Optimizing Resource Management and Load Balancing in Supply

Chain through Integrating Digital Technologies to Enhance Resource

Efficiency and Workload Management in Manufacturing Firms

Janmejai Kumar Shah

1

, Sudhanshu Joshi

2

and Manu Sharma

1

1

Department of Management Studies, Graphic Era Deemed to be University, Dehradun, Uttarakhand, India

2

School of Management, Doon University, Dehradun, Uttarakhand, India

Keywords: Digital Technologies, Supply Chain Management Resource Management and Load Balancing.

Abstract: Digital integration across supply chains offers significantly improved resource management and load

balance in industrial enterprises. This study aims to examine the favorable effects of Industry 4.0

technologies, enterprise resource management systems, blockchain, and dynamic capabilities on resource

efficiency and workload optimization. The research employs a descriptive literature analysis to identify

principal themes, including sustainability, operational resilience, and performance enhancement, with an

emphasis on green supply chain practices and agility. The paper portrays the limitations associated with

fragmented research, the dynamic technology landscape, and supply chain procedures that are sometimes

context-specific, thereby limiting their universal applicability. The findings support theoretical frameworks

that illustrate the collaborative impact of digital technology in fostering sustainable and efficient supply

chains. The research provides practical recommendations for manufacturing companies to efficiently

leverage digital tools to maintain competitiveness, enhance decision-making, and foster resilience. We

present a conceptual framework for the application of digital technology in supply chain processes and offer

organized techniques to address resource optimization concerns. Research indicates that digital

transformation of supply chains can effectively facilitate the achievement of sustainability objectives.

Ultimately, it indicates prospective research avenues, including sector-specific analyses and emerging

technologies like artificial intelligence and the Internet of Things, to enhance the adaptability and resilience

of supply chains. This study offers a thorough foundation for resource management and optimization of load

balancing through digital innovation in manufacturing supply chains.

1 INTRODUCTION

Balancing workloads and managing resources

remains a significant issue with many manufacturing

firms facing inconsistencies in their operations due to

the complexities of modern day supply chains,

especially in a world that is perpetually changing.

This fact has spurred interest in some digital

technologies that could help to increase resource

efficiency and better manage workloads. The

technologies discussed here have shown to improve

the utilization of resources, promote sustainability

and increase resilience in the supply chain

infrastructure (Rouhani, S., & Deters, R. 2019),

(Kesidou, S., & Sovacool, B. K. 2019) and (Belhadi

et al., 2022). Although important, there is still a lack

of holistic frameworks for the implementation of

digital technologies in supply chains (Di Vaio, A., &

Varriale, L. 2020). We seek to address this gap by

reviewing literature on this subject, reviewing how

long-term practice evolves and adapts following the

impact of technology upon it, and proposing themes

which encourage the introduction of digital solutions.

While this article contributes to building such a

comprehensive view, certain limitations need to be

acknowledged: The literature studied is

predominantly biased towards certain technologies

or elements of the supply chain management cycle,

without being able to provide a comprehensive or

holistic view. Because these have been generated on

a very specific aspect, thus, the knowledge acquired

is not generalizable (Patil et al., 2022) and (Trujillo-

Gallego et al., 2022). In addition, digital technologies

are always developing; therefore, it is difficult to

fully understand their influence, or to forecast the

818

Shah, J. K., Joshi, S. and Sharma, M.

Optimizing Resource Management and Load Balancing in Supply Chain through Integrating Digital Technologies to Enhance Resource Efficiency and Workload Management in Manufacturing

Firms.

DOI: 10.5220/0013921300004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 4, pages

818-825

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

consequences of their further development (Kesidou,

S., & Sovacool, B. K. 2019), (Bui et al., 2023). A

significant number of studies depend on case studies

from regions or industries and lack empirical

evidence, which restricts the practicality of their

findings (Murguia et al., 2023) and (Noor, Z. Z.

2023). Moreover, practices and challenges within

supply chains differ greatly between industries and

regions, complicating the development of universally

applicable frameworks (de Oliveira-Dias et al.,

2023). Ultimately, there is a lack of longitudinal

studies that investigate the enduring effects of digital

transformation on resource efficiency and workload

management over extended times (Di Vaio, A., &

Varriale, L. (2020) and (Sugianto et al., 2023).

