Thermal Performance Enhancement of Earth Tube Heat Exchanger

R. Vasanthakumar, P. Murugesan, S. Balamurugan, K. Akash, K. Dharunesh and K. Tamilselvi

Department of Mechanical Engineering, K.S.R. College of Engineering, Tiruchengode‑637215, Tamil Nadu, India

Keywords: Air Low Optimization, CFD Simulation, Cooling Air, Cop, etheGeothermal Energy, HVAC System, Natural

Convection.

Abstract: The fabrication of an earth tube heat exchanger involves designing an efficient system for natural cooling or

heating using underground pipes. The system circulates air through buried tubes, leveraging the earth's stable

temperature to cool or warm the air, reducing reliance on traditional HVAC systems. Aluminium tube of

length 21 m, 205 w/mk thermal conductivity, results in COP of 1.5 to 2.9.A copper tube of length 15m, 385

w/mk thermal conductivity results in COP 1.3 to 3.2. A 15m copper serpentine tube with thermal conductivity

of 385 W/m·K exhibits a COP improvement from 1.3 to 3.2 at increased inlet velocity. This suggests that

increased fluid velocity enhances the efficiency, heat transfer, and thermal performance of the system, hence

the earth tube heat exchanger becomes more efficient. The result indicates that the analysed earth tube heat

exchanger with copper serpentine tube and calculated COP will significantly improve the thermal

performance of an earth tube heat exchanger.

1 INTRODUCTION

Leveraging the natural thermal characteristics of the

Earth, Earth Tube Heat Exchanger (ETHE) is an

alternative to efficient temperature control in this

contemporary period. Air is supplied through copper

tubing of 15 m length and 385 W/mK thermal

conductivity at varying velocities of 1, 2, 3, and 4 m/s

in a soil environment with a blower for 12 V, 0.45

amps DC. This system employs the earth's perpetual

temperature of 26.2 °C to generate outlet

temperatures at similar rates of 33.6 °C, 34.5 °C,

34.8 °C, and 35.2 °C.

