.

doi: 10.1109/TVT.2011.2122272.

J. Macaulay and Z. Zhou, ‘‘A fuzzy logical-based variable

step size P&O MPPT algorithm for photovoltaic

system,’’ Energies, vol. 11, no. 6, p. 1340, May 2018,

doi: 10.3390/en11061340.

K. Suresh, C. Bharatiraja, N. Chellammal, M. Tariq, R. K.

Chakrabortty, M. J. Ryan, and B. Alamri, ‘‘A

multifunctional non-isolated dual input-dual output

converter for electric vehicle applications,’’ IEEE

Access, vol. 9, pp. 64445–64460, 2021.

L. Wang, E. G. Collins, and H. Li, ‘‘Optimal design and

realtime control for energy management in electric

vehicles,’’ IEEE Trans. Veh. Technol., vol. 60, no. 4,

pp. 1419–1429, May 2011,

M. Zandi, A. Payman, J. P. Martin, S. Pierfederici, B.

Davat, and F. Meibody-Tabar, ‘‘Energy management of

a fuel cell/supercapacitor/ battery power source for

electric vehicular applications,’’ IEEE Trans. Veh.

Technol., vol. 60, no. 2, pp. 433–443, Nov. 2011, doi:

10.1109/TVT.2010.2091433.

M. R. Banaei, H. Ardi, R. Alizadeh, and A. Farakhor,

‘‘Non-isolated multiinput-single-output DC/DC

converter for photovoltaic power generation systems,’’

IET Power Electron., vol. 7, no. 11, pp. 2806– 2816,

Nov. 2014, doi: 10.1049/iet-pel.2013.0977.

M. Dhananjaya, D. Ponuru, T. S. Babu, B. Aljafari, and H.

H. Alhelou, ‘‘A new multi-output DC–DC converter for

electric vehicle application,’’ IEEE Access, vol. 10, pp.

19072–19082, 2022.

P.-J. Liu, Y.-K. Lo, H.-J. Chiu, and Y.-J. Emery Chen,

‘‘Dual-current pump module for transient improvement

of step-down DC–DC converters,’’ IEEE Trans. Power

Electron., vol. 24, no. 4, pp. 985– 990, Apr. 2009, doi:

10.1109/TPEL.2008.2010322.

S. R. Khasim and C. Dhanamjayulu, ‘‘Selection parameters

and synthesis of multi-input converters for electric

vehicles: An overview,’’ Renew. Sustain. Energy Rev.,

vol. 141, May 2021, Art. no. 110804, doi:

10.1016/j.rser.2021.110804.

S. R. Khasim and C. Dhanamjayulu, ‘‘Design and

implementation of asymmetrical multilevel inverter

with reduced components and low voltage stress,’’

IEEE Access, vol. 10, pp. 3495–3511, 2022, doi:

10.1109/ACCESS.2022.3140354.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

18