Automated Level Detection and Conveyor Control System for

Polymer Manufacturing

R. Mouleeshuwarapprabu, T. Kalavathidevi, P. Revathi, S. Pavithra, S. Poovizhi and L. Sanjay Kanth

Department of Electronics and Instrumentation Engineering, Kongu Engineering College, Perundurai, Erode, Tamil Nadu,

India

Keywords: Node MCU, Ultrasonic, Speed Control.

Abstract: This project in relation to the transformation of polymer manufacturing system to automated system with

improved control on level of material available and control of speed of conveyor belt. This IoT system of

molecular movement is real time service for right movement of the memorials using ESP8266 with Node

MCU. These smart sensors for detection whether it is ultrasonic, capacitive, float switches are used with the

system to obtain the exact level of the material on the conveyor. Having all this data, Node MCU is capable

of controlling speed of conveyor using techniques Pulse Width Modulation (PWM) and voltage variation. To

further combat these challenges, the project aims at deploying state-of-the-art sensor technologies and

advanced control algorithms as a package to improve efficiency and reliability within the industry while

eliminating the incurring problems with common industrial system, such as inaccuracy, inflexibility and high

cost. Finally, the integrated revolution counter and speed sensor enhance the system's versatility while also

being very easy to handle and safe, thanks to the adoption of numerous protections, including the emergency

stop buttons and anti-overheating protection, ideal for contemporary industrial settings. Offering high-speed

performance at low complexity, this automated solution is an effective low-cost modular replacement for the

existing industrial systems, opening up prospects for future industrial automation.

1 INTRODUCTION

The increasing automation requirements in industrial

manufacturing have placed a focus on the demand for

efficient, precise, and cost-effective solutions for

material handling systems. In applications like

polymer production, where there is no second off, and

involve successive and repetitive material and

conveyor operations, conventional solutions fall short

on precision, adaptability, and response time. These

deficiencies reduce operational efficiency, increase

down-time, and thus higher maintenance costs that

affect the overall productivity of the system.

Integration with the latest technologies, i.e. IoT-

enabled control systems is a game-changing solution

to avoid these challenges. Node MCU with ESP8266,

a strong feature and Wi-Fi capability for processing

real-time sensor data from different sensors are

utilized in the project, such as an automated material

level sensor and conveyor belt speed control system.

The system consists of the use of ultrasonic,

capacitive, and float switch sensors to efficiently

measure material level. They all possess various

advantages that are useful for various applications

during polymer production. Node MCU is at the heart

of this system, not only reading sensor information

but also executing sophisticated algorithms to

dynamically control the conveyor speed. That ensures

unbroken material flow, avoids bottlenecks, and

maximizes production efficiency. Other safety

aspects like emergency stop buttons and overheat

protection have also been integrated to ensure fail-

safe and safe operation.

2 EXISTING PROBLEM

Current level detection and conveyor control systems

are vital elements of most industrial processes,

ranging from materials handling and processing to

manufacturing and packaging. Although valuable,

however, systems like these today are plagued by a

succession of chronic problems subtracting from their

overall performance, reliability, and responsiveness

Mouleeshuwarapprabu, R., Kalavathidevi, T., Revathi, P., Pavithra, S., Poovizhi, S. and Kanth, L. S.

Automated Level Detection and Conveyor Control System for Polymer Manufacturing.

DOI: 10.5220/0013876000004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 2, pages

11-16

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

11

to the needs of modern industry. Most often the most

important challenge is inaccuracy and imprecision of

conveyor position and level measurement, usually

due to old sensor technology, erosive operating

conditions, and improper calibration. These

inconsistencies may result in process inefficiencies,

wastage of materials, and even safety risks in some

high-hazard scenarios. Moreover, these systems

possess low flexibility and flexibility, which

disallows them to be customized for alternative

operation requirements or alternative production

needs with high agility Classical systems are static

and inflexible to upgrade, which has implications on

their applications in changing industrial settings such

as Industry 4.0 or intelligent manufacturing plants.

3 PROPOSED SOLUTION

The proposed approach Our approach is to create an

adaptive and efficient automatic system for detecting

levels and conveyor control in industrial processes.

Our system employs automation using Node MCU,

ultrasonic sensors for accurate detection of the

material level, and relay-switched DC motors to

dynamically set conveyor speed. Ultra sonic sensors

are used to continuously monitor the level of material

by sending sound waves and determining real-time

measurements from reflection delay. Intelligent

control programs manipulate the information,

modulating conveyor speed to facilitate smooth

material movement and preventing jams or spills. The

system has been designed to be flexible and scalable

and may be installed in various small-scale as well as

large-scale production plants. It has a modular

structure that makes it easy to integrate with existing

infrastructure and upgrade in the future. It is also

Industry 4.0-compliant, with IoT technologies used to

provide maximum connectivity and data-driven

decision-making capability in order to enhance

operational efficiency.