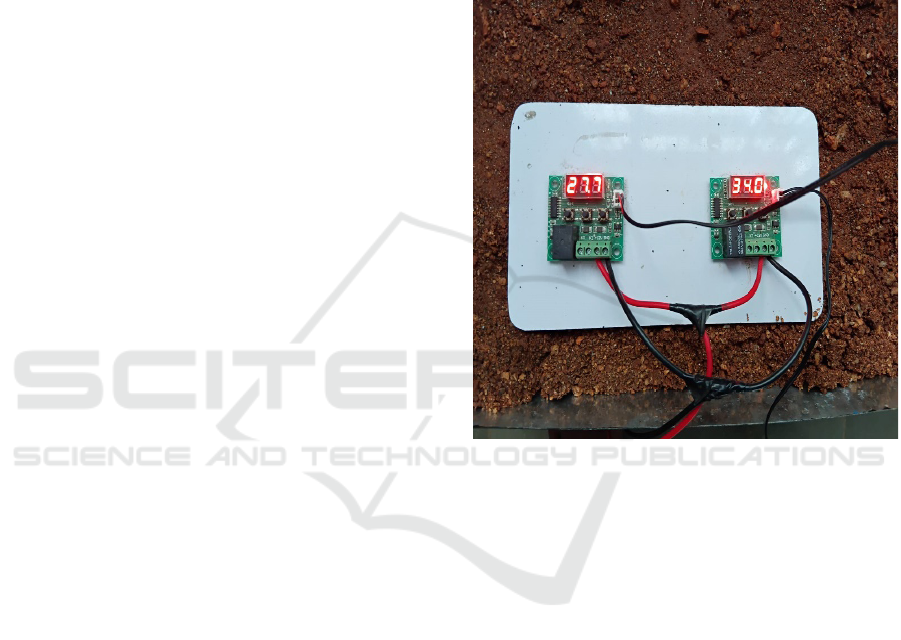

Observation and system control based on desired

and ambient temperature levels allow a relay and

temperature sensors to reduce the use of conventional

heating and cooling systems and significantly reduce

energy consumption and costs. By making use of

constant earth temperatures underground to provide

winter heat and summer coolness, earth-air heat

exchangers (ETHE) reduce building energy

consumption. Design, performance, and ground

temperature fluctuations of ETHE are the focus of

this research, its ability to lessen greenhouse gas

emissions and energy consumption, especially in

India with a COP of 1.5(Shams Forruque

Ahmed,et.al., 2021). Heat Exchanger in conjunction

with natural ventilation to create the best of indoor

conditions with reduced costs and energy use. It will

give the heat transfer rate to 600 watts (Giouli

Mihalakakou, et.al.,2022). An Earth-to-Air Heat

Exchanger (ETHE) utilizes ground thermal energy to

provide heat in winters with higher efficiency.

Simulation using CFD for a 13-meter pipe indicated

higher heat transfer and efficiency with lower

velocities of air in winter in Bhopal with a cop of

1.8(Ahmed A Serageldin, et.al.,2016). (GAHE)

employs geothermal energy in effective cooling and

heating. Its performance was simulated in this work

with ANSYS Fluent and SOLIDWORKS, and its

COP values and best temperatures were between

0.5

to 1.3(Hadi,et.al., 2024). The Earth-Air Heat

Exchanger (EHX) improves home comfort and

conserves energy. A 2021 Baghdad experiment

revealed 12.3°C increase in January and 17.2°C in

June demonstrated that it was extremely effective

(Lattieff,et.al., 2022).

2 RELATED WORKS

Number of papers published on this topic in the last

five years is more than 95 papers in IEEE Xplore, 60

papers in Google Scholar, 110 papers in Academia. A

soil-to-air heat exchanger (EAHE) using an

evaporative cooler can minimize pipe length by as

78

Vasanthakumar, R., Murugesan, P., Balamurugan, S., Akash, K., Dharunesh, K. and Tamilselvi, K.

Thermal Performance Enhancement of Earth Tube Heat Exchanger.

DOI: 10.5220/0013877100004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 2, pages

78-82

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

much as 93.5%. Surface-to-volume ratio, airflow rate,

and pipe diameter are the most significant factors

influencing outlet temperature with a COP of

2.5(Benzaama, M. H.,et.al., 2022). Earth tubes are an

environmentally friendly method of saving energy

expenses through cooling houses and warming

houses during winter, with studies showing notable

savings in energy and a smaller climate footprint with

a COP of 1.9(Sofyan,et.al., 2024).Earth tube heat

exchangers use geothermal energy for heating and

cooling, providing a green HVAC system that is

energy-saving and simple to install achieves 40% air

ventilation. Optimization of earth-air heat exchanger

(EAHE) systems involves pipe properties and airflow

rate 4 m/s, and also exploration of the impact of soil

density and moisture on performance temperature up

to 35 degree Celsius(Omer AM , 2008).Earth tube

heat exchangers energy- efficient heating and

cooling, satisfying HVAC requirements effectively

with COP of 1.9(Esen H,et.al.,2007).The research

maximizes the Naples, Italy Earth to Air Heat

Exchanger (EAHX) and discovers that an ETHE of

diameter 0.1 m, 1.5 m/s velocity, and length 50 m has

maximum output temperatures 40% more

efficient(Givoni B, et.al.,1981). Earth-air tunnel

ventilation relies on constant ground temperatures to

control air, yet soil- atmosphere exchanges may be

underestimated, and this leads to performance

overestimation. Good simulations are highly critical

max COP of 2.5(Deshmukh MK, et.al., 1991).

