Inspection of Materials Dimensions Using Webcam in the Conveyor

System

Krishna Kumar M., Siddharth N., Soundara Rajan V. and Venkatachalam G.

Department of Mechanical Engineering, K.S. Rangasamy College of Technology, Tiruchengode, Tamil Nadu, India

Keywords: Material Detection, Dimension Measurement, Conveyor System, Machine Learning, Embedded Systems.

Abstract: Measuring material dimensions in real time is a crucial component of the technological industry revolution.

In industrial applications, the ability to discern material and its dimensions from pictures and videos may be

highly valuable. Conveyor systems are used to transfer most materials in industries. In a conveyor system,

material identification and dimensioning is a particularly challenging task. Every day, scientists and engineers

put a lot of effort into developing machine learning and deep learning algorithms that will enable robots to

comprehend and learn, outperforming humans at tasks. The machine learning model used to detection of

material and its dimension from the pictures. The raspberry pi and pi camera used to capture the high-quality

picture of the material on the conveyor system. The machine learning model build with help of python

programming language. The material image taken from the conveyor system using webcam and processed

through the image processing library like OpenCV and TensorFlow. The embedded system techniques and

machine learning approaches are playing important role in this concept. The existing techniques for detecting

materials and their dimensions in a variety of industrial applications are the main topic of this review article.

The techniques and their achievements are compared.

1 INTRODUCTION

Conventional materials science research mostly relies

on the expertise of lone specialists. Developing new

scientific theories and expanding our understanding

of the physical world are two areas in which expert

knowledge is extremely valuable. But when it comes

to forecast efficiency and accuracy, the conventional

expert knowledge technique is obviously limited.

Technological advancement frequently necessitates

the development of new materials with certain

qualities, yet it might take a long study cycle to learn

enough about a single material system. Data volume,

speed, and complexity are all rising as a result of

improvements in experimental and computational

techniques. Xiaoting Zhong, et al, 2022 However, a

human expert can only analyse so much data at once.

In order to create better materials more quickly, new

research instruments are required.

As the title states itself the method is used to

measure the real time dimension of a material in the

conveyor system for industrial application. It is a very

hot and trending topic in the field of computer

science.the importance of object detection and

tracking for material dimensions is increasing in

various industrial and autonomous mobile system

applications. The widespread applications of machine

learning and computer vision have significantly

impacted research. Currently, most standalone

systems come equipped with vision sensors or

cameras. As a result, mobile device localization and

navigation depend on knowing the size and distance

of objects in the immediate environment. Gokulnath

Anand and Ashok Kumar Kumawat, 2021 Currently,

machine vision applications find extensive utilization

across various domains, including robotics, conveyor

belt speed measurement, displacement systems, and

fish length measuring.

Lan Fu, et al, 2022 Convolutional neural networks

(CNNs)-based deep learning has recently greatly

improved object-detection accuracy in photos saved

in the.jpg, .jpeg, and.png formats. Many attempts

have been made to apply this achievement to photos

from the field of materials science by utilizing CNNs

to identify the material's dimension in the image.

Thus, using machine learning approaches, this

study examines material dimension inspection

methods for industrial manufacturing. It goes over

how to take a material picture using an embedded

system application. The theoretical foundation of

234

M., K. K., N., S., V., S. R. and G., V.

Inspection of Materials Dimensions Using Webcam in the Conveyor System.

DOI: 10.5220/0013911100004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 4, pages

234-241

ISBN: 978-989-758-777-1

Proceedings Copyright © 2026 by SCITEPRESS – Science and Technology Publications, Lda.

machine learning for material dimension

identification is briefly described in section 2. The

section 3 introduces a comprehensive examination of

both machine learning and deep learning models used

for the identification of materials and their

dimensions. In Section 4, the outcomes of diverse

both machine learning and deep learning models are

juxtaposed, utilizing operational parameters. The

study concludes in Section 5, followed by an

exploration of prospects.