4 METHODOLOGY

4.1 Block Diagram

The Proposed system for material level detection &

conveyor control is a computerized system based on

Node MCU (ESP8266) which is working as the

controlling unit as shown in figure 1 block diagram.

Ultrasonic Sensor: The Node MCU processes real-

time data from different sensors including an

ultrasonic sensor which constantly detects the level of

material in the tank by emitting sound waves and

measuring the duration of their bounce-back time.

Figure 1: Block Diagram of the Automated in Level

Detection and Conveyor Control System for Polymer

Manufacturing.

Depending on the kind of material in use, level

sensing can also be achieved with a combination of

float switches and capacitive sensors. Control

Algorithms : The algorithms controlling the system

on the Node MCU interprets the signals from the

sensors and accordingly controls the speed of the

conveyor belts. A relay safely activates the motor

which in turn powers the conveyor belt. The motor

speed is controlled via PWM (Pulse Width

Modulation) or varied voltage to ensure flow is

optimal and to avoid a jam. It comes with safety

measures, including an emergency stop button and

thermal shut-off, making it possible for the machine

to immediately stop working in an emergency to

ensure safe and reliable operation. The modular

nature of the system enables it to be adapted to the

precise requirements of multiple industrial-sectors

and can also help expand the nature of jobs that are

assigned amongst machines in the future.

4.2 Ultra Sonic Sensor

Ultrasonic sensor detects the distance to the material

level on the conveyor belt and interfaces with Node

MCU for on-line acquisition and processing of data

to ensure reliable and accurate level detection. As the

sensor is non-contact, there is no possibility of

contamination or damage due to harsh, abrasive, or

corrosive conditions, and the sensor is placed inside

the container and senses material levels therein.

Ultrasonic sensors are very versatile, they are easy to

adjust to different conveyor heights and material

types and can be used in almost all types of plant

floor environments. They provide real-time feedback

that enables automatic adjustment of conveyor speeds

or material replenishment systems to optimize

production flow.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

12

4.3 Relay

The relay component in control and automation level

detection of polymer production is a factor that

controls the conveyor motor. A relay US1 used as a

switch that regulates power to the motor depending

on the instruction from the control system to provide

precise speed control according material levels

detected by the sensors. The relay also taking on the

duty of providing on/off control of the motor which

allows the motor to start and stop smoothly as

needed. In terms of safety, the relay serves an

important function, as it is used in conjunction with

mechanisms like emergency stop buttons and fault

detection systems that operate to de-energize the

circuit quickly when a safety violation occurs to

prevent damage to the equipment or operators. The

relay also serves as the control system and motor

interface to provide coordination and

communication.

4.4 Alarm

Alarms are crucial in ensuring the safety and

effectiveness of the system that automatically detects

polymer production levels and operates a conveyor.

They continuously supervise vital parameters and

alert operators of any discrepancies or anomalies.

Alarms, for instance, are triggered when material

levels are near preset thresholds and issue a

notification for replenishment if the levels are low or

for overflow risk if it is high. So, alarm system is also

important for the fault detection in the system and

there could be some fault in sensors or motors that

need to be detected and resolved as soon as possible

such that it reduces the downtime. Alarms, equipped

with emergency stop mechanisms that trigger alerts

in the event of a hazard is detected under the safety

procedures, alert operators to unsafe situations as

soon as possible.

4.5 Node MCU

The implementation of automated level detection and

conveyor control system for polymer production

system with the use of Node MCU at the core

involves programming, which can be done using

ESP8266 chip and its internal Wi-Fi. It acts as the

system brain, which takes real-time data from various

sensors like ultrasonic and capacitive and controls the

DC motor for conveyor speed control. It collects data

from the sensors regarding material levels and

process this information with the help of embedded

algorithms and make smart decisions like changing

the speed of conveyor based on the material levels

sensed.

4.6 Conveyor Belt

A critical element of the integrating smart sensor

system for plastic defect detection and quality

measurement in plastic production. At the center of

the system, the conveyor belt is the key method of

moving plastic through the different phases of

production. Made up of a never-ending loop of

material, most often rubber or PVC, the conveyor belt

transports plastic from workstation to workstation in

a regulated process. Its smooth and constant

movement allows for efficient plastic flow, making it

possible to apply defect checking and quality

checking processes. The variable speed conveyor belt

also enables operators to control the production rate

according to demand, maximizing efficiency and

productivity. Completely integrated into the system

design, the conveyor belt plays a crucial role in timely

and accurate provision of plastic and thus overall

quality and success of plastic manufacturing

processes. The conveyor belt is the backbone of a

conveyor system, generally rubber, plastic, or metal,

and the primary surface where material movement

takes place.