Inference: From the previous findings, it is concluded

that

the

use

of an

Aluminium tube

will result in

less COP due to less thermal conductivity and poor

pipe design. The aim of this is to enhance the thermal

performance of an earth tube heat exchanger by using

copper tube which having high thermal conductivity

and serpentine (design)

3 MATERIALS AND METHODS

Indian earth tube heat exchangers are affordable,

offering cooling and heating. BMR-HVAC in

Faridabad saw temperature fluctuations of 3.93°C to

12.6°C in summer and 6°C to 10°C in winter (Esen

H,et.al., 2017). Aluminium tube of length 21m, 205

w/mk thermal conductivity, results in COP of 1.5 to

2.9. A copper waveflow tube of length 15m, 385

w/mk thermal conductivity results in COP of 1.3 to

3.2. Earth-air heat exchangers utilize earth

temperatures to provide cooling and heating by

minimizing energy utilization. Ventilation

Information Paper prescribes their operation and

specifications (Lucia U,et.al., 2017).

3.1 Flowchart/Process

Steps/Method/Block Diagram

An Earth Tube Heat Exchanger employs buried pipe

to passively control air temperature. External fresh air

is pulled through the pipe and cooled or heated by the

soil seasonally. The conditioned air is fed to the

ventilation system in the building, creating an energy-

saving means of creating comfortable indoor

temperatures.

Figure 1: Temperature Monitoring Setup.

SSPL Tool: The ANSYS Fluent R19.0 CFD

simulation of a serpentine heat exchanger used a k-ε

turbulence model and tetrahedral meshing. Velocity

inlet, pressure outlet, and no-slip walls were used by

the solution that used second-order upwind

discretization and 1e-6 convergence. Results

indicated pressure drop (103618 Pa to 100745 Pa),

temperature range (299.47 K to 350 K), and

maximum velocity of 55.69 m/s, which indicated

design optimization.

Design Calculation

Amount of heat transfer Q = mCpdt (J) (1)

Coefficient of performance Q/W (2)

By using above these formulas, we found out the

length of ETHE. Calculation results are given below.

