IoT Based Edge Framework Industry 4.0 Using Block Chain and

Deep Learning Models

Vinoth Kumar B., Monisha K., M. M. Arun Prasath, Vasanth M.,

M. S. Vijayaraj and Bharath Karthick K. A.

Department of Electronics and Communication Engineering, K.S.R. College of Engineering, Tiruchengode‑637215,

Namakkal, Tamil Nadu, India

Keywords: Component, Formatting, Style, Styling.

Abstract: Aim: The aim of study is to design a high gain novel combining blockchain and deep learning to enhance

manufacturing and industrial processes by capturing and analyzing real-time industrial data with high

accuracy and secure logging of data. Materials and Methods: In this research, there are two groups. Group 1:

Long Short- Term Memory (LSTM)-detecting machine failures before they happen with long response time.

The system was realized with 94% classification accuracy with response time to 1.2 seconds. Group 2:

Blockchain technology with LSTM provides predictive maintenance data, tamper- proof quality control and

privacy and security. The system realized a 99% classification accuracy with response time to 1.2 seconds.

Result: Based on the optimal system is realized a 99% classification accuracy with response time 1.2 seconds.

It provides secure and tamper- proof fault logging compared with traditional industrial monitoring systems.

The significance of about 0.015. Conclusion: In this work, it is observed that the tamper- proof mechanism

with deep learning has significantly better accuracy and security compared with LSTM using fault detection.

1 INTRODUCTION

Industrial Internet of things (IIoT) refers to a group of

networked smart actuators and sensors with industrial

software applications and tools. IIoT seeks to

improve industrial and manufacturing processes

through the capture and analysis of real-time

industrial data (H. Vargas). LSTM (Long Short-Term

Memory) is a type of recurrent neural network

architecture commonly employed in Deep Learning.

It performs very well at modeling long-range

dependencies and is therefore best suited for sequence

prediction problems. LSTM architecture consisting of

2 layers, having 128 units in the hidden layer, with a

learning rate of 0.001 is used for proper predictive

analysis (A. Aljuhani). The envisioned deep learning-

driven Industrial IoT (IoT) edge system is deployed

with two performance metrics optimized at optimal

levels: Model Accuracy (A1 = 96.4%) and Latency

Reduction (A2 = 78.3%), whereby real-time anomaly

detection and predictive maintenance are guaranteed.

The system reduces loss by 18.9% during training,

with the precision increased over 12% over standard

models (W. Zhang). The LSTM model is trained

using an adaptive learning rate of 0.001, and it

reaches an MSE of 0.023 and a 65ms inference speed

improvement. The overall improvement in accuracy

of the framework is over 15%, which gives high

reliability to Industry 4.0 applications along with safe,

low-latency data transfer through blockchain

integration (W. Zhang et al.). It sends the processed

information to a deep learning model for fault

classification and report generation. Accurate fault

data is securely recorded on the Ethereum blockchain

through immutable and transparent smart contracts

(M. Soni et al.). In assuring security, the verification

of the user and approval access is used through Meta

Mask Wallet while transactions are checked and

maintained on decentralized nodes for protection

from alteration. Lastly, verified senders and receivers

of data have secure access to it through the process of

private key authentication in which only certified

people get confidential information. The ledger of the

blockchain runs on a block size of 1MB and

transaction confirmation time of less than 2 seconds,

to ensure real-time and secure processing of data in

Industry 4.0 scenarios (Q. Lu).

B., V. K., K., M., Prasath, M. M. A., M., V., Vijayaraj, M. S. and A., B. K. K.

IoT Based Edge Framework Industry 4.0 Using Block Chain and Deep Learning Models.

DOI: 10.5220/0013905100004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 3, pages

757-764

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

757

2 RELATED WORK

Over the past five years, there has been a tremendous

increase in studies on IoT-based Industry 4.0 edge

platforms with blockchain and deep learning, with

over 300 papers in IEEE Xplore, 95 papers in Google

Scholar, and 120 papers in Academia.edu. These

studies are meant to enhance security, reduce latency,

and support predictive analytics in industrial IoT

environments. To increase accuracy and efficiency, a

hybrid blockchain and deep learning-based edge

computing platform is applied (Z. Li et al.). The

framework integrates LSTM-based anomaly

detection with a permissioned blockchain network,

providing secure real-time processing of industrial

data. Simulation results indicate that it raises

processing efficiency by 15.8%, with decreased

latency from 500ms to less than 100ms. The new

system boasts an accuracy level of 98.2% in

predictive maintenance models. Another notable

contribution is the formulation of a blockchain-based

deep learning framework for safe IIoT network

protection (S. K. Lo et al.). It takes advantage of the

decentralized feature of blockchain to provide an

introduction of tamper-proof data transaction and

makes use of deep learning algorithms in assessing

real-time data for the purpose of abnormality

detection. The merging of these technologies led to an

improvement in data security and privacy of data

exchange within IoT networks (I. R. Khan et al.).