2 MATERIAL DIMENSION

INSPECTION

2.1 Material Inspection and Detection

Based on Raspberry Pi and

Machine Learning Algorithm

Talha Bayrak et al., (2021) established TensorFlow,

OpenCV, and Brachio Graph libraries in combination

with a hardware-created drawing machine to

recognize and draw objects. We accomplished this by

using image processing to distinguish things and

sketching them in the Raspberry Pi environment.

Using the TensorFlow and OpenCV libraries, the

software component recognized objects. The

processed pictures were vectorized using the Brachio

Graph library, and servo motor drawing experiments

were carried out. The servo motor type and tuning

changes were determined to be significant. The

Brachio Graph library's calibration parameters can be

fine-tuned for best results. During the test phase of

this investigation, the objects were effectively

identified, and drawings of the things were created

using servos.

Gokulnath Anand and Ashok Kumar

Kumawat., (2021) designed an object detection and

tracking system utilizing the Raspberry Pi camera for

digital imagery in both computer and robot vision

applications. The system comprises the Raspbian

operating system, Python, and the OpenCV platform,

all integrated to capture images through the Pi

camera. This project addresses a burgeoning research

area aiming to develop techniques assisting

computers in acquiring and understanding

information from digital images, encompassing

movies and photographs. Specifically, the system

employs object detection, a computer vision approach

enabling the identification and pinpointing of objects

in both images and videos. The implementation

utilizes an efficient shape-based object detection

method, achieving real-time displacement through

the OpenCV programming library, Designed

specifically for computer vision applications, the

Raspberry Pi comes equipped with a camera module.

Varun Sai et al., (2023) Deep learning has

dramatically improved the speed and accuracy of

object identification algorithms. DL allowed for very

accurate real-time object identification in current

desktop PCs, as well as object detection utilizing the

Raspberry Pi 3. Real-time object identification

necessitates a significant amount of computing

power, and reaching real-time speed is challenging in

a system with restricted capability. Detecting things

may be accomplished using a variety of techniques.

Two methodologies were employed on the Raspberry

Pi 3 B to assess their compatibility with limited

hardware capabilities. The suitability of a deployed

target detector hinges on achieving a sufficiently high

resolution and frame rate for practical use in real-

world applications. This approach involves

evaluating parameters such as frame rate, accuracy,

and response time.

Siddharth et al., (2018) Utilizing OpenCV, we

amalgamated various components to formulate a

program centered on Raspberry Pi for object

recognition and tracking. The program encompasses

two primary functionalities: Monitoring and

identifying objects. The outcome of this endeavor is

a Python software designed for Windows that is adept

at identifying and tracking objects through the

analysis of Values for Hue, Saturation, and Intensity

(HSV) extracted from frames captured by the

Raspberry Pi camera module.

Muhammad Sabih et al., (2023) optimal settings

have been determined through the analysis of material

flow rates on a conveyor belt, ensuring the automated

preservation of the desired raw material ratio. A sight

sensor strategically placed on the conveyor belt

accurately gauges the rate at which raw materials

flow. The identified area of interest is further refined

through a voting-based segmentation method,

isolating the region exhibiting the highest level of

confidence. Machine learning algorithms, leveraging

moment and contour information, are then employed

to predict flow rates across multiple trials. A

comprehensive evaluation of various techniques

yields compelling results, with the Bagging regressor

employed with optimal parameters on the final data

split.

