Investigation of Mechanical Properties of Concrete by Partially

Replacing Fine Aggregate with Cupola Slag

Ashwin Kumar S., Sona P., Saritha V. and Thomas Eucharist A.

Civil Engineering, KSR College of Engineering, Tiruchengode, Namakkal District, Tamil Nadu, India

Keywords: Slag from Cupola, Strength of Compression, Strength in Tensile, Permeability of Water, Resistance to

Abrasion, Statistical Analysis.

Abstract: Cupola furnaces, which are typically used in foundry industries to melt metals, produce cupola slag, one of

the industrial byproducts Waseem, S. A., et al. (2021). There aren't many studies in the literature that show

cupola slag being used in the making of concrete, and it is underutilized Waseem, S. A., et al. (2021). An

attempt has been made to look into how cupola slag, when utilized in part in the form of a fine aggregate

substitute, affects the mechanical characteristics and concrete's resilience Thakur et al., (2021). Five different

percentages of Cupola slag were utilized to replace fine aggregate: 0%, 10%, 20%, 30%, 40% Veena, N et

al., (2021). Moreover, the Water cement ratio is varied from 0.400 to 0.450 to 0.500 at a consistent 380 kg/m3

cement content Lanjewar, B et al., (2021).At lower water cement ratios are the improvement in strength of

compression was larger. For split tensile strength, similar trends were seen Bhat, S et al., (2022). As the

percentage of replacement cupola (CR) increased from 0% to 40%, a A reduction in the amount of water that

penetrates depth was seen for all curing ages; This decrease was very noticeable at the water cement ratio of

0.4 Meshram, S. S et al., (2024). In a similar vein, all of the aforementioned metrics showed a notable

enhancement in resistance to abrasion in terms of a decrease in the depths of wear Adese et al., (2021). To

validate the experiment's results, strength and durability qualities were correlated Nainwal, A. Both the

"effect" and the "size of effect" of the water cement ratio and CR percentage on the characteristics of concrete

were examined using statistically significant findings using two-way analysis of variance Venkatesan, B et

al., (2021. To demonstrate how CR and w/c ratio affect concrete quality at every age of curing, a quadratic

correlation was created. According to the study's findings, one substance that is sustainable is cupola slag.

That may be applied to partially replace natural sand Sambhaji, Z. K., & Autade, P. B. (2016).

1 INTRODUCTION

In place of natural river sand, a variety of industrial

byproducts have been used, such as waste Concrete is

now a major an aspect of a country’s economic

development worldwide as a result of increased use

brought on by growing industrialization. Recent data

from the US Geological Survey Waseem, S. A., et al.

(2021) shows that 4100 million metric tons of cement

are manufactured annually throughout the world,

corresponding to an approximate yearly consumption

of 27000 million metric tonnes of concrete. Because

it makes about 30–40% of the concrete’s volume, fine

aggregate has significant effect on natural resources.

There are efforts underway to identify substitutes

sources of river sand found naturally for the

construction industry’s future development because

of the shortage of fine aggregates brought on by

ongoing quarrying and rising transportation costs

Waseem, S. A., et al. (2021). To protect natural

resources and create a more sustainable construction

sector, researchers from all over Researchers

worldwide are looking into the possibility of using

solid waste in the manufacturing of concrete Veena, N

et al., (2021). Organic coarse or fine aggregates can be

easily replaced with recyclable industrial waste

products. Slag, a byproduct of the foundry industry, is

one of these sources of fine aggregates Lanjewar, B et

al., (2021). The disposal of slag has become an issue for

the environment due to its large- scale production.

Concrete made with slag instead of natural sand

contributes to a more sustainable environment by

lowering the quantity of waste that ends up in

landfills. Additionally, less energy will be required for

S., A. K., P., S., V., S. and A., T. E.

Investigation of Mechanical Properties of Concrete by Partially Replacing Fine Aggregate with Cupola Slag.

DOI: 10.5220/0013920000004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 4, pages

733-740

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

733

the extraction or refinement of aggregates, thus

reducing the quantity of greenhouse gases discharged

into foundry sand, copper slag, and slag from electric

arc furnaces Meshram, S. S et al., (2024) the atmosphere.

Because of their underutilization, these leftovers are

usually disposed of at waste disposal sites. Cupola

slag is a manufacturing byproduct that might be used

to partially replace aggregate in concrete. In foundry

industries, among the cupola furnaces are common

tool for melting materials like cast iron and bronze. A

cupola furnace produces roughly 50 kg of slag for

every ton of molten metal Adese et al., (2021). Only a

small amount of study has been published in the

research on the viability of substituting for some or all

of the cupola slag the cement or aggregates in concrete

Nainwal, A. The possible combination of cupola slag

and blast furnace as an alternative to coarse aggregates

entirely in the production of concrete was investigated

by Baricova and associates Venkatesan, B et al., (2021).