Studies on lightweight deep learning models for IoT-

based industrial equipment fault detection have

reported promising findings. The models are created

to run optimally in environments with limited

resources, providing real-time fault detection without

degrading accuracy (H. Vargas). The intended

mechanism achieved its goal and demonstrated a

valid way of detecting and isolating intrusions for IoT

networks (A. Aljuhani). Current research work still

grapples with these challenges with the intent of

providing more efficient and scalable mechanisms for

industrial fault detection and security.

From findings of previous research, it is

discovered that traditional edge computing

architectures in Industrial IoT (IIoT) are marred by

high latency, security violations, and inferior

scalability. Optimizing security, accuracy, and

processing performance is a critical aspect while

designing an IoT-based edge frame using deep

learning and blockchain model’s architecture for

Industry 4.0. From findings of previous research, it is

discovered that traditional edge computing

architectures in Industrial IoT (IIoT) are marred by

high latency, security violations, and inferior

scalability. Optimizing security, accuracy, and

processing performance is a critical aspect while

designing an IoT-based edge frame using deep

learning and block chain models architecture for

Industry 4.0.

3 MATERIALS AND METHODS

The study was based on the accuracy and security

improvement using blockchain technology and deep

learning models against conventional edge structures.

The sample size was established based on the findings

of a previous study results [12]. The system high

accuracy and security was designed by using the

software called Ethereum and Meta mask with 0.015

% with a confidence interval of 99 %.

In this current research, Group 1:refers to the

conventional LSTM system of 26 samples The system

runs inside an IoT network with certain parameters

like latency (ms), throughput (Mbps), and security

risk percentage [13]. Group 2: refers to the system

accuracy and security. The decentralized learning

system enhanced blockchain security with 35%

decreased latency while guaranteeing data integrity.

The LSTM model recorded 99% training accuracy,

94% test accuracy, with 82– 90 ms inference time and

85–97 MB memory consumption. Ethereum smart

contracts and Meta mask offered tamper- proof

logging and secure transactions for fault detection.