1.1 Objectives

This study focuses on exploring the integration of

digital technologies in supply chain operations to

tackle challenges related to resource management

and workload optimization.

(RO1): Grasp the impact of digital technologies on

supply chain resource management and workload

optimization, integrate and analyze the existing

literature.

(RO2): Examine the ways in which digital

technologies transform and enhance supply chain

practices following their implementation.

(RO3): Develop Themes for Integration to support

manufacturing companies in the effective

implementation of digital technologies within their

supply chain operations.

1.2 Significance

This study enhances the existing understanding of

supply chain innovation by addressing significant

gaps in the knowledge of digital integration. This

offers practical insights for professionals aiming to

enhance resource utilization and workload

management. It also outlines potential avenues for

further investigation for scholars. This study offers

valuable insights for policymakers by guiding the

creation of conducive environments for technology

adoption; it emphasizes that digital transformation

should enhance sustainable and resilient supply

chains (Rodríguez-González et al., 2023) and (Luo

et al., 2024).

1.3 Approach

The objectives of the study are approached through a

descriptive and thematic analysis. This study

conducts a descriptive review of existing literature

utilizing R Studio and thematic analysis through

VOS viewer to identify patterns, trends, and themes

in the application of digital technology within supply

chains. This systematic approach allows the study to

concentrate on significant inquiries, while also

striving to encompass a broad range of insights

(Noor, Z. Z. 2023) and (Fiorini et al., 2022). This

study compiles insights on supply chain practices

from previous investigations, aiming to chart the

progression of these practices while offering

actionable suggestions for manufacturing companies

to utilize digital technologies for achieving resource

efficiency and optimizing workloads.

The study comprises five sections: section 2

consists of literature review followed by

methodology in section 3 and then Implication in

section 4 and Discussion, Conclusion, and Future

Scope in section 5.

2 SYSTEMATIC LITERATURE

REVIEW

A Systematic Literature Review (SLR) is a

structured approach for thorough evaluation of

literature within one or more specialized study

domains. This methodology facilitates the

identification of trends, limits, and prospective

opportunities for future research, hence enhancing

the understanding of the topic. This research

specifically analyses digital technologies and their

impact on supply chain resource management and

workload distribution.

2.1 Select Database and Keywords

This study utilized the Scopus database due to its

extensive compilation of peer-reviewed journals

featuring high-quality scientific papers. Historically,

we employed a more focused search query utilizing

keywords associated with “Digital,” “Supply

Chain,” “Resource Management,” “Load

Balancing,” and “Performance.” This combination is

specifically intended to discover research that

examine the interface of digital technology and

supply chain optimization.

2.2 Criteria for Acceptance and

Rejection

Strict inclusion and exclusion criteria were

implemented in this review of papers to ensure the

Optimizing Resource Management and Load Balancing in Supply Chain through Integrating Digital Technologies to Enhance Resource

Efficiency and Workload Management in Manufacturing Firms

819

inclusion of pertinent and high-quality research. The

criteria for inclusion were Articles and review

papers published between 2019 and 2024. Research

disseminated in the English language. Research

papers focused on supply chains and digital

technologies, emphasizing resource management,

workload optimization, and performance

enhancement. Studies were omitted if they: They

lacked empirical proof or were not peer-reviewed.

Concerning various topics that are either irrelevant

or pertain to general discourse on digital

technologies. Initially, there were 57 results. Forty-

four studies were evaluated for relevance, and

duplicates were eliminated. Following a

comprehensive content analysis, we refined the

selection to 33 high-quality publications that

constituted the foundation of this study. Table 1

shows the SLR Approach.

Table 1: SLR Approach.

