A Novel Methodology to Ensure Rider Safety Measures Based on

Helmet Detection System Using Deep Learning Mechanism

Gokulkannan M., Elandhiraiyan K., Gokulraj G. and Thirunavukkarasu G.

Department of Computer Science and Engineering, Mahendra Engineering College, Namakkal, Tamil Nadu, India

Keywords: Rider Safety, Helmet Detection, Image Processing, Deep Learning, EYOLO, Convolutional Neural Network,

CNN, Driver Safety.

Abstract: Motorbikes are a prevalent mode of conveyance in numerous countries. Nevertheless, the absence of the

appropriate safety apparatus poses a significant danger when operating a motorcycle. Consequently, it is

strongly advised that individuals don helmets while operating a bicycle to ensure their safety. In order to

eliminate this manual dependence, it is imperative to develop a self-powered helmet detection system that can

identify motorcycle offenders. This research is dedicated to the development of a helmet detection system for

two-wheelers that is both reliable and efficient. The Enhanced You Only Look Once (EYOLO) algorithm is

employed in this system and it is cross-validated with the traditional deep learning algorithm, Convolutional

Neural Network (CNN), to assess the effectiveness of the proposed model. The headgear status of the rider is

continually monitored by this system, which operates in real-time. It rapidly determines whether the

motorcyclist is donning a helmet by utilizing sophisticated artificial intelligence techniques. The primary goal

of this system is to ensure that riders adhere to helmet regulations in order to enhance their safety. The system

automatically precludes the vehicle from commencing in cases where the rider is not wearing a helmet,

thereby encouraging the use of helmets. This proactive approach is designed to substantially reduce the risk

of head injuries in the event of incidents, thereby contributing to the overall safety of the road as well as

decreasing the severity of prospective injuries. Our system endeavors to improve passenger safety and reduce

the negative repercussions of noncompliance with helmet regulations by combining state-of-the-art

technology with regulatory compliance.

1 INTRODUCTION

Today, traffic accidents involving scooters and

motorbikes are surprisingly widespread, making the

safety of passengers on two-wheelers an urgent issue

Gopinath D, et al., 2024. In order to tackle this

pressing problem, our research utilizes artificial

intelligence to identify helmet wear in real-time. Our

objective is to utilize state-of-the-art technologies in

a proactive manner to improve rider safety and

decrease the number of serious injuries caused by

accidents. The incidents are that cases of two-

wheeler accidents are greatly on the rise, and the

riders necessitate wearing a helmet. However, still a

good number of motorcyclists prefer riding without

such basic safety features, knowing very well that it

is important. This system aims to develop and

implement a helmet-detecting system in real-time to

back up helmet regulation enforcement and accident

prevention (Xuejun Jia, et al., 2020). Project

objectives include enhancing rider safety and

addressing environmental problems related to road

accidents. Efforts are being made to lessen the toll

that road accidents take on the environment by

increasing safety measures and decreasing the

severity of injuries through prompt medical attention.

Furthermore, we aim to promote helmet usage by

taking proactive steps like not allowing the vehicle to

start without a helmet. This will help establish a

safety culture among riders and promote a more

sustainable way of getting about. With this system in

place, not only would individual riders reap many

benefits, but healthcare systems already

overburdened by injuries sustained in accidents may

also see substantial relief. We encourage sustainable

mobility behaviors and contribute to society's well-

being by minimizing the frequency and severity of

injuries occurring from two-wheeler accidents. We

want to build healthier communities and safer roads

552

M., G., K., E., G., G. and G., T.

A Novel Methodology to Ensure Rider Safety Measures Based on Helmet Detection System Using Deep Learning Mechanism.

DOI: 10.5220/0013869100004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 1, pages

