Enhancing Construction Site Safety: Personal Protective Equipment

Detection Using Yolov11 and OpenCV

Ruchitraa Rajagopal, Harshitha Pulluru, Aaradhya Joshi and Shanmuganathan C.

Department of Computer Science and Engineering, SRM Institute of Science and Technology, Ramapuram, Chennai, Tamil

Nadu, India

Keywords: Construction Site Safety (CSS), Personal Protective Equipment (PPE), You Only Look once (YOLO),

Real‑Time Object Detection (RTOD), Site‑Risk Assessment (SRA), Worker Safety Compliance (WSC),

Machine Learning (ML), Computer Vision (CV).

Abstract: One of the most emerging industries in the world is construction. Even after installing a lot of safety rules and

regulations, construction site accidents are a major threat. This is because of non-compliance with the assigned

safety protocols and the lack of a system assigned for supervision. The paper provides a model that can

automate the safety system using Computer Vision (CV) and Machine Learning (ML) techniques. The model

analyzes the surveillance footage to detect workers and their personal protective equipment (PPE), such as

safety vests, masks, and hard hats. It also calculates the distance between workers and machinery and sends

alerts in case of unsafe distances. The system also provides a graphical user interface where the site managers

or supervisors can easily monitor the surveillance footage with the model results in real time. The warnings

are stored in a database along with a video clip and other essential information. This way, the supervisors can

view the database and get an idea about the type of warnings and when and where they occurred. This way,

they can guide the workers regarding site safety. The model used by the system is YOLOv11. It is trained and

tested to give better results in various weather conditions. The model achieves a mAP of 81% at 0.5 IoU and

a mAP of 60.3% at 0.5 to 0.95 IoU, with an overall accuracy, precision, and recall of 97%, 87%, and 76%,

respectively. It is computationally efficient, with 14.7GB FLOPs, 6.4MB parameters, and an inference speed

of 2.4ms, making the model applicable for real-time analysis.

1 INTRODUCTION

Construction sites are naturally as well as inherently

dangerous environments where the worker’s safety is a

constant challenge. The presence of heavy machinery,

hazardous materials, and complex workflows increases

the likelihood of accidents, thus making compliance

with safety regulations critical. While PPE such as

safety vests, masks, and hard hats play a key role in

injury prevention, monitoring them manually takes up

much time, and is often ineffective in large-scale sites

Chen et al., (2021).

Traditional safety methods, which were quite

laborious, such as manual checking and surveillance

cameras, are often slow and difficult to scale, making

it difficult to detect and prevent accidents.

Advancements in the field of CV and ML have opened

a lot of new techniques to automate safety monitoring.

AI-powered detection models, such as YOLO (You

Only Look Once), have shown promising results in

identifying safety gear and worker behavior from video

feeds. However, challenges such as detecting small

objects, handling occlusions, and maintaining accuracy

in varying lighting and environmental conditions

remain. This research introduces a safety monitoring

system that leverages AI and integrates YOLOv11 to

identify PPE and monitor worker proximity to heavy

machinery in real-world systems Chen et al., (2021).

Included in the system is a graphical user interface

(GUI), where the site managers can monitor the

workers and their compliance with safety protocols.

The proposed system improves detection accuracy by

incorporating multi-scale feature extraction, attention

mechanisms, and bounding box regression Feng et al.,

(2024). Mosaic data augmentation is applied to the

training part of the set, while the testing part is

modified to simulate various weather conditions, such

as high brightness, dust, and motion blur. To further

improve site safety, the system includes a proximity

344

Rajagopal, R., Pulluru, H., Joshi, A. and C., S.

Enhancing Construction Site Safety: Personal Protective Equipment Detection Using Yolov11 and OpenCV.

DOI: 10.5220/0013882800004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 2, pages

344-353

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

detection algorithm that helps prevent worker-

machinery collisions.

This paper discusses the methodology,

implementation, performance evaluation, and also

potential future improvements of the proposed system.

The findings highlight how AI-driven monitoring can

transform workplace safety, minimize accidents, and

enhance regulatory compliance in high-risk industries.

2 RELATED WORKS

One of the most emerging industries in the world

construction. Although these industries contribute a

lot to the nation's GDP, even after installing a lot of

safety rules and regulations, construction site

accidents are a major threat. Therefore, a lot of

methods are being implemented to reduce the risk of

accidents. Some of these methods include the Safety

Detection method based on improved YOLOv8,

integrating an AI model for construction site safety,

and using Fast R-CNN and CNN to detect bounding

box coordinates. A summary of these findings is

presented in Table 1.

Table 1: Summary of Findings.

S.No. Paper’s Name Targeted Object Findings

1

“Safety Detection Method based on

improved YOLOv8”

Safety Helmet

Proposed study includes an

improved algorithm

YOLOv8n-SLIM-CA. It uses

mosaic data augmentation and

coordinate attention

mechanism.

2

“Deep Learning Based Workers

Safety Helmet Wearing Detection

on Construction Sites Using Multi-

Scale Features”

Safety Helmet

This study focuses on the

addition of multi-scale features

and attention mechanism along

with the baseline YOLOv5

model.

3

“A Novel Implementation of an AI-

Based Smart Construction Safety

Inspection Protocol in the UAE”

Safety Harness

This study focuses on

developing a CNN-based

model to detect safety harness.

The deep learning network

uses YOLOv3.

One of the articles, “A Novel Implementation of

an AI-Based Smart Construction Safety Inspection

Protocol in the UAE”, focuses on integrating AI,

precisely a deep learning approach which is used to

supervise and detect safety violations Shanti et al.,

(2021). This paper focuses on the development of a

CNN-based technique for safety that provides

supervising workers working at construction sites

using a real-time detection and monitoring algorithm,

YOLOv3. It trains a CNN that is used for detecting

equipment such as safety vests and safety helmets.