Heads Details

Database Sco

p

us

Search Query

(TITLE-ABS-KEY ("Digital") AND TITLE-ABS-KEY ("supply chain") AND TITLE-ABS-

KEY ("resource management") OR TITLE-ABS-KEY ("load balancing") AND TITLE-ABS-

KEY ("performance"))

Filters Applied Publication years (2019–2024), document type (articles and reviews), language (English)

Initial Search Results 57 studies

First Screening Excluded irrelevant studies, leaving 44 papers

Final Screening Removed duplicates and non-specific studies, resulting in 33 high-quality papers

3 METHODOLOGY

The study achieves this purpose through a

systematic and structured methodology that uses

descriptive and thematic analyses to investigate the

incorporation of digital technology in supply chain

management to optimize resource management and

load balancing. The technique comprises two

essential components: A comprehensive evaluation

of the current literature was initially performed

utilizing bibliometric methods in R Studio. This step

involved producing a quantitative analysis of the

patterns, trends, and publishing dynamics in the

fields. The descriptive review consolidates existing

research by examining the prevalence of pertinent

studies, citation networks, and the distribution of

research findings. On the other hand, a thematic

analysis using VOS viewer as a cutting-edge

visualization software for text analysis was

performed to uncover the patterns and clusters found

in the implementation of digital technology. The

study aims to clarify prominence themes visualized,

elucidate important concepts correlated and

highlight emergent themes and research gaps with

the help of VOS viewer. It is an amalgamation of the

two methodologies, helping in a holistic

understanding of the matter. The descriptive review

section gives a global overview of the research topic,

while in the thematic analysis section specific

themes and patterns are being analyzed in order to

make them actionable. Simultaneously, the dual

framework bolsters both the reliability and

comprehensiveness of the study and remedies major

gaps in the existing literature. This approach not

only encapsulates the existing knowledge into an

integrated synthesis but also provides the

evolutionary journey of digital technologies within

supply chains and a systematic framework to

incorporate them into resource management and

workload optimization.

3.1 Descriptive analysis

Table 2: Year wise evolution.

YEAR ARTICLES

2019 2

2020 1

2021 0

2022 6

2023 10

2024 14

Table 2 shows the year wise evolution. Research on

the integration of digital technologies in supply

chains to enhance resource management and load

balancing has significantly increased throughout the

2019–2024 timeframe, emphasizing resource

management and workload optimization. In 2019

and 2020, only two and one articles were published,

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

820

respectively, indicating preliminary investigation

(Patil et al., 2022) and (Trujillo-Gallego et al., 2022)

In 2022, there was a significant increase to six

articles, escalating in 2023 to ten articles, and

culminating in 2024 with fourteen articles as

innovations in Blockchain and Industry 4.0

progressed rapidly (Murguia et al., 2023) and

(Sugianto et al., 2023). It is also associated with

several global supply chain challenges and

sustainability objectives, highlighting the

significance of this domain and the study's purpose

(Kesidou, S., & Sovacool, B. K. 2019), (Patil., et al.,

2022) and (Bui et al.,2023) Table 3 shows the

geographical contribution.

Table 3: Geographical Contribution.

Country TC Average citations

Canada 210 210.00

France 100 50.00

United Kingdom 72 36.00

Colombia 60 60.00

Italy 60 20.00

Sweden 51 51.00

Spain 49 24.50

China 44 6.30

Indonesia 15 5.00

India 13 13.00

Investigations into the application of digital

technology for the optimization of resource

management and load balancing in supply chains

yield diverse contributions from various nations.

Canada possesses the most total citations (TC) at

210, with an average TC of 210.00, attributed to its

advanced emphasis on digital solutions for resource

efficiency (referenced as (Patil., et al., 2022) and

(Murguia et al., 2023). Conversely, France (100 TC,

50.00 average) and the United Kingdom (72 TC,

36.00 average) emphasize significant studies on

integrating digital technology to enhance workload

management (Trujillo-Gallego et al., 2022) and

(Sugianto et al., 2023). Colombia and Sweden

exhibit specialized research initiatives, with TCs of

60 and 51, respectively, suggesting that the

application of digital tools for industrial enterprises

should be prioritized (Bui et al.,2023) and (de

Oliveira-Dias et al., 2023). China (44 TC, 6.30 avg.)

and India (13 TC, 13.00 avg.) exemplify regional

stakeholders' aspiration to enhance efficiency, hence

facilitating additional engagement from rising

contributors (Kesidou, S., & Sovacool, B. K. 2019)

and (Noor, Z. Z. 2023). Research is a global

phenomenon that underscores the importance of

incorporating digital technologies into supply

networks. Prominent contributors, such as Canada

and Sweden, are providing exemplary frameworks

for resource management and load balancing;

concurrently, developing participants are indicating

the potential for regional innovation and cross-

border collaboration. These results highlight the

imperative for manufacturing organizations to adopt

internationally scalable systems that are resource-

efficient and promote sustainable workload

management techniques. Figure 1 shows the

geographic collaboration network.