552-561

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

for everyone via teamwork and new ideas, such as the

real-time helmet detection system (Hanhe Lin, et

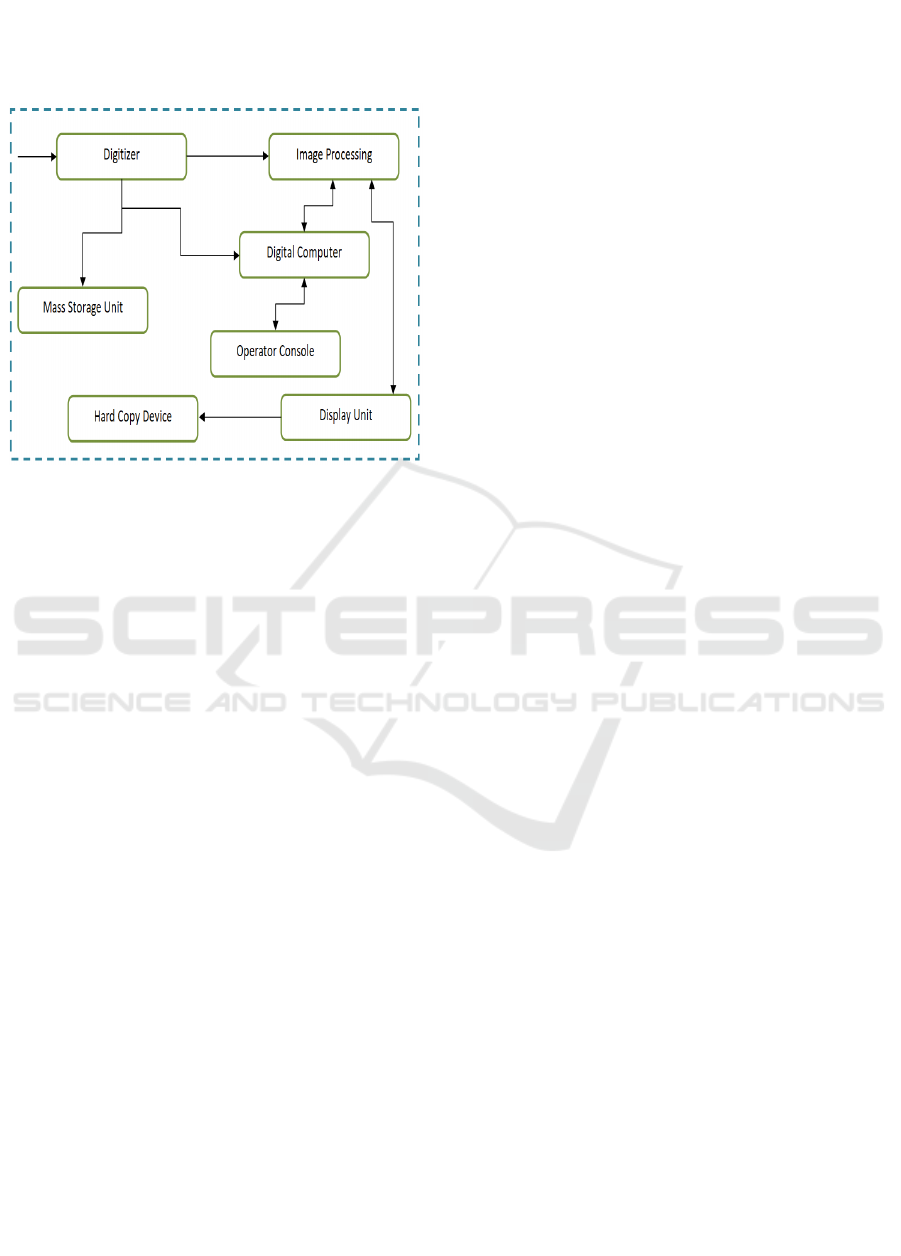

al., 2020). The following figure 1 shows the image

processing block diagram.

Figure 1: Image processing block diagram.

A digital image is a two-dimensional picture that

has been processed by a digital computer. Any two-

dimensional data may be digitally processed in a

larger sense. In digital storage, each bit represents an

integer array that can be either real or complex. The

initial step in digitizing and storing an image in

computer memory is to convert it from a digital

format, such as a transparency, slide, picture, or X-

ray. Digitizing the image allows for high-quality

processing and/or display on a (TVYongze Ji, et al.,

2022). A rapid-access buffer memory stores the

image for display, and it refreshes the monitor at 25

frames per second to provide an optically continuous

display (Bingyan Lin 2024). A digitizer is a machine

that takes an image and turns it into a numerical form

that a digital computer can understand. A few

popular digital converters include

• Microdensitometer

• Flying spot scanner

• Image dissector

• Videocon camera

• Photosensitive solid- state arrays.

(Wei Jia, et al., 2021) Once an image has been

acquired, stored, preprocessed, segmented,

represented, recognized, and interpreted, finally, this

image could be displayed or recorded by an image

processor. The image sensor and digitizer work

together in capturing an image, which is the first stage

in the process (M. Saravanan, et al., 2024) The next

stage is the preprocessing stage, where the image is

enhanced for subsequent operations. Enhancement,

noise removal, area isolation, etc. are common topics

in preprocessing. An image can be "segmented" into

its individual elements by using this technique. Raw

pixel data, including either the region's border or the

pixels inside the region, is often what comes out

during segmentation. To prepare the raw pixel data

for further processing by the computer, a procedure

known as representation must be carried out. The

primary focus of description is the extraction of

characteristics that serve as fundamental

differentiators between various object classes. Based

on the data supplied by the object's descriptors,

recognition provides it a label. The process of

interpretation entails giving significance to a set of

identified items. The knowledge base is enriched

with knowledge acquired from the knowledge body

relevant to the problem domain. (Sheela S

Maharajpet, et al., 2024). The knowledge base further

governs the inner workings of the processing modules

and their interactions among themselves. Not all

modules need to be in place to do a particular job. The

application specifies the composition of the image

processing system. Typically, the image processor's

frame rates are around 25 fps (Maros Jakubec, et al.,

2023).

(i) Digital Computer: On the digital image, the

computer applies mathematical operations including

adding, subtracting, averaging, and convolution.

(ii) Mass Storage: Auxiliary storage devices like as

floppy discs and CD ROMs are widely used.

(iii) Hard Copy Device: This device stores the

relevant software and creates a permanent copy of the

picture.

(iv) Operator Console: In order to make software

adjustments or verify intermediate results, the

operator console has the necessary tools and

configurations. Moreover, the operator may validate

the entering of all necessary data and any errors that

may have arisen in consequence.

Digital image processing is when image data is

processed supported by some digital means. Images

originate most of the time in an optical way; the

modern state of the cameras just takes images

massively in digital form. The other option is to

video-capture them and converts to the digital form.

During the digitization process, sampling and

quantization are performed. These images would

normally be processed by one or more of the five

basic operations (Chentao Shen, et al., 2023). Several

A Novel Methodology to Ensure Rider Safety Measures Based on Helmet Detection System Using Deep Learning Mechanism

553

methods for processing images are detailed in this

section.

(i) Image Enhancement: Operations that increase a

image quality, such as enhancing its contrast and

brightness, decreasing its noise content, or sharpening

its features, are known as image enhancement. This

only improves the image by making it more

comprehensible while still revealing the same

information. It doesn't enrich it with any new details.

