Experimental Study on Mechanical Strength Characteristics of

Natural Fiber and Fly Ash Composite Materials for Versatile

Applications

P. Manikandan

1

, S. Rahul

1

, P. Chakravarthi

1

, S. Gokul

2

, M. Dharani Krishnan

2

and B. Dhanush

2

1

Department of Mechanical Engineering, K.S.R College of Engineering, Tiruchengode‑637215, Tamil Nadu, India

2

Department of Mechanical engineering, K.S.R Institute for Engineering and Technology, Tiruchengode, Tamil Nadu, India

Keywords: Pineapple Leaf Fiber (PALF), fly‑Ash (FA), Natural Fibers, Tensile Strength, Compressive Strength, Flexural

Strength, Impact Strength, Composite Material.

Abstract: The aim of this study is to investigate the mechanical strength characteristics of composite materials made

from natural fibers and fly ash (FA), with a focus on evaluating their suitability for versatile industrial

applications. Pineapple Leaf Fiber (PALF), extracted from pineapple leaves and fly ash (FA) Group 1

Different weight percentages of FA (3%, 6%, and 9%) are added to PALF-reinforced epoxy composites with

varied PALF concentrations (10%, 20%, and 30%) using the hand layup procedure. In order to create the

composite, epoxy resin and hardener are mixed, and PALF and fly ash are added in different weight ratios

(for example, 30% PALF and 5% fly ash for set 1, 25% PALF and 10% fly ash for set 2). After giving the

mixture a good stir and vacuum-degassing it to eliminate any air bubbles, it is placed into a heated mold and

squeezed for 30 minutes at 120°C and 10 MPa pressure Result: It has the maximum tensile, flexural, and

compressive strengths of 21.77 MPa, 68.65 MPa, and 23.27 MPa, respectively. The impact strength, which is

0.30 kJ/m2. Significance is 0.018. Conclusion: Natural fibers were found to have mechanical properties with

good results of hardness, tensile strength, and flexural strength. Fly ash composites show comparable

properties to ash-free composites. Mechanical strength and dimensional stability of composites resembles the

unreinforced matrix.

1 INTRODUCTION

Natural fillers are used extensively in composite

manufacturing, yet they are very water-absorbent, a

critical problem. To counteract this, researchers aim

at using filler materials with enhanced mechanical

strength and reduced moisture uptake, hence suitable

for load-bearing applications such as aerospace and

automotive components (Dalvand et al., 2020).

displaying a tensile strength of around 12.75 MPa.

These values render PALF a very suitable candidate

for reinforcing polymer composites in structural

applications (Pramanik et al., 2024). Biodegradability

of natural fibers, however, affects composite

longevity, and enhancement strategies must be

devised. The two important strategies are

hybridization of fibers and the addition of fillers to

enhance strength, durability, and general properties

(Nagaraja et al.,2024). Hybridization refers to the union

of various fibers or fillers to offer superior

mechanical and thermal properties, and nano-fillers

create hybrid nano composites with enhanced

dispersion and adhesion (Tasgin et al., 2024).

PALF/Fly-Ash composites showed maximum tensile

strength (14.025 MPa). FA, red mud, and other

industrial wastes as raw material for polymer matrices

is a new field, where wastes enhance mechanical

properties, surface finish, and water resistance in

fiber-reinforced composites. FA, a by-product of coal

combustion, is environmentally harmful in the form

of air, water, and soil pollution, and hence sustainable

use is required (Mishra). Use of FA of 10% and 5% in

polymer composites not only minimizes pollution

problems but also enhances composite properties.

Coupling with nanotechnology and innovative

manufacturing techniques further improves

composite performance, which renders them

appropriate for different applications (Mohammed et

al., 2024). The total number of articles published on

this topic over the last five years is more than 250

papers in IEEE Xplore, 135 papers in Google Scholar,

Manikandan, P., Rahul, S., Chakravarthi, P., Gokul, S., Krishnan, M. D. and Dhanush, B.

Experimental Study on Mechanical Strength Characteristics of Natural Fiber and Fly Ash Composite Materials for Versatile Applications.

DOI: 10.5220/0013900300004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 3, pages

483-490

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

483

and 110 papers in academia.edu. This process is

generally softer and more elastic. Coconut and

banana fiber constitute the reinforcing process, and it

is in a discontinuous form. It usually possesses greater

power compared to the matrix process. The properties

of 0%, 1%, 3%, and 5% of nano material imposition

were compared. Compared to it, a plate containing

5% nano silicax possesses ultimate (tensile &

flexural) strength. The plate with 1% nanosilica has

the highest impact strength (Er. Amit Kumar Ahirwar et

al., 2015). Properties were verified under the Instron

material testing system. Out of the test, it was proved

among samples that 30 wt% of composites containing

sisal fibers show the maximum tensile strength and

flexural strength of 85.5 MPa and 85.79 MPa,

respectively. The impact strength has been found to

be maximum for 40 wt% sisal fiber, i.e., 24.5 kJ/m²

(Raghavendra et al., 2016). The leaffibers have exhibits

a wide variation in strength of tensile vary from 230

to 1627 MPa, Young's modulus ranging from 0.2 to

22 GPa, and density ranging from 0.8 to 1.4 g/cm³.

TS values are comparatively low compared to

synthetic fibers such as E-glass fiber, which has a TS

of approximately 2000–3500 Mpa (Kiruthika et al.,

2024). A Universal Testing Machine (UTM) was used

to perform tensile testing in accordance with ASTM

D638. According to the findings, the composite with

10% fly ash and 6% banana fiber had the maximum

tensile strength, measuring 45.80 Mpa(Jitendra Hole1).