Figure 1: Geographic Collaboration Network.

The visualization illustrates global collaboration

patterns in the integration of digital technologies for

optimizing resource management and load balancing

within the supply chain. Node size represents the

relative contribution of countries, with major

regional and inter-regional links apparent. Canada is

a big part of that, forming key partnerships with

India and Bangladesh. This also matched with

Canada's aim of fostering supply chain innovation

and digital adoption, with an emphasis on

developing nations (Kesidou, S., & Sovacool, B. K.

2019) and (Patil., et al., 2022). Specifically, the

European Countries (UK, France, Italy) show an

intuitive and dense network architecture with

focused powered optimization and digitalization of

supply chains (Trujillo-Gallego et al., 2022) and

(Murguia et al., 2023). They are centers of

innovation, deploying the latest technologies to

improve resource efficiency and workloads.

Emerging economies, in particular, Indonesia and

China, also play essential roles in the network and

connect regional peers in Asia such as Malaysia and

Hong Kong. This suggests that these nations are

employing digital technologies as a means of

overcoming supply chain resilience and operational

efficiency challenges (de Oliveira-Dias et al., 2023)

and (Rodríguez-González et al., 2023). So that goes

back to what I said, which is the need to solution

Optimizing Resource Management and Load Balancing in Supply Chain through Integrating Digital Technologies to Enhance Resource

Efficiency and Workload Management in Manufacturing Firms

821

from all over the world, bring the best ideas and the

best technology and habits over to address the

problems. Drawing linkages between developed and

developing countries provides an opportunity for

cooperation in creating scalable solutions along the

knowledge-sharing process by all stakeholders.

These unprecedented findings, presented on the

network, highlight the importance of international

collaborative frameworks to enable the incorporation

of digital technology into supply chains. With this

in mind, cross-border affiliations help countries

implement comprehensive strategies for improving

resource management and workload repartition in

industrial businesses. Such global intermingling

means that these solutions can be steered for a wide

variety of operational settings, ensuring resilience,

sustainability and efficiency in supply chain

practices. Moreover, such partnerships can bridge

the technological gap between developed and

developing economies, enabling inclusive growth

and innovation. Table 4 gives the key research

focus areas.

Table 4: Key Research Focus areas.

Terms Frequenc

y

Supply chains 16

Su

pp

l

y

chain mana

g

ement 11

Enter

p

rise resource mana

g

ement 10

D

y

namics ca

p

abilit

y

8

Human resource management 8

Industry 4 0 6

Performance 6

Sustainable develo

p

ment 6

Di

g

ital technolo

g

ies 5

Resource management 5

Environmental management 4

Information management 4

Com

p

etition 3

Decision makin

g

3

Digital technology integration in supply chain

management to optimize resources and manage

workload are examined in detail. Recent research

has focused on optimizing "supply chains" (Kandpal

et al., 2024). The cases emphasize digital innovation

to understand and improve supply chain operations

(Kesidou, S., & Sovacool, B. K. 2019) and (Patil., et

al., 2022). These include 11 supply chain

management and 10 enterprise resource management

incidents, which address managerial and operational

standards for efficient resource usage. This

emphasizes automating and streamlining supply

chain processes (de Oliveira-Dias et al., 2023) and

(Trujillo-Gallego et al., 2022). Ideas that innovate

Digital transformation should emphasize agile

methods and human resources, according to

'dynamic capability' and 'human resource

management'. Agile and skilled workers are needed

to implement and maintain digital tools in supply

chain ecosystems (Murguia et al., 2023) and

(Sugianto et al., 2023). The continuous reference of

"Industry 4.0" and "Sustainable development"

emphasizes technology-driven innovation and

supply chain sustainability. Smart technologies like

IoT and AI help green and streamline supply

networks (Bui et al., 2023) and (Rodríguez-

González et al., 2023). Other names like "Digital

techniques," "Resource management," and

"Environmental management" show supply chain

digitization ambitions. These statements stress using

technology to achieve environmental sustainability

and resource optimization. Supply chain

management and resource optimization are

becoming more important, along with dynamic

capabilities, human resource integration, and

sustainability. Thus, strategic and environmental

engagement must accompany technological

advances to restructure the supply chain. The results

reveal that firms must develop comprehensive

digital strategies to improve operational efficiency,

personnel preparation, and sustainability to stay

competitive and resilient. Sustainable development

goals require international cooperation and supply

chain alignment to address global issues.