(ii) Restoring Images: Just like image enhancement,

image restoration works to restore a image quality,

but it relies heavily on measurements or known

degradations to do so. Geometric distortion, out-of-

focus areas, repeated noise, and camera shake are all

examples of image restoration issues. Images have

the means for the correction of known degradations.

(iii) Analyzing Images: Operations in image analysis

can turn attributes of the original image into either

numerical or graphical data. Dismantle them to put

them in categories. The statistics of the images will

govern their use. Common tasks include object

categorization, automated measurement, scene and

image feature extraction and description, and

automated measurement. The majority of image

analyzers' usage is in machine vision tasks.

(iv) Image Compression: Compressing and

decompressing images lessens the amount of data

needed to describe a image. Compressing photos gets

rid of all the unnecessary data that is often included

in them. The size is lowered by compression, making

it ideal for convenient storage or transportation.

Decompression occurs when seeing the image.

Lossy compression enhances compression at the

expense of the original picture, in contrast to lossless

compression, which preserves all of the original

image's data.

(v) Image Synthesis: Operations in image synthesis

generate new images from existing ones or from data

that does not contain images at all. In most cases,

image synthesis techniques produce results that

would be extremely difficult.

Several methods of image encoding are detailed

below.

• A binary image, in which each pixel is either

black or white. We just require one bitper pixel

since each pixel may take on one of two

potential values (0 or 1).

• A grayscale image typically uses a range of

grayscale values, from 0 (black) to 255 (white),

for each pixel. Because of this range, a single

byte—eight bits can represent each pixel. In

most cases, grayscale values are a power of 2,

however, other values are utilized.

• A color map matrix plus an array makes up an

indexed image. In this array, each pixel value is

an index into a color map. The array is denoted

by the variable name X in this text, whereas the

color map is referred to as map.

• A RGB image, often known as a true color

image, is one in which the relative amounts of

red, green, and blue give rise to distinct colors

for each pixel. There would be 2563 distinct

color combinations if the values of these

variables could vary from 0 to 255. A "stack" of

three matrices, one for each pixel's red, green,

and blue values, constitutes such an image. So,

there are three values that correspond to each

pixel.

2 RELATED WORKS

Motorbike use as a mode of transportation is a

common practice in many countries. However, the

absence of certain protective gear while riding poses

a threat to a rider (Rupesh Chandrakant Jaiswal, et al.,

2022). Therefore, wearing a helmet is very necessary

for your safety while riding. Therefore, it is cardinal

to build such a system to identify motorcycle helmets

and criminals in order to eliminate this dependence

on the human inspectors. Some biker riders don't see

the need to wear a helmet, but some only do when

they see a traffic cop. This project endeavors to

design an autonomous system functional in real-time,

with a focus on the YOLO deep learning approach.

The YOLO CNN is trademarked for real-time object

detection.

Safety helmets are essential in many outdoor and

indoor industrial settings, including high-temperature

metallurgical activities and the construction of

towering buildings (Qing An, et al., 2023).

Nevertheless, human error and a lack of compliance

are common problems with manual monitoring,

which also adds to its high cost. In addition, accuracy

is often lacking while detecting tiny target objects. A

potential solution to these problems is to enhance

safety helmets using the helmet detection algorithm.

Lightweight deep learning object identification

model YOLOv5s was updated and showcased in this

study. Recalculating the prediction frames,

clustering using the IoU metric, and altering the

anchor frames using the K-means++ approach

improve the performance of the suggested model,

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

554

which is an extension of the YOLOv5s network

model. In order to strengthen the YOLOv5s

network's backbone and neck networks, a mix of the

global attention mechanism and the convolutional

block attention module was utilized. Deep learning

neural networks are able to extract more features

thanks to these attention techniques, which enhance

the representation of global interactions and minimize

the loss of information characteristics. Improving

target feature extraction and reducing computation

required for model operation are both achieved by the

inclusion of the CBAM into the CSP module. The

suggested model employs the most current SIoU

(SCYLLA-IoU LOSS) as the boundary box loss

function to enhance the prediction box regression. A

lightweight network model that meets the demands of

real-time monitoring is constructed on top of the

upgraded YOLOv5s model. Knowledge distillation

technology reduces the model's computational effort

while enhancing detection speed. All three

metrics—precision, recall, and mean average

precision—show that the suggested model beats the

prior YOLOv5s network model in experimental

results. Even in dim light and from varying distances,

the suggested model might be able to better detect

helmet wear.

The workplace must be visually inspected and

immediately inform the workers when they do not

wear a safety helmet so that injuries on the job could

be avoided (Yange Li, et al., 2020). For that matter, a

need arises for automatic real-time detection from the

great amounts of unstructured visual data created by

on-site video monitoring systems. Despite the

abundance of research on deep learning-based helmet

detection models for traffic surveillance, there has

been surprisingly little discussion of a suitable

solution for industrial use, especially when

considering the complexity of the environment on a

construction site. To that end, we create a system that

uses deep learning to identify safety helmets on the

job site in real time. This approach makes use of the

convolutional neural network-based SSD-MobileNet

algorithm. A public dataset with 3,261 photos of

safety helmets was created and made available to the

public. The photographs came from two sources: the

workplace's video surveillance system and open

images retrieved with web crawler technology. The

picture set is sampled in a manner that is about 8:1:1,

with each set serving as a training set, validation set,

and test set. Using the SSD-MobileNet method, the

experimental findings show that the given deep

learning-based model can efficiently and accurately

detect risky operations including the failure to wear a

helmet on a construction site.