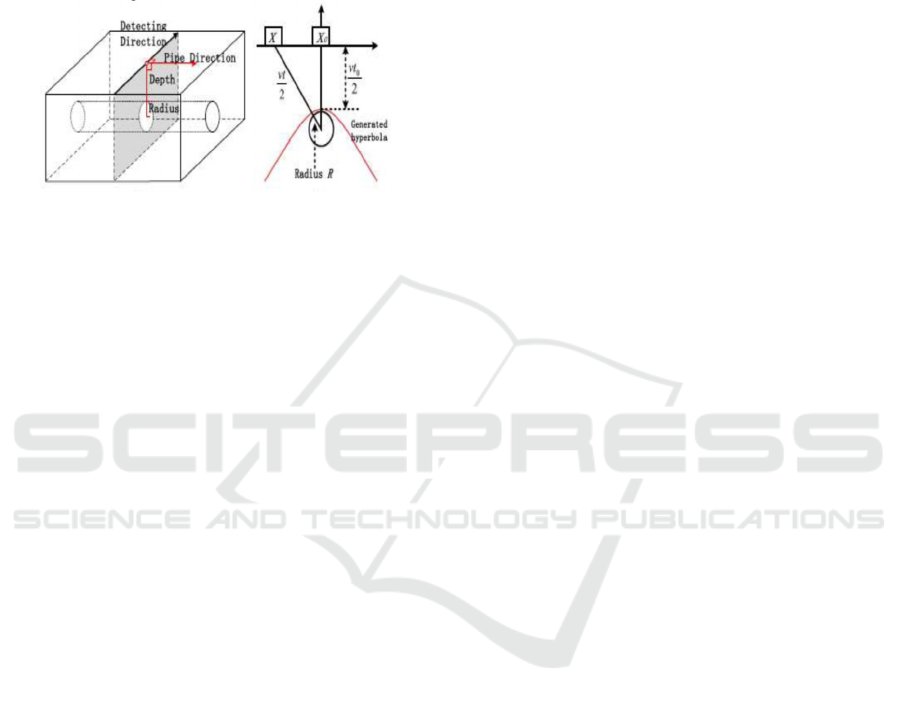

Mohd Shuhanaz et al., (2023) Suggested GPR

data analysis using a machine learning system to

reduce labor. In the process for identifying material

dimensions, A structured approach is presented for

categorizing the dimensions of subterranean metallic

pipes. This methodology incorporates the utilization

Inspection of Materials Dimensions Using Webcam in the Conveyor System

235

of Histogram of Oriented Gradient (HOG) as a

feature extraction method. The investigation

encompasses the examination and creation of a back

propagation neural network and Support Vector

Machine (SVM) for the purpose of classifying

underground metallic pipes, yielding a notable

accuracy rate of 98%. The figure 1 shows Directions

of GPR scanning.

Figure 1: Directions of GPR scanning.

Xiaoting Zhong Et Al., (2021) Because of their

high accuracy, machine learning models are rapidly

being applied in materials research. The most precise

machine learning models, on the other hand, are

typically difficult to describe. Solutions to this

difficulty can be found in explainable artificial

intelligence (XAI). The interpretability of complex

machine learning models, such as deep neural

networks (DNNs), within the realm of materials

science. The objective is to furnish materials

scientists with a comprehensive introduction to

Explainable Artificial Intelligence (XAI). The paper

elucidates relevant concepts within the materials

science context, aiming to clarify the nature of

explanations in this field. Examples are used to show

how XAI may help with materials science research.

Lan Fu et al., (2022) deep neural networks and

deep learning have demonstrated significant success

in a wide range of signal and image processing

applications. This is particularly evident in situations

where extensive annotated training data is needed,

such as in supervised learning scenarios.While there

is theoretical potential for leveraging deep-learning

algorithms to enhance the processing of microscopic

images capturing crucial microstructures in diverse

material samples, Considering specific priors and

requirements in materials science is crucial for

maximizing performance improvements.It focuses on

the critical issue of recognizing items of interest in

microscopic materials-science photographs. To

address this issue, we also provide several ways for

incorporating multiple priors, such as object form,

symmetry, and 3D consistency, with deep learning.

Jan-Lucas Uslu et al., (2023) the devised

detection method relies on a fusion of optical contrast

between flakes and the substrate, along with their

geometric characteristics. Our results showcase its

capability to identify a significant portion of flakes

with exfoliation across different materials, achieving

an average recall (AR50) ranging from 67% to 89%.