Examined the potential for replacing coarse particles

entirely in the manufacturing of concrete using cupola

slag and blast furnace slag. These concretes are said to

be suitable for the middle sections of framed structures

as well as the base or leveling layers and foundation

of buildings. Granulated cupola slag was used by

Arum and Mark Saravanakumar, A et al., (2019) to

create low permeability concrete. A 31% increase in

compressive strength was seen when 15% cupola slag

was substituted for cement. According to them,

concrete’s porosity dropped, indicating that it is

suitable for hard environmental conditions were

minimal Permeability is necessary.

When Alabi and Afolayan Sambhaji, Z. K., &

Autade, P. B. (2016) looked into how Slag from a

granulated cupola furnace affected the concrete’s

mechanical characteristics, they discovered that it

marginally improved compressive strength. Alabi and

Mahachi Velumani, M (2023) discovered that at all

higher temperatures, the compressive strength of

concrete mixed with slag from a cupola furnace was

superior to that of regular concrete. Cupola slag was

added in different amounts up to 12% to create high-

performance concrete, according to Thomas and

associates. The mechanical properties were said to

have improved by 10%. Primulova et al. conducted A

thorough investigation on the characteristics and uses

of slag from cupola boilers Kaish et al., (2021). They

concluded that the building industry may considerably

profit from the usage of cupola slag, pointing out that

it is completely underutilized in several countries.

Thomas et al. conducted a thorough experimental

program that included microstructural

2haracterization and assessment of the powder’s

mechanical and fresh properties Rajasekar, A et al.,

(2019) investigated whether cupola slag powder

might be used in mortars. 20% cupola slag was found

to be the optimal percentage of cement substitution,

and the resulting mortars were shown to have

improved mechanical and durability attributes. Sosa et

al. conducted experimental study with cupola slag

powder up to 30% in place of cement to examine the

feasibility of using it as a binder instead of cement.

Chakravarty and associates carried out a

comprehensive investigation into the possible uses of

cupola slag Afolayan et al., (2022). Except for of a

little amount utilized in the construction sector to

replace cement and fine and coarse stones, they

concluded that cupola slag has no purpose

whatsoever.

2 MATERIALS AND METHODS

The materials utilized for a project that looks at the

mechanical qualities of concrete with the use of cupola

slag instead of some of the fine aggregate include both

conventional and specialty components. In concrete,

cement, usually Ordinary Portland Cement, or OPC is

the main binding agent that promotes hydration and

strengthens the mixture. Cupola slag partially replaces

fine aggregate natural river sand or crushed stone

sand, a byproduct that is collected during iron casting.