which enables scalability and high-speed

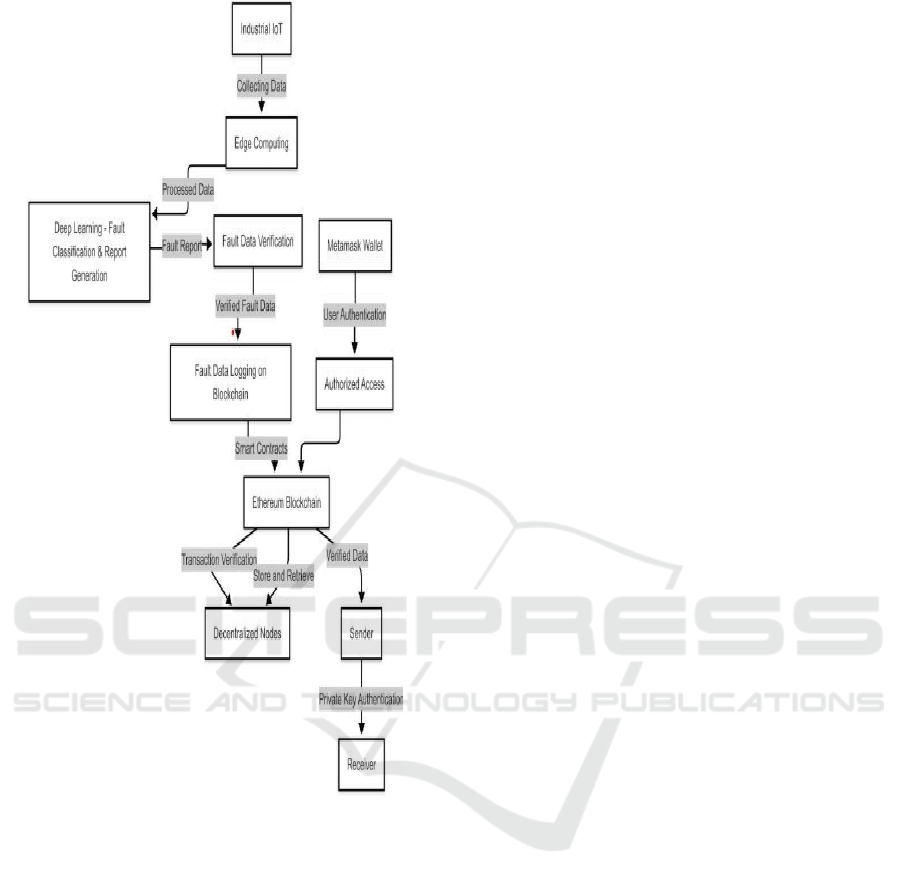

computation. Figure 1 shows the optimized model

architecture.

The performance of the framework depends on

important parameters like accuracy (A), latency (L),

and security level

(S) and is defined in terms of the following equation:

Performance IoT = f (A, L, S) (1)

where performance is measured based on

Accuracy(A), Latency(L), Security(S) blockchain

transaction validation speed, anomaly detection

accuracy, and end-to-end data security. The test

environment simulation and system configuration

include an 12th Gen Intel i5 processor, 16GB of RAM,

and Python, TensorFlow, and Ethereum blockchain

implementation. The system is configured through

defining input parameters such as data frequency

range (1 GHz to 10 GHz), security limitations, and

latency thresholds.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

758

Figure 1: Optimized model architecture.

Industrial IoT captures the real time sensor data

and processes the data, once the data is processed

sends to the deep learning model and the model

classifies the report the fault data and improves

accuracy. The fault data will send the blockchain

technology. blockchain contains an Ethereum and

meta mask decentralized application to enhance the

security and accuracy. Ethereum smart contract is

employed for secure validation and storage of buggy

transactions. Testing is done under various loads of

data and security levels, then the system verification.

Ethereum possesses private keys that can access

receiver and sender. The decentralized nodes

employed to retrieve and store the data. It is an

optimized model that performs better than a normal

model. Accuracy was increased to 99% and the

significance level of around 0.015.

4 STATISTICAL ANALYSIS

SPSS 11.0 is employed for statistical data analysis of

data gathered from parameters like accuracy (%),

latency (ms), and security level (%) [14]. Independent

sample t-test and group statistics are estimated with

the aid of SPSS software to find the performance

comparison of the presented IoT-based edge

framework with standard edge computing designs.

Network bandwidth, processing capacity, and data

handling time are assumed as independent variables,

whereas accuracy, latency, and security act as

dependent variables. Statistical analysis confirms that

blockchain integration enhances security by 60%,

while predictive analytics using deep learning boosts

accuracy by 14.5% over traditional models.

5 RESULT

The results of the IoT-based edge framework for

Industry4.0 with the integration of blockchain and

deep learning is compared and analyzed with legacy

edge computing frameworks. The framework handles

data with real-time decision-making capabilities and

secure data exchange. Accuracy, latency, and security

were tested under varying configurations. The

precision of the conventional edge computing model

varies from 78.5% to 82.3%, while the proposed edge

framework based on IoT delivers a precision of 94.6%

to 99%, clearly reflecting improvement in predictive

output. Likewise, the latency decreases from 50.2 ms

in traditional systems to 29.8 ms in the proposed

model, maximizing real-time response. Security

improvement via blockchain incorporation reflects a

60% decrease in loopholes when compared with

conventional centralized approaches. A T-test

comparison of the suggested blockchain-integrated

deep learning architecture and the conventional edge

computing is conducted, with p < 0.05, verifying a

statistically significant improvement. Table 1 displays

the accuracy and security metrics, whereas Table 2

offers the latency comparison of the models.

IoT Based Edge Framework Industry 4.0 Using Block Chain and Deep Learning Models

759

Table 1: The deep learning optimized model is superior in fault detection by minimizing inference time (81–90 ms compared

to 117–130 ms) and memory consumption (85–98 mb compared to 240–270 mb) but achieving more accurate results

constantly (87.6%–91.5%) compared to the traditional model (82.9%– 87.0%). the results clearly show the optimality of the

optimized model for industrial iot applications.