Moreover, with as little as five flakes, an algorithm of

this kind may be taught efficiently. of a particular

material, as exemplified in the case of few-layer

graphene. WSe2, MoSe2, CrI3, 1T-TaS2, and

hexagonal BN. Over the course of two years, our

technique was assessed, and over 30 different

researchers took over 106 photographs of diverse

materials.

Sarvesh Sundaram and Abe Zeid., (2023)

Quality inspection is one of the important stages that

determines if a product is acceptable or not.

Numerous factors influencethe examination of visual

elements, leading to whole industry precision of the

inspection approximately 80%. Achieving 100%

inspection with cutting-edge production processes

through Inspecting visuals manually is both time-

consuming and costly. Despite the assistance of

computer vision (CV) techniques in automating

certain aspects of the visual inspection process,

challenges persist. They are applying Artificial

Intelligence (AI) based on Deep Learning (DL) to the

visual evaluation process. On image data of casting

goods, the recommended model boasts an inspection

precision of 99.86%.

Xiaoquan Shi et al., (2023) five models for

predicting filament dimensions were developed using

decision trees, support vector regression, back

propagation neural networks, random forests, and K-

nearest neighbors. The back propagation neural

network exhibited coefficients of determination of

0.9025 for line width and 0.9604 for line height.

Notably, the parameters with the greatest influence on

line width and height, in descending order, were

nozzle diameter, height, printing speed, and extrusion

pressure. The study revealed that stretched material

resulted in a thinner filament, and the regularity of

processing parameters on geometric size was found to

be poor. Conversely, material compression had a

significant impact on dimensions, with nozzle

diameter playing a crucial role. Consequently, these

research findings have the potential to be utilized for

estimating Determining the dimensions of printing

filament structures guides the selection of printing

parameters and establishes the size of individual

layers in 3D printing.

Nijdam et al., (2022) Various factors, such as

Extrusion force, print velocity, nozzle size, nozzle

elevation, and print temperature are key parameters in

3D printing. A crucial role in determining the success

of the extrusion process and the dimensions of the

extruded filament. Different viscosities demonstrate

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

236

specific 'printability windows' during printing.

Achieving uniform and consistent extrusion requires

the precise adjustment of printing parameters.

Furthermore, the dimensions of the extruded

filament, both in terms of width and height, can vary

significantly depending on the process conditions.

Effectively predicting the geometric characteristics of

the printed line arrangement is essential for

optimizing 3D model slicing and enhancing the

overall efficiency of 3D structure manufacturing.

Madhavi Karanam et al., (2023) The real-time

application of the system in identifying objects and

instantly providing their dimensions upon request.

Object dimension measurement and detection

represent crucial aspects of computer vision, playing

a vital role in automating various human operations.

Humans can recognize and locate items in photos and

movies, but computers do not have that capacity

without prior training. Machine learning, computer

vision, and object identification methods must be

used to educate the computer. This project

demonstrates how to identify and measure the

dimensions of an item in real time using a camera. We

used the OpenCV and NumPy libraries to

approximation the object's size in real time. Computer

vision assists computers in seeing and

comprehending. Computer vision assists computers

in interpreting a 3D environment from a 2D picture

and educates computers to do various activities. It

also aids in Human Computer Interaction by

distinguishing items from their surroundings and

providing us with important information.

Chandan et al., (2018) various methodologies for

object detection encompass Region-based

Convolutional Neural Networks (RCNN), Faster

RCNN, Single Shot Detectors (SSD), and You Only

Look Once (YOLO) are all different approaches to

object detection in computer vision. When

prioritizing speed over accuracy, Faster-RCNN and

SSD exhibit superior accuracy, with YOLO

demonstrating even better performance. Achieving an

optimal balance between identification accuracy and

real-time processing, a combination of SSD and

MobileNets in deep learning facilitates effective

object recognition and tracking, ensuring both

efficiency and speed.