A comprehensive system of safety management

has been built up by power grid enterprises within

China to regulate restrictions, such as all safety rules

and two tickets embodied into one, for the assurance

of the operation's stability and protection of staff

(Songbo Chen, et al., 2020). On the other hand, a

good number of workers still show lack of safety

consciousness by not wearing helmets in their jobs

inside substations. Electric power workers must

always wear safety helmets to protect their heads

from potentially lethal accidents including electric

shock and strikes. Not only does working without a

helmet contradict the safety control system; it depicts

one as careless with the lives and possessions of

people. However, these controlling measures

currently are not efficient, effective, and quick

enough to detect and prevent such acts. This research

suggests using the Improved Faster R-CNN algorithm

to check if a person is wearing a safety helmet so that

we may better prevent this dangerous behavior.

Taking into account the actual circumstances, the

Retinex image improvement is implemented to

increase the quality of images captured in substations

of outside complex situations. Additionally, the K-

means++ technique is utilized to enhance the helmet's

adaptability to its little size. The findings of the

experiments demonstrate that the Improved Faster R-

CNN algorithm achieves better mean-average

precision than the Faster R-CNN method, allowing

for the automated identification of safety helmet

wears in real-time.

The construction industry is still sky-high in its

expansion, hence new and unique dangers to workers'

health and safety arise out of active construction.

Wearing helmets while on a construction site can

greatly lower the chance of incurring an injury

(Lihong Wei, et al., 2024). Hence, the objective of

this research is to propose a deep learning approach

in real-time for detecting whether construction

workers are using helmets or not. This study

examines the training outcomes of the YOLOv5s

network that was chosen through trials. Given that it

has a weak ability to identify tiny items and objects

that are partially obscured. This leads to a number of

improvements to the YOLOv5s network, a change to

the feature pyramid network to a BiFPN bidirectional

feature pyramid network, and an upgrade to Soft-

NMS from NMS, the post-processing methodology.

The loss function is optimized hereby enhancing the

convergence and detection speed of the model, which

introduces BiFEL-yolov5s: A YOLO V5 series

model enhanced by a combination of BiFPN

networks and Focal-EIoU Loss. The model's average

accuracy is improved by 0.9%, its recall rate is

A Novel Methodology to Ensure Rider Safety Measures Based on Helmet Detection System Using Deep Learning Mechanism

555

enhanced by 2.8%, and its detection speed is kept

relatively constant. It meets the needs of helmet

detection in a variety of work situations and is thus

more suitable to real-time safety helmet object

detection.

3 METHODOLOGY

A wide range of scientific and technological

disciplines can benefit from image processing

techniques. Some examples of the many uses for

image processing are presented in this brief list.

(i) Processing Documents: scanning and

transmitting them involves processing the documents,

which involves transforming them into digital

images, compressing them, and then storing them on

magnetic tape. It also has additional applications in

document reading, such as automatic feature

detection and recognition.

(ii) Health Care: examining and interpreting X-ray,

magnetic resonance imaging (MRI), computed

tomography (CT) pictures, images of individual cells,

and chromosomal karyotypes. The processing of

medical images from radiology, nuclear magnetic

resonance (NMR), and ultrasonic scanning, including

chest X-rays, cineangiograms, and projection pictures

of transaxial tomography, is one area of interest in

medical applications. These images may find value

in cancer and other illness screenings, patient

monitoring, and diagnosis.