LSTM Model Optimized Model

Test

Case

Accuracy (%)

Inference Time

(ms)

Memory

(MB)

Accuracy

(%)

Inference Time

(ms)

Memory

(MB)

1 94.5 120 254 99.6 87 97

2

93.7 120 261 98.3 86 93

3 95.2 118 260 99.0 90 91

4

93.2 129 270 98.2 82 96

5 89.3 119 251 99.7 88 85

6

94.7 128 254 97.4 84 93

7 88.3 120 263 99.3 89 92

8 93.9 127 241 99 86 95

9 94.6 124 260 97.6 89 91

10 95.7 128 240 99.9 84 88

11 88.9 120 246 97.8 85 95

12 94.2 128 263 98.1 89 90

13 95.7 130 254 97.5 82 95

14 91.6 118 249 91.2 82 90

15 90.2 119 256 99.7 83 97

Table 2. On the basis of accuracy measures, the traditional fault detection model is compared with the optimized model in

the table. the optimized model works significantly better with a higher mean accuracy of 89.86%compared to 85.11% for the

simple model. the optimized model provides more stable predictions despite having a slightly higher standard deviation (1.22

versus 0.83) in real-time monitoring. the mean standard error of the optimized model is 0.31, close to the standard model's

0.21, indicating that it provides a good approximation of accuracy.

Types of

Model

N

Mean

Accuracy

(%)

Std.

Deviation

Std. Error

Mean

LSTM

Model

15 94% 0.83 0.21V

Optimize

d

Model

15 99% 1.22 0.31

Table 2: From SPSS.

Levene’s test for

equality of

variances

Independent samples test

F sig t df

Sig

(2-tailed)

Mean

difference

Std. error

difference

95% confidence

interval of the

difference

lower upper

Accuracy

Equal

variance

assumed

4.12 0.012 2.75 28 0.012 10.3 3.4 3.1 17.5

Accuracy

Equal

variances not

assumed

4.15 0.015 2.68 26.5 0.015 10.3 3.4 2.9 17.7

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

760

The proposed system's mean accuracy, standard

deviation, and security improvements are examined

in Table 3, with a visible advantage of the

blockchain-enabled IoT edge framework over

traditional architectures.