5 TECHNICAL DESCRIPTION

5.1 System Description

The automation-based level sensing and conveyor

control system is specially developed for polymer

production processes in a bid to maximize efficiency,

reliability, and material handling safety. The system

basically consists of a mix of crucial elements such as

a Node MCU (ESP8266), ultrasonic sensor, DC

motor, conveyor belt, relay module, as well as other

sensors such as capacitive sensors and float switches.

Node MCU is the controller, reading information

from the ultrasonic sensor, which determines material

level to the conveyor belt. The sensor sends sound

waves and measures the time for the waves to bounce

back, gives accurate real-time material levels. The

conveyor belt is powered by a DC motor to transport

polymer material between production stages. The

Node MCU reads the data of the ultrasonic sensor and

determines the degree of adjustment in conveyor

speed required and regulates it through the relay

module. The relay is used to act as a switch to regulate

the supply of power given to the DC motor for

effective speed control and turning on and off and

Automated Level Detection and Conveyor Control System for Polymer Manufacturing

13

incorporates safety components such as emergency

stop functions. It is a feedback system, and the

ultrasonic sensor continuously checks the material

level, and out-of-spec alarms are given to the

operators for alerting the operators. The automated

system minimizes material loss, prevents jams or

spills, and maximizes production throughput, which

eventually contributes to energy efficiency. Its

modular structure also makes it more customizable

and scalable, and it has the potential to provide

flexibility to suit changing manufacturing

requirements. With the merging of advanced

technologies and control algorithms, the system

transforms polymer manufacturing material handling

and sets the stage for higher productivity, safety, and

sustainability

5.2 Circuit Operation of Automated in

Level Detection and Conveyor

Control System for Polymer

Manufacturing

The automated conveyor level detection and

conveyor control system functions as follows: An

appropriate DC power supply is used to supply power

to the circuit, offering the required voltage to the

Node MCU (ESP8266) and other elements, such as

the ultrasonic sensor and relay module, using a

common ground shared by all components. The Node

MCU acts as the control unit, using its GPIO pins to

interface with different sensors. The ultrasonic sensor

is interfaced with GPIO pins 5 (D1) for trigger and 4

(D2) for echo. It sends out sound waves to detect the

distance to the material level on the conveyor belt and

estimate the time taken by the waves to travel back.

After getting the distance data, the Node MCU

compares the data with pre-set thresholds to identify

the material level. If the material level falls short of a

predetermined level, the Node MCU switches on the

DC motor to carry more material; if it exceeds a

threshold, it can stop or continue operating at the

momentary state. The relay module, wired into GPIO

pin 16 (D0), enables the Node MCU to switch the

power supply to the DC motor on and off, providing

for momentary control of speed and direction as

needed. Extra sensors, such as a capacitive sensor on

GPIO pin 12 (D6) and a float switch on GPIO pin 14

(D5), deliver extra information on material presence

detection and liquid levels monitoring, respectively.

An emergency stop button is also included, wired to

GPIO pin 13 (D7), which activates the Node MCU to

stop the motor and ring alarms instantly upon button

press. The system runs in an endless feedback loop as

the ultrasonic sensor constantly detects material

levels, with real-time changes controlled by the Node

MCU. The circuit can be alarmed for any off-normal

readings from sensors for reasons of safety and to

reduce wastage of material. The process of circuit

running improves efficiency, reliability, and safety in

material management, adding to increased

productivity in polymer processing operations. Figure

2 shows the circuit diagram of the project.

Figure 2: Circuit Diagram of the Project.