The replacement is proposed to study the impact of

cupola slag on the mechanical and sustainability

properties of concrete. In this study, the coarse

aggregate (crushed stone/gravel) is used as

recommended and not replaced. The quantity and

quality of water, which is used in cement hydration

and workability control, are strictly controlled. In

some cases, the addition of superplasticizer can be

added into the mixture to overcome the consistency

change of concrete due to cupola slag. To improve

strength and durability over time, fly ash or other

pozzolanic minerals may also be added as optional

ingredients. Additives like accelerators or retarders

could also be used to optimize curing conditions and

regulate the setting time Mounika et al., (2024). A

number of concrete combinations designed to

evaluate the effects of slag cupola on workability,

mechanical functionality along with environmental

sustainability are based on the combination of these

components. The concrete mixtures were designed in

accordance with IS 10262. Three control concrete

mixes in all with 0.40, 0.45, and 0.50 water cement

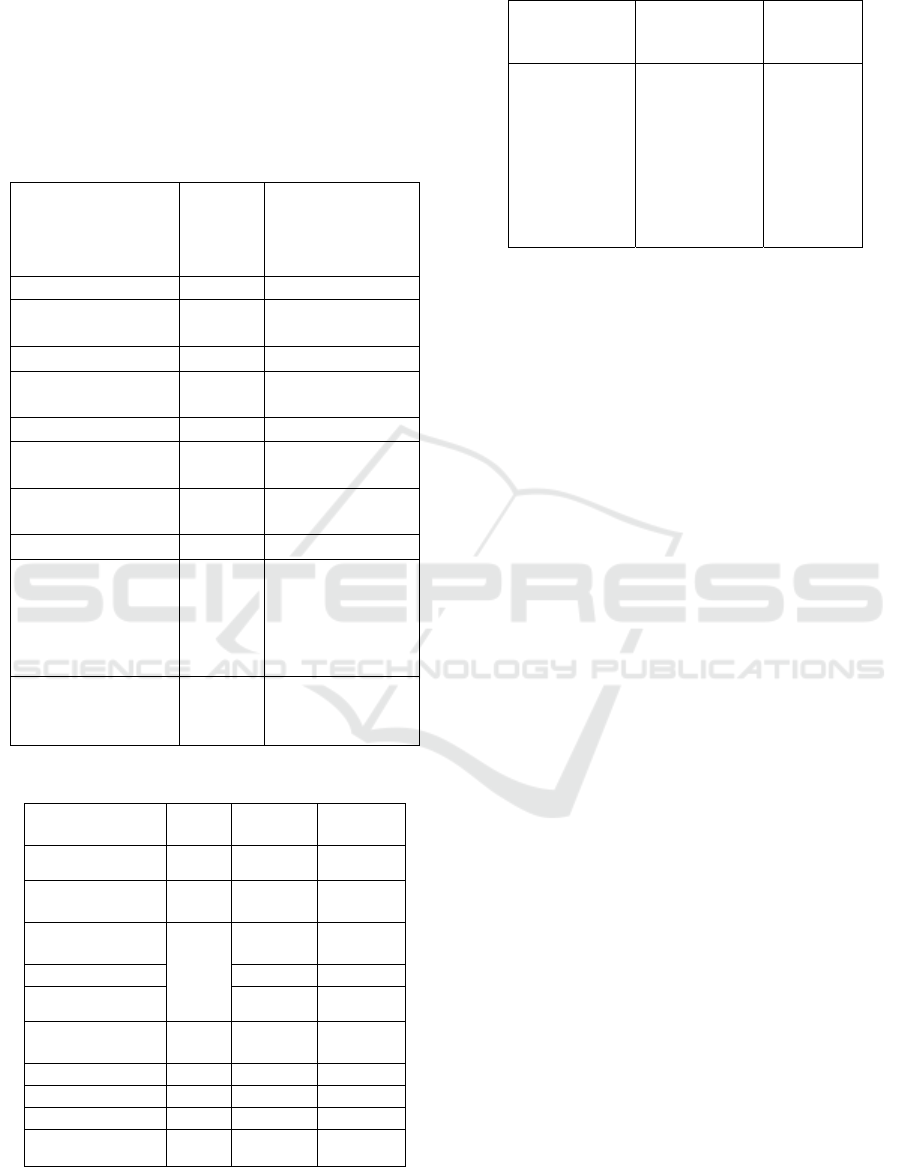

ratios were produced. Table 1. Shows the Chemical

Composition of Cupola Slag and Comparison with IS

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

734

8112 Standard Limits. Table 2. Shows the Cement's

physical characteristics. Table 3. Shows the

Aggregate's physical characteristics.

Varying proportions of cupola furnace slag (10%,

20%, 30%, and 40%). Table 6 provides information

about each concrete combination.

Table 1: Chemical composition of cupola slag and

comparison with is 8112 standard limits.

Chemical

composition

Test out

(%)

(%) Restrictions

outlined in IS

8112

[20] (%)

(SiO2)Silica 22 –

Ferric,or oxide

(Fe2O3)

3.3 –

(Al2O3)Alumina 5.4 –

Calcium,or oxide

(CaO)

61.2 –

(MgO)Magnesia 3.4

≤6.5

Anhydride of

sulfur (SO3)

1.44

≤3.4

Insoluble The

residue

1.4

≤4.3

Ignition Loss 2

≤5.5

Ignition Alkali

content loss due to

insoluble residues

in terms of Na2O

K2O

0.43

≤0.6

Ratio of

Al2O3/Fe2O3

1.52

0.81

≥0.66

≥0.66 &

≤

1.03

Table 2: Cement's physical characteristics.

Property Units

Test

result

Limiting

values

Soundness Mm 1.6

≤10.6

Relative

densit

y

_ 3.19 3.15

Minutes of

setting time

First time 93

≥30

Last time 400

≤600

Strength of

compression

MPa

3 days

7 days 24.1

≥23

28 days 34.2

≥33

44.2

≥43

Table 3: Aggregate's physical characteristics.

Physical

attributes

Coarse-

grained

material

Fine-

grained

material

Relative

density

Water

absorption

(%) Color

Zone

2.67

1.3

Grey

_

2.66

2.5

_

I

I

The proportions of the corresponding mix containing

cupola slag as fine aggregates were intended to be

partially replaced using the DWR approach, or direct

weight replacement, has been applied in the literature

for circumstances where materials with varying

specific gravities are swapped out for one another.

During this process, the amount of weight that each

ingredient contains remains constant, with the

exception of the material that needs to be changed, in

this case fine aggregate. Since its specific gravity

(2.65) is larger compared to cupola slag (2.45), fine

aggregate quantities are reduced in the current study to

get identical volumetric output. This is due to the fact

that cupola slag and fine aggregate with similar

weights may take up various quantities depending on

the specific gravity. Very little volumes of

superplasticizer were used to generate the mixtures,

which had a consistent slump of 75 ± 10 mm. A

traditional concrete mixer with a 300-liter rotating

drum was utilized to thoroughly mix all of the

ingredients. Every sample was castat the standard

temperature. Three layers of the samples were cast to

guarantee adequate compaction and the elimination of

air gaps. For 7, 28, and 56 days, the concrete samples

were demolded and allowed to moisten after a 24-hour

casting time Gupta and Bakshi (2023).