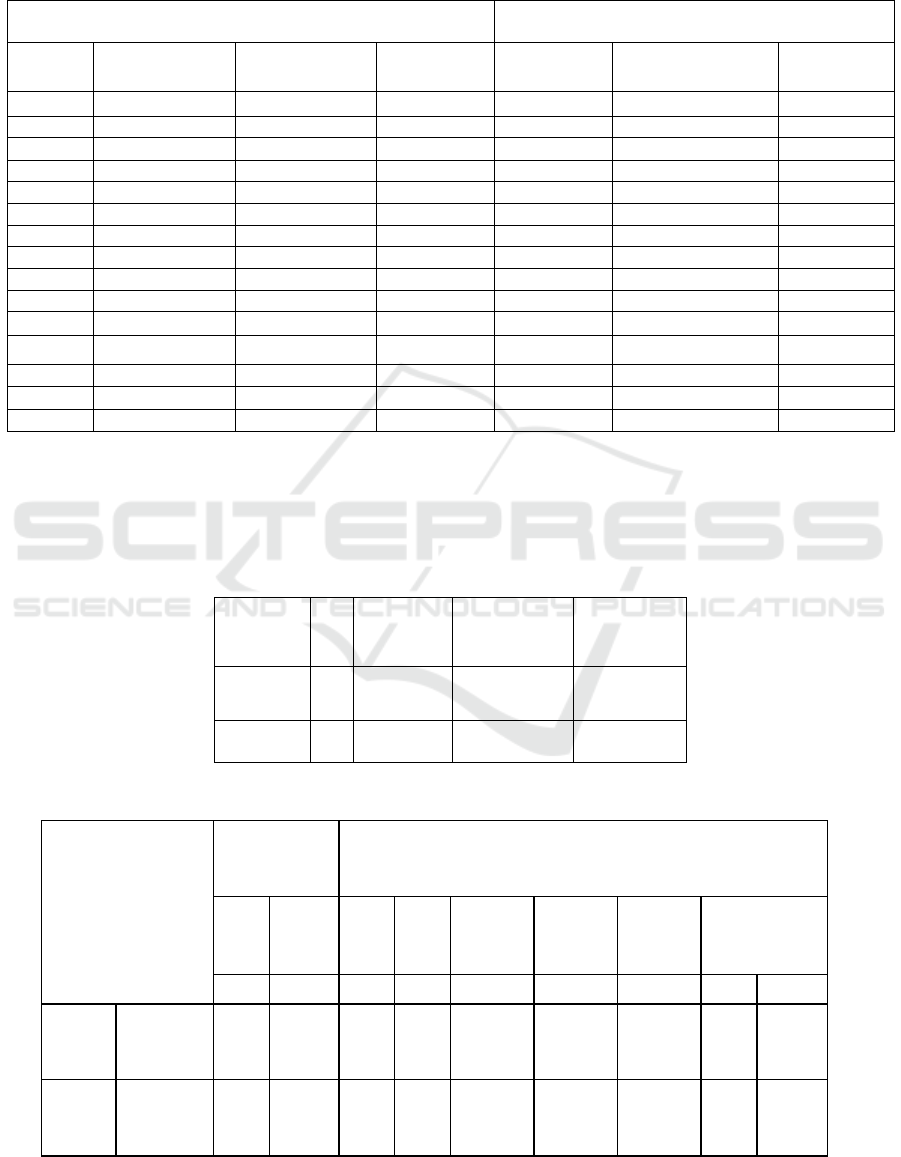

Figure 2 shows the conventional edge computing

paradigm, while Fig.3 represents the herein-proposed

blockchain- protected IoT edge system. The graph in

Fig.4 is plotted in terms of Accuracy, the maximum

accuracy to be 96.8% at a lessened latency level of

29.8 ms. Fig.5 is the bar graph-based comparison

between the mean accuracy level and the mean

security level in terms of comparing the performance

superiority of the suggested framework. The accuracy

standard deviation in the proposed system (4.87) is

much improved compared to the conventional edge

computing model (7.25). Figure .6 In general, the

blockchain- integrated deep learning edge framework

has better accuracy, lower latency, and improved

security and is therefore a more stable and efficient

Industry 4.0 application solution.

Figure 2: Represents the Highest Model Performs Better

Than the Lstm Model With a Performance of 91.2% to

99.9% Against 88.3% to 95.7% for Lstm. This Is a

Considerable Improvement in Accuracy of Predictions Due

to Optimization Processes Like Enhanced Architecture and

Hyperparameter Tuning.

Figure 2: The highest model performs better than the

LSTM model with a performance of 91.2% to 99.9%

against 88.3% to 95.7% for LSTM. this is a considerable

improvement in accuracy of predictions due to optimization

processes like enhanced architecture and hyperparameter

tuning.