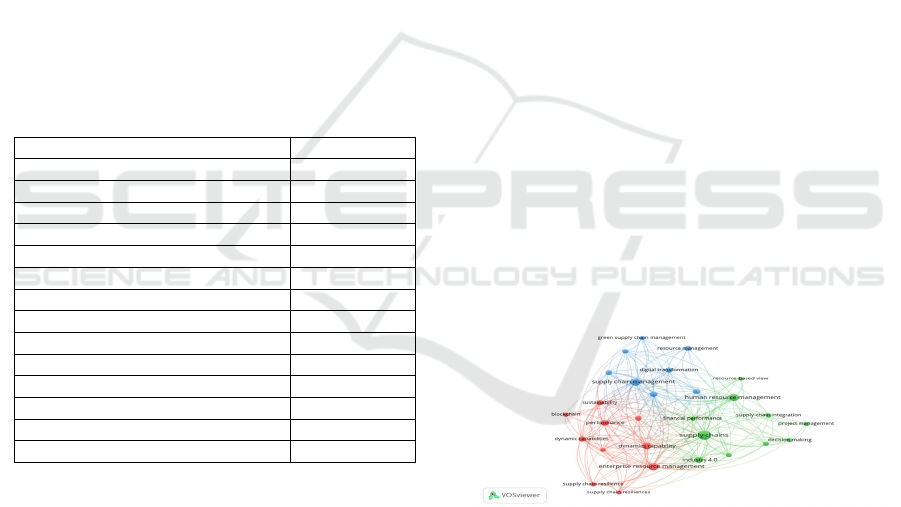

3.2 Thematic Analysis

Figure 2: Thematic network.

The visualization of the network map of themes

highlights the connections between key subjects and

organizes related terms into distinct groups, aligning

with the focal directions observed in recent years

within both academic and industrial discussions

(figure 2). The connections illustrate the co-

occurrence relationship between these themes, with

their size indicating the frequency of occurrence for

each theme. Table 5 shows the themes develop for

resource and load management.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

822

Table 5: Themes develop for resource and load management.

Theme Key Insights References

Enhancing Connections and

Efficiency in Digital Supply

Chain Integration

Digital technologies like Blockchain, IoT, and cloud

platforms improve inventory management, logistics

transparency, and demand forecasting. Industry 4.0

streamlines decision-making, enhances connectivity,

and fosters green innovation for sustainability

compliance.

Di Vaio, A., &

Varriale, L.

(2020), de

Oliveira-Dias ET

AL., 2023 and

Luo, S., Xiong, Z.,

& Liu, J. (2024).

Resource and

Environmental Efficiency:

Addressing Errors to Foster

Positive Progress Towards

Sustainability

AI, predictive analytics, and energy optimization

systems enable resource efficiency and waste

reduction. Circular supply chains and green

initiatives are critical for sustainability in industries

like textiles. Emerging technologies enhance

operational efficiency while reducing environmental

impact.

(Trujillo-Gallego

et al., 2022), (Bui

et al., 2023) and

(Fiorini et al.,

2022).

Human-Centric Digital

Transformation:

Empowering the Workforce

Workforce upskilling and digital HRM facilitate the

effective use of AI and IoT. Green HRM

competencies support green supply chain

management (GSCM) and enhance operational

performance while focusing on environmental

objectives.

(Trujillo-Gallego

et al., 2022),

(Fiorini et al.,

2022) and (Verma

et al., 2022).

Industry 4.0 and

Performance Enhancement:

Employing Innovative

Technology

Robotics, blockchain, and digital twins improve

operational efficiency and resource management.

Technologies enhance performance assessment

systems and bolster supply chain resilience and

adaptability. Additive manufacturing drives dynamic

capabilities for greater efficiency.