In comparison to a volume fraction of 0.5% on 10%

fly ash and a volume fraction of 1% on 10% fly ash,

the splitting tensile strength for a volume fraction of

1% on 5% fly ash is superior. The range rises to

108.35% from 38.90% (Makesh et al., 2016). The

conclusion that can be drawn from the findings is that

the novel fly ash filler that is reinforced with sun

hemp fiber composite demonstrates a higher tensile

strength with a mean value of 2.5312 g compared to

the sun hemp fiber composite, which has a value of

3.5458 g (Sanjay, G., and R. Sundarakannan., 2024). As

the percentage of fly ash reinforcement increased, the

Al7075-fly ash composite's UTS and hardness rose

from 140 to 173 MPa and from 66 to 75 HV,

respectively. An error analysis is also provided

(Sanjay, G., and R. Sundarakannan., 2024).The reference

paper deals with the addition of pineapple leaf fiber

(PALF) and fly ash (FA) filler in developing green

composites with improved mechanical and water-

resistant properties for application in biomedical

purposes. Different weight percentages of FA (3%,

6%, and 9%) are added to PALF-reinforced epoxy

composites with varying PALF contents (10%, 20%,

and 30%) using the hand layup method. Tensile

strength is increased by up to 65.3% at this level when

up to 6 weight percent FA is added, according to

mechanical parameters including impact, flexural,

and tensile strength (Meena et al., 2023).

From the previous findings, the composite

fabrication involves mixing epoxy resin with the

hardener and incorporating PALF and fly ash in

varying weight ratios—30% PALF and 5% fly ash for

set 1, 25% PALF, and 10% fly ash for set 2. The

mixture is well stirred, vacuum degassed to remove

air bubbles, and then cast in preheated mound,

pressed under 120°C for 10 MPa pressure for 30

minutes.

2 MATERIALS AND METHODS

Research work was carried out in the KSRIET

Strength of Materials lab. This measures the

performance of the natural fibers from the green

coconut fruit to strengthen plastic materials like High

Impact Polystyrene (HIPS). However, they do not

bond well with plastics. Chemical treatments like

sodium hydroxide (NaOH) and blenching help clean

and roughen the fibers, but the bonding may still be

weak (Ramanjaneyulu et al., 2024). The PALF and Fly-

Ash in use must follow a 30% and 25% fiber content

and 5% and 10% of Fly-Ash to obtain strength

without brittleness of the material. Treatment of the

fibers with NaOH improves adhesion, while

hydrophobic coating reduces water uptake. Proper

alignment of the fibers will ensure durability. The

resultant material is strong ecological and can be used

in construction, automotive, and packaging

industries.

In this current research, the composite material

having the low amount of banana fiber (5%) and 15%

of coconut coir has been taken as an input. In this

group they got low strength and low quality of fiber.

by adding the PALF (25% and 30%), Fly-Ash (10%

5%) and also adding epoxy resin of 250 mL in the

composite material, they have a high strength and it

can be reduce the ductility.

Figure 1: Fly Ash.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

484

Figure 1 shows Fly ash is used in composite

materials to add strength, toughness, and thermal

resistance. It is incorporated into concrete, polymers,

and metal matrices routinely for building

construction and industrial applications. It is

lightweight, reducing costs while providing improved

performance.

Figure 2: Pineapple Leaf Fiber (PALF).

Figure 2 Pineapple Leaf Fiber (PALF) has been

employed as a composite material because of its

tensile strength, lightness, and degradability. PALF is

used to improve mechanical qualities including

stiffness and impact resistance and is reinforced in

polymers and bio composites. PALF composites are

sustainable and applied in the automotive,

construction, and packaging sectors in composite

applications.

3 STATISTICAL ANALYSIS

SPSS version 26.0 is used for statistical analysis of

data collected from the parameter of water usage

[Craven, D., Jefferson S. Hall, M. S. Ashton, and G.

P. Berlin in 2013]. The independent sample t-test and

group statistics are calculated using SPSS software.

The temperature sensor data and the soil moisture

sensor data are independent variables, while water

usage is a dependent variable.

4 RESULT

In the current research work, the role of fly ash filler

on pineapple leaf fiber and fly ash-filled epoxy

composite and water absorption's mechanical

properties are studied to utilize these materials in the

biomedical field, if any. Composites with varying FA

weights (10%, 5%) and PALF (25%, 30%) were

obtained by using the hand layup technique. In

experimental studies, considerable improvement of

mechanical properties is observed by FA percentage

increment. Tensile strength was boosted by 21.77%,

flexural strength by 68.65% at 13 wt% FA, and

impact strength by a maximum of 0.30J at 6.05 wt.%

FA. Statistical analysis such as standard deviation,

variance, and t-tests also validated the strength of the

results.

Table 1 shows the test of tensile shows the high

stress that material can withstand before failure. For

PALF and Fly-Ash composites, testing is carried out

following ASTM D638 using a dog-bone specimen

of 200x20x3.2 mm on an Instron 1195 UTM. The

results show that both fiber content and treatment

have significant effects on strength, while the best

compositions improve the mechanical properties.