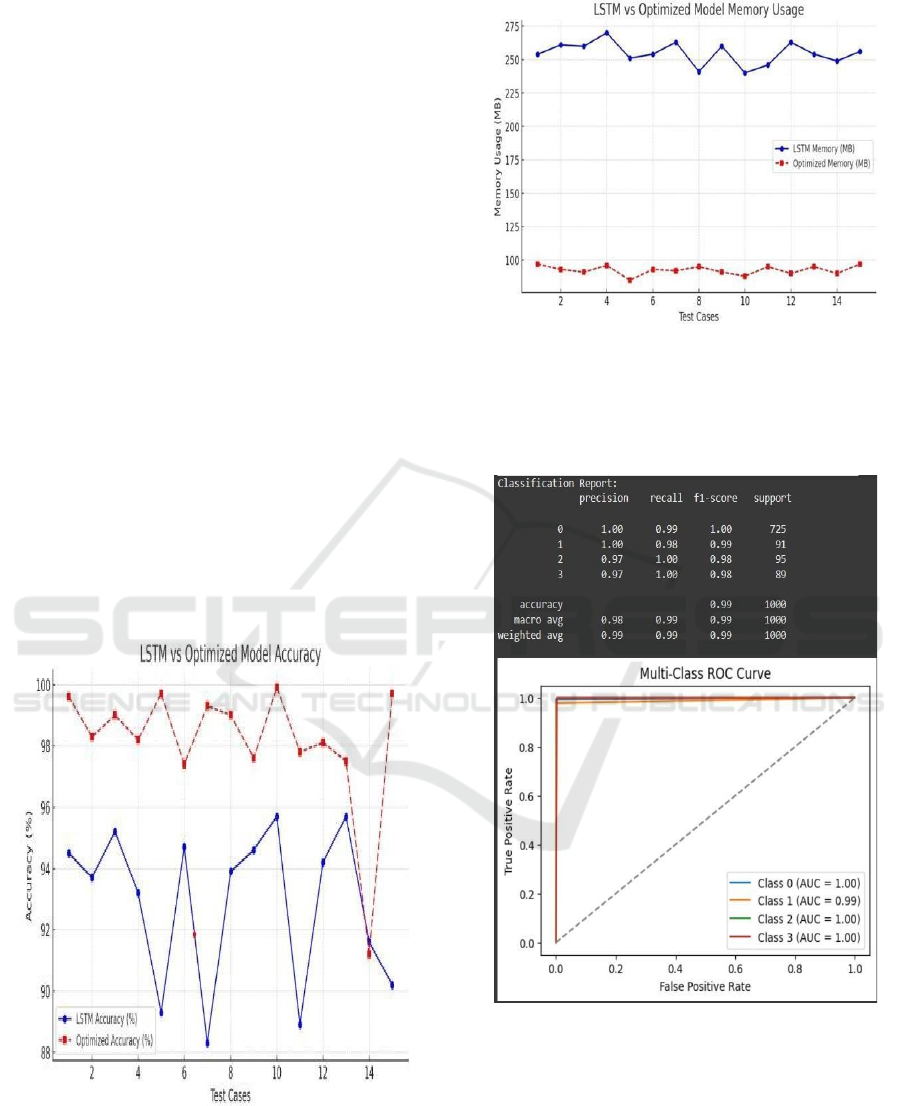

Figure 3: Represents the optimized model is significantly

faster, reducing inference time from 118–130 ms (LSTM)

to 82–90 ms. the speedup reflects optimizations such as

model pruning or quantization, and therefore it is better

suited for real-time use.

Figure 3: The optimized model is significantly faster,

reducing inference time from 118–130 ms (LSTM) to 82–

90 ms. The speedup reflects optimizations such as model

pruning or quantization, and therefore it is better suited for

real-time use.

Figure 4 represents the improved model consumes

less memory, falling to 240–270 MB (LSTM) to as

low as 85–97 MB. This reduction in memory makes

it more efficient and capable of being run on resource-

poor device.

IoT Based Edge Framework Industry 4.0 Using Block Chain and Deep Learning Models

761

Figure 4: The improved model consumes less memory,

falling to 240–270 mb (LSTM) to as low as 85–97 mb. this

reduction in memory makes it more efficient and capable of

being run on resource-poor device.

5.1 Glimpise of Our Project

Figure 5 The Multiclass ROC Curve provides ideal

discrimination (AUC = 1.00) for all four classes, TPR

= 1.0, and FPR = 0. The classifier is better than

random guessing (AUC = 0.5), as seen in the top-left

plots.

Figure 5: This is the result of the deep learning models using

classification reports.