The main challenge that this method faces is the

difficulty of obtaining surveillance video and training

all the data sets required by the CNN models.

Another research paper that proposes using CV

and ML for the detection of safety helmets is "Safety

Helmet Detection Based on Improved YOLOv8" Lin,

B, (2024). Safety helmets are essential for protecting

workers from head injuries on construction sites, but

relying on manual supervision to ensure compliance

can be inefficient and prone to mistakes. Deep

learning models like YOLO have made helmet

detection possible in real-world implementation, but

they often struggle with spotting small or partially

hidden helmets in busy environments. To overcome

it, the paper uses YOLOv8n-SLIM-CA. This

improved detection model enhances accuracy using

Mosaic data augmentation, a Slim-Neck structure,

and Coordinate Attention. These upgrades help the

model focus better on safety helmets, reduce

complexity, and improve detection in challenging

conditions.

Compared to the standard YOLOv8n, the model

boosts accuracy by 2.151% (mAP@0.5), reduces

model size by 6.98%, and lowers computational load

by 9.76%, making it faster and more efficient Lin, B,

(2024). Tested on the Safety Helmet Wearing Dataset

(SHWD), it outperforms other detection models by

identifying helmets more accurately, even in

crowded, distant, or cluttered backgrounds. This

makes YOLOv8n-SLIM-CA a powerful tool for real-

world safety monitoring Lin, B, (2024). Looking

Enhancing Construction Site Safety: Personal Protective Equipment Detection Using Yolov11 and OpenCV

345

ahead, integrating this model into edge devices could

make real-time helmet detection even more practical

and accessible for industrial safety.

Another research paper that focuses on a CNN

based detection of safety helmets is "Deep Learning

Based Workers Safety Helmet Wearing Detection on

Construction Sites Using Multi-Scale Features"

Han

et al., (2022). Ensuring people wear safety helmets

on-site is crucial for preventing injuries from falling

objects, but traditional monitoring methods can take

much time and are inclined to a lot of mistakes. This

study presents an improved deep learning approach

using YOLOv5, enhanced with a fourth detection

scale to identify small objects better and an attention

mechanism to improve feature extraction.

To address the challenge of limited training data,

targeted data is augmented, followed by the usage of

transfer learning resulting in a 92.2% mean average

precision (mAP) and an improvement of 6.4% in

accuracy, with object detection of just 3.0 ms speed

at 640×640 resolution Han et al., (2022). This makes

the model precise and applicable for real-time

analysis. Thus, automating safety compliance checks

minimizes the need for constant manual supervision,

allowing site managers to identify and respond to

potential risks more efficiently.

3 METHODOLOGY

3.1 Proposed System Architecture

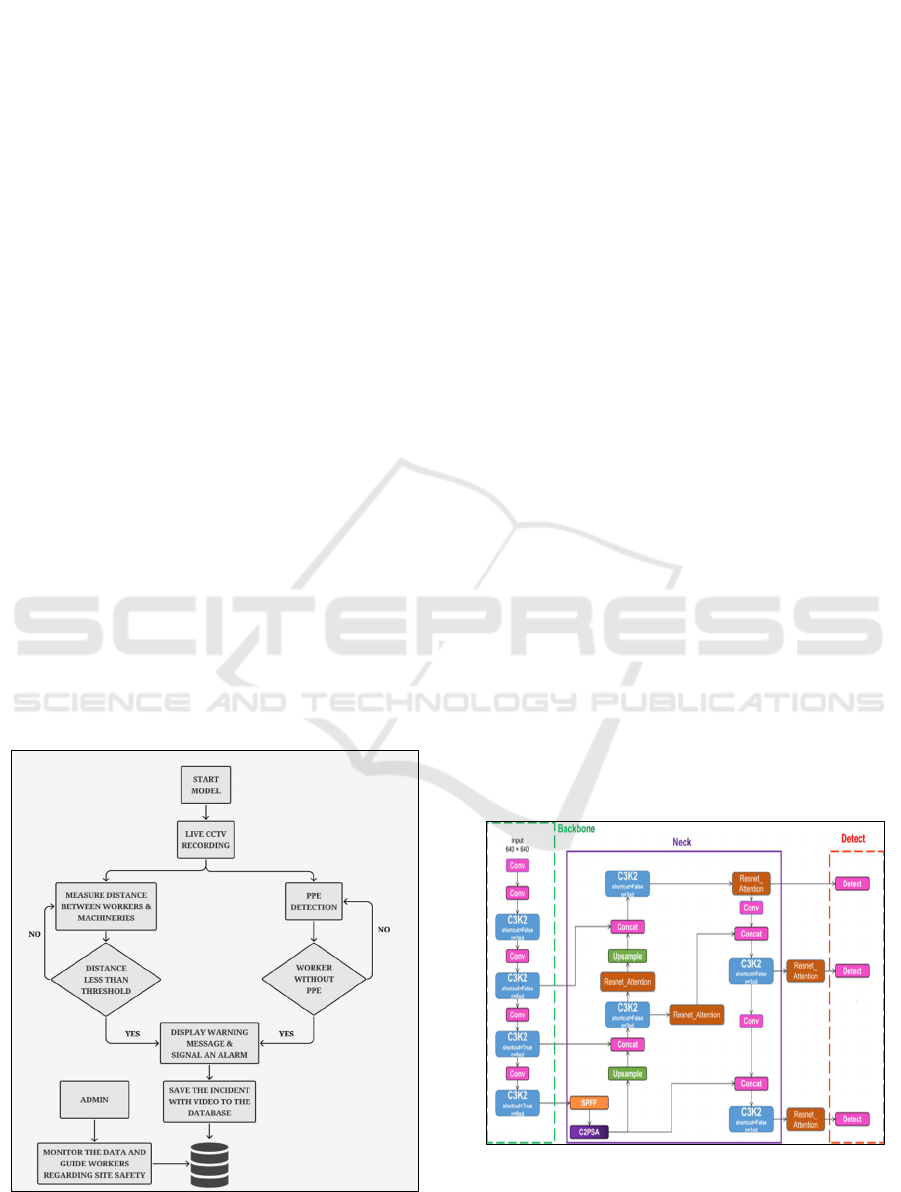

Figure 1: Architecture Diagram.