Thermal Performance Enhancement of Earth Tube Heat Exchanger

79

4 RESULTS

A copper tube of length 15m, 385 w/mk thermal

conductivity results in COP 1.3 to 3.2. Thus the data

indicates that with the rise in inlet velocity,

temperature, heat flow, and COP all rise. This

indicates that the efficiency and ability of heat

transfer of the system improve with higher fluid

velocity Table 2 This table illustrates the inlet

velocity (in m\s) and the associated temperature (in

°C). When the inlet velocity increases from 1 m/s to

4 m/s, the numerical solution output temperature

increases from 27.9°C to 32.7°C, proving the positive

correlation of inlet velocity and temperature. Table3

Inlet velocity rises from 1 m/s to 4 m/s, and heat flow

and COP are also increased. Heat flow is increased

from 332.8 W to 819.2 W, and COP is increased from

1.3 to 3.2, which indicates higher efficiency and heat

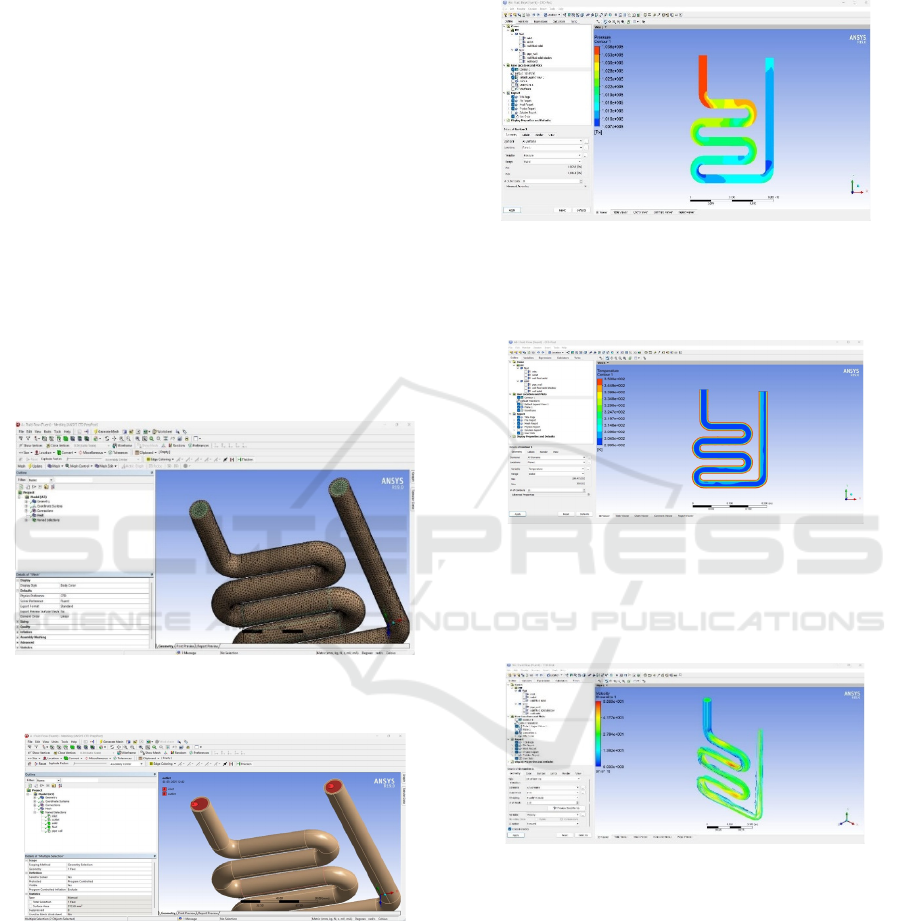

transmission at elevated velocities. Figure 2. The

picture depicts a helical pipe mesh in ANSYS Fluent

(R19.0), which is optimized for CFD simulation.

Figure 2: A helical pipe mesh in ANSYS Fluent (R19.0),

which is optimized for CFD simulation.

Figure 3: ANSYS Fluent Meshing (R19.0) with a piping

system ready to be used for CFD simulation, specifying

inlet, outlet, and boundary conditions for fluid flow or heat

transfer.

Figure 3 this figure depicts ANSYS Fluent Meshing

(R19.0) with a piping system ready to be used for

CFD simulation, specifying inlet, outlet, and

boundary conditions for fluid flow or heat transfer.

Figure 4. It shows pressure contours with numeric

values in Pascals (Pa), from about 1.010e+005 Pa up

to 4.036e+005 Pa, which suggests a fluid flow or heat

transfer calculation.

Figure 4: ANSYS Fluent Meshing (R19.0) with a piping

system ready to be used for CFD simulation, specifying

inlet, outlet, and boundary conditions for fluid flow or heat

transfer.

Figure 5: Temperature contour plot of fluid flow through a

serpentine tube. High temperatures (red) are at the walls,

and low temperatures (blue) are within the core flow,

showing heat transfer. Analysis enhances the analysis of

thermal performance and flow behaviour.

Figure 6: Velocity streamline plot of fluid flow through

serpentine pipe. Red indicates higher velocities in bends

and blue for low velocities in straight sections, which shows

flow behaviour and turbulence.

Figure 5. ANSYS Fluent (R19.0) CFD-Post and a

temperature contour plot of fluid flow through a

serpentine tube. High temperatures (red) are at the

walls, and low temperatures (blue) are within the core

flow, showing heat transfer. Analysis enhances the

analysis of thermal performance and flow behavior.

Figure 6. Velocity streamline plot of fluid flow

through serpentine pipe. Red indicates higher

velocities in bends and blue for low velocities in

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

80

straight sections, which shows flow behavior and

turbulence. Figure 7. This graph is depicted between

inlet velocity vs temperature output and heat flow.

Figure 7: Inlet velocity vs temperature output inlet velocity

vs heat transfer.