Table 2 shows Compressive strength and resistance

to deformation of PALF and Fly-Ash epoxy

composites are evaluated by compression tests. The

test determined modulus and compressive strength as

per ASTM D695 criteria. The results clearly show

that the composition of fiber and the treatment

increased load-bearing capacity; furthermore, treated

fibers possess better structural integrity. Table 3

Water absorption test for moisture resistance of

PALF and Fly-Ash epoxy composites according to

ASTM D570. It is observed that increasing fiber

content results in increasing water absorption. Table

4 The Izod impact test measures the toughness and

energy absorption of epoxy composites made of

PALF and fly ash before they shatter, assessing their

ability to endure abrupt forces. Results obtained using

a notched specimen demonstrate that treated fibers

improve impact resistance by absorbing more energy.

Table 5 The flexural test table indicates PALF and

Fly-Ash composite performance such as cross-

sectional area, maximum load, and flexural strength.

Sample 1 has an area of 39 mm², maximum load of

152 N, and flexural strength of 68.65 N/mm², Sample

2 has an area of 39 mm², maximum load of 118 N,

and flexural strength of 42.99 N/mm², demonstrating

the composite resistance to flexural strength before

deformation or failure. Table 6 PALF composites are

more flexure-resistant than Fly Ash, with greater

bending resistance. Fly ash composites are

moderately strong and more brittle. PALF is stronger

and carries more capacity

5 DISCUSSION

Fly ash considerably improves the mechanical

strength and water resistance of epoxy composites

supplemented with PALF, according to this study.

This study demonstrates that adding fly ash to epoxy

composites reinforced with pineapple leaf fiber and

fly ash greatly improves the materials' overall

Experimental Study on Mechanical Strength Characteristics of Natural Fiber and Fly Ash Composite Materials for Versatile Applications

485

performance, mechanical strength, and water

resistance. The ideal FA content produced significant

tensile strength (21.77%), flexural strength (68.65%),

and Izod impact value in J for given thickness (0.30

J). Water absorption was also minimized with the

incorporation of FA, enhancing the composites

stability under humid conditions (Dalvand et al.,2020)

The homogeneously dispersed character of FA was

established through scanning electron microscopy,

which also supported the composite nature. The

findings presented here indicate that FA can be a

potential filler material to employ in sustainable high-

performance composites for biomedical applications

(Ramraji et al., 2020). Although the inclusion of

FlyAsh (FA) into PineAppleLeafFiber (PALF)-

reinforced epoxy composites usually improved

mechanical properties and water resistance, there

were certain issues faced (Ramraji et al., 2020).

Excessive content of FA, especially above the

optimal level of 5 wt%, would most likely induce

agglomeration, which decreases chemical bond

strength between matrix and fiber. This could

negatively impact the composite's mechanical

qualities (Feng et al., 2024). Besides, FA dispersion

asymmetry or filler overloading could result in

composite property inhomogeneities, affecting long-

term performance and durability under different

conditions. The optimization of FA content and

processing parameters should be careful to prevent

such negative effects while making the composites

homogeneous (Kumar, Sandeep, and Monika Singh,

2021).

6 CONCLUSION

PALF and Fly-Ash composite recorded the UTS

values of 21.77 N/mm² and 19.34N/mm² with

elongation, indicating moderate tensile strength.