The model analyzes live video feeds. This ensures

real-time monitoring of worker compliance. The

model training is done on diverse construction site

datasets. So, PPE can be detected in varying lighting

and diverse environmental conditions Sridhar et al.,

(2024). YOLO gives a bounding box as an output for

the detected object, which streamlines safety

enforcement. YOLOv11 significantly improves

workplace safety as well as adherence to various

safety rules. Figure 1 shows the proposed system’s

architecture diagram.

3.2 YOLOv11 Architecture

YOLOv11 is an object detection model applied in a

single shot. It is built for real-time applications, which

offers both speed and accuracy. Traditional models

process images in multiple stages. While YOLOv11

analyzes the entire image in just a single pass, which

makes it highly efficient. Its working involves the

division of the image into a grid and then the

prediction of their object locations and their

classifications simultaneously. It comes with

improved feature extraction and attention

mechanisms. Thus, it excels in identifying small or

overlapping objects with greater precision. To

enhance its accuracy, it utilizes optimized loss

functions like Complete IoU (CIoU) Mahmud et al.,

(2023). This helps fine-tune object localization as

well as minimize incorrect detections. YOLOv11

comes with a lightweight design, which ensures quick

processing. Thus, YOLOv11 is a perfect choice for

tasks that demand real-time object recognition

without compromising performance. Figure 2 shows

the architecture of the YOLOv11 model.

Figure 2: YOLOv11 Architecture Diagram.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

346

3.3 Single Shot Detector

SSD uses the technique of Non-Max Suppression,

which is used to eliminate any duplicate detections

that would occur. So, by using non-max suppression,

only the most relevant bounding boxes will be

retained. In dynamic construction sites, speed and

accuracy are of utmost importance when we need to

employ it for real-time detection of PPE. The

architecture of the SSD is also lightweight. This is

essential as it can ensure easy deployment on edge

devices Jankovic et al., (2024). This also enables the

system to work without relying on high-end

hardware. Such deployment in construction sites

allows the workers and supervisors to be provided

with instant alerts (2024). Thus, SSD plays a huge

role in enhancing worker safety. So, the integration of

SSD and OpenCV with deep learning techniques

enhances the model and allows it to perform real-time

safety monitoring with minimum latency Shetty et al.,

(2024). The reliability of the model has also increased

because of its ability to work in different lighting

conditions and various environmental variations.

Through proper training, SSD can improve

compliance enforcement and significantly reduce

workplace hazards.

3.4 Bounding Box Regression for PPE

Detection and Machinery

Proximity

Bounding box regression is a fundamental technique

used in object detection models like YOLO and SSD

to localize objects within an image precisely. In the

context of construction site safety, bounding box

regression is used to detect PPE compliance by

identifying helmets, vests, gloves, and other safety

gear. Merely enclosing the detected objects in

bounding boxes is not sufficient. Thus, Bounding Box

Regression calculates x, y, width and height.

Bounding Box Regression is important in

construction site monitoring. By calculation of

Euclidean distance between the workers and

machinery, proximity alerts are designed to trigger

when the computed distance between the two

bounding boxes falls below a certain threshold. Such

trigger alerts help minimize the chances of accidents

by sending proactive notifications to the workers as

well as the supervisors Al-Azani et al., (2024). The

method also benefits from non-maximum

suppression (NMS). Bounding box regression

accuracy depends on proper dataset labelling and

model training with diverse construction site images.

The attention mechanism is one of the advancements

of deep learning, and it further refines the accuracy of

bounding boxes. This ensures precise detection even

in complex environments. Thus, the BBR technique

can be efficiently used to optimize the real-time

monitoring of safety compliances Gautam et al.,

(2024). When combined with an alert system,

workplace safety is enhanced as the hat workers are

instantly made aware of potential hazards.

3.5 Attention Mechanism-Based CNN

Attention mechanisms in deep learning have

revolutionized object detection by improving feature

extraction and focusing on the most relevant image

regions. In PPE detection for construction site safety,

attention mechanisms help CNN models prioritize

critical areas, such as worker faces, helmets, and

vests, while ignoring irrelevant background details.

So, the approach of ignoring irrelevant parts and

focusing on significant features improves detection

accuracy in cluttered environments as well as other

complex environments. This is done by an attention

mechanism based on CNN, which assigns higher

weights to the important regions of the image Guan et

al., (2024). This ensures that the model captures the

local as well as global dependencies efficiently

without any compromise. This means that the model

is enhanced to detect PPE even in challenging

conditions like poor lighting, occlusions or even low-

lighting video feeds. Thus, the integration of

Attention Mechanism based CNN with YOLO and

OpenCV for detection of PPE in real-time achieves

greater precision. Construction sites have different

environments, which the model can quickly adapt to

Ponika et al., (2023). This is a major advantage to

ensure safety compliance across such diverse

environments. Another advantage is the visual

highlight of the area influencing the prediction. Such

transparency helps the safety officers to detect errors

more easily.

The usage of attention-based mechanisms helps in

processing large-scale datasets efficiently. Real-time

applications require such machinations to handle

large data. Thus, the model training is proceeded with

a diverse dataset consisting of various combinations

of colors, textures, and placements using this

methodology Han et al., (2024). This methodology

ensures a reliable and efficient safety monitoring

system that proactively mitigates construction site

hazards.