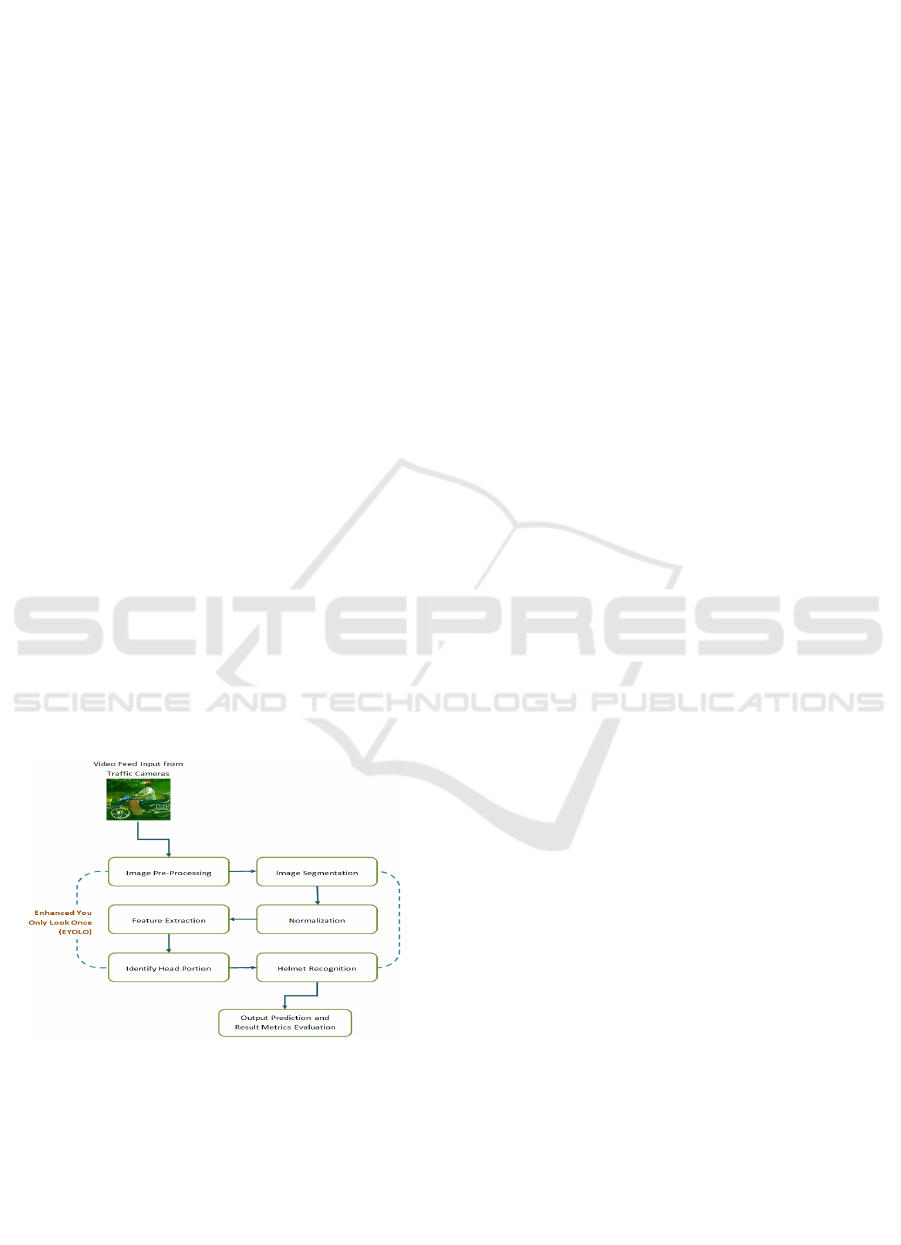

Figure 2: Proposed block diagram.

(iii) Industry: Paper sample inspection, automated

checking of manufacturing line items.

(iv) Defense/Intelligence: Applications include

reconnaissance photo-interpretation, which uses

automated analysis of Earth satellite imagery to seek

for sensitive targets or military threats, and target

acquisition and guidance, which aids in the

identification and tracking of targets in real-time

smart-bomb and missile-guidance systems.

(v) Radar Imaging System: Aircraft and missile

systems obtain their guiding and maneuvering

information from radar and sonar images, which are

utilized for target identification and recognition.

(vi) Agriculture: Satellite and aerial images of land

may be utilized for a variety of reasons, such as

measuring land usage, researching which places are

most suited for certain crops, and inspecting product

to determine if it is fresh or old.

3.1 Video Feed from Camera

The camera on-board to record all activities of a two-

wheeler rider is the most vital technology for helmet

recognition. The camera stands right at the forefront

of sensory input for the AI system by providing live

visual information about the activities of the rider and

the environment around them. As a streaming device,

the camera allows live monitoring of the rider for any

possible helmet compliance violation. The camera

captures the activities and motions of the rider to

determine whether the person is wearing a helmet or

not. Information that a live video stream provides

would give the system enough room to spring into

action anytime the rider is not wearing a helmet. With

this contextual information, such as traffic and road

barriers from the camera, the overall safety of the

rider can be assessed in a more effective manner. This

function of capturing live video input is an important

aspect of the helmet detection system, which is

designed to take proactive measures toward

enhancing rider safety in two-wheelers. Figure 2

shows the Proposed Block Diagram.

3.2 Capture the Image

The two-wheeler helmet recognition system relies on

the following steps: the capturing of images that will

mostly contain everything required by the recognition

analysis. The images are basically frames extracted

from the real-time video stream captured from the

camera. An image therefore, is like a snapshot during

a period in time, the raw material that makes up every

processing and analysis that will go on afterward. The

system is that it enables continuous data feed for

helmet detection whereby frames are taken at regular

intervals to allow for real-time checks on the state of

the rider's helmet. It, therefore, assists better in the

efficient utilization of computing resources and

speedy decisions on the wearing of helmets. This step

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

556

thus becomes the important component in detecting

the helmet and enables the system to determine the

rider's actions while taking requisite measures toward

the safety security of two-wheelers.

3.3 Preprocessing

The two-wheeler helmet identification system relies

heavily on preprocessing to get the recorded images

ready for analysis. Several preprocessing processes

are performed on the collected frames from the live

video feed to improve their quality and make them

more suitable for further analysis. Since various

images need to be processed fast and with lower

computational complexity, it is predetermined that

their sizes must be equal. There are various

normalization techniques which can standardize the

pixel values to allow for better comparison and study

of different images. Other noise filtering methods

such as median filtering and Gaussian blurring can

really help in reducing interference caused by noise

and beautifying the image quite nice. After these

preprocessing techniques, which enhance the

obtained photographs for accurate helmet detection,

the system can safely and rightly evaluate the rider's

helmet standing and therefore take measures to

provide safety on two-wheelers.

3.4 Feature Extraction

The important thing in helmet identification system

of two-wheelers is feature extraction, which

punctuates absorbing knowledge from the pre-

processed images whereby they will tell the system if

the rider is armed with a helmet. Important features

extracted from the pre-processed images may include

color, shape, and texture. While shape features detail

the external outline and structure of possible helmets

in the image, color features captured assist in

analyzing the patterned colors of helmets. Anyway,

texture features sometimes help distinguish helmets

from other items or backgrounds in the picture by

serving as a clue to some properties of the surface of

these items. Thus, the feature extraction process

serves to strengthen the information providing a

clearer picture of the shots enabling the system to

distinguish between helmet on or off instances. This

will allow the system to check when the rider is

wearing a helmet and then take measures concerning

perhaps a safety crackdown concerning two-

wheelers.