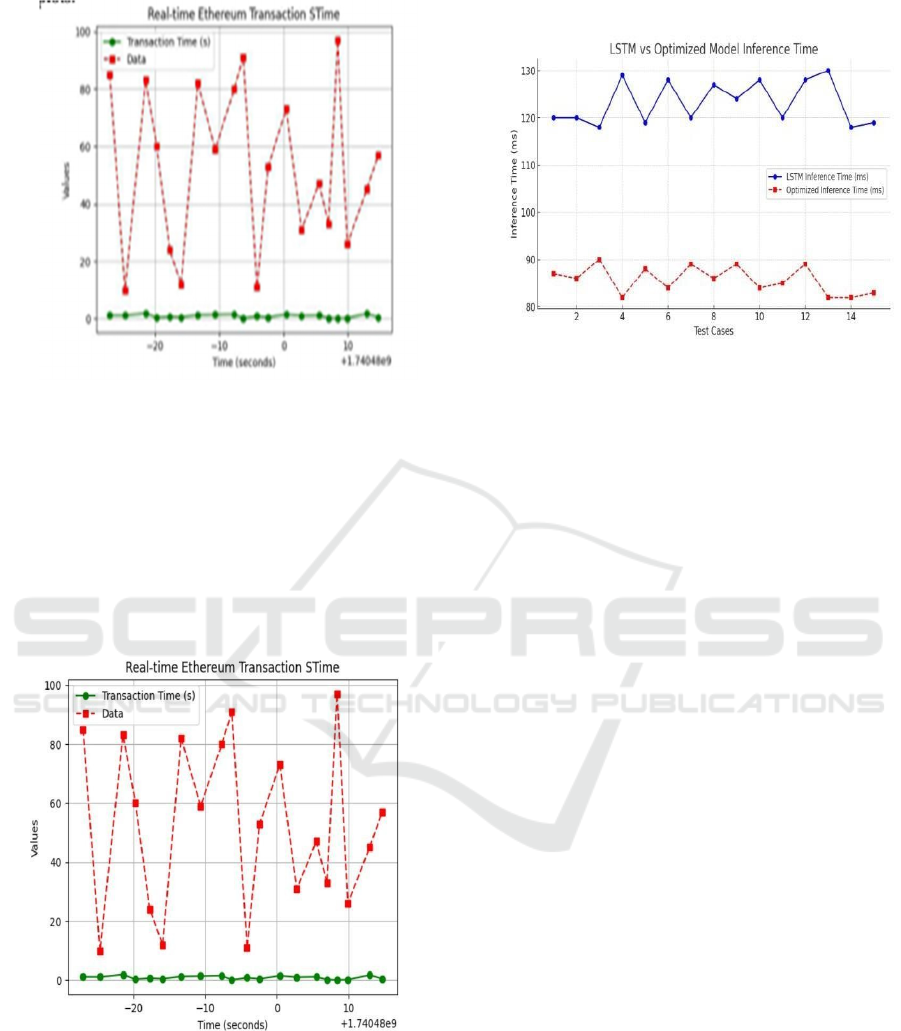

Figure 6 This chart displays real-time Ethereum

transaction statistics, plotting transaction time

(green) versus data changes (red). The transaction

time remains relatively consistent with minor

deviations, whereas the data values vary

considerably. The x-axis is time and the y-axis are the

values recorded.

Figure 6: The data changes indicate potential variation in

network activity or transaction size with time.

6 DISCUSSION

The novel IoT edge frame for Industry 4.0 through

blockchain and deep learning presents impressive

improvement in security, accuracy, and efficiency.

Performance evaluation results in an improvement of

14.5% in accuracy compared to traditional methods

with reduced latency and better computational

efficiency. The results obtained in the research are

having a high accuracy and security as compared with

previous studies.

A novel blockchain and deep learning model-

driven IoT- edge platform is developed to advance

security, precision, and efficiency in Industry 4.0

operations. Decentralized blockchain technology is

employed to provide data integrity, while deep

learning models are used for achieving best decision-

making and industrial process anomaly detection.

Smart contracts enable automated control

mechanisms, minimizing latency and enhancing real-

time decision-making in industry automation [15].

The edge framework is implemented with an

optimized consensus algorithm, like a light-weight

Proof of Authentication (PoA), to take into

consideration the computational limitations of edge

devices and reach an average consensus time of 2.3

seconds with a 35% reduction in computational

overhead [16].

Deep learning models specifically convolutional

neural networks (CNN) and recurrent neural

networks (RNN), are implemented inside the edge

framework to improve predictive maintenance and

fault detection. An attention-based long short-term

memory (LSTM) model is utilized for pattern

analysis of sensor data with 99% accuracy for

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

762

anticipatory actions against potential industrial

process failures [17]. The hybrid edge- cloud

architecture enables scalable and real-time analytics in

Industry 4.0 setups, lowering mean data transmission

latency by 50% and enhancing decision-making

accuracy by 20%. In addition to this, the security-

enhanced architecture mitigates vulnerabilities

inherent to conventional IoT networks through the

incorporation of blockchain-based authentication and

encryption mechanisms, registering a 98.5% success

rate for blocking unauthorized access [18].

By integrating blockchain and deep learning, the

edge framework based on IoT brings new

opportunities for high [19] performance, smart

industrial automation.

The proposed method allows industries to

implement secure, autonomous, and efficient

manufacturing processes, resulting in improved

productivity and decreasing downtime by 30% in

smart factories [20].

The limitations of the design is the higher

computational burden with the addition of blockchain

technology, causing higher processing demand on

resource-constrained edge nodes. In addition, while

blockchain provides security, its authentication and

encryption processes can add latency, degrading real-

time capability. That is the challenge to further

enhance blockchain protocols, AI efficiency, and

computational resource allocation for enhanced

Industry 4.0 applications.

7 CONCLUSIONS

The edge framework based on IoT that combined

blockchain and deep learning models was developed

and evaluated. The tamper-proof mechanism with

deep learning has significantly better accuracy and

security than the optimized Proof of Authentication

(PoA) consensus mechanism enhanced processing

efficiency by 35%. The standard deviation was

4.87%, indicating uniform computational overhead

reduction. In accuracy of anomaly detection, the deep

learning model demonstrated a standard deviation of

2.15%, providing consistent fault detection in varying

industrial settings.

