Tool Wear and Fault Prediction Systems Powered by AI

M. Amareswara Kumar, G. Jayasai Karthik, D. Hussain Basha, S. Ashraf,

P. Ramesh and O. Yogeeswar

Department of Computer Science and Engineering, Santhiram Engineering College, Nandyal, Andhra Pradesh, India

Keywords: Artificial Intelligence Techniques, Artificial Neural Networks (ANNs), Support Vector Machines (SVMs),

Convolutional Neural Networks (CNNs), Recurrent Neural Networks (RNNs), Random Forest.

Abstract: Tool wear and fault prediction to preserving the efficiency and productivity of the manufacturing process,

which ensure the quality of the product and reduce downtime. In recent years, the progress of Artificial

Intelligence (AI) has exposed new possibilities to develop future systems that can autonomously monitor and

analyse machine conditions. The project proposes the development of a tool wear and fault prediction systems

powered by AI, which takes advantage of the leveraging machine learning algorithm in real time to decline

and predict potential defects. During the system operation, to catch the dynamic behaviour of the tools will

collect data from various sensors embedded in the machinery, such as vibration, cutting force, temperature,

current and acoustic sensors, such as the dynamic behaviour of the tools. Using AI techniques, especially

supervised learning models such as neural networks and support vector machine (SVM) are monitored, the

system will be trained to identify patterns and correlations between sensor data and tool wear or fault position.

1 INTRODUCTION

In the current manufacturing processes, the

performance and reliability of tools have a direct

effect on the efficiency, quality and profitability of

production operations. Tool wear and sudden tool

failure are common problems that manufacturers

face, causing unplanned downtime, costly repairs

and product quality issues (Xu et al., 2021; Zhang et

al., 2024). In the manufacturing environment,

detecting tool wear or defects usually relies on

manual inspection or scheduled maintenance

(Gouarir et al., 2018). As a result, either the

continuous use of tools in premature replacement or

sub-avoidance conditions can occur, both of which

are expensive.

Well, the arrival of Artificial Intelligence (AI) is

a groundbreaking opportunity for solving these

problems (Chen et al., 2024). An AI-managed system

can analyze large volumes of sensor data from

equipment, such as vibrations, temperature changes,

and acoustic signals, generating useful information

for timely interventions and tailored production

maintenance schemes, helping to catch early signs of

wear or fault (Chehrehzad et al., 2024; Mohanta et al.,

2020). Our project focuses on developing AI-based

tool wear and fault prediction systems that can enable

manufacturers to shift from reactive to proactive

maintenance strategies (Oh et al., 2024). This system

will strengthen the assurance of manufacturing

processes, bolster productivity, while reducing the

environmental and economic cost triggered by

breakdowns and unknown preservation.

To achieve accurate predictions, machine learning

(ML) and deep learning (DL) approaches are applied

to train an AI model to predict tool wear and faults

(Zhang et al., 2024; Xu et al., 2021). Classification

and regression tasks using traditional ML models like

Decision Trees, Support Vector Machines (SVM),

Random Forest, and Gradient Boosting are also used

to find patterns in tool wear data (Gouarir et al., 2018;

Kumar, 2024a). Alternatively, deep learning models

such as Convolutional Neural Networks (CNNs) or

Recurrent Neural Networks (RNNs), are used for

complete autonomy of feature extraction from

complex sensor signals to provide a more detailed and

adaptable knowledge of wear progression (Xu et al.,

2021; Chehrehzad et al., 2024).

Moreover, surmounting generalization ability for

more powerful and precise predictions is also

achieved through hybrid approaches such as those

which integrate ML and DL models with simulation

through physics-based simulations (Chen et al.,

2024). A combination of multiple techniques leads to

226

Kumar, M. A., Karthik, G. J., Basha, D. H., Ashraf, S., Ramesh, P. and Yogeeswar, O.

Tool Wear and Fault Prediction Systems Powered by AI.

DOI: 10.5220/0013880500004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 2, pages

226-231

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

higher fault detection, real-time monitoring, and

enhanced performance of a tool (Mohanta et al.,

2020; Oh et al., 2024). Techniques like those applied

in other domains—such as IoT-based monitoring

(Kumar et al., 2024a), traffic signal optimization

(Kumar et al., 2022), network security (Mahammad

et al., 2024), healthcare AI (Suman et al., 2024), and

heart disease prediction (Kumar, 2024b)—

demonstrate the versatility and applicability of AI-

assisted prediction systems across sectors, including

manufacturing.