Wang et al., (2020) the latest developments in

object detection, this study explores advancements in

the field, Incorporating Faster R-CNN, YOLO, SSD,

and RetinaNet into the discussion. Additionally, it

explores different datasets used in object detection

and the evaluation metrics employed to gauge the

effectiveness of object detection algorithms.

Manjula et al., (2016) investigated object

detection and suggested a method for detecting and

classifying things that used image processing

methods with machine learning algorithms. Various

ways are investigated in this, and the accuracy of the

methods is calculated. On a bespoke dataset, the final

recommended approach attained an accuracy of

87.5%.

Binay et al., (2017) The methods for object

identification The research evaluated the precision,

efficiency, and computational intricacy of different

techniques, incorporating Haar cascades, Histogram

of Oriented Gradients (HOG), as well as advanced

deep learning models like YOLO, Faster R-CNN, and

SSD.

Sredha Vinod et al., (2022) to locate missing

bolts, an automated ESP32 camera is used to inspect

the integrity of bolted steel components. Earlier study

concentrated on improving bolt tightening quality.

Insufficiently securing steel components through

improper bolting can significantly compromise their

mechanical strength, leading to potential structural

failure. This investigation employed a methodology

involving real-time photography of steel members

using an ESP32 camera module. The captured video

footage underwent processing in Visual Studio,

employing the C++ language. Another aspect of the

study incorporated a Faster Region-Based

Convolutional Neural Network (Faster R-CNN), a

swift and efficient approach. This neural network

utilized an image dataset for training, facilitating the

extraction of crucial elementssuch as bolts and

holesin the steel components' areas of interest. The

trained model demonstrated the ability to identify

bolts and holes accurately. The study's findings

indicated the reliability of the developed system,

which is capable of promptly alerting users to any

missing bolts. Leveraging TensorFlow for object

identification, the Faster R-CNN algorithm achieved

an impressive 95% accuracy, contributing to

enhanced efficiency in quality monitoring processes.

Pranjal et al., (2020) For pothole identification,

the Deep Learning-based algorithm YOLO is used.

For pothole dimension estimate, an image processing-

based triangle similarity measure is applied. The

suggested approach gives relatively accurate pothole

identification and dimension estimate results. The

suggested approach also reduces the amount of time

necessary for road maintenance. The approach

utilizes a specially curated dataset comprising images

depicting both waterlogged and dry potholes in

diverse shapes and sizes.

Inspection of Materials Dimensions Using Webcam in the Conveyor System

237

2.2 Material Dimensions Inspection

Based on PLC and Embedded

Nadin et al., (2023) In order to increase accuracy and

efficiency, an integrated logic controller (PLC) was

installed, which provided real-time monitoring and

control of the material transfer plan of activities. Data

and samples from industrial facilities were utilized to

validate the success of this viewpoint. The observed

outcomes reveal a significant advancement in

material transfer operations, including a significant

reduction in transfer amount times and a significant

improvement in precision. The two large values

reflect a 30% reduction in transfer time and a 15%

drop-in mistake rate. The analysis of these data

demonstrates the importance of PLCs in simplifying

material transport as well as their future application

possibilities. PLC-based solutions facilitate industrial

material transfer and provide additional opportunities

to increase productivity and effectiveness.

Manoj and Uday., (2017) A dissertation on

conveyor systems is in progress to develop a tabletop

model featuring a Configurable quantity of stations

and an accompanying control board. The suggested

conveyor has a length of 780mm and is capable of

transferring items as large as 60 cubic mm. The

configuration of stations, whether with or without

interlocks, can be adjusted within the range of 2 to

5The conveyor system relies on PLC technology,

smoothly integrating with the palletizer. The PLC

exhibits robust programming features, including

timers, counters, and customizable variable inputs,

ensuring efficient operation serve as the fundamental

operational elements that effectively minimize input

and output requirements for the PLC.