3 STATISTICAL ANALYSIS

3.1 Mechanical Characteristics

Testing the concrete's mechanical characteristics is

crucial to ensure that it performs well and is safe for

use in construction. Several common tests are used to

evaluate how concrete behaves under different

conditions .The test for compressive strength is the

most commonly utilized, in which cubes of concrete

or cylinders are pressed until they break. This

Investigation of Mechanical Properties of Concrete by Partially Replacing Fine Aggregate with Cupola Slag

735

measures the concrete's ability to withstand crushing

forces. The tensile strength test checks how well

concrete can resist stretching or pulling apart, often

using a split cylinder method where a concrete

cylinder is cracked by pressure. The flexural strength

test is used to measure how concrete bends or resists

breaking when subjected to bending forces, usually

by placing a beam on supports and applying pressure

in the middle Venkatesan, B et al., (2021) and

Saravanakumar, A et al., (2019).

The elasticity modulus test measures Concrete's

stiffness, or how much it will bend under pressure.

Rebound hammer tests are a quick way to check the

surface strength of concrete without damaging it,

using a tool that bounces back after hitting the surface,

giving an estimate of its strength. Not only strength,

but concrete's durability is also put to the test. The

water absorbtion test measures the amount of water

absorbtion of the concrete, while the chlorid

penetration test checks if harmful chemicals can

penetrate the concrete and create damage to the

concrete in aggressive environments. Engineers use

these tests to ascertain how strong and flexible and

how resilient to the ravages of time concrete will be,

to ensure that it is safe and appropriate to be used in

a construction project Waseem, S. A and Lanjewar, B

(2021).

3.2 Durability Properties

How resistant it is to damage and strength when

exposed to various environmental conditions over

time is the durability of concrete. DIY-2 Concrete:

The Good, The Bad, the Ugly Concrete can be

susceptible to hitting water, chemicals, and extreme

weather, plus things that can weaken it. One

important thing is water resistance concrete has to

keep the water out, water coming in can crack the

concrete, rust the steel within. Freeze-thaw resistance

is also critical in cold climates where water that

becomes trapped inside concrete can freeze and

expand, cracking it.) Concrete also has to be resistant

to chloride ions, which can be found in seawater or

de-icing salts and will attack the steel reinforcing rods

inside. In places where soil or water has high sulfates,

concrete must be resistant to that attack that can cause

it to expand and crack. A second problem is

carbonation, which occurs when carbon dioxide from

the air interacts with the concrete, reducing its ability

to protect the internal steel Sambhaji, Z. K (2016)

and Velumani, M et al., (2023).

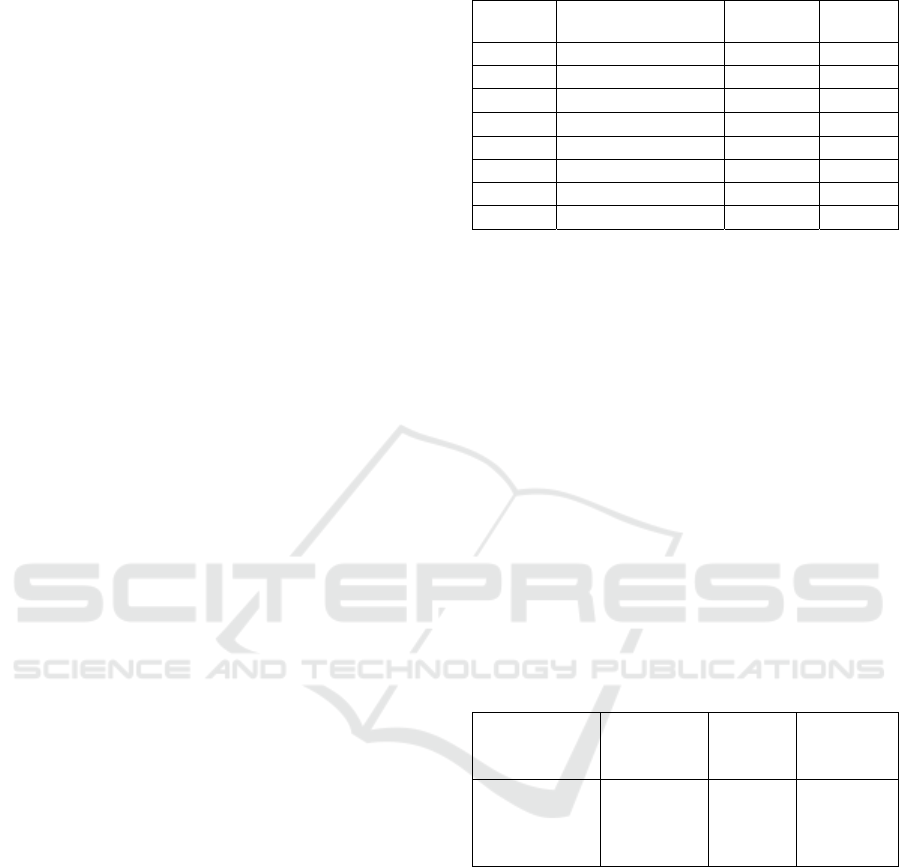

Table 4: Chemical composition of slag examples.