Enhancing Construction Site Safety: Personal Protective Equipment Detection Using Yolov11 and OpenCV

347

3.6 Image Pre-Processing

Image preprocessing also is used to ensure that the

model focuses on relevant objects. This is done before

enhancing visual clarity. Normalization is applied to

scale pixel values between 0 and 1. This is to prevent

intensity variations from affecting detection

performance. Sobel and Canny filters are edge

detection techniques that are used to sharpen image

boundaries. This helps in the easy detection of PPE

equipment like vests and helmets by the model. The

Grayscale Conversion also simplifies the image

complexity by reducing the amount of unnecessary

data which is processed. This method is done while

retaining key object structures. This method is also

quite useful in cases of background distractions.

Segmentation is a technique that can be used to

separate or isolate the workers and their PPE from the

cluttered environments. Thus, when segmentation is

used, it leads to more precise detections Krishna et al.,

(2021). Thus, before inputting the input image to

modal for training, preprocessing them leads to the

deep learning algorithms to work more efficiently. As

a result, a robust and adaptable PPE detection system

can be achieved.

Image preprocessing is used to enhance visual

clarity. Not only this but it is also used for the

extraction of features by focusing only on relevant

objects. Normalization is such a technique. This is

used to scale the pixel values between the range of 0

and 1 inclusive. Thus, even with varying intensities,

the detection performance is not affected. There are

many edge detection techniques like Sobel and Canny

filters. They are used to sharpen the boundary of

images. This sharpening ensures easier detection of

PPE equipment like safety helmets and vests. In

grayscale conversion, the image is retained only of its

key structures. This simplification reduces the

unnecessary processing of data. When there are

background distractions, segmentation techniques

can be used Gautamet al., (2024). This is a very

powerful deep-learning technique which isolates the

key image parts from unnecessary key structures.

Thus, refining images in preprocessing is vital to

ensure that model training works efficiently.

3.7 Image Augmentation

This is a technique when we need to artificially

expand our datasets. This helps models better

generalize to real-world scenarios. PPE detection

should be able to work across various lighting

conditions, angles and environments for real-time

deployment. Thus, augmentation helps the model to

be trained with a diverse set of images. Flipping or

rotating the images provides the model with various

data points. Scaling is also used to adjust the size of

the images. Thus, the model trained using various

augmentation techniques can recognize PPE from

multiple orientations. Thus, the model can reliably

identify PPE of different sizes. Random cropping of

the images is also added to the dataset Han et al.,

(2022). This prepares the model to identify PPE even

if it is partially visible in cases where vests or helmets

may be partially obscured. Thus, the application of

augmentation techniques prevents overfitting. It also

allows the model to perform reliably even in

unpredictable conditions.

Colour-based augmentations are also applied to

enhance the detection further. This includes

brightness, contrast and hue adjustments.

Construction sites often have varying lighting

conditions. The adjustment of brightness levels in

images ensures that the model is exposed to diverse

image lighting. This ensures effectiveness in both

well-lit and dim conditions. A contrast enhancement

application is used so that clear differentiation of PPE

from the background is achieved. Noise is added to

the training dataset to simulate real-world scenarios

where camera imperfections may occur. This makes

the model resilient to real-world scenarios Shanti et

al., (2021). Finally, techniques like image overlays

and motion blur are applied to the dataset. At the same

time, the data recorded by the camera would have

images or video live feeds of workers who are

partially covered. They might also be moving. Such

real-world scenarios need to be considered while

training the model Azatbekuly et al., (2024). Using

augmentation, the model becomes highly adaptable to

such scenarios. As a result, a detection system across

challenging and diverse environments is achieved.

4 DATA AND EXPERIMENTAL

SETUP

4.1 Computer Configurations

The model was trained on a laptop equipped with a

NVIDIA GeForce GTX 1650 Ti GPU. The detection

model was implemented using CUDA, Ultralytics,

OpenCV, and PyTorch. Table 2 provides the

computer configurations.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

348

Table 2: Computer Configuration.

CONFIGURATION TYPE

System Windows 11

CPU

AMD Ryzen 7

4800HS (8 cores, 16

threads)