3.5 Database Collection

A reliable AI model built on the two-wheeler helmet

recognition system relies on database collection. The

first step is to prepare a large dataset of labeled

images containing both helmeted and helmetless

bikers. Each image in the collection is doted by well-

defined annotation to indicate the presence of a

helmet or not. The deep learning algorithm is then

trained over the labeled dataset, which is intended to

convey the model to find features relating to helmet

identification. The dataset, when used to train the

model, allows the model to generalize better on

unseen data by showing the examples of various

conditions under which the helmets are worn and

non-worn. Creating a strong and dependable two-

wheeler helmet detection system would depend on

database collecting.

3.6 Training

The phase during which identification of helmets on

two-wheeled vehicles is being undertaken is the

training one, which must be handled with extreme

care since it's here where the AI model gets to learn

to differentiate among different types of helmets

through observing patterns from a labeled dataset.

The training is generally performed using deep

learning algorithms like YOLO, which means "You

Only Look Once." In training, the model gets its

internal parameters tuned, i.e., reduces the difference

in predictions and actual ground truth labels, by

iteratively iterating over the labeled dataset. The

model learns how to identify helmets distinguishing

images of people wearing helmets from the images of

people not wearing helmets by modifying its

parameters repeatedly through backpropagation. The

model's training is aimed toward making it the best in

detecting helmets in varied environments,

illumination, and orientation and background. The

model's training helps it to be good at detecting

helmets on live video feeds, improving the safety of

motorcyclists.

3.7 Testing

In the two-wheeler helmet recognition system, testing

holds great importance. It is used to assess both the

efficacy of the training techniques and how well the

trained model may generalize. After having trained

itself on the labeled data sets, the model is evaluated

with another new set of test images, unseen

previously. The test images incorporated some real-

life scenes such as varying lighting, different rider

A Novel Methodology to Ensure Rider Safety Measures Based on Helmet Detection System Using Deep Learning Mechanism

557

positions, or many backgrounds. Each test picture

will be analyzed by the model for the presence of

helmets and outputs are made based on the analyses.

The predictions made by the model are then

compared to the ground truth labels in order to assess

model performance, i.e., accuracy, precision, recall,

and so forth. Testing on unseen data is important for

assessing a model's generalizability along with its

potential for high accuracy in helmet detection in

various real-life situations. This step is critical to

ensuring that the helmet detection system is both

reliable and effective in enhancing the rider's safety

while riding two-wheelers.

3.8 Identified Helmet Wear (or)

Helmet not Wear

In each frame of the live video feed in real-time, the

model trained on helmet detection infers decision

from past data as whether a helmet is in use or not.

Based on criteria set for attributes learned during

training, this once again assures, based on one frame,

the model decides whether a biker has put on a helmet

or not. This makes it possible for the vehicle to

proceed if the model sees a helmet that is sufficiently

confident to meet safety standards. If, however, a

helmet is not seen or seen with low confidence by the

model, the system would not allow the rider to move

forwards on the bike until one was placed on. In doing

so, the preventive measures aim at lowering the

chances of head injuries during mishaps and the

compulsory wearing of the helmet for rider safety. By

keeping a constant check on the state of the rider's

helmet in real-time, the technology establishes a

culture of safety and compliance on two-wheelers.

4 RESULTS AND DISCUSSION

Using the EYOLO (Enhanced You Only Look Once)

architecture, this research suggests a real-time helmet

identification system that has been trained on 4,956

photographs, with 80% of the images being used for

training and 20% for validation. This suggested

EYOLO achieved the highest prediction accuracy of

98.84% among the numerous deep learning variations

that were assessed, demonstrating exceptional

performance in the identification of safety helmets,

even in low-light conditions. The EYOLO model, in

conjunction with learning and classification methods,

was employed to identify helmet infractions among

motorcyclists in this research. The model

demonstrated the ability of deep learning to identify

helmet rule violators in challenging illumination and

weather conditions after being trained on 250 films

that were captured at 25 frames per second and each

lasted 25 seconds. The proposed model's potential for

real-time traffic surveillance and enforcement is

underscored by its high accuracy score. In general,

helmet detection systems have been significantly

improved by advancements in deep learning,

particularly in the context of EYOLO architectures.