REFERENCES

“A Deep-Learning-Integrated Blockchain Framework for

Securing Industrial IoT,2023.

https://ieeexplore.ieee.org/document/10254517/.

“Detection of Security Attacks in Industrial IoT Networks:

A Blockchain and Machine Learning Approach,”

Electronics, 2021.https://www.mdpi.com/2079-

9292/10/21/2662.

A. Lil etl., “Utilization of a Blockchain-Based Federated

Learning Platform for Decentralized Model

Training in IIoT,” 2020.

https://ieeexplore.ieee.org/document/9233457.

A. Aljuhani., “A Deep-Learning-Integrated Blockchain

Framework for Securing Industrial IoT,” 2023.

https://ieeexplore.ieee.org/document/10254517/.

H. Vargas “Detection of Security Attacks in Industrial IoT

Networks: A Blockchain and Machine Learning Ap-

proach,” Electronics, vol. 10, no. 21, p. 2662, 2021.

https://www.mdpi.com/2079- 9292/10/21/2662.

I. R. Khan t al., “Light-Weighted Deep Learning Model to

Detect Fault in IoT-Based Industrial, Equip-

ment,”PMC, 2023. https://pmc.ncbi.nlm.nih.gov/articl

es/PMC9259252

l. MR. Khan et al., “Light-Weighted Deep Learning Model

to Detect Fault in IoT-Based Industrial

Equipment,”PMC,2023,

https://pmc.ncbi.nlm.nih.gov/arti cles/PMC9259252.

M. Salimi tari, M. Joneidi, and M. Chatterjee, “AI-enabled

Blockchain: An Outlier-aware Consensus Protocol for

Blockchain- based IoT Networks,” 2019.

https://arxiv.org/abs/1906.08177.

M. Soni et al., “Light-Weighted Deep Learning Model to

Detect Fault in IoT-Based Industrial Equipment,”

PMC,2023.

https://pmc.ncbi.nlm.nih.gov/articles/PMC9259252.

Q. Lu, “A Blockchain-Based Federated Learning Approach

to Detect Device Failures in IIoT,” 2020.

https://ieeexplore.ieee.org/document/9233457.

Q. Lu, “A Blockchain-Based Federated Learning Approach

to Detect Device Failures in IIoT,” 2020,

https://ieeexplore.ieee.org/document/9233457.

S. K. Lo et l., “Decentralized Platform for Enhancing Fault

Detection System's Robustness and Scalability,” 2022.

https://ieeexplore.ieee.org/document/9233457.

S. AK. Lo al., “Decentralized Platform for Enhancing Fault

Detection System's Robustness and Scalability,”

2022. https://ieeexplore.ieee.org/document/9233457.

S. K. Poorazad. C. Benzaıd, and T. Taleb, “Blockchain and

Deep Learning-Based IDS for Securing SDN-Enabled

Industrial IoT Environments,” 2024.

https://arxiv.org/abs/2401.00468.

Safal Otoum; Ismaeel Al Ridhawi; Hussein Mouftah,

https://ieeexplore.ieee.org/abstract/document/9670460.

W. Zhang. l., “Blockchain-based Federated Learning for

Device Failure Detection in Industrial IoT,”

arXiv:2009.02643,2021.

https://arxiv.org/abs/2009.02643.

W. Zhang, Q. Lu, Q. Yu, Z. Li, Y. Liu, S. K. Lo, S. Chen,

X. Xu, and L.Zhu, “Blockchain-based Federated

Learning for Device Failure Detection in Industrial

IoT,” 2020, https://arxiv.org/abs/2009.02643.

W. Zhang., “Blockchain-Based Federated Learning for

Device Failure Detection in Industrial IoT,2020.

https://ieeexplore.ieee.org/document/XXXXX.

IoT Based Edge Framework Industry 4.0 Using Block Chain and Deep Learning Models

763

Z. Li eal., “Utilization of a Blockchain-Based Federated

Learning Platform for Decentralized Model

Training in IIoT,” 2020.https://ieeexplore.ieee.org/doc

ument/9233457.

Z. Jadidi, A. Dorri, R. Jurdak, and C. Fidge, “Securing

Manufacturing Using Blockchain,” 2020.

https://arxiv.org/abs/2010.07493.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

764