5 DISCUSSIONS

This project shows that the fluid flow velocity can be

enhanced in an Earth Tube Heat Exchanger with a

copper serpentine tube for greater heat transfer to

improve the Coefficient of Performance (COP) from

1.3 to 3.2. Copper's high thermal conductivity

improves efficiency, and the system is more energy

efficient and effective. The research maximizes the

Naples, Italy Earth to Air Heat Exchanger (EAHX)

and discovers that an ETHE of diameter 0.1 m, 1.5

m/s velocity, and length 50 m has maximum output

temperature (Inalli M,et.al., 2004). This research

analyzes the thermal efficiency of an Earth- to-Air

Heat Exchanger (EAHX) during warm weather. A 60

m long, 100 mm diameter model with 239 fins is

subjected to a temperature drop of 20.5°C (Wu W,

et.al., 2014).

Table 1: Input parameters.

S.NO INPUT PARAMETERS SYMBOL

S

VALUE

1 Inlet Temp T

in

35

2 Length of Tube L 15

3 Pipe wall Temp (below

5ft)

T

wall

25

4 Thermal conductivity of

the ai

r

K

air

0.0266

5 Thermal conductivity of

the pip

e

K

Pipe

385

6 Thermal capacity C

p

1006

7 Viscosity µ 0.000018

4

8 Density of air P 1.1465

9 Velocity of air v

air

1,2,3,4

The system's performance was analyzed under 72-

hour conditions of temperature fluctuation, COP, and

efficiency (Balbay A,et.al., 2010). This research

mimics a 45m, 0.08m diameter EATHE pipe 5m

deep, with air speed at 1 m/s. ANSYS and CFD

Fluent are used to model heat transfer and

temperature changes according to Bhopal's climate

from June 2016 to May 2017(Balbay A,et.al., 2010).

Table 1 shows the input parameters. Table 2

shows the inlet velocity (in m\s) and the associated

temperature (in °C). When the inlet velocity increases

from 1 m/s to 4 m/s, numerical solution output

temperature increases from 27.9°C to 32.7°C, proving

the positive correlation of inlet velocity and

temperature.

Table 2: Inlet velocity vs associated temperature.

S.

No

Inlet Velocity

(m/s)

Numerical Method

Output

Temperature

1 1 27.9

2 2 28.5

3 3 29.8

4 4 32.7

Table 3 shows the Inlet velocity rises from 1 m/s to 4

m/s, and heat flow and COP are also increased. Heat

flow is increased from 332.8 W to 819.2 W, and COP

is increased from 1.3 to 3.2, which indicates higher

efficiency and heat transmission at elevated

velocities.

Table 3: Inlet velocity, heat flow & COP.

S.

No

.

Inlet Velocity

(m/s)

Heat flow

(watt)

COP

1 1 332.8 1.3

2 2 486.4 1.9

3 3 691.2 2.7

4 4 819.2 3.2

6 SCOPE FOR FUTURE WORK

The future of Earth Tube Heat Exchangers lies in

increased efficiency through integration with

renewable power, better materials, and intelligent

automation. They can also be made suitable for urban

settings, tailored to particular climates, and integrated

with energy storage, and thus more scalable, cheaper,

and more sustainable.

Thermal Performance Enhancement of Earth Tube Heat Exchanger

81

7 CONCLUSIONS

It is observed that by increasing the velocity of the

inlet of the 15m copper serpentine tube, heat transfer

is increased dramatically, from 1.3 to 3.2. This

indicates that fluid velocity improves system and

thermal efficiency, thereby making the earth tube

heat exchanger more efficient.

REFERENCES

Ahmed A Serageldin, Ali K Abdelrahman, Shinichi

Ookawara Energy Conversion and management 122,

25-38, 2016.

Balbay A, Esen M. Experimental investigation of using

ground source heat pump system for snow melting on

pavements and bridge decks. Sci Res Essay

2010;5(24):3955–66.