Compou

nds

Weight of Jalandhar

Slag (%)

Slag in

Ludhiana

Slag in

Batala

MgO 8.97 4.81 7.32

Al

2

O

3

16.01 8.78 12.61

SiO

2

47.06 23.56 48.20

SO

3

0.39 – 0.13

K

2

O

1 – 1.33

CaO 12.10 17.59 15.02

Feo 16.51 5.32 16

CO

2

43.61

Alkali-aggregate reaction can also happen when

certain aggregates react with the cement, causing

cracks. Abrasion resistance is important for concrete

exposed to wear, like floors or roads, to prevent

surface damage. Concrete must also resist chemical

attacks from substances like acids or oils, which can

break it down. Shrinkage and expansion are natural

changes that happen as concrete dries or absorbs

moisture; if they’re too severe, they can cause cracks.

Lastly, corrosion resistance is essential to protect the

steel reinforcement inside concrete, especially in

areas with water or aggressive chemicals. Testing

these durability properties helps ensure concrete lasts

longer, especially in harsh conditions, and reduces the

need for repairs, making buildings and structures

safer and more reliable. Table 4. Shows the Chemical

composition of slag examples. Table 5. Shows the

Physical Properties of slag samples.

Table 5: Physical properties of slag samples.

Physical

Property

Values

obtained

Jalandha

r

Ludhiana

Batala

Slag

Specific

gravity Water

absorption

Colo

r

2.22

1.51%

Light Grey

1.75

1.62%

Light

Gre

y

2.46

1.46%

Dark black

4 RESULT

4.1 Strength of Compression

The results of each cube specimen's strength of

compression evaluation after 7, 28, and 56 Days are

displayed. All concrete mixes received the include

cupola slag, which increased the strength of

compression by up to 30% when fine particles were

replaced. Then, as additional cupola slag was added to

the concrete mixtures, a decrease in strength was seen.

For example, substituting 10% cupola slag for fine

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

736

aggregates following seven days of curing, yields

increases in strength of compression of 15.76%,

14.12%, and 1.93%, respectively. These increases

correspond to 0.40, 0.45 and 0.50 water-binder

ratios.A 20% replacement of slag from cupola

furnaces for fine aggregates may result in

Compressive strength growth of the corresponding

w/c ratios were 20.40, 0.5, and 13.9%, 21.97%, and

24.22%. Furthermore, increases using w/c ratios of

0.40, 0.45, and 0.50, respectively, with compression

strengths of 30.08%, 27.81%, and 29.11%-occur

When using cupola slag instead of fine aggregates by

30%. Strength was then shown to diminish with the

addition of more cupola slag.

Table 6: Proportions of the mixture for different water-to-cement ratios and cupola replacement percentages.

Cupola

Replacement

ratio (%)

w/c

ratio

Water

(kg/m3)

Cement

(kg/m3)

Fine

aggregate

(kg/m3)

Coarse

aggregate

(10mm-20mm)

(

k

g

/m3

)

Coarse

aggregate

(4.75mm-

10mm

)

(

k

g

/m3

)

Cupola

slag

(kg/m3)

0 0.5 190 380 650 700 420 -

10 0.5 190 380 579 700 420 66

20 0.5 190 380 508 700 420 131

30 0.5 190 380 440 700 420 196

40 0.5 190 380 370 700 420 260

0 0.45 171 380 671 710 426 -

10 0.45 171 380 599 710 426 68

20 0.45 171 380 525 710 426 132

30 0.45 171 380 453 710 426 201

40 0.45 171 380 380 710 426 268.4

0 0.4 152 380 695 730 438 -

10 0.4 152 380 620 730 438 69.6

20 0.4 152 380 545 730 438 138

30 0.4 152 380 470 730 438 208.4

40 0.4 152 380 394 730 438 279

4.2 Split Tensile Strength

The correlation between cupola replacement (CR)

percentages and split tensile strength for different

curing ages and w/c ratios. Table 4 shows that Slag

from cupola furnaces is up to 30% replaced with fine

aggregates replacement only as the concrete's

increased split tensile strength. For every concrete

mix utilized in this investigation, this is generally the

case. There's a noticeable reduction in the split tensile

strength. When using cupola slag instead of 10% of

fine aggregates at a curing age of seven days, for

instance, the tensile strength increases by with w/c

ratios of 0.40, 0.45, and 0.50, respectively, of 11.11%,

8.75%, and 3.94%. Likewise, for 20% and 30%

cupola slag replacement levels with fine aggregate,

respectively, tensile strength rose by 31.48%, 22.91%,

19.73%, and 32.09%, 30.41%, and 22.8% for the

previously stated w/c ratios. That pattern is almost

exactly the same as the compressive strength

numbers. It is also clear that the rate of growth in

compressive strength is Situated a little above the rate

of rise in Tensile strength of split for lower ratios.