2 LITERATURE REVIEW

Modern manufacturing processes involve key

characteristics such as tool wear and prediction of

faults. Predictive maintenance with Artificial

Intelligence (AI) enables increased efficiency,

decreased downtime, and financial savings

(Mahammad & Viswanatham, 2018; Bhaskar et al.,

2024a). This literature review aims to analyze the

most recent AI-based tool wear and fault prediction

systems including different variants of machine

learning (ML), deep learning (DL), and hybrid

techniques (Devi et al., 2022; Chaitanya, 2022).

2.1 Support Vector Machine (SVM)

Support Vector Machine (SVM) is an effective

algorithm used in this project since it classifies

different patterns of wear and could identify

anomalies in the machining operation. SVM models

are applied to identify abnormal (defective)

conditions from normal, based on sensor data that

enables proactive maintenance. This minimizes

downtime, enhances tool lifespan, and increases the

quality of overall production (Mahammad,

Balasubramanian, & Babu, 2019; Paradesi Subba

Rao, 2024a).

2.2 Convolutional Neural Network

(CNN)

Convolutional Neural Networks (CNN) is used for

reading in sensor data, images, and detecting small

changes in tool condition. This deep learning method

improves the predictive maintenance which helps in

minimizing downtime and hence the operation cost.

Overall, CNN-based models have given high

accuracy in detecting faults and predicting the

lifespan of the components, thanks to continual

learning through experience (Bhaskar et al., 2024b;

Devi et al., 2023; Chaitanya et al., 2024a).

2.3 Random Forest

Random Forest is a context in which you are provided

with sensor data with which to figure out for

abnormalities and trends of wear. It improves

accuracy and reduces overfitting through its

ensemble learning mechanism that makes it more

appropriate for real-time monitoring. With Random

Forest, companies can minimize downtimes,

automate processes and extend tool durability

(Chaitanya & Bhaskar, 2014; Mandalapu et al., 2024;

Paradesi Subba Rao, 2024b).

3 TOOL WEAR AND FAULT

PREDICTION SYSTEM

Wherein, identify the wear modes and predict the

failures during the machining, tool conditions and

manufacturing process for real-time monitoring of

sensor data in this system. The system uses machine

learning and predictive analytics to improve

efficiency, reduce downtime, and extend tool life.

They facilitate preventive upkeep, preventing

unexpected failures, and making production

scheduling more efficient. This leads to significant

cost savings, improved product quality and higher

overall reliability of operations. There are diverse

hardware limitations of fault prediction system

including sensors, data acquisition, storage and

memory limitations.

3.1 Sensors

Different sensors are crucial in gathering real-time

data in the fault prediction system where different

sensors are used for feeding machine learning for

better prediction:

Vibration sensors: Vibration sensor measures

vibrations or oscillations of the tools during operation

in the machines. Changes in vibration pattern may

represents the wearing, imbalance or defects in the

device. Machine learning models analyse these signs

to predict the fault condition of the tools.

Cutting force sensors: These sensors measure the

forces working on the tools during cutting or

machining processes. Variety in force may reveal

early signs of wearing tools or failure. By monitoring

the cutting forces, the future model tools may

estimate the decline.

Temperature sensors: The temperature variation is

another indicator of tool wear. As such tool wears,

friction increases, causing high temperatures.

Tool Wear and Fault Prediction Systems Powered by AI

227

Thermocouples or infrared sensors track temperature

sudden changes, providing the important data for

fault prediction algorithms.

Acoustic emission sensors: These sensors detect

high-existing sound waves generated by contact with

the tools in the machines. Captured data can identify

micro-cracks, material deformation, or other signs of

wear, which can help the AI systems predict adjacent

failures and sense the sound waves changes during

operation.

Current/Voltage Sensors: Electric consumption

pattern can be monitored to detect unusual energy

use, which can be caused by tool wear or defects.

Monitoring current or voltage diversity provides

insight into system performance and tools health.