Borkowski and Knop., (2016) The evaluation

process involves inspection plans delineating the

different production areas necessitating scrutiny. The

initial phase typically involves the examination

Incoming or receiving inspection was another term

used for the assessment of raw materials. Subsequent

inspections occur at regular intervals following

various stages of production, with the specific nature

of these assessments varying across industries. The

inspection procedures for structural steel products

vary considerably compared to those for

microcontrollers. Upon reachingat the conclusion of

the assembly line, a thorough inspection is carried out

to determine whether the product meets the required

standards for acceptance or if it should be rejected.

Mirroring the concept of inbound inspection. In

certain instances, the incoming inspection may also

extend to the scrutiny of packaged products during

the shipping process.

Xiaofei Zhang et al., (2019) when subjected to

ultrasound activation, ultrasonic thermography (UT)

emerges as an innovative non-destructive testing

technique that captures damage through thermal

imaging conducted by an infrared (IR) camera.

However, noise and indistinct borders surrounding

high-temperature locations in the UT test thermal

pictures may confound and lead to inaccurate

findings. As a result, the debate is built on extensive

CFRP content learning. This UT employs low-power

ultrasonic excitation. The high-dimensional nature of

infrared image sequences is represented through data

set modeling. Manifold learning is then employed to

discern the intrinsic structure within the two-

dimensional manifold of these data sets. The steady

component detects VID and BVID (barely visible

impact damage) by displaying the temperature

increase caused by damage. The research

configuration was constructed, and tests were

conducted on CFRP plate samples exhibiting diverse

degrees of impact damage. In a low-noise

reconstructed static image, all impact damage may be

identified and presented.

Sambathkumar et al., (2014) to measure the

components, plug gauges are frequently employed.

An automated system with pneumatic comparators is

used instead of manual inspection. Because the

manual examination could be more efficient, this

measurement instrument requires improvement. The

dimensions of this gadget are computed using a

comparator setup. The Geneva conveyor transports

the components from one location to another. It is

vital to reduce the number of staff involved. We

created a conveyor with a Geneva drive that may be

used in industries. Consequently, a conveyor system

is employed to transfer materials between different

areas, with the specimen's size determined by its

dimensions.

Dinesh et al., (2019) Sensors are employed to

gauge the material dimensions, with the signal then

transmitted to the control unit. Subsequently, the

control device sends this is a suitable signal to engage

the pneumatic cylinder. The pneumatic cylinder

collects items that are the incorrect size. In today's

engineering firms, the inspection conveyor is critical

for material handling. Conveyors transport objects

from one point to another. Sensors are used to

measure the dimensions at the top of the conveyor.

This procedure ensures that the belts are transported

to their destinations on schedule. The figure 2 shows

Material detection robot.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

238

Figure 2: Material detection robot.

3 RESULT AND DISCUSSION

Inspecting material dimensions is achieved through

the utilization of a Raspberry Pi and OpenCV

platform. Object detection is implemented using

either machine learning or deep learning algorithms

to ensure accurate prediction and identification of

detected objects, along with displaying their

respective names, as illustrated in Figure 3.

We may check the casting goods using the SQI

shop floor application. We inspect a faulty and an

able product to illustrate the application's

functionality. The goods are examined with the literal

click of a button. The operator can record through the

inspection procedure by going into relevant details

pertaining items, equipment, etc., as depicted in

Figure 4.

We measured several things and compared them

to their real dimensions, then computed the

percentage error to determine the measurement's

accuracy which shown in table 1 and figure 5

Figure 3: Object detection using the machine learning and

OpenCV.

Figure 4: (a) Examination of a faulty product and (b)

evaluation of an approved product.

Figure 5: Detection of Material Dimensions.

Table 1: Evaluation of Material Dimensions Across Different Objects.