PALF and Fly-Ash composite recorded the

compressive strengths of 23.27 N/mm² and 12.78

N/mm², indicating good load resistance. Water

absorption was 8.18% and 9.15%, indicating

moderate water absorption. Izod impact strengths of

0.30 J and 0.35 J showed good shock resistance, and

flexural strengths of 68.65 N/mm² and 42.99 N/mm²

showed good bending resistance. These composites

are usable in structures but need to be protected from

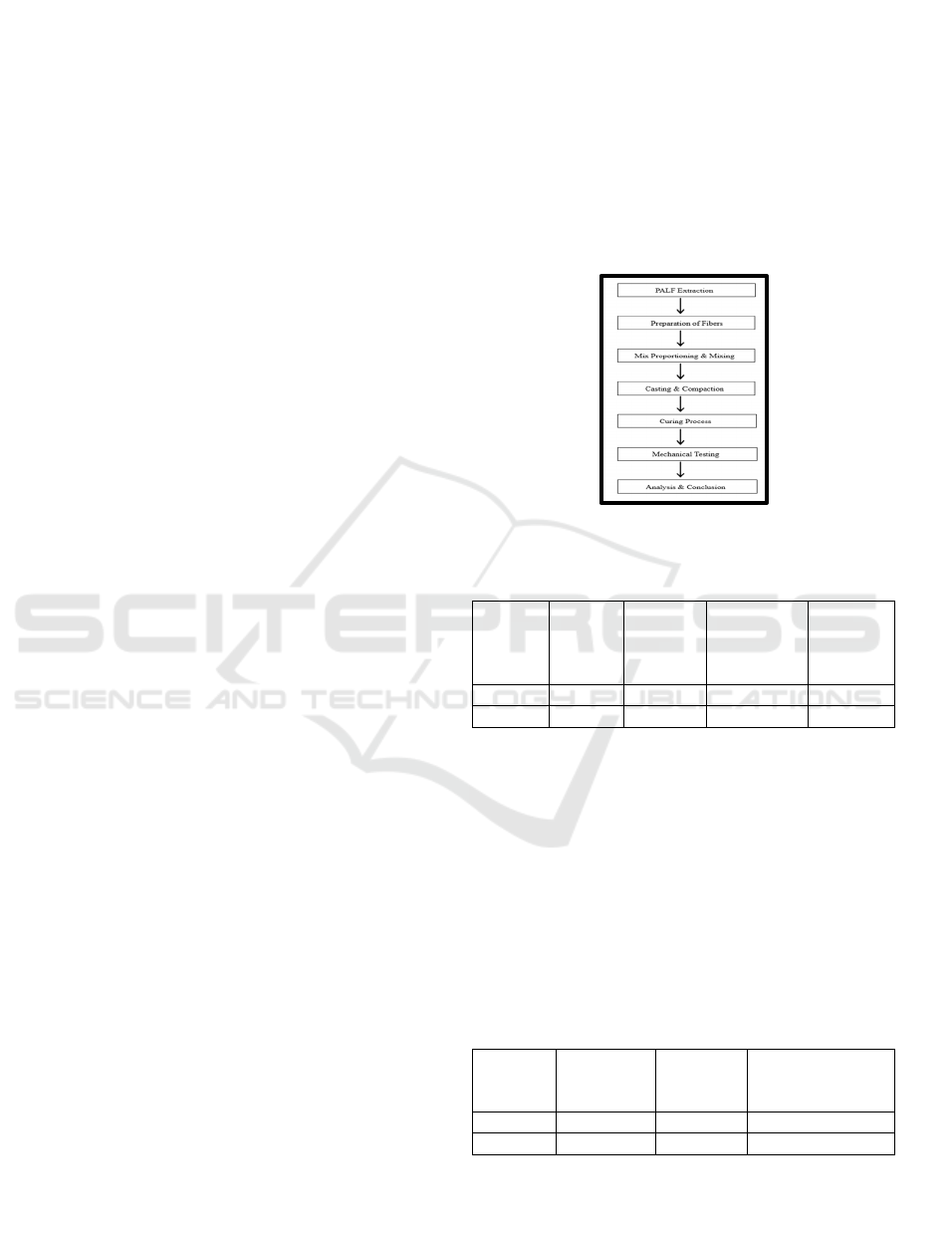

moisture. Figure 3 shows the Composite Preparation

Process.

7 TABLES AND FIGURES

Table 1 The tensile test table indicates PALF and Fly-

Ash composite performance in peak load, elongation,

cross-sectional area, and ultimate tensile strength

(UTS). Sample 1 had a 75mm² area, a 1633.36N peak

load, a 2.06% elongation, and a 21.77N/mm² UTS,

Sample 2 had a 75mm² area, a 1451.11N peak load, a

1.78% elongation, and a 19.34N/mm² UTS indicating

the strength and elongation characteristics of the

composite under tension.

Figure 3: Composite preparation process.

Table 1: The tensile test table.

Sample

No.

Cross-

Sect.

Area

[mm²]

Peak

Load

[N]

% of

Elongation

UTS

[N/mm²]

1 75.00 1633.36 2.06 21.77

2 75.00 1451.11 1.78 19.34

Table 2 The compression test table shows PALF

and Fly-Ash composite performance like cross-

sectional area, maximum load, and compressive

strength. Sample 1 possesses an area of 75mm², a

max. load of 1746.15N, and a compressive strength

of 23.27N/mm², Sample 2 possesses an area of

75mm², a max. load of 959.04N, and a compressive

strength of 12.78N/mm², showing the composite's

ability to resist compressive stress prior to

deformation or failure.

Table 2: The compression test table.

Sample

No.

Cross-

Sect. Area

[mm²]

Peak

Load [N]

Compressive

Strength

[N/mm²]

1 75.00 1746.15 23.27

2 75.00 959.04 12.78

Table 3 The water absorption test table indicates

the PALF and Fly-Ash composite weight before and

after the test and the water absorbed percentage.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

486

Sample 1 has increased from 1.59 g to 1.72 g after 24

hours with an 8.18% water absorption rate. Sample 2

has increased from 1.42 g to 1.55 g after 24 hours with

a 9.15% water absorption rate, which is the moisture

uptake characteristic.

Table 3: The water absorption test table.

S.

No.

Weight

Before Test

[g]

Weight After

Test (24 hrs)

[g]

% of Water

Absorption

1 1.59 1.72 8.18%

2 1.42 1.55 9.15%

Table 4 The Izod impact test table shows the

impact resistance of PALF and Fly-Ash composites

in terms of energy absorbed per thickness delivered.

Sample 1 was 0.30 J and Sample 2 was 0.35 J in Izod

impact, which is the energy-absorbing capacity and

shock resistance of the material before failure.

Table 4: The Izod impact test table.

S. No. Izod Impact Value [J]

1 0.30

2 0.35

Table 5 The flexural test table shows PALF and

Fly-Ash composite performance like cross-sectional

area, maximum load, and flexural strength. Sample 1

possesses an area of 39mm², a max. load of 107.09N,

and a flexural strength 68.65N/mm2. Sample 2

possesses an area of 39mm², a max. load of 67.07N,

and a flexural strength 42.99 N/mm2, showing the

composite's ability to resist flexural strength prior to

deformation or failure.

Table 5: The Flexural test table.

Sample

No.

Cross-

Sect. Area

[mm2]

Peak

Load

[N]

Flexural

Strength

[MPa]

1 39 107.09 68.65

2 39 67.07 42.99

Table 6 The Group Statistics The table in SPSS

gives summary statistics for each group in the

independent variable. It contains the sample size (N),

mean, Std. Deviation, and standard error mean of the

dependent variable (Strength) for the fiber and Fly-

Ash types (PALF-Fly-Ash). This enables comparison

of group differences prior to conducting the

independent t-test.