Memory 16GB

GPU

NVIDIA GeForce

GTX 1650 Ti

OS type 64-bit

Python version 3.12.7

N

VIDIA Drive

r

version 555.97

CUDA version 12.6

Ultralytics version 8.3.78

PyTorch version 2.6.0+cu126

OpenCV version 4.11.0

4.2 Dataset

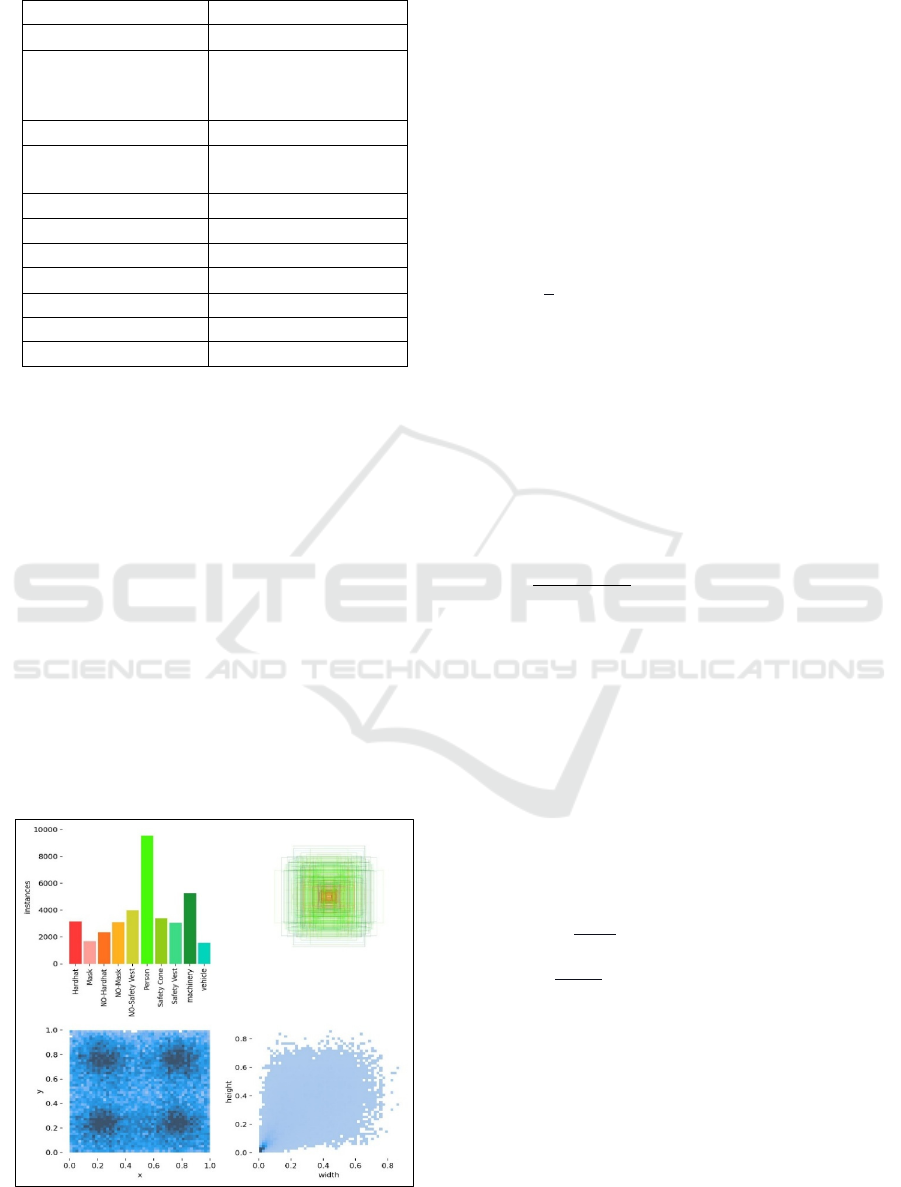

The dataset consists of 717 images, divided into the

following parts: the train part (73%) contains 521

images, the validation part (16%) contains 114

images, and the test part (11%) contains 82 images.

Each set includes images and corresponding label

files (.txt). The dataset contains 10 labels, numbered

0 to 9: Hardhat, Machinery, NO-Hardhat, Mask,

Safety Cone, NO-Mask, Safety Vest, Vehicle, NO-

Safety Vest, and Person. The train set is modified

using mosaic data augmentation, and each model is

trained on that set (2025). The model is then

evaluated on a modified set under different

conditions, including RGB, grayscale, blur, dust, and

maximum brightness, ensuring evaluation across all

scenarios. Figure 3 presents the graphical results of

the train set.

Figure 3: Graphical Results of the Train Set.

4.3 Evaluation Metrics

4.3.1 Mean Average Precision (mAP)

mAP determines the overall detection efficiency by

averaging the precision scores across multiple recall

thresholds. It is widely used in detection to assess the

accuracy of bounding box predictions (2025). For

PPE detection, a greater mAP indicates correctly

identifying helmets, vests, gloves, and other safety

gear with high recall and precision. This is useful in

ensuring compliance monitoring in real-time

environments.

mAP =

∑

AP

(1)

4.3.2 Intersection over Union

IoU evaluates the intersection of the ground truth with

the predicted bounding box. A high IoU is better for

object localization, which is critical for PPE detection

in construction sites. Poor IoU may result in

misclassification or failure to detect safety gear,

leading to compliance issues. It is commonly used to

filter out incorrect detections in object detection

tasks.

IoU =

(2)

where the numerator is the intersection of actual and

predicted bounding boxes, and the denominator is

their combined area.

4.3.3 Precision and Recall

Precision measures how many detected PPE items are

correct, while recall measures the actual PPE items

were successfully identified. High precision results in

lower false alarms, while high recall results in lower

missed detections. In PPE detection, striking a

balance is crucial for reliable compliance monitoring

in workplaces.

Precision =

(3)

Recall =

(4)

4.3.4 Accuracy

Accuracy is a fundamental metric used to determine

the overall efficiency of a PPE detection system. It

measures the correctly classified instances (PPE and

non-PPE) from the total number of predictions

(2025). A greater accuracy indicates correctly

identifying workers wearing PPE and those without

it, minimizing misclassifications. However, accuracy

Enhancing Construction Site Safety: Personal Protective Equipment Detection Using Yolov11 and OpenCV

349

alone may not always reflect model reliability,

especially if there is an imbalance in the dataset (e.g.,

more PPE-wearing workers than non-compliant

ones). To get a clearer picture, accuracy is often

analyzed alongside precision and recall to ensure a

balanced performance.

Accuracy =

(5)

4.3.5 F1-Score

It is the harmonic mean of recall and precision. It

provides a metric to determine the overall efficiency

of the PPE detection model. It is particularly useful

when there is an imbalance between detected and

actual PPE items, ensuring that false negatives and

false positives are minimized.

F1 = 2 ×

×

(6)

A higher F1-score indicates a well-balanced

model that effectively detects safety gear while

minimizing incorrect detections.