3.2 Data Acquisition

Data acquisition plays a critical function in the design

of an AI-driven tool wear and fault predicting system,

because data quality along with quantity critically

affect model performance. Real-time sensor

measurements in the form of vibration signals via

accelerometers, acoustic emission signals via

microphones, force sensors via dynamometers, and

temperatures via thermocouples or infra-red sensors

play a crucial role in determining the conditions of a

tool. In addition to this, the machine parameters and

operating conditions of cutting speed, feed rate,

spindle speed, torque, and material characteristics

continue to enhance predictability. As a precursor for

the construction of a good ground truth, the failure

and wear annotations such as flank wear, crater wear,

chipping, fractures, and lifecycle must be annotated.

Furthermore, surface roughness measurements give a

critical quality indicator that not only foretells failures

but also guarantees that machining performance is

always optimal.

3.3 Storage & Memory Constraints

AI-based tool wear and defect prediction systems also

need effective storage of data as they handle lots of

sensor data, machine history, and log files. Sensing

data, especially high-frequency vibration,

temperature, and acoustic emission data, produce

huge amounts of data demanding intense data

compression, effective indexing, and near real-time

processing to keep the overhead low. While cloud-

based models like AWS, Azure, and Google Cloud

provide elastic storage for big data analysis, latency

and security requirements can make local or hybrid

models necessary, with SSDs or industrial-grade SD

cards providing offline predictions. AI models also

need ample RAM (8GB+ for edge nodes and 32GB+

for servers) to process big data, with embedded

devices having restricted RAM needing model

compression approaches like quantization and

pruning.

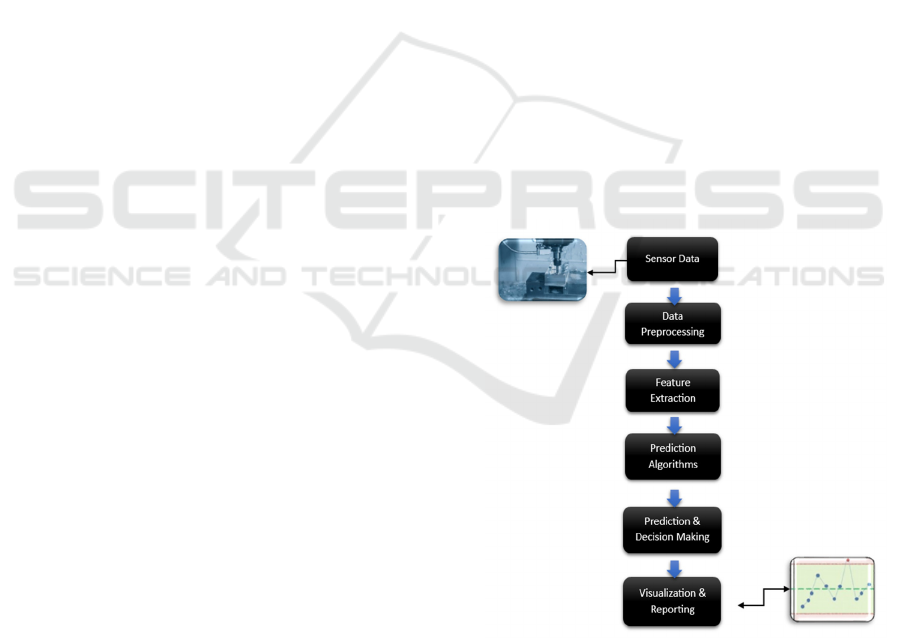

3.4 Architecture & Working System

A system that predicts tool wear and faults using AI

for increases manufacturing productivity by

monitoring cutting tools in real time and detecting

failures ahead of time. The system design includes

sensors, data acquisition, analytics based on AI,

decision support system and reporting system.

Accelerometers, vibration sensors, cutting force

sensors, acoustic emission sensors, and temperature

sensors are few sensors that gather real-time data

from condition of tools in machines. This information

is processed through the process of feature extraction

like shape and size, which screens and sends

important data to a cloud-based AI system. Machine

learning (ML) models such as deep learning and time-

series analysis methods evaluate trends in the

information to identify anomalies, categorize tool

wear stages, predict the condition of tools and

estimate remaining tool lifespan.

Figure 1 shows the

evolution of fault prediction system.

Figure 1: Evolution of Fault Prediction System.