Balbay A, Esen M. Temperature distributions in pavement

and bridge slabs heated by using vertical ground-source

heat pump systems. Acta Sci-Technol 2013;35(4):677–

85.

Benzaama, M. H., S. Menhoudj, A. M. Mokhtari, and M.

Lachi. "Comparative study of the thermal performance

of an earth air heat exchanger and seasonal storage

systems: Experimental validation of Artificial Neural

Networks model." Journal of Energy Storage 53 (2022):

105177.

Deshmukh MK, Sodha MS, Sawhney RL. Effect of depth

of sinking on thermal performance of partially

underground buildings. Int J Energy Res

1991;15(5):391–403.

Esen H, Inalli M, Esen M. Numerical and experimental

analysis of a horizontal ground-coupled heat pump

system. Build Environ 2007;42(3):1126–34.

Esen H, Inalli M, Esen M. A techno- economic comparison

of ground-coupled and air-coupled heat pump systems

for space cooling. Build Environ 2007;42(5):1955–65.

Esen H, Esen M, Ozsolak O. Modelling and experimental

performance analysis of solar-assisted ground source

heat pump systems. J Exp Theor ArtifIntell

2017;29(1):1–17.

Giouli Mihalakakou, Manolis Souliotis, Maria Papadaki,

George Halkos, John Paravantis, Sofoklis Makridis,

Spiros Papaefthimiou Renewable and Sustainable

Energy Reviews 155, 111921, 2022

Givoni B, Katz L. Earth temperatures and underground

buildings. Energy Build 1985;8(1):15–25.

Givoni B. Earth-integrated buildings an overview. Archit

Sci Rev1981;24(2):42– 53.

Hadi, Faeza Mahdi, Muntadher Hashim Abed, and Karrar

Abed Hammoodi. "Thermal Performance of Earth Air

Heat Exchanger for Geothermal Energy Application in

Hot Climate using CFD Simulation." Journal of

Advanced Research in Fluid Mechanics and Thermal

Sciences 115, no. 1 (2024): 99-117.

Inalli M, Esen H. Experimental thermal performance

evaluation of a horizontal ground-source heat pump

system. Appl Therm Eng 2004;24(1415):2219–2232.

Khatry AK, Sodha MS, Malik MAS. Periodic variation of

ground temperature with depth. Sol Energy 1978;2

Lattieff, Farkad A., Mohammed A. Atiya, Rudainah Ali

Lateef, Anmar Dulaimi, Muhsin J. Jweeg, Azher M.

Abed, Jasim M. Mahdi, and Pouyan

Talebizadehsardari. "Thermal analysis of horizontal

earth-air heat exchangers in a subtropical climate: An

experimental study." Frontiers in Built Environment 8

(2022): 981946.

Lucia U, Simonetti M, Chiesa G, Grisolia G. Ground-

source pump system for heating and cooling: review

and thermodynamic approach. Renew Sustain Energy

Rev 2017.

Omer AM. Ground-source heat pumps systems and

applications. Renew Sustain Energy Rev

2008;12(2):344–71.

Shams Forruque Ahmed, Suvash C Saha, JC Debnath, G

Liu, M Mofijur, Ali Baniyounes, SMEK Chowdhury,

Dai-Viet N Vo Environmental Chemistry Letters 19

(6), 4191-4210, 2021.

Sofyan, Sarwo Edhy, Teuku Meurah Indra Riayatsyah, Eric

Hu, Akram Tamlicha, Teuku Muhammad Reza Pahlefi,

and H. B. Aditya. "Computational fluid dynamic

simulation of earth air heat exchanger: A thermal

performance comparison between series and parallel

arrangements." Results in Engineering 24 (2024):

102932.

Wu W, You T, Wang B, Shi W, Li X. Simulation of a

combined heating, cooling and domestic hot water

system based on ground source absorption heat pump.

Appl Energy 2014; 126:113–22.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

82