The reactive properties of cupola slag are

responsible for this increase in tensile strength. which

strengthen the connections among the particles in the

ITZ. Split tensile strength is comparable to

compressive strength seen to decline as cupola slag

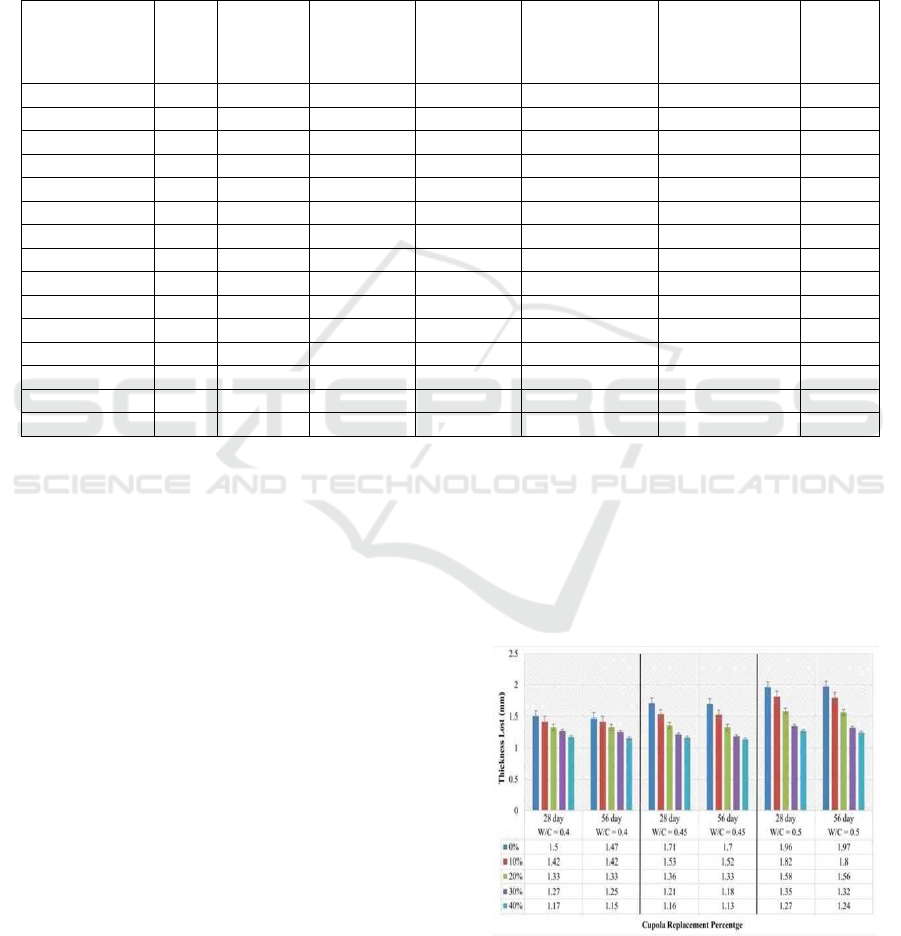

additions go over 30%. Figure 1 Shows the Effect of

Cupola Replacement Percentage on Thickness Loss at

Different Water-Cement Ratios and Curing Periods

Figure 1: Effect of Cupola Replacement Percentage

on Thickness Loss at Different Water-Cement Ratios

and Curing Periods.

Investigation of Mechanical Properties of Concrete by Partially Replacing Fine Aggregate with Cupola Slag

737

4.3 Water Permeability

This study examines the effects of adding cupola slag

to concrete in place of some of the fine sand on the

material's strength and durability. Using cupola slag,

a byproduct of the manufacturing of iron, in concrete

can help cut waste and increase sustainability. In the

project concrete cubes are prepared by replacing the

ordinary sand with various percentage of cupola slag

(5%, 10% & 15%). The compressive strength of the

cubes is tested at different periods (7, 14, and 28 days)

to assess the durability of the concrete. In addition,

to determine the water resistance of the concrete, a

water permeability test is conducted that is important

for durability. Other testing methods, like stress

testing of the concrete and examining the tensile

strength and elasticity of the concrete, provide insight

into the performance of the concrete as a whole. The

study aims to determine whether cupola slag can be

used as a partial sand replacement in concrete to

improve concrete durability and mechanical

properties and to decrease its environmental impact.

4.4 Abrasion Resistance Test

Therefore, a study was carried out using cupola slag,

an iron-producing residue, to investigate the

properties of concrete. Different proportions (5%

10% and 15%) of cupola slag are used with the

concrete. and tested for its mechanical properties the

cube test assesses slag influence on strength over

time by determining compression strength at the 7th,

14th, and 28th day. The abrasion resistance Examine

was designed to simulate difficult or busy

atmospheres to evaluate how good the concrete deals

with surface area damage. It aims to serve as a better

alternative to conventional materials by assessing

whether cupola slag has an impact on the advantages

of concrete such as strength, durability, and

sustainability. (Bakshi 2019)

4.5 Discussion

The regression analysis reveals insights into the

compressive strength and split tensile strength of

concrete at different curing periods, influenced by the

water-cement ratio and varying levels of cupola

replacement. For compressive strength, the R² value

observed at 7 days is 0.864, indicating a strong

correlation between the variables and the strength

outcome. After 28 days, the compressive strength

shows a slightly lower R² value of 0.743, reflecting

moderate predictability. At 56 days, the compressive

strength shows improvement, with an R² of 0.811,

suggesting an enhanced level of correlation over time.