Data pipeline facilitates smooth and clean transfer

data from sensors to the AI model by utilizing signal

processing and feature extraction and selection

methods. Historical data and real-time data, including

predictive maintenance algorithms like Random

Forest, CNNs, and SVMs are trained for the AI based

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

228

model. It has integration with a dashboard-based

interface, supplying operators with messages, alarms,

and notification of every condition of tools during the

operation and maintenance advisories. Feedback loop

continuously adjusts the AI model with improved

efficiency and accuracy. The decision support system

provides recommendations for perfect measures,

reducing downtime and improving productivity. Fault

prediction through AI reduces tool breakdowns, saves

costs, and increase the quality products, and hence it

is the most critical element in smart manufacturing.

3.5 Advantages

• Improved Maintenance and Reduced

Downtime.

• Cost savings on Repairs.

• Increased Tool Lifespan.

• Enhanced Product Quality.

4 RESULTS

Sensor data (e.g., vibration, temperature, acoustic

emissions) and machine learning are used in AI-based

tool wear and fault prediction systems to predict fault

or mistakes and optimize maintenance. The systems

increase productivity, reduce downtime, and optimize

tool life. The following is an example of outputs that

such a system may provide:

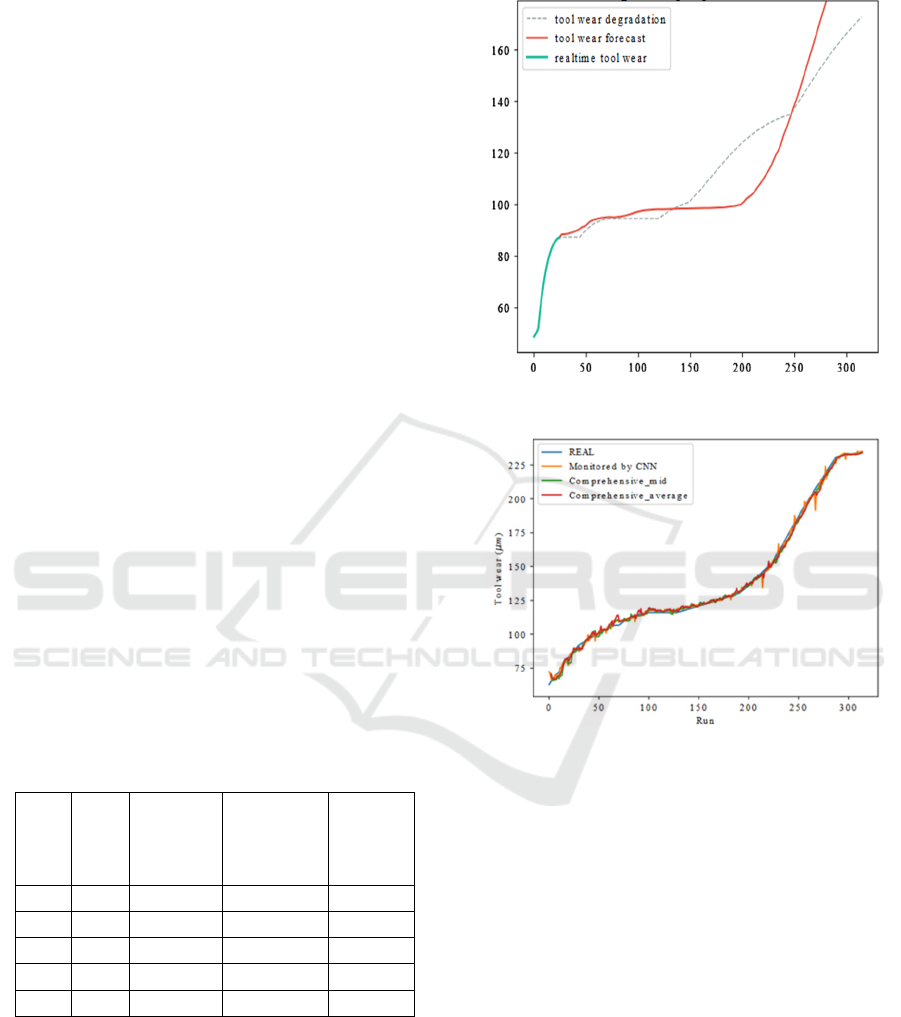

4.1 Tool Wear Prediction Results

(Table)

Table 1: Fault Detection Tools.