(Belhadi et al.,

2022), (Patil et al.,

2022), (de

Oliveira-Dias et

al.,2023) and

(Kandpal et al.,

2024).

Resilience and Adaptability

in Supply Chains:

Readiness for Disruptions

Digital culture and absorptive capacity drive supply

chain resilience. Technologies enable firms to

respond dynamically to market changes, ensuring

continuity during disruptions, as seen in the

Indonesian trucking industry.

(Belhadi et al.,

2022), (Sugianto

et al., 2023) and

(Rodríguez-

González et al.,

2023).

Sustainable Development

and Competitive

Advantage: Efficiency vs

Sustainability

Balancing efficiency and sustainability are key.

Green digital technologies enhance resource

efficiency, boost brand reputation, and drive long-

term competitiveness. Supply chain digitalization

fosters green innovation and ensures adherence to

environmental standards.

(Fiorini et al.,

2022) and (Jauhar

et al., 2021).

4 IMPLICATIONS

4.1 Theoretical Implications

This study applies dynamic capacity theory to

supply networks and demonstrates how digital

technologies enhance adaptability to unforeseen

conditions (de Oliveira-Dias et al., 2023). Industry

4.0 concepts like IoT, blockchain, and AI help

explain how technology innovation improves

resource management and task balancing. Digital

tools improve sustainability by linking resource

efficiency to supply chain environmental

performance. HRM also facilitates technology

adoption and boosts supply chain labor efficiency,

creativity, and innovation (Trujillo-Gallego et al.,

2022) and (Fiorini et al., 2022).

4.2 Practical Implications

The research (Bui et al., 2023) state’s various

themes regarding digital technology to enhance

resource utilization, waste reduction, and cost

effectiveness in industrial enterprises. Live analytics

Optimizing Resource Management and Load Balancing in Supply Chain through Integrating Digital Technologies to Enhance Resource

Efficiency and Workload Management in Manufacturing Firms

823

and predictive modeling increase supply chain

performance by balancing workloads. Green digital

technology will help firms meet sustainability goals,

follow environmental laws, and compete (Fiorini et

al., 2022). IoT, AI, and blockchain allow

transparency, monitoring, and predictive

environmental impact assessments. Effective

integration of digital solutions requires workforce

upskilling to enhance decision-making and

productivity (Rodríguez-González et al., 2023).

5 DISCUSSION, CONCLUSION AND

FUTURE SCOPE

This study explores the ways in which digital

technologies can revolutionize resource management

and load balancing within manufacturing supply

chains. The theoretical contributions emphasize the

interplay between digital tools, including Industry

4.0, dynamic capabilities, and enterprise resource

management, in enhancing resource efficiency,

operational resilience, and sustainability. The

findings indicate that these technologies enable

organizations to enhance decision-making, improve

agility, and address challenges related to resource

allocation and workload optimization. The findings

contribute practically by showing that advanced

digital technologies facilitate leaner operations,

enhance sustainability, and bolster resilience against

disruptions, as evidenced by supply chain

competitiveness. This study proposes a conceptual

framework for the adoption of digital technology

aimed at enhancing efficiency and promoting

sustainable practices. This highlights the importance

of connecting sustainable and flexible policies,

offering practical guidance for manufacturers

preparing to thrive in an increasingly unpredictable

supply chain landscape. Further investigation is

necessary to explore the distinct applications and

challenges of digital transformation through sector-

specific studies. An in-depth investigation into the

incorporation of emerging technologies like artificial

intelligence, IoT, or blockchain into supply chain

optimization can provide valuable insights.

Furthermore, one can establish a trajectory for

sustainable and competitive supply chain strategies

globally by examining the effects of digital

transformation over the long term, as well as by

integrating digital transformation to enhance circular

economies and achieve carbon neutrality.

ACKNOWLEDGMENT

“We extend our gratitude to the department of

management studies at Graphic Era deemed to be

University for providing us with the opportunity and

encouragement to conduct this study.” “The contributions

and dedicated engagement were essential to making this

achievement a reality.”

REFERENCES

Rouhani, S., & Deters, R. (2019). Security, performance,

and applications of smart contracts: A systematic

survey. IEEE Access, 7, 50759-50779.