5 RESULTS AND DISCUSSION

5.1 Model Training

We trained the model using the same training set as

the default YOLOv11 detection models. We

conducted the training on 640 × 640 pixels images for

100 iterations. The accuracy improved as the no. of

epochs increased. On the other hand, the box_loss,

dfl_loss, and cls_loss gradually decreased to 0.75,

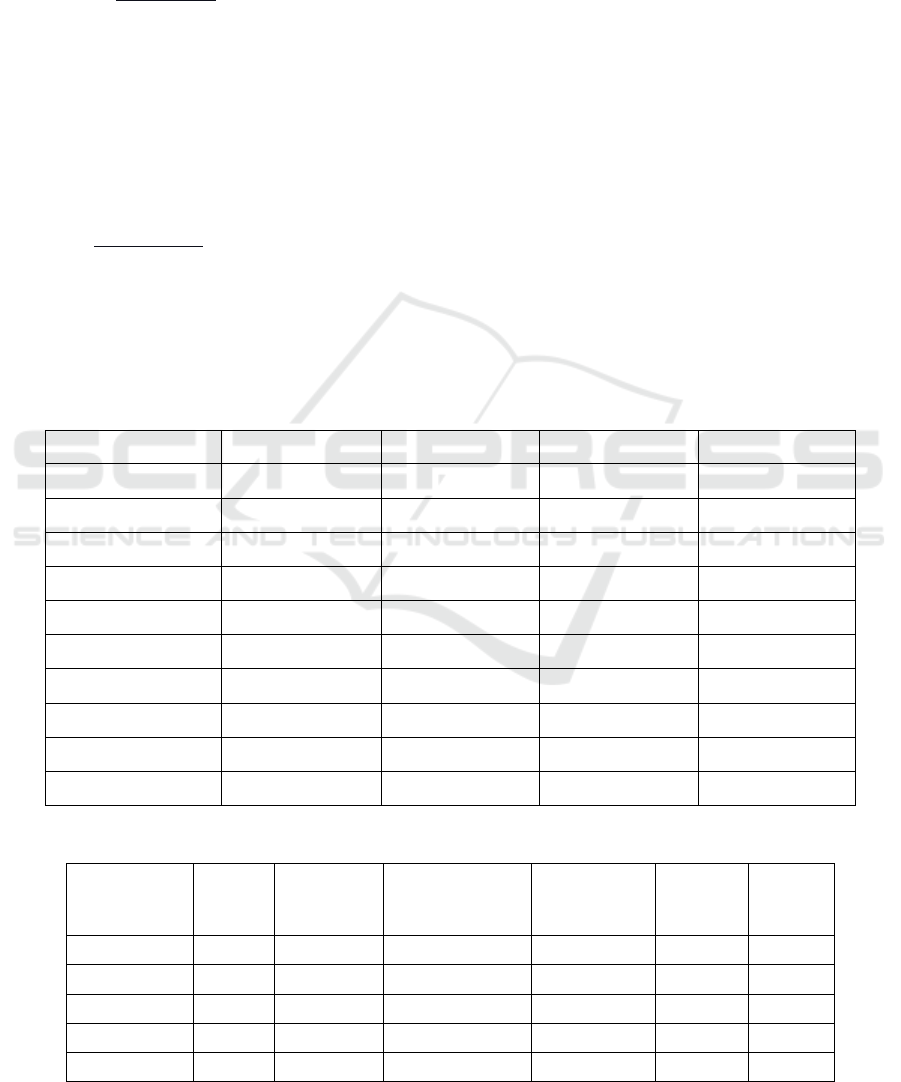

1.04, and 0.56, respectively. Table 4 shows the

Comparison of existing object detection models with

the proposed model. Figure 4 depicts a decline in loss

for both training and validation. Figure 6 (b) shows

the precision-recall curve used to analyze mAP. The

mAP@0.5 stabilized at approximately 0.771 after 58

iterations and reached 0.810 after 100 iterations,

while mAP@0.5-0.95 progressively increased to

0.603. Moreover, Figure 6 (a), (c), and (d) illustrate

the F1-score, precision, and recall curves in relation

to confidence levels for each class. Accuracy,

Precision, Recall, and F1-Score of each class detected

by the proposed model Shown in Table 3.

Table 3: Accuracy, Precision, Recall, and F1-Score of Each Class Detected by the Proposed Model.

Class Accuracy Precision Recall F1-Score

Hardhat 0.970883 0.904762 0.760000 0.826087

Mask 0.989081 0.978261 0.900000 0.937500

NO-Hardhat 0.960874 0.911765 0.626263 0.742515

NO-Mask 0.957234 0.835443 0.660000 0.737430

NO-Safety Vest 0.955414 0.786517 0.700000 0.740741

Person 0.953594 0.720721 0.800000 0.758294

Safety Cone 0.985441 0.928571 0.910000 0.919192

Safety Vest 0.975432 0.939759 0.780000 0.852459

Machinery 0.985441 0.911765 0.930000 0.920792

Vehicle 0.947225 0.791667 0.570000 0.662791

Table 4: Comparison of Existing Object Detection Models with the Proposed Model.

Model

size

(MB)

mAP

@0.5(%)

mAP

@0.5:0.95(%)

Parameters

(MB)

FLOPs

(GB)

Speed

(ms)

YOLO11n 5.4 58.0 39.5 2.6 6.5 1.5

YOLO11s 18.4 70.1 47.0 9.4 21.6 2.5

YOLO11m 38.8 73.3 51.5 20.1 68.0 4.7

YOLO11l 49.0 77.3 53.4 25.3 86.9 6.2

Our Model 10.5 81.0 60.3 6.4 14.7 2.4

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

350

Figure 4: Training and Validation Loss Curves.

Figure 5: Detection Results Before and After Model

Analysis.

Figure 6: Evaluation Curves: (A) F1-Score Vs. Confidence;

(B) Precision Vs. Recall; (C) Precision Vs. Confidence; (D)

Recall Vs. Confidence.

Figure 7: Confusion Matrix.

5.2 Testing and Validation

After training, the testing and validation part is where

we evaluate the model's efficiency. Fig. 7 shows the

confusion matrix generated by comparing the model's

results with the image labels from the test set. The

accuracy, precision, recall, and F1-Score were then

computed for each class, as shown in Table 3.