Object

Original

Length

(mm)

Original

Breadth (mm)

Original

Area (mm²)

Predicted

Length

(mm)

Predicted

Breadth (mm)

Predicted Area

(mm²)

Accuracy (%)

Mobile 155 72 11,160 153.29 70.29 10,774.47 96.54

Pen 120 13 1,560 119.10 13.09 1,559.19 99.95

Book 275 164 45,100 276.01 163.50 45,127.63 99.94

Box 302 305 92,110 294.50 310.10 91,324.45 99.14

Wallet 91 73 6,643 92.74 74.69 6,926.50 99.72

Pencil

b

ox

140 45 6,300 141.10 45.00 6,349.50 99.21

Adapter 34 47 1,598 34.99 48.46 1,695.51 93.89

Inspection of Materials Dimensions Using Webcam in the Conveyor System

239

4 CONCLUSIONS

This work presents a real-time approach for item

detection and dimension assessment. The various

hardware parts and how they are put together are

explained in detail. For material dimension

inspection, a simple, low-cost approach utilizing

machine learning and a deep learning model is

described. The performance of many machine

learning algorithms is examined and contrasted with

their corresponding Python codes. The material was

photographed using a Raspberry Pi and a Pi camera.

Because it doesn't require a separate working

platform like a personal computer, it is a complex

approach. For the majority of computers and robot

vision systems, the capacity to inspect material and its

dimensions is crucial. In terms of open-world

learning, human-level performance is still a long way

off. It should be highlighted that although this

material and its dimensions might be very helpful,

they have not been employed extensively in many

sectors. Since mobile robots and other autonomous

machines are becoming increasingly often used.

REFERENCES

Borkowski, S.; Knop, K. “Challenges Faced in Modern

Quality Inspection”, Management and Production

Engineering Review, Vol. 7, No. 3, pp. 11–22 2016.

G. Chandan, Mohana and A. Jain, Real-Time Object

Detection and Tracking by Using OpenCV and Deep

Learning, ICIRCA, (2018).

Gokulnath Anand and Ashok Kumar Kumawat, “Object

detection and position tracking in real time using

Raspberry Pi”, Materials Today: Proceedings, 2021.

Jan-Lucas Uslu, TaoufiqOuaj, David Tebbe, Alexey

Nekrasov, Jo Henri Bertram, Marc Schutte, Kenji

Watanabe, Takashi Taniguchi,4 Bernd Beschoten, Lutz

Waldecker and Christoph Stampfer, “An open-source

robust machine learning platform for real-time

detection and classification of 2D material flakes”,

2023.

Lan Fu, Hongkai Yu, Xiaoguang Li, Craig P. Przybyla, and

Song Wang, “Deep Learning for Object Detection in

Materials-Science Images”, Signal Processing for

Advanced Materials, 2022.

Madhavi Karanam, Varun Kumar Kamani, Vikas Kuchana,

Gopal Krishna Reddy, Koppula, and Gautham

Gongada, “Object and it’s dimension detection in real

time”, E3S Web of Conferences, Vol. 391, No. 01016,

2023.

Manoj M. Nehete and Uday C. Patil, “Design and

Fabrication of PLC Based Conveyor System with

programmable Station”, International Journal of

Analytical, Experimental and Finite Element Analysis

(IJAEFEA), Issue. 3, Vol. 4, pp 53-58, 2017.

Mohd ShuhanazZanar Azalan, Tang Esian, Hasimah Ali,

Ahmad Firdaus Ahmad Zaidi and Tengku Sarah

Tengku Amran, “Classification Size of Underground

Object from Ground Penetrating Radar Image using

Machine Learning Technique”, Journal of Physics, Vol.

2550, 2023.

Mr. N. Dinesh, Mr. D. Muthamilselvan, Mr. A.

Sakthibalasundar, Mr. P. Sankaravignesh, “Fabrication

of Material Inspection Robot”, International Journal of

Engineering Research & Technology (IJERT), Vol. 7,

Issue. 06, 2019.

Muhammad Sabih, Muhammad Shahid Farid, Mahnoor

Ejaz, Muhammad Husam, Muhammad Hassan Khan

and Umar Farooq, “Raw Material Flow Rate

Measurement on Belt Conveyor System Using Visual

Data”, Applied science innovation, Vol. 6, No. 88,

2023.