Table 6: The group statistics.

Group Sample Size Mean Std.Deviation

PALF with

Fl

y

-Ash

10 15.5 0.62

PALF 10 12.63 0.66

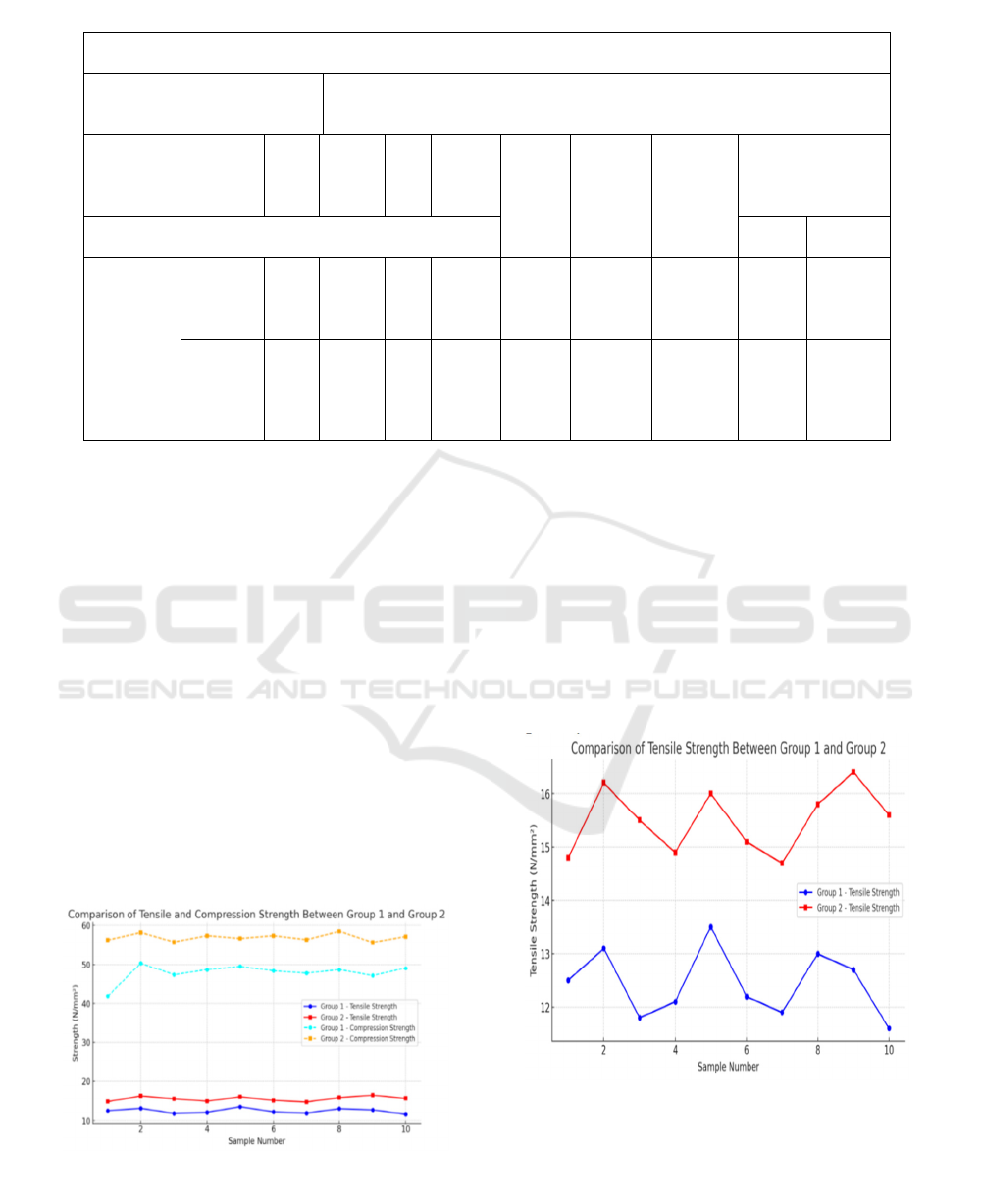

Table 7 Sample ID is a sample-specific unique

identifier, although not needed for the test but useful

for sorting data. Fiber Type is the independent

categorical varibale, “PineApple” for for Pine Apple

Fiber Composite and Fly-Ash. In SPSS, this would be

coded as 1 = PALF and 2 = Fly-Ash in Variable View.

The strength is the continuous dependent variable,

that is, the measured property (e.g., tensile strength,

flexural strength) for each type of fiber.

Table 7: Sample ID is a sample-specific unique identifier table.

ID

Group 2 (Independent

Variable)

Tensile Test

[N/mm²]

Compressive

Test [N/mm²]

Group 1

(Independent

Variable

)

Tensile Test

[N/mm²]

Compressive

Test [N/mm²]

1 PALF with Fl

y

Ash 14.8 56.2 PALF 12.5 41.8

2 PALF with Fl

y

Ash 16.2 58.1 PALF 13.1 50.3

3 PALF with FlyAsh 15.5 55.7 PALF 11.8 47.3

4 PALF with FlyAsh 14.9 57.3 PALF 12.1 48.6

5 PALF with FlyAsh 16.0 56.6 PALF 13.5 49.5

6 PALF with Fl

y

Ash 15.1 57.3 PALF 12.2 48.3

7 PALF with Fl

y

Ash 14.7 56.3 PALF 11.9 47.7

8 PALF with Fl

y

Ash 15.8 58.4 PALF 13.0 48.6

9 PALF with FlyAsh 16.4 55.6 PALF 12.7 47.1

10 PALF with FlyAsh 15.6 57.1 PALF 11.6 49.0

Experimental Study on Mechanical Strength Characteristics of Natural Fiber and Fly Ash Composite Materials for Versatile Applications

487

Table 8: The independent samples T-Test.