The model that has been proposed underscores the

exceptional accuracy and real-time performance of

various EYOLO architectures in the detection of

helmet usage, thereby promoting enhanced safety

measures in traffic surveillance and construction

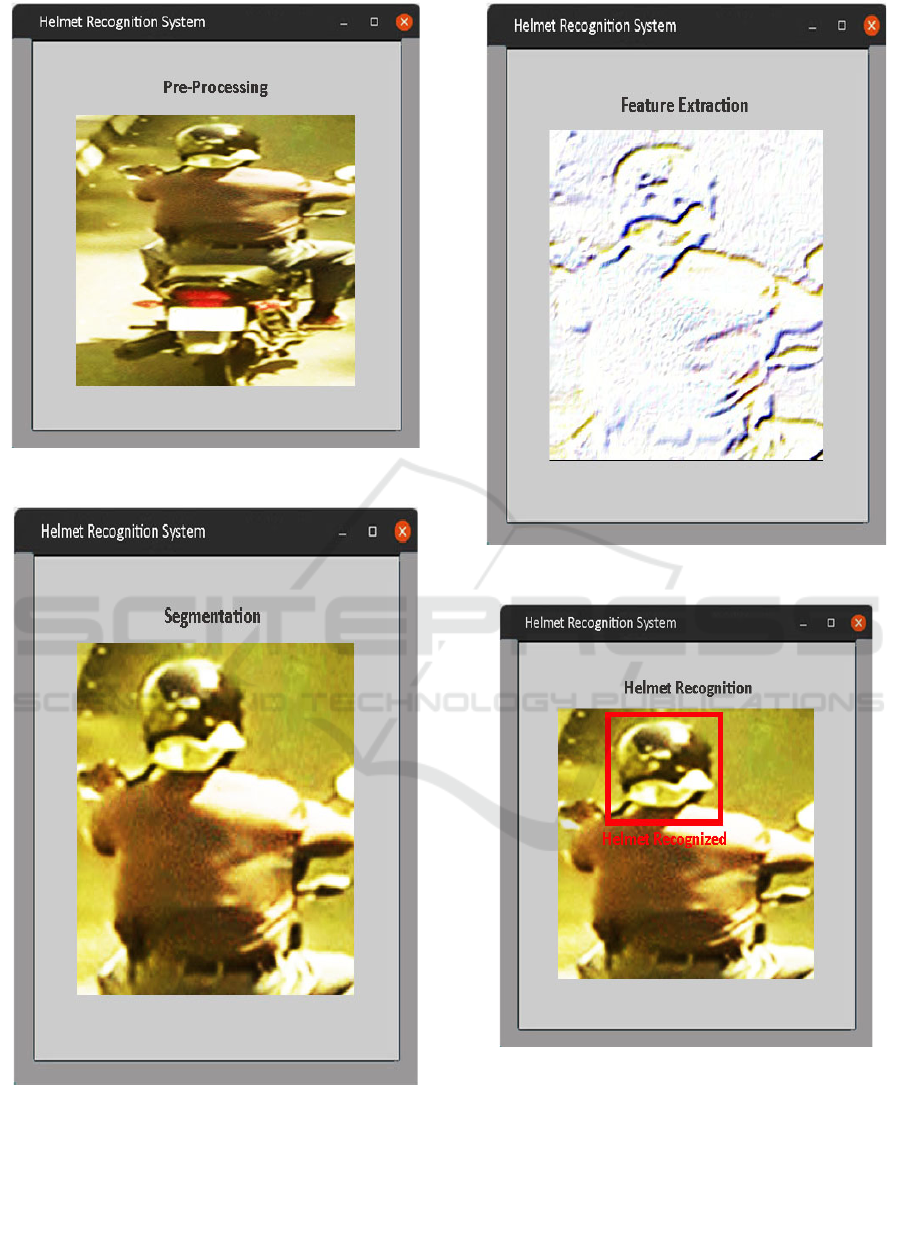

areas. A representation of the input image for the

proposed technique may be seen in the accompanying

figure, which is referred to as Figure 3. This image is

obtained from the video feed of traffic cameras.

Figure 3: Input image gathered from traffic cameras video

feed.

The consequences of the suggested method for

picture pre-processing and segmentation are depicted

in the accompanying figures, namely Figure 4 and

Figure 5.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

558

Figure 4: Image pre-processing.

Figure 5: Segmentation.

The outputs of the feature extraction and helmet

identification stages of the proposed technique are

depicted in the accompanying figures, namely Figure

6 and Figure 7.

Figure 6: Feature extraction.

Figure 7: Helmet recognition.