We further validated the model by testing it on the

following scenarios: (1) RGB, (2) gray-tone, (3) Blur

effect, (4) Dust effect, (5) High brightness, and (6)

Real-time Videos. Fig. 5 depicts the before and after

for the first five conditions. For RGB and grayscale

testing, we first evaluated the images in their original

RGB format and then again in grayscale. For

maximum brightness, dusting, and blur effects, the

same set of images was processed under extreme

brightness and with added noise to simulate real-

world conditions such as strong sunlight or dusty

environments. In the case of the blur effect, images

were blurred up to 30% to mimic humid weather

conditions.

Apart from image analysis, the model is also

capable of processing videos by capturing and

analyzing frames in real-time. It supports multiple

video formats, including MP4, AVI, 3GP, WMV,

MOV, FLV, MKV, WEBM, HTML5, AVCHD,

MPEG-2, and MPEG-1. We can analyze CCTV

footage for PPE detection and worker-machinery

proximity monitoring in real time. The model can

process videos ranging from 144p to 2160p without

noticeable delays and supports frame rates of 30 FPS,

60 FPS, and beyond Alvarez et al., (2023).

Enhancing Construction Site Safety: Personal Protective Equipment Detection Using Yolov11 and OpenCV

351

5.3 Comparison of Detection

Algorithms

In this study, we selected various sizes of YOLOv11

detection models for comparative experiments.

Training the model using the same training set as the

default YOLOv11 detection models rather than using

transfer learning, because pre-trained models used

different datasets for training. The primary

comparison parameters include model size,

processing speed, mAP values at 0.5 and 0.5-0.95

IoU, FLOPs, and the number of parameters. Table 4

presents the comparison results. We can see in Table

4 that our model performs better than other

YOLOv11 models. Achieving a 3.7% increase in

mAP at 0.5 IoU as well as 6.9% increase in mAP

going from 0.5 to 0.95 IoU than YOLOv11l while

maintaining size and speed between YOLOv11n and

YOLOv11s. With a higher mAP and lower size and

speed, it is computationally efficient compared to

other models, making the model applicable for real-

time analysis Azatbekuly et al., (2024).

5.4 Research Novelty

As mentioned earlier, multiple researchers have tried

to automate construction site safety protocols using

AI. Most studies focus on ML and CV techniques for

safety helmet detection. Some research extends to

detecting masks and vehicles alongside safety

helmets using computer vision. However, none of

these studies have performed PPE detection along

with worker-machinery proximity monitoring. The

proximity detection algorithm is a crucial component

that, when integrated with PPE detection, could

enhance workplace safety and prevent accidents.

The research achieved an overall accuracy of 97%

and an overall precision of 87% in detecting PPEs.

The results achieved are better than those of the

previous studies and show slight improvements over

existing models. Furthermore, the model is trained to

detect objects under various weather conditions,

including sunny, humid, and dusty environments. In

contrast, most previous studies used only RGB

images for training and testing. Our model, however,

accurately detects all necessary PPEs, machinery,

vehicles, and worker-machinery proximity with high

precision across different weather conditions Sridhar

et al., (2024).

6 CONCLUSIONS

This paper presents a fast and accurate model for

detecting PPEs worn by workers and issuing alerts in

case of non-compliance. The model detects objects in

images with an inference speed of 2.4 seconds and

outperforms YOLOv11l with a 3.7% increase in mAP

at 0.5 IoU as well as 6.9% increase in mAP going

from 0.5 to 0.95 IoU. To improve detection accuracy,

mosaic data augmentation was included during

training, allowing the model to detect small-scale

objects effectively. Furthermore, the model can also

track worker movements near machinery using

bounding box regression and issue alerts if unsafe

proximity is detected. We also trained the model to

function under different weather conditions. The

model achieves a mAP of 81% at 0.5 IoU and a mAP

of 60.3% at 0.5 to 0.95 IoU, with an overall accuracy,

precision, and recall of 97%, 87%, and 76%,

respectively. It is computationally efficient, with

14.7GB FLOPs, 6.4MB parameters, and an inference

speed of 2.4ms, making the model applicable for real-

time analysis.

REFERENCES

Al-Azani, S., Luqman, H., Alfarraj, M., Sidig, A. A. I.,

Khan, A. H., Al-Hamed, D.: Real-Time Monitoring of

Personal Protective Equipment Compliance in

Surveillance Cameras. IEEE Access, 12, 121882–

121895 (2024).

https://doi.org/10.1109/ACCESS.2024.3451117

Alvarez, M. R., Vega, C. Q., Wong, L.: Model for

Recognition of Personal Protective Equipment in

Construction Applying YOLO-v5 and YOLO-v7. In:

2023 International Conference on Electrical, Computer

and Energy Technologies - ICECET, pp. 1–6. IEEE,

Cape Town (2023). https://doi.org/10.1109/ ICECET

58911.2023.10389215

Azatbekuly, N., Mukhanbet, A., Bekele, S. D.:

Development of an Intelligent Video Surveillance

System Based on YOLO Algorithm. In: 2024 IEEE 4th

International Conference on Smart Information

Systems and Technologies - SIST, pp. 498–503. IEEE,

Astana (2024). https://doi.org/10.1109/ .2024.

10629617

Biswas, M., Hoque, R.: Construction Site Risk Reduction

via YOLOv8: Detection of PPE, Masks, and Heavy

Vehicles. In: 2024 IEEE International Conference on

Computing, Applications and Systems - COMPAS, pp.

1–6. IEEE, Cox’s Bazar (2024).

https://doi.org/10.1109/COMPAS60761.2024.107962

53

Chen, B., Wang, X., Huang, G., Li, G.: Detection of

Violations in Construction Site Based on YOLO

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

352

Algorithm. In: 2021 2nd International Conference on

Artificial Intelligence and Computer Engineering -

ICAICE, pp. 251–255. IEEE, Hangzhou (2021).

https://doi.org/10.1109/ICAICE54393.2021.00057

Dermatology 2.0: Deploying YOLOv11 for Accurate and

Accessible Skin Disease Detection: A Web-Based

Approach. Scientific Figure on ResearchGate (2024).

https://www.researchgate.net/figure/Shows-the-

architecture-of-YoloV11_fig2_389021414

Feng, R., Miao, Y., Zheng, J.: A YOLO-Based Intelligent

Detection Algorithm for Risk Assessment of

Construction Sites. J. Intell. Constr., 2(4), 1–18 (2024).

https://doi.org/10.26599/Jic.2024.9180037

Gautam, V., Maheshwari, H., Tiwari, R. G., Agarwal, A.