Tool

ID

Wear

Level

(%)

Predicted

Remaining

Life

(Hours)

Maintenance

Required?

Fault

Detected?

T001 20% 50 No No

T002 55% 20 Yes No

T003 75% 10 Yes Yes

T004 30% 40 No No

T005 90% 5 Yes Yes

This result shown in table 1 and figure 2 & 3 can be

used in the development of real time monitoring of

the tools condition or positions while they are

working, by the use of Convolutional Neural Network

(CNN). This allows prediction of accurate results by

processing amazingly the sensors data and the

utilization of a feature extraction process is very

helpful in enhancing the system efficiency, reducing

the downtime and prolonging the tool life.

Figure 2: Experimental Result.

Figure 3: Using CNN with Median or Average Correction.

5 CONCLUSIONS

Therefore, the AI-Powered Intelligent tool wear and

fault prediction system designed and implemented as

part of this project holds great potential that can be

harnessed to improve manufacturing efficiency,

reduce tool downtime and life. By integrating

machine learning algorithms with real-time sensor

inputs, the system accurately predicted wear

behaviour and identified faults before they caused

significant damage. By enabling earlier intervention,

the system enables the minimization of production

loss along with reduced maintenance costs and

improved overall process reliability. Incorporating

predictive maintenance using AI techniques, such as

supervised learning models, increases the accuracy of

machining operations, which subsequently improves

Tool Wear and Fault Prediction Systems Powered by AI

229

both product quality and operational continuity.

Future technologies incorporating AI frameworks and

data analytics will be able to make the system even

more flexible and accurate by updating it in various

industrial applications.

REFERENCES

“Babycare warning system based on IoT and GSM to

prevent leaving a child in a parked car”, M.

Amareswara Kumar; Farooq Sunar Mahammad;

Parumanchala Bhaskar; G. Vani; B. Umamaheswari; B.

Dhanalakshmi; R. Pavani; U. Keerthi & AIP Conf.

Proc. 3028,020071(2024)https://doi.org/10.1063/5.021

2518

“Deep learning-based tool wear prediction and its

application for machining process using multi-scale

feature fusion and channel attention mechanism”,

Xingwei Xu, Jianwen Wang, Bingfu Zhong, Weiwei

Ming, Ming Chen & Measurement Volume 177, June

2021,109254https://doi.org/10.1016/j.measurement.20

21.109254

“In-process Tool Wear Prediction System Based on

Machine Learning Techniques and Force Analysis”, A.

Gouarir, G. Martínez-Arellano, G. Terrazas, P.

Benardos, S. Ratchev & Procedia CIRP Volume 77,

2018, Pages501504https://doi.org/

10.1016/j.procir.2018.08.253

“Key distribution scheme for preventing key reinstallation

attack in wireless networks”, Farooq Sunar

Mahammad; V. Madhu Viswanatham; Asma Tahseen;

M. Sharmila Devi; M. Amareswara Kumar & AIP

Conf.

Proc. 3028,020067(2024)https://doi.org/10.1063/5.021

2685

“M. Amareswara Kumar, “Effective Feature Engineering

Technique for Heart Disease Prediction with Machine

Learning”, In International Journal of Engineering &

Science Research, Volume 14, Issue 2, April-2024

with ISSN 2277-2685.

“Model-based tool wear detection and fault diagnosis for

end mill in various cutting conditions”, Jun-Young Oh,

Jae-Eun Kim, Wonkyun Lee & Manufacturing Letters

Volume 41, Supplement, October 2024, Pages 595-604

https://doi.org/10.1016/j.mfglet.2024.09.076

“Online Monitoring System for Tool Wear and Fault

Prediction Using Artificial Intelligence”, Neha

Mohanta; Rabesh Kumar Singh; Anuj Kumar Sharma

& Publisher is IEEE and published in: 2020

International Conference on Contemporary Computing

andApplications (IC3A) https:// ieeexplore.ieee.org /

document/9077155

“Tool Wear Feature Extraction and Result Prediction Based

on Machine Learning”, Xiyang Zhang; Rui Zhou;

Yongze Ma; Xusheng Lin; Yanqing Zhao & Publisher

is IEEE and published in 2024, 13th International

Conference of Information and Communication

Technology (ICTech)https://

ieeexplore.ieee.org/document/10900896

“Tool wear prediction through AI-assisted digital shadow

using industrial edge device”,

Mohammadreza Chehrehzad; Gamze Kecibas;