The split tensile strength values are detailed

across several model evaluations. One model lists an

intercept value of 57.376 with a cupola replacement

coefficient of 48.156. Another model presents

coefficients of -99.383 and -78.521 for the intercept

and cupola replacement, respectively. In subsequent

models, the intercepts and cupola coefficients vary:

48.820 and 52.775 in one, and -108.787 and -45.110

in another. A more comprehensive regression

includes an intercept of 72.076, with cupola

replacement values of 55.941 and -121.691, and a

water-cement ratio coefficient of -85. The associated

standard errors are also reported—5.585 and 4.385

for the first model, followed by 5.095 and 11.321.

Another model lists errors of 27.125 and 11.124, then

5.776 and 12.826, and later 30.745 and 12.600.

The t-values and p-values correspond to the

respective models. For example, t-values of -3.661

and -7.058 are paired with p-values of 0.00000024

and 0.00135872. Another model includes t-values of

-3.534 and 10.646, with p-values of 0.00374134 and

0.00002100. Additional models show values like -

3.376 and -6.738 (t-values), and p-values of

0.00000387 and 0.00172665. For 7-day split tensile

strength, the R² remains 0.743. This trend continues

across 28-day and 56-day split tensile strength

measurements, both maintaining R² values of 0.743.

Water permeability results are also consistent

across durations. At 28 days, water permeability has

an R² value of 0.743, and the same is observed at 56

days. In terms of abrasion resistance, the analysis at

28 days includes coefficients like 8.453 for the

intercept and -7.881 for cupola replacement. A more

complex model includes values of 4.526, 4.478, -

9.072, and -4.550 for the intercept and other

parameters. Another includes 4.448, 3.835, -7.951,

and -3.860. The standard errors range from 0.473 to

35.600 across models.

T-values and p-values for abrasion resistance are

similarly documented. For example, values include -

3.488 and -4.278 with associated p-values of 0.024

and 0.016, while another model notes values such as

-2.466 and -2.909, with p-values of 0.04303907 and

0.00000144. These results again suggest strong

statistical significance.

Finally, for abrasion resistance at 56 days, the

water-cement ratio becomes more influential. The

model includes an intercept of 2.580 and coefficients

of 0.564, -1.410, and 2.540 for cupola replacement

and water-cement ratio. The standard errors for this

model are 0.054, 0.026, 0.017, and 0.058. The p-

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

738

values recorded for these variables are 0.00043216,

0.05476431, 0.00000235, and 0.00091579

respectively, reinforcing the statistical significance of

the model. The R² value for this 56-day abrasion

resistance model also remains at 0.743, suggesting

consistent reliability across the study's models.

5 CONCLUSIONS

This study examined the effects of substituting cupola

slag for some of the sand in concrete on the material's

strength. The findings demonstrated that adding up to

30% slag in place of sand strengthened the concrete.It

also improved how well the concrete resists pulling

forces, but not as much as it did for pressure. The

concrete was a little harder to mix because the slag

particles are rough, but this can be fixed by adding

more water or special chemicals. Using cupola slag is

also good for the environment because it helps recycle

waste and lowers the cost of concrete. It may also

make the concrete last longer. The best results were

seen when 20-30% of the sand was replaced, but using

too much slag could make the concrete weaker. In the

end, using cupola slag in concrete can make it stronger

and more affordable while being better for the

environment, but more studies are needed to see how

it holds up over time.

REFERENCES

Adese, A. J., Olajide, O. D., & Olaoyenikan, O. A. (2021).

Properties of concrete made from cupola furnace slag

and recycled construction aggregates. Retrieved from

(Website)

Afolayan, J. O., & Alabi, S. A. (2013). Investigation on the

potentials of cupola furnace slag in concrete. Retrieved

from Fedorov, P., & Sinitsin, D. (2022). Alkali-

activated binder based on cupola dust of mineral wool

production with mechanical activation. Retrieved from

https://www.mdpi.com/2075-5309/12/10/1565

Bhat, S., Sood, H., & Waseem, S. A. (2022). Recycling

cupola slag in concrete as partial replacement of fine

aggregate for sustainable construction. International

Journal for Research in Applied Science & Engineerin

g Technology. Retrieved from https://www.ijraset.com

/research-paper/recycling-cupola-slag-in-concrete-as-

partialreplacement-of-fine-aggregate

Dos Anjos, M. A. G., Sales, A. T. C., & Andrade, N. (2017).