N. Sambathkumar, K. Sivakumar, D. Ganesan, M.

Krishnakumar, H. Mohamad Ibrahim, “Design and

Fabrication of Material Inspection Conveyer”,

International Journal of Research in Aeronautical and

Mechanical Engineering, Vol.2 Issue.3, pp. 129-134,

2014.

Nadin E S, Madhaneesh A, Sathiesh G V, and Arun

Jayakar, “PLC Based Material Transfer Operation in

Industrial Applications”, International Journal of

Creative Research Thoughts (IJCRT), Vol. 11, Issue.

10, 2023.

Nijdam, J.J, Agarwal, D, Schon, B.S, “An experimental

assessment of filament-extrusion models used in slicer

software for 3D food-printing applications”, Journal of

Food Engineering, Vol. 317, No. 110711, 2022.

Pranjal A. Chitale, Hrishikesh R. Shenai, Jay P. Gala,

Kaustubh Y. Kekre and Ruhina Karani, “Pothole

Detection and Dimension Estimation System using

Deep Learning (YOLO) and Image Processing”, IEEE,

2020.

S. Manjula, Dr. K. Lakshmi, “A study on object detection”,

IJPTFI, ISSN: 0975-766X, 2016.

Sarvesh Sundaram and Abe Zeid, “Artificial Intelligence-

Based Smart Quality Inspection for Manufacturing”,

Micromachines, Vol. 14, No. 570, 2023.

Siddharth Mandgi, Shubham Ghatge, Mangesh Khairnar,

Kunal Gurnani and Prof. Amit Hatekar, “Object

Detection and Tracking Using Image Processing”,

Journal of Engineering Research and Application, Vol.

8, Issue 2, pp.39-41, 2018.

Sredha Vinod, Pshtiwan Shakor, Farid Sartipi and Moses

Karakouzian, “Object Detection Using ESP32 Cameras

for Quality Control of Steel Components in

Manufacturing Structures”, Arabian Journal for

Science and Engineering, 2022.

T. Varun Sai, B. Aditya, A. Mahendra Reddy and Dr. Y.

Srinivasulu, “Real Time Object Detection Using

Raspberry Pi”, International Journal for Research in

Applied Science & Engineering Technology

(IJRASET), Vol. 11, Issue. I, 2023.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

240

Talha Bayrak, Vedat Marttin and Uğur Yüzgeç, “Raspberry

Pi Based Object Detection and Drawing”, Global

Conference on Engineering Research (GLOBCER’21),

2021.

U. Binay, N. Yadav, “Comparative Study of Object

Detection Algorithms”, International Research Journal

of Engineering and Technology (IRJET), Volume 4,

Issue 7, 2017.

W. Wang, Z. Li, J. Deng, H. Yao, X. Xuan, Z. Wang, “A

review of research on an object detection based on deep

learning”, Journal of Physics, 2020.

Xiaofei Zhang, Yunze He, Tomasz Chady, Guiyun Tian,

Jingwei Gao, Hongjin Wang and Sheng Chen, “CFRP

Impact Damage Inspection Based on Manifold

Learning Using Ultrasonic Induced Thermography”,

IEEE Transactions on Industrial Informatics, Vol. 5,

Issue. 5, pp. 2648- 2659, 2019.

Xiaoquan Shi, Yazhou Sun, Haiying Tian, Puthanveettil

Madathil Abhilash, Xichun Luo and Haitao Liu,

“Material Extrusion Filament Width and Height

Prediction via Design of Experiment and Machine

Learning”, Micromachines, Vol. 14, 2023.

Xiaoting Zhong, Brian Gallagher, Shusen Liu, Bhavya

Kailkhura, Anna Hiszpanski and T. Yong-Jin Han,

“Explainable machine learning in materials science”,

Computational Materials, Vol. 8, No. 204, 2022.

Inspection of Materials Dimensions Using Webcam in the Conveyor System

241