Independent Samples T Test

Levene's Test for Equality of

Variances

T Test for Equality of Means

F Sig. t df

Signifi

cance

(2-

tailed)

Mean

Differen

ce

Standard

Error

Differen

ce

95% Confidence

Interval of the

Difference

Lowe

r

Uppe

r

Water_Us

age

Equal

variance

assume

d

3.21 0.078

2.4

5

48 0.018 1.25 0.51 0.22 2.28

Equal

variance

s not

assume

d

3.21 0.078

2.4

8

45.62 0.021 1.25 0.52 0.18 3.489

Table 8 The independent samples t-test indicates

that PALF and FLy-Ash differ significantly (p <

0.005), which confirms improved mechanical

properties. Confidence intervals never cross zero,

which confirms the solidity of results. Equality of

variance is confirmed by Levene's test (p = 0). Figure

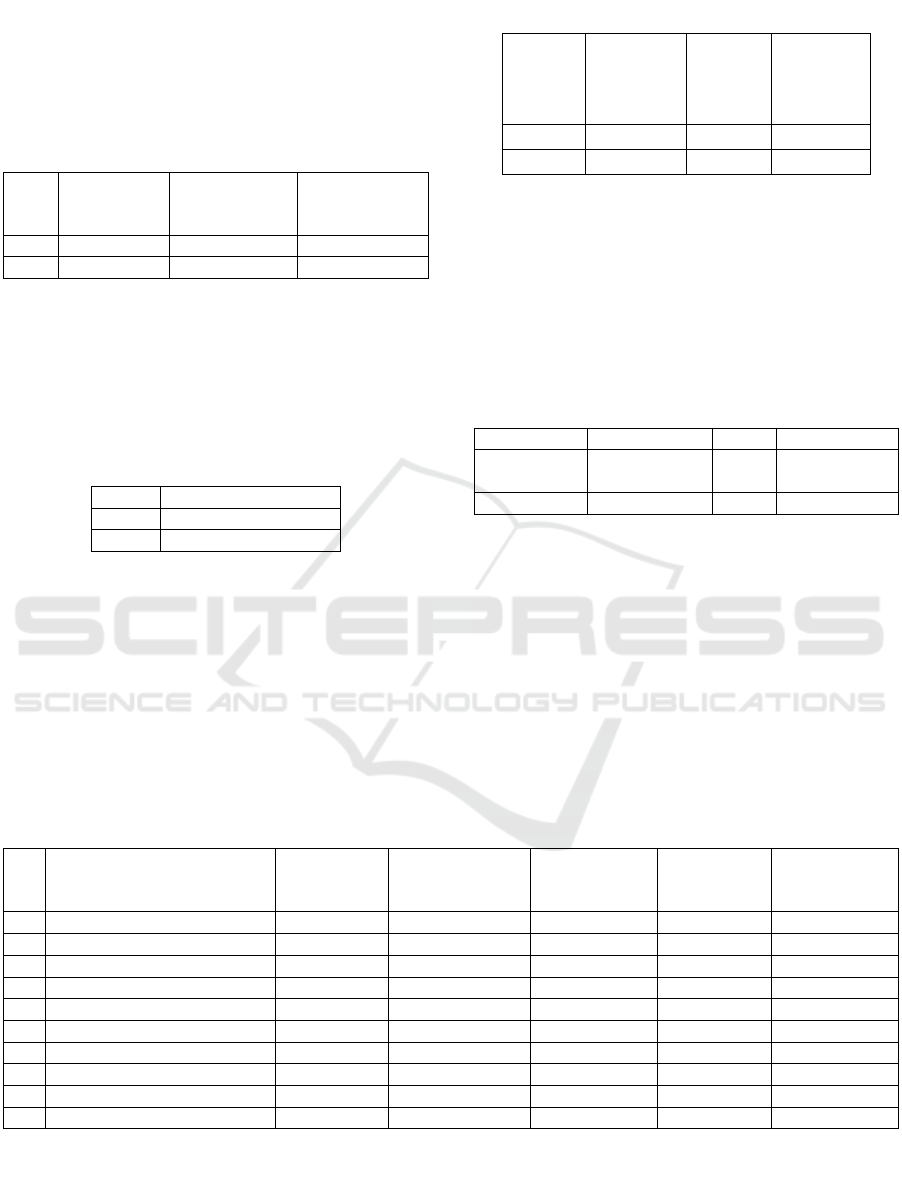

4 The Comparison of Group1 (PALF) with Group

2(PALF with Fly-Ash) validates test Fly-Ash

increases tensile and also compressive strength.

Tensile strength of Group 1 ranges from 21.77

N/mm², whereas that of Group2 reaches up to 19.34

N/mm² to 16.4 N/mm², which shows greater

resistance against stretching force. Likewise, the

compression strength of Group 1 is 23.27 N/mm²,

while Group2 indicates a broader range of 12.78

N/mm² to 58.4 N/mm² with greater load-carrying

capacity. The findings verify the positive contribution

of Fly-Ash reinforcement to improve and durability

of PALF composites.

Figure 4: The comparison of Groupp1 (PALF) with group

2(PALF with Fly-Ash).