5.3 Flow Chart of Automated in Level

Detection and Conveyor Control

System for Polymer Manufacturing

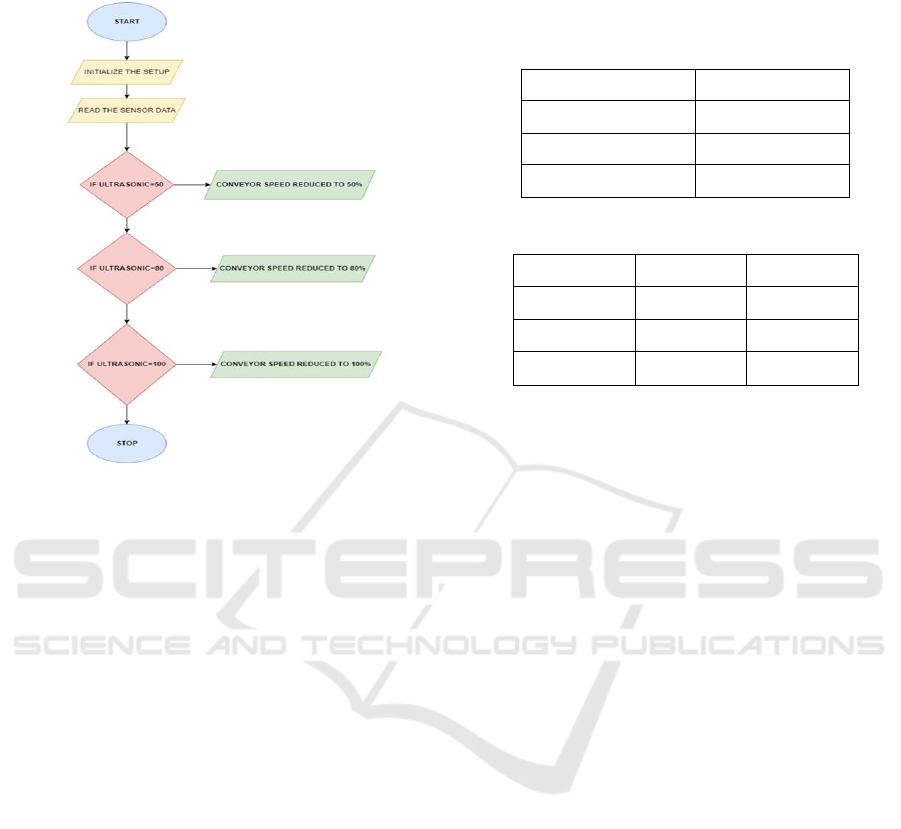

The flowchart for the automated level detection and

conveyor control system using figure 3 represents the

sequence of actions in controlling the conveyor speed

based on input from an ultrasonic sensor, along with

other functionalities in the project. The flowchart

starts by initializing the setup, which is done by

turning on the system and setting up the Node MCU

and the corresponding GPIO pins for the sensors and

relay. The system then captures data from the

ultrasonic sensor by causing it to produce sound

waves, measuring the time taken for the waves to

return, and computing the distance to the material

level on the conveyor belt. According to the sensor's

reading, the system assesses the distance: below 50,

the conveyor speed is decreased to 50%, and a low-

level alarm might be generated. For 50 to 80

distances, the conveyor speed is 80%, and distances

of 80 or higher initiate full speed (100%). In addition,

the system monitors input from a capacitive sensor; if

material is sensed, operations proceed normally, but

otherwise, the system warns operators and slows

down. The float switch is a safety device, causing an

emergency stop if tripped. The system runs in a

continuous feedback loop, constantly monitoring the

ultrasonic sensor for distance changes and adjusting

conveyor speed in real-time. Finally, the process ends

with finalized adjustments, keeping conveyor

operations according to the most recent sensor data

while recording information for performance analysis

and future improvements. This holistic approach

maximizes production efficiency, reduces waste, and

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

14

increases safety in polymer manufacturing and other

industrial processes.

Figure 3: Flow Chart of the Automated in Level Detection

and Conveyor Control System for Polymer Manufacturing.

6 RESULTS AND DISCUSSION

Features of the conveyor system’s intelligent speed

control for energy-saving and safe material handling

the system operates at its nominal value when there

are less than 10 units of distance between points of

designation on the conveyor, thus ensuring

continuous and smooth flow of materials. Such

reduction is important for managing the flow of

material, in order to prevent clogging and also to

avoid overloading in some parts of the conveyor. The

system ensures optimal material processing, at the

same time providing safety at work by deceleration in

this time interval. However, if the distance between

the points is greater than 20 units, then the conveyor

system sends a signal and brings the system to a

complete halt. This proactive measure takes

precautions to prevent issues that might arise, such

as material spillage, machinery breakdown, followed

by accidents. This ensures that process-monitoring

approaches over sufficient distance will be performed

whenever they are beyond the established limit before

resuiting conveyor use case system. Dynamic

adjustment makes the conveyor system run at a high

level of effectiveness and ensures the safety of

material handling operations, making operations

reliable and minimizing the risk of interruptions. The

operation of conveyor concerning sensor value is

shown in table 1 whereas status of relay will be shown

in table 2.

Table 1: Conveyor Speed Behavior Based on the Distance.