K., Trivedi, N. K., Garg, N.: Feature Fusion-Based

Deep Learning Model to Ensure Worker Safety at

Construction Sites. In: 2024 1st International

Conference on Advanced Computing and Emerging

Technologies - ACET, pp. 1–6. IEEE, Ghaziabad

(2024).https://doi.org/10.1109/ACET61898.2024.1073

0698

Han, C.; Zhang, J.; Wu, H.: Fall Detection System Based

on YOLO Algorithm and MobileNetV2 Model. In: 10th

International Conference on Systems and Informatics

(ICSAI), pp. 1–5. IEEE, Shanghai

(2024).https://doi.org/10.1109/ICSAI65059.2024.1089

3853

Han, K., Zeng, X.: Deep Learning-Based Workers Safety

Helmet Wearing Detection on Construction Sites Using

Multi-Scale Features. IEEE Access, 10, 718–729

(2022).

https://doi.org/10.1109/ACCESS.2021.3138407

Jankovic, P., Protić, M., Jovanovic, L., Bacanin, N.,

Zivkovic, M., Kaljevic, J.: YOLOv8 Utilization in

Occupational Health and Safety. In: 2024 Zooming

Innovation in Consumer Technologies Conference -

ZINC, pp. 182–187. IEEE, Novi Sad

(2024).https://doi.org/10.1109/ZINC61849.2024.1057

9310

Krishna, N. M., Reddy, R. Y., Reddy, M. S. C., Madhav, K.

P., Sudham, G.: Object Detection and Tracking Using

YOLO. In: 2021 Third International Conference on

Inventive Research in Computing Applications -

ICIRCA, pp. 1–7. IEEE, Coimbatore

(2021).https://doi.org/10.1109/ICIRCA51532.2021.95

44598

Li, Z., Guan, S.: Efficient-YOLO: A Research on

Lightweight Safety Equipment Detection Based on

Improved YOLOv8. In: 2024 2nd International

Conference on Artificial Intelligence and Automation

Control - AIAC, pp. 246–249. IEEE, Guangzhou

(2024).https://doi.org/10.1109/AIAC63745.2024.1089

9732

Lin, B.: Safety Helmet Detection Based on Improved

YOLOv8. IEEE Access, 12, 28260–28272 (2024).

https://doi.org/10.1109/ACCESS.2024.3368161

M, L., J, R., M, A.: Real-time Hazard Detection System for

Construction Safety Using Hybrid YOLO-ViTs. In:

2024 International Conference on Emerging Research

in Computational Science - ICERCS, pp. 1–5. IEEE,

Coimbatore (2024). https://doi.org/10.1109/ ICERCS

63125.2024.10895680

Mahmud, S. S., Islam, M. A., Ritu, K. J., Hasan, M.,

Kobayashi, Y., Mohibullah, M.: Safety Helmet

Detection of Workers in Construction Site Using

YOLOv8. In: 2023 26th International Conference on

Computer and Information Technology - ICCIT, pp. 1–

6. IEEE, Cox’s Bazar (2023).

https://doi.org/10.1109/ICCIT60459.2023.10441212

Menon, S. M., George, A., N, A., James, J.: Custom Face

Recognition Using YOLO.V3. In: 2021 3rd

International Conference on Signal Processing and

Communication - ICSPC, pp. 454–458. IEEE,

Coimbatore (2021).

https://doi.org/10.1109/ICSPC51351.2021.9451684

N, S., Sridhar, S., Sudhir, S., Adithan, V. M., Vignesh, G.:

Safefaceyolo: Advanced Workplace Security Through

Helmet Detection and Facial Authorization. In: 2024

2nd International Conference on Artificial Intelligence

and Machine Learning Applications - AIMLA, pp. 1–5.

IEEE, Namakkal (2024). https://doi.org/ 10.1109/

AIMLA59606.2024.10531484

Ponika, M., Jahnavi, K., Sridhar, P. S. V. S., Veena, K.:

Developing a YOLO-Based Object Detection

Application Using OpenCV. In: 2023 7th International

Conference on Computing Methodologies and

Communication - ICCMC, pp. 662–668. IEEE, Erode

(2023). https://doi.org/10.1109/ ICCMC56507.

2023.10084075

Roboflow Universe Projects: Construction Site Safety

Dataset. Roboflow Universe (2024). Accessed on: Feb.

26, 2025. https://universe.roboflow.com/roboflow-

universe-projects/construction-site-safety

Shanti, M. Z., Cho, C.-S., Byon, Y.-J., Yeun, C. Y., Kim,

T.-Y., Kim, S.-K.: A Novel Implementation of an AI-

Based Smart Construction Safety Inspection Protocol in

the UAE. IEEE Access, 9, 166603–166616 (2021).

https://doi.org/10.1109/ACCESS.2021.3135662

Shetty, N. P., Himakar, J., Gnanchandan, P., Prajwal, V.,

Jamadagni, S. S.: Enhancing Construction Site Safety:

A Tripartite Analysis of Safety Violations. In: 2024 3rd

International Conference for Innovation in Technology

- INOCON, pp. 1–6. IEEE, Bangalore

(2024).https://doi.org/10.1109/INOCON60754.2024.1

0511598

Enhancing Construction Site Safety: Personal Protective Equipment Detection Using Yolov11 and OpenCV

353