Cemile Besirova; Ugur Uresin; Mumin Irican;

Ismail Lazoglu & Journal of Manufacturing Processes

Volume 113, 15 March 2024, Pages 117-130

https://doi.org/10.1016/j.jmapro.2024.01.052

“Traffic Length Data Based Signal Timing Calculation for

Road Traffic Signals Employing Proportionality

Machine Learning”, M. Amareswara Kumar, Farooq

Sunar Mahammad, M Naga Dhanush, D Partha Rahul,

K L Sreedhara, B Azbin Rabi, A Kedarnath Reddy &

Journal of Algebraic Statistics, Issue Vol. 13 No. 3

(2022)https://www.publishoa.com/index.php/journal/a

rticle/view/540

Chaitanya, V. Lakshmi, and G. Vijaya Bhaskar. "Apriori vs

Genetic algorithms for Identifying Frequent Item Sets."

International journal of Innovative Research

&Development 3.6 (2014): 249-254.

Chaitanya, V. Lakshmi. "Machine Learning Based

Predictive Model for Data Fusion Based Intruder Alert

System." journal of algebraic statistics 13.2 (2022):

2477-2483

Chaitanya, V. Lakshmi, et al. "Identification of traffic sign

boards and voice assistance system for driving." AIP

Conference Proceedings. Vol. 3028. No. 1. AIP

Publishing, 2024.

Devi, M. Sharmila, et al. "Machine Learning Based

Classification and Clustering Analysis of Efficiency of

Exercise Against Covid-19 Infection." Journal of

Algebraic Statistics 13.3 (2022): 112-117.

Devi, M. Sharmila, et al. "Extracting and Analyzing

Features in Natural Language Processing for Deep

Learning with English Language." Journal of Research

Publication and Reviews 4.4 (2023): 497-502.

Jian Wen Chen, Meng Shiun Tsai, Che Lun Hung “Towards

an Effective Tool Wear Monitoring System with an AI

Model Management Platform” & Publisher is IEEE and

published in 2024, IEEE 22nd International Conference

on Industrial Informatics (INDIN)

https://ieeexplore.ieee.org/document/10774399

Mahammad, Farooq Sunar, Karthik Balasubramanian, and

T. Sudhakar Babu. "A comprehensive research on

video imaging techniques." All Open Access, Bronze

(2019).

Mahammad, Farooq Sunar, and V. Madhu Viswanatham.

"Performance analysis of data compression algorithms

for heterogeneous architecture through parallel

approach." The Journal of Supercomputing 76.4

(2020): 2275-2288.

Mandalapu, Sharmila Devi, et al. "Rainfall prediction using

machine learning." AIP Conference Proceedings. Vol.

3028. No. 1. AIP Publishing, 2024.

Paradesi Subba Rao,”Detecting malicious Twitter bots

using machine learning” AIP Conf. Proc. 3028, 020073

(2024) https://doi.org/10.1063/5.0212693

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

230

Paradesi SubbaRao,” Morphed Image Detection using

Structural Similarity Index Measure” M6 Volume 48

Issue 4 (December 2024)

Parumanchala Bhaskar, et al. "Machine Learning Based

Predictive Model for Closed Loop Air Filtering

System.", Journal of Algebraic Statistics 13.3 (2022):

416-423.

Parumanchala Bhaskar, et al. "Incorporating Deep Learning

Techniques to Estimate the Damage of Cars During the

Accidents" AIP Conference Proceedings. Vol. 3028.

No. 1. AIP Publishing, 2024.

Parumanchala Bhaskar, et al “Cloud Computing Network

in Remote Sensing-Based Climate Detection Using

Machine Learning Algorithms” remote sensing in earth

systems sciences(springer).

Suman, Jami Venkata, et al. "Leveraging natural language

processing in conversational AI agents to improve

healthcare security." Conversational Artificial

Intelligence (2024): 699-711.

Sunar, Mahammad Farooq, and V. Madhu Viswanatham.

"A fast approach to encrypt and decrypt of video

streams for secure channel transmission." World

Review of Science, Technology and Sustainable

Development 14.1 (2018): 11-28.

Tool Wear and Fault Prediction Systems Powered by AI

231