Blasted copper slag as fine aggregate in

Portland cement concrete. Retrieved from https://www

.sciencedirect.com/science/article/abs/pii/S030147971

7302475

Gupta, A., & Das, P. (2023). Impact of cupola blast furnace

slag on mortar and concrete M20. Retrieved from

https://seyboldreport.net/pdf/2023/05/13.pdf

Kaish, A. B. M. A., Odimegwu, T. C., Zakaria, I., & Abood,

M. M. (2021). Effects of different industrial waste

materials as partial replacement of fine aggregate on

strength and microstructure properties

of concrete. Retrieved from https://www.sciencedirect

.com/science/article/abs/pii/S2352710220337244

Lanjewar, B., Jayan, N., Chaware, A., Kondawar, S.,

Chippagiri, R., Dakwale, V., & Ralegaonkar, R. (2021).

Effect of cupola slag as a coarse aggregate on

compressive strength of concrete. Retrieved from

https://www.sciencedirect.com/science/article/abs/pii/

S2214785323021107

Meshram, S. S., Raut, S. P., Giri, J., Sathish, T., Khan,

S., & Giri, P. (2024). Physico chemical characterizatio

n of cupola slag: Enhancing its utility in

construction. Retrieved from https://www.researchgat

e.net/publication/382941729_Physicochemical_charac

terization_of_cupola_slag_Enhancing_its_utilit

Mounika, G. V. V., & Ramesh, B. (2024). Experimental

investigation of M35 grade self-compaction concrete

by using bagasse ash as a partial replacement of cement

and cupola slag with coarse aggregate.

Retrieved from https://doi.org/10.22214/ijraset.2024.6

5828

Nainwal, A. (n.d.). Mechanical and durability properties of

concrete made by replacing copper slag with fine

aggregates: A review. Retrieved from https://www.ijea

st.com/papers/33-39,Tesma308,IJEAST.pdf

Patil, A., & Kapure, H. (2023). Durability and microstruct

ure analysis of cupola replacement in fine aggregate

and reinforced graphene oxide. Retrieved

from https://assetseu.researchsquare.com/files/rs30708

56/v1/bc8c08d672e447f8bbc353d74ba2ecbc.pdf?c=16

91144551

Rajasekar, A., Arunachalam, K., & Kottaisamy, M. (2019).

Assessment of strength and durability characteristics of

copper slag incorporated ultra-high

strength concrete. Retrieved from https://www.scienc

edirect.com/science/article/abs/pii/S095965261833134

2

Sambhaji, Z. K., & Autade, P. B. (2016). Effect of copper

slag as fine aggregate on properties of

concrete. Retrieved from https://www.irjet.net/archive

s/V3/i6/IRJET-V3I675

Saravanakumar, A., Krishna, B., Ponsanthosh, G., &

Krishnan, K. N. (2019). Suitability of concrete by using

cast iron slag and cupola slag as partial replacement of

fine and coarse aggregate: A critical

review. Retrieved from http://hbrppublication.com/OJ

S/index.php/JACCT/article/view/752

Thakur, K. K., Shafeeq, M. M., Rahman, A., & Mondal, D.

P. (2021). Effect of sintering temperature and binder

addition on the properties of cupola slag

glass ceramic tiles. Retrieved from https://link.springe

r.com/article/10.1007/s13762-021-03755-8

Investigation of Mechanical Properties of Concrete by Partially Replacing Fine Aggregate with Cupola Slag

739

Veena, N., Chaithra, C. V., Kaveri, Yadav, B., & Goudar,

S. S. (2021). Experimental investigation on properties

of concrete by partial replacement of bagasse ash with

cement and cupola slag with coarse aggregate.

International Journal of Engineering

Research & Technology. Retrieved from https://www.i

jert.org/research/experimentalinvestigation on properti

esofconcretebypartial replacementof bagasseashwithce

mentand cupolaslagwithcoarseaggregateIJERTV10IS0

80098.pdf

Velumani, M., Gowtham, S., Dhananjayan, M. P., &

Eniyan, G. T. (2023). Strength assessment of concrete

with copper slag as fine aggregates. Retrieved from

https://www.sciencedirect.com/science/article/abs/pii/

S2214785323033527

Venkatesan, B., Lijina, V. J., Kannan, V., & Devasena, P.

R. (2021). Partial replacement of fine aggregate by steel

slag and coarse aggregate by walnut shell in

concrete. Retrieved from https://www.sciencedirect.co

m/science/article/abs/pii/S2214785320354717

Waseem, S. A., Thakur, N., Islam, S. U., Kumar, M., &

Saini, J. S. (2021). Cupola slag as partial replacement

of fine aggregate in concrete – An experimental

study. Retrieved from https://www.sciencedirect.com/

science/article/pii/S2352710221012018

Waseem, S. A., et al. (2021). Cupola slag as partial

replacement of fine aggregate in concrete–An

experimental study. Journal of Building Engineering.

Retrieved from https://www.sciencedirect.com/scienc

e/article/pii/S2238785423004106

Waseem, S. A., et al. (2021). Cupola slag as partial

replacement of fine aggregate in concreteAn experime

ntal study. Journal of Building Engineering, 44. Retrie

ved from https://paperpile.com/c/lwdH3z/sgUZ

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

740