Kesidou, S., & Sovacool, B. K. (2019). Supply chain

integration for low carbon buildings: A critical interdis

ciplinary review. Renewable and sustainable energy

reviews, 113, 109274.

Belhadi, A., Kamble, S. S., Venkatesh, M., Jabbour, C. J.

C., & Benkhati, I. (2022). Building supply chain

resilience and efficiency through additive manufacturi

ng: An ambidextrous perspective on the dynamic

capability view. International Journal of Production

Economics, 249, 108516.

Di Vaio, A., & Varriale, L. (2020). Digitalization in the

sea-land supply chain: experiences from Italy in

rethinking the port operations within inter organization

al relationships. Production Planning & Control, 31(2

-3), 220-232.

Patil, A., Madaan, J., Chan, F. T., & Charan, P. (2022).

Advancement of performance measurement system in

the humanitarian supply chain. Expert Systems with

Applications, 206, 117844.

Trujillo-Gallego, M., Sarache, W., & de Sousa Jabbour, A.

B. L. (2022). Digital technologies and green human

resource management: Capabilities for GSCM adoptio

n and enhanced performance. International Journal of

Production Economics, 249, 108531.

Bui, T. D., Tseng, J. W., Aminah, H., Sulistiawan, J., Ali,

M. H., & Tseng, M. L. (2023). Causality of total

resource management in circular supply chain implem

entation under uncertainty: a context of textile industry

in Indonesia. Annals of Operations Research, 1-41.

Murguia, D., Vasquez, C., Demian, P., & Soetanto, R.

(2023). BIM adoption among contractors: a longitudin

al study in Peru. Journal of Construction Engineering

and Management, 149(1), 04022140.

Noor, Z. Z. (2023). Examining the role and position of the

digital human resource management in economic

development. Економічний часопис-ХХІ, 205(9-10),

39-43.

de Oliveira-Dias, D., Maqueira-Marin, J. M., Moyano-

Fuentes, J., & Carvalho, H. (2023). Implications of

using Industry 4.0 base technologies for lean and agile

supply chains and performance. International Journal

of Production Economics, 262, 108916.

Sugianto, I. M., Pujawan, I. N., & Purnomo, J. D. T.

(2023). A study of the Indonesian trucking business:

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

824

Survival framework for land transport during the

Covid-19 pandemic. International Journal of Disaster

Risk Reduction, 84, 103451.

Rodríguez-González, R. M., Madrid-Guijarro, A., &

Maldonado Guzmán, G.

(2023). Digital organizational

culture and absorptive capacity as precursors to

supply chain resilience and sustainable performance. J

ournal of Cleaner Production, 420, 138411.

Luo, S., Xiong, Z., & Liu, J. (2024). How does supply

chain digitization affect green innovation? Evidence

from a quasi-natural experiment in China. Energy

Economics, 136, 107745.

Fiorini, P. C., Jabbour, C. J. C., Latan, H., de Sousa

Jabbour, A. B. L., & Mariano, E. B. (2022). Green

emerging digital technologies, green supply chains,

and the performance of environmentally friendly

firms: the underpinning role of human resources. IEEE

Transactions on Engineering Management.

Verma, P., Kumar, V., Daim, T., Sharma, N. K., & Mittal,

A. (2022). Identifying and prioritizing impediments of

industry 4.0 to sustainable digital manufacturing: A

mixed method approach. Journal of Cleaner

Production, 356, 131639.

Kandpal, V., Jaswal, A., Santibanez Gonzalez, E. D., &

Agarwal, N. (2024). Sustainable Energy Transition,

Circular Economy, and ESG Practices. In Sustainable

Energy Transition: Circular Economy and Sustainable

Financing for Environmental, Social and Governance

(ESG) Practices (pp. 1-51). Cham: Springer Nature

Switzerland.

Jauhar, S. K., Pant, M., Kumar, V., Sharma, N. K., &

Verma, P. (2021). Supply chain and the sustainability

management: selection of suppliers for sustainable

operations in the manufacturing industry. In Sustainab

ility in Industry 4.0 (pp. 75-93). CRC Press.

Optimizing Resource Management and Load Balancing in Supply Chain through Integrating Digital Technologies to Enhance Resource

Efficiency and Workload Management in Manufacturing Firms

825