Distance

Conveyor Speed

Distance < 10

Normal Speed

10 ≤ Distance ≤ 20

Reduced Speed

Distance > 20

Conveyor Stops

Table 2: Relay Condition According to the Distance.

Distance

Relay 1

Relay 2

0–20

Low

High

20–30

Low

Low

30–50

High

Low

7 CONCLUSIONS

The initiative aims at creating an innovative

automatic level detection and conveyor control

system dedicated to polymer production. Utilizing

cutting-edge sensors, control programs, and

automation solutions, the system is intended to

maximize material handling, reduce production

losses, and achieve constant quality. Prioritizing

energy conservation, safety, and flexibility of

operation, the suggested system meets the needs of

polymer production and provides a robust solution for

today's industrial processes. Future efforts will

concentrate on prototype creation, testing, and

validation to evaluate performance in different

industries. We will highlight the benefits of next-

generation sensor technology (like ultrasonic

sensors) in automation through the outcomes of this

project. it cuts down waste and increases productivity

leading to cost savings and preservation of resources

by reporting real-time material levels and enabling

accurate conveyor control. The modular design

allows the machine seamlessly to fit into existing

manufacturing facilities, making it suitable for both

large-scale as well as small-scale operations. The

project will lead to an elevated version of an

automatic conveyor level detection and management

system tailored for polymer production. By

integrating new sensors, software controls, and

automation devices, the system aims to optimise the

handling of material and drive productivity while

maintaining product consistency of quality. Long

standing issues experienced in polymer making are

Automated Level Detection and Conveyor Control System for Polymer Manufacturing

15

resolved through the emphasis on power efficiency,

safety considerations and flexible operation

capability, providing a field proven solution

throughout the spectrum of modern industrial

application.

Future activities will emphasize prototype

construction, testing, and validation for performance

evaluation in different fields. Figure 4 shows the

Prototype of Automated in Level Detection and

Conveyor Control System for Polymer

Manufacturing.

Figure 4: Prototype of Automated in Level Detection and

Conveyor Control System for Polymer Manufacturing.

8 FUTURE SCOPE

Further development and enhancement of the

automated level detection and conveyor control

system offer several promising avenues for future

research and development. One of the most important

areas is the incorporation of advanced sensors, e.g.,

LIDAR or infrared, that would be capable of

improving accuracy of material level detection and

enabling improved sorting on the basis of different

material properties. Moreover, applying machine

learning techniques will help improve predictive

maintenance and fault detection to a great extent so

that the system can be trained from experience and

anticipate failures before they happen, thereby

reducing downtime and maintenance expenses.

Research on the integration of collaborative robots

will further enhance material handling and sorting

operations by providing such robots with the

capability of collaborating with human workers,

increasing efficiency and safety. Utilizing high-end

data analytics platforms to analyze data in real-time

can give more insightful information regarding

production processes.

REFERENCES

Gonzalez and Rodriguez (2021) ‘IoT-Based Conveyor

Monitoring Systems for Polymer Manufacturing’ Vol.

17, No. 4, pp. 321-335

Kim et al and Susin, A. A. (2018) ‘Optimization of

Conveyor Speed in Polymer Processing’ Vol. 7, No. 3,

pp. 215-230

Martinez et al and Jonathon (2019) ‘Energy Efficiency in

Polymer Manufacturing: Conveyor Control Strategie’

Vol. 8, No. 4, pp. 321-335.

Nguyen et al and Pihnastyi (2021) ‘Integration of Robotics

with Conveyor Control Systems in Polymer

Manufacturing’ Vol. 18, No. 1, pp. 75.

Patel and Paulraj (2019) ‘Smart Manufacturing in Polymer

Industry: Challenges and Opportunities’ Vol. 11, No. 2,

pp. 112-125.

Smith et al and Ch Kargel (2018) ‘Automation

Technologies in Polymer Manufacturing’ Vol. 5, No. 2,

pp. 112-125.

Thompson and Wilson (2019) ‘Real-Time Monitoring and

Control Systems for Polymer Manufacturing’ Vol. 10,

No. 1, pp. 45-58.

Wijaya and Lee et al. (2020) ‘Conveyor Control Strategies

in Polymer Processing’ Vol. 13, No. 4, pp. 410-425

Williams and Brown (2019) ‘PLC-Based Control Systems

for Polymer Manufacturing’ Vol. 12, No. 3, pp. 212-

225.

Zhao and Li (2020) ‘Machine Learning Algorithms for

Conveyor Control in Polymer Processing’ Vol. 15, No.

2, pp. 85-98

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

16