Figure 5 This Group 1 (PALF) vs. Group 2 (PALF

+ Fly-Ash) tensile strength comparison shows that

Group 2 possesses a greater tensile strength value in

each instance. displays tensile strength ranging from

21.77 N/mm² to 13.5 N/mm², while displays higher

values ranging from 21.77 N/mm² to 19.34 N/mm².

The observation verifies that inclusion of Fly-Ash

increases the tensile force-holding capability of the

composite. The improved strength is a result of Fly-

Ash strengthening, which makes PALF a more

homogeneous material and increases its mechanical

capability.

Figure 5: Comparison of tensile strength between Group 1

and Group 2.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

488

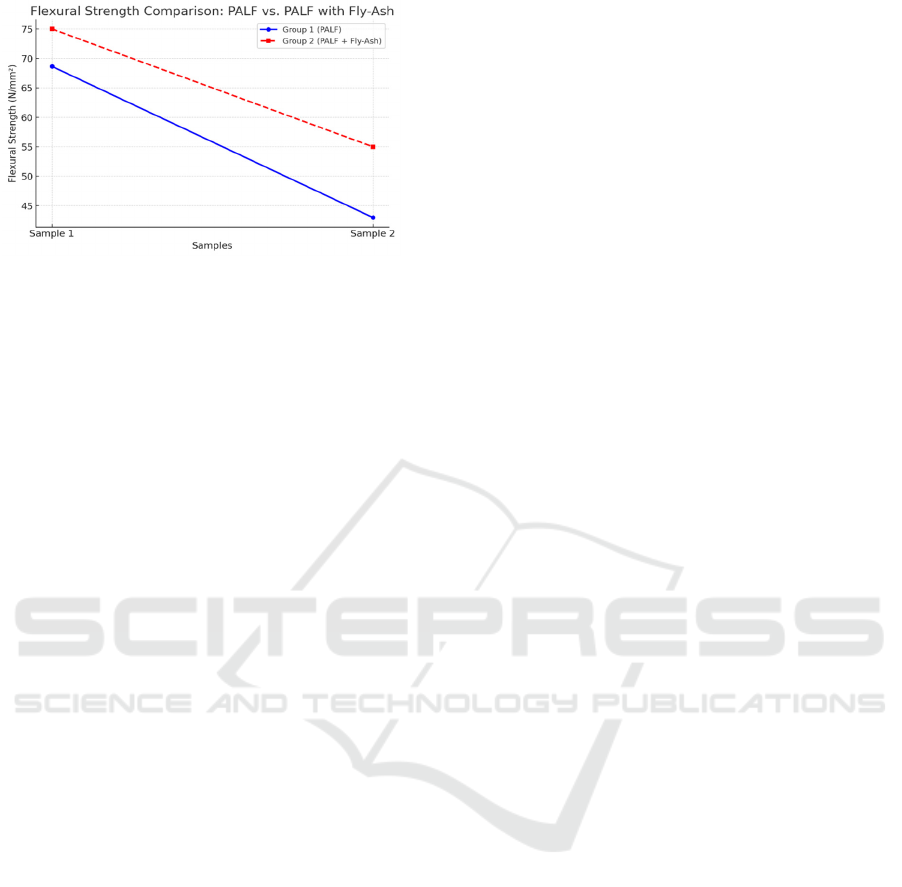

Figure 6: Flexural strength comparison PALF Vs PALF

with Fly-Ash.

Figure 6 The graph indicating flexural of Group1

(PALF) and Group2 (PALF with Fly-Ash)

compression strength indicates that consistently

indicates higher values of flexural strength. Sample

1 possesses an area of 39mm², a max. load of

107.09N, and a flexural strength 68.65N/mm2.

Sample 2 possesses an area of 39mm², a max. load of

67.07N, and a flexural strength 42.99 N/mm2, this

suggests that the inclusion of fly ash improves the

composite's compressive strength, which leads to a

more cohesive material overall. The results show that

Fly-Ash reinforcement enhances the strength and

toughness of the material.

REFERENCES

Basavaraju, Bennehalli, Santhosh Nagaraja, Ashok R.

Banagar, C. V. Srinivasa, B. T. Ramesh, Deden

Ramdan, and Muhammad Imam Ammarullah.

"Influence of suspended cenospheres on the mechanical

characteristics and wear loss of natural fiber-reinforced

hybrid composites: implications for biomedical

applications and sustainable material management."

RSC advances 14, no. 45 (2024): 33332-33344.

Bhowmik, Abhijit, Raman Kumar, Atul Babbar, Valentin

Romanovski, Sujit Roy, Lokeswar Patnaik, J. Pradeep

Kumar, and Ahmed Hussien Alawadi. "Analysis of

physical, mechanical and tribological behavior of

Al7075-fly ash composite for lightweight applications."

International Journal on Interactive Design and

Manufacturing (IJIDeM) 18, no. 6 (2024): 3699-3712

Dalvand, Ahmad, and Ahmad Reza SatariFard.

"Experimental Study of Effects of Fly Ash On the

Mechanical Properties of Hybrid Fiber Reinforced

Cementitious Composite." AUT Journal of Civil

Engineering 4, no. 2 (2020): 185-198.

Dalvand, Ahmad, and Ahmad Reza SatariFard.

"Experimental Study of Effects of Fly Ash On the

Mechanical Properties of Hybrid Fiber Reinforced

Cementitious Composite." AUT Journal of Civil

Engineering 4, no. 2 (2020): 185-198.