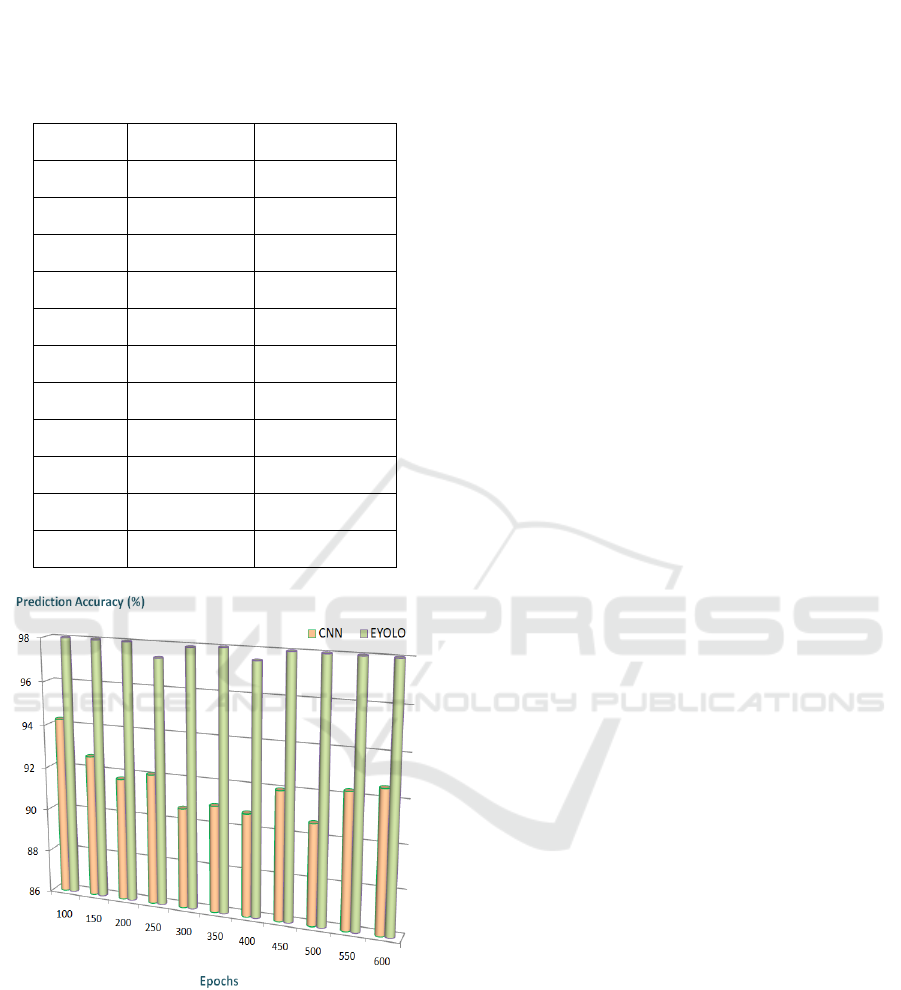

The prediction accuracy level analysis of the

proposed scheme, EYOLO, is depicted in the

accompanying figure, Figure 8. This analysis is

conducted by cross-validating the proposed model

with the traditional learning algorithm, CNN, in order

A Novel Methodology to Ensure Rider Safety Measures Based on Helmet Detection System Using Deep Learning Mechanism

559

to assess its prediction accuracy. Table 1 is a

descriptive representation of the aforementioned.

Table 1: Analysis of prediction accuracy between CNN and

EYOLO.

Epochs CNN (%) EYOLO (%)

100 94.25 98.83

150 92.64 98.58

200 91.72 98.49

250 92.08 97.37

300 90.67 97.92

350 90.96 98.09

400 90.78 97.53

450 91.99 98.34

500 90.69 98.52

550 92.27 98.84

600 92.56 98.84

Figure 8: Prediction accuracy.

5 CONCLUSIONS

In summary, the helmet detection system for two-

wheelers is a proactive measure that integrates real-

time monitoring capabilities and artificial intelligence

to enhance passenger safety. The system effectively

determines whether motorcyclists are wearing

helmets by analyzing live video transmissions,

thereby facilitating the enforcement of safety

regulations. The system obtains commendable

accuracy in detecting helmets across diverse real-

world scenarios through extensive testing, rigorous

model training, and meticulous database collection.

Consequently, it cultivates a culture of safety, thereby

reducing the likelihood of head injuries on two-

wheelers and making a substantial contribution to the

safety of roads and the overall well-being of

motorcyclists. In conclusion, the helmet detection

system is a critical technological solution in the field

of road safety, providing tangible advantages in the

areas of regulatory compliance and injury prevention.

Its significance in promoting safer riding practices

and decreasing the incidence of head injuries is

emphasized by its capacity to promptly identify non-

compliance and implement enforcement measures.

This system not only improves the safety of

individual motorcyclists but also contributes to the

overarching objective of establishing safer road

environments for all road users, thereby fostering a

culture of responsibility and well-being within the

community, by utilizing state-of-the-art AI

technologies.

This work can be improved in the future by

promoting safer cycling behaviors and encouraging

helmet usage by providing real-time alerts or

feedback to the rider. In addition to enhancing rider

safety by expanding the system to detect other safety

gear or objects of interest, such as reflective clothing

or road hazards, and by integrating the helmet

detection system with vehicle systems to enable

features such as automatic emergency braking or

adaptive cruise control based on the rider's safety

status.

REFERENCES

Bingyan Lin, "Safety Helmet Detection Based on Improved

YOLOv8", IEEE Access, 2024.

Chentao Shen, et al., "Small-scale helmet detection based

on improved YOLOv5 and moving object detection",

Proceedings of the 2023 ACM Symposium on Spatial

User Interaction, 2023.

Gopinath D, et al., "Detection of Helmet and License Plate

Using Machine Learning", International Journal of

Intelligent Systems and Applications in Engineering,

2024.

Hanhe Lin, et al., "Helmet Use Detection of Tracked

Motorcycles Using CNN-Based Multi-Task Learning",

IEEE Access, 2020.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

560

Lihong Wei, et al., "Research on helmet wearing detection

method based on deep learning", Scientific Reports,

2024.

M. Saravanan, et al., "Comprehensive study on the

development of an automatic helmet violator detection

system (AHVDS) using advanced machine learning

techniques", Computers and Electrical Engineering,

2024.

Maros Jakubec, et al., "Deep Learning-Based Automatic

Helmet Recognition for Two-Wheeled Road Safety",

Transportation Research Procedia, 2023.

Qing An, et al., "Research on Safety Helmet Detection

Algorithm Based on Improved YOLOv5s", Sensors,

2023.

Rupesh Chandrakant Jaiswal, et al., "Helmet Detection

Using Machine Learning", Journal of Emerging

Technologies and Innovative Research, 2022.

Sheela S Maharajpet, et al., "Advanced Safety Helmet

Detection: Enhancing Industrial Site Safety with AI",

QTanalytics Publication, 2024.

Songbo Chen, et al., "Detection of Safety Helmet Wearing

Based on Improved Faster R-CNN", International Joint

Conference on Neural Networks, 2020.

Wei Jia, et al., "Real-time automatic helmet detection of

motorcyclists in urban traffic using improved YOLOv5

detector", IET Image Processing, 2021.

Xuejun Jia, et al., "High-Precision and Lightweight Model

for Rapid Safety Helmet Detection", Sensors, 2024.

Yange Li, et al., "Deep Learning-Based Safety Helmet

Detection in Engineering Management Based on

Convolutional Neural Networks", Advances in Civil

Engineering, 2020.

Yongze Ji, et al., "Research on the Application of Helmet

Detection Based on YOLOv4", Journal of Computer

and Communications, 2022.

A Novel Methodology to Ensure Rider Safety Measures Based on Helmet Detection System Using Deep Learning Mechanism

561