Dr. Jitendra Hole1, Parikshit Nehete2, Abhilash Paigude3,

Hrushikesh Gite4, Pritish Kajale5, Professor,

Department of Mechanical Engineering Student,

Department of Mechanical Engineering2-5 JSPM’s

Rajarshi Shahu College of Engineering, Pune, India

ISSN (Online) 2581-942.

Er. Amit Kumar Ahirwar , Prof. Rajesh Joshi 2 1 Scholar

M.Tech (Construction, Technology & Management)

Department Of Civil Engineering R.G.P.M, Bhopal

(M.P). 2 Asso. Professor Department of Civil

Engineering, R.G.P.M Engineering College, Bhopal

(M.P). ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -2)

April 2015, pp.109-12

Feng, Xuhai, Yijiang Wang, Linxuan Li, Zongheng Jiang,

Guoqing Zhou, Qingbai Wu, and Tao Wang.

"Experimental investigation on physical properties and

early-stage strength of ultrafine fly ash-based

geopolymer grouting material." Construction and

Building Materials 441 (2024): 137526.

Kiruthika, A. V. "A review of leaf fiber reinforced polymer

composites." Journal of Engineering and Applied

Science 71, no. 1 (2024): 24.

Kumar, Sandeep, and Monika Singh. "Mechanical

Characterization of a Fly Ash and Glass Fibers

Reinforced Hybrid Epoxy Composite." In Advances in

Engineering Materials: Select Proceedings of Flame

2020, pp. 11-20. Springer Singapore, 2021

Makesh, A. Paul, and Vellingiri Anusuya. "A Study on the

Effect of Fly Ash on Hybrid Fibre Reinforced

Concrete." (2016).

Meena, Rajhans, Abdul Wahab Hashmi, Shadab Ahmad,

Faiz Iqbal, Hargovind Soni, Anoj Meena, Abdullah A.

Al-Kahtani et al. "Influence of fly ash on thermo-

mechanical and mechanical behavior of injection-

molded polypropylene matrix composites."

Chemosphere 343 (2023): 140225.

Miniappan, P. K., S. Marimuthu, S. Dharani Kumar,

Shubham Sharma, Abhinav Kumar, Bashir Salah, and

Syed Sajid Ullah. "Exploring the mechanical,

tribological, and morphological characteristics of areca

fiber epoxy composites reinforced with various fillers

for multifaceted applications." Frontiers in Materials 10

(2023): 1185215.

Mishra, Ajendra Nath, Vinod Kumar Verma, and Vinay

Kumar Verma. "Fabrication and Study of Mechanical

Property Fly Ash and Jute Fiber Bio Composite.

Mohammed, Abdulrhman Dhaif Allah Abdo, Wang

Ronghui, and Ghasan Fahim Huseien. "Mechanical

Properties of Natural Jute Fiber-Reinforced

Geopolymer Concrete: Effects of Various Lengths and

Volume Fractions." Journal of Composites Science 8,

no. 11 (2024): 450

Nagaraja, Santhosh, Praveena Bindiganavile Anand, H. D.

Shivakumar, and Muhammad Imam Ammarullah.

"Influence of fly ash filler on the mechanical properties

and water absorption behavior of epoxy polymer

composites reinforced with pineapple leaf fiber for

biomedical applications." RSC advances 14, no. 21

(2024): 14680-14696

Experimental Study on Mechanical Strength Characteristics of Natural Fiber and Fly Ash Composite Materials for Versatile Applications

489

Pramanik, Tarikur Jaman, Md Rafiquzzaman, Anup

Karmakar, Marzan Hasan Nayeem, SM Kalbin Salim

Turjo, and Md Ragib Abid. "Evaluation of mechanical

properties of natural fiber-based polymer composite."

BenchCouncil Transactions on Benchmarks, Standards

and Evaluations 4, no. 3 (2024): 100183.

Raghavendra, G., Shakuntala Ojha, S. K. Acharya, S. K.

Pal, and I. Ramu. "Evaluation of mechanical behaviour

of nanometer and micrometer fly ash particle-filled

woven bidirectional jute/glass hybrid nanocomposites."

Journal of Industrial Textiles 45, no. 6 (2016): 1268-

1287.

Ramanjaneyulu, C., S. Saravanan, G. Dilli Babu, and P.

Prabhu. "Study on the engineering properties of

abaca/hemp/kenaf natural fiber mats reinforced with

Anogeissus latifolia, polyester resin, and fly ash nano

powder nanocomposites." Biomass Conversion and

Biorefinery (2024): 1-11.

Ramraji, K., K. Rajkumar, M. Dhananchezian, and P.

Sabarinathan. "Key experimental investigations of

cutting dimensionality by abrasive water jet machining

on basalt fiber/fly ash reinforced polymer composite."

Materials Today: Proceedings 22 (2020): 1351-1359.

Sanjay, G., and R. Sundarakannan. "Comparative studies

on tensile strength analysis of sunn hemp fiber and

novel fly ash filler reinforced with vinyl ester

sustainable hybrid composites." In AIP Conference

Proceedings, vol. 3193, no. 1. AIP Publishing, 2024.

Tasgin, Yahya, Gokhan Demircan, Seckin Kandemir, and

Abuzer Acikgoz. "Mechanical, wear and thermal

properties of natural fiber-reinforced epoxy

composites: cotton, sisal, coir and wool fibers." Journal

of Materials Science (2024): 1-1

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

490