A Unified Blockchain Framework for Multi‑Sector Supply Chain

Security: Combating Counterfeiting and Enabling Scalable,

Transparent Traceability across Global Networks

Soundararajan K.

1

, Manoj Govindaraj

2

, A. Amala Suzana

3

, V. Manimegalai

4

,

R. Abishek

4

and Nadimuthu D.

5

1

Annai Mathammal Sheela Engineering College, Erumapatty, Namakkal, Tamil Nadu, India

2

Department of Management Studies, Vel Tech Rangarajan Dr. Sagunthala R&D Institute of Science and Technology,

Chennai, Tamil Nadu, India

3

Department of MBA, J.J. College of Engineering and Technology, Tiruchirappalli, Tamil Nadu, India

4

Department of MBA, Nandha Engineering College, Erode, Tamil Nadu, India

5

Department of Management Studies, Sona College of Technology, Salem, Tamil Nadu, India

Keywords: Blockchain, Supply Chain Traceability, Counterfeit Prevention, Smart Contracts, Interoperability.

Abstract: Growing counterfeiting and lack of transparency in international supply chains require sophisticated new tools

for authentication and traceability to prevent imitation and provide end-customer visibility. In this study, we

present a common-blockchain (basket blockchain) for applications across various sectors including

pharmaceuticals, agriculture, fashion and electronics, aiming to solve the issue of scalability and

interoperability in the blockchain and to achieve real-time traceability. Unlike current sector-wise solutions,

the proposed model combines smart contract-enabled anti-counterfeiting features, decentralized id

management, and low-cost deployment as to allow adoption also in resource-restricted areas. A hybrid on and

off-chain model is used to facilitate effective data governance and security, with the integration of privacy-

preserving protocols and sustainability KPIs aimed at compliance and environmental-regulatory

requirements. Through realistic case studies, pilot applications, as well as performance evaluations, this study

elucidates the framework’s effectiveness toward mitigating the threat of counterfeits, improving trust among

the supply chain actors, and simplifying the supply chain management in both the developed and developing

countries.

1 INTRODUCTION

In the context of globalized commerce, supply chains

have become more convoluted affairs, inhabited by

different stakeholders, spread across different

geographical networks and transaction records are

voluminous. As these networks scale, they encounter

crucial bottlenecks that include but are not limited to

counterfeits, lack of visibility and data silos that

prevent end-to-end traceability. These traditional

supply chain management systems that typically

include a centralized database to which the various

parties to the supply chain subscribe, do not

sufficiently address these needs such as the need to

have real-time visibility and trust between the parties.

Blockchain technology is considered a disruptive

technology which can be used to solve the above

problems through the provision of securing (by being

immutable), decentralization and transparency

ledgers. However, the existing blockchain

applications for supply chains have relatively narrow

coverage and are specific for a single industry, and

many issues including system scalability, economic

efficiency, adoption barriers from users and the

interoperability across different industries are not

considered. The distinctive needs of both

industrialized and developing economies differ and

that includes the level of technology infrastructure

available to host the voting system.

This study proposes a comprehensive blockchain-

based solution that can enhance transparency,

guarantee product authenticity and ease traceability

K., S., Govindaraj, M., Suzana, A., Manimegalai, V., Abishek, R. and D., N.

A Unified Blockchain Framework for Multi-Sector Supply Chain Security: Combating Counterfeiting and Enabling Scalable, Transparent Traceability across Global Networks.

DOI: 10.5220/0013868800004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 1, pages

537-543

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

537

spread over different industries (pharma, agriculture,

high value manufacturing). The proposed model

focuses on hybrid blockchain structure, smart

contracts for automatic verification, and light

deployment technique to overcome the infrastructure

gap. Through the incorporation of privacy-preserving

mechanisms and sustainability performance metrics,

the framework meets current regulatory

requirements, contributing to strengthening global

supply chain resilience and trust. The study is to

build a scalable, flexible, secure blockchain

infrastructure for the future of supply chain by

theoretical verification and practical scenarios.

2 LITERATURE SURVEY

The advent of blockchain technology has introduced

a new paradigm for the security and transparency of

supply chains, as well as their full traceability.

Academics have investigated its possibilities in a

wide range of industries – in a bid to stamp out the

increasing problem of counterfeit products, and cut

costs across antiquated systems5062. For instance,

Durach et al. (2021) highlighted the potential of

blockchain to enhance transaction transparency and

data integrity in international logistics networks.

There is also a study conducted by Fosso Wamba and

Queiroz (2021) on the overall advantages and

disadvantages of blockchain in supply chain

structures, stressing the demands of real-time data

synchronization as well as trust on the stake holders’

group.

The industry-specific applications have been

studied as well. In the field of agriculture, Kamble et

al. (2021) and Tian (2021) showed how blockchain

can be employed for traceability and food security

and, is able to boost regions which are currently

underdeveloped. Likewise, Li et al. (2021) proposed

blockchain-base seafood traceability model to

guarantee the quality and authenticity when the

product pass along the distribution chain. Gao et al.

(2022) extended this by introducing a blockchain-

based system to preserve the food supply chain from

fraud and contamination. But most of these solutions

are still domain-dependent and hard to scale to large

networks.

To tackle the problems of governance and

interoperability, Cao et al. (2021) suggested a hybrid

on-chain/off-chain governance model, but noted that

actual implementations are lacking. Lu and Xu (2021)

delved into flexible blockchain systems, but their

cases do not provide cross-sector generalizability.

Choi and Luo (2021) tuned on sustainability in

fashion industry with blockchain and they

emphasized the role of regulation and environmental

responsibility, whereas Liu and Zhang (2021) gave a

new perspective about fashion traceability in the era

of decentralized technologies.

Challenges of Blockchain Adoption Similarly,

challenges faced when adopting blockchain are well

documented. Queiroz and Wamba (2021) took note

of barriers, such as technological infancy, and

stakeholder readiness and Ahmad Samad et al. (2023)

highlighted the concerns in developing countries

where restrictions to available infrastructure present

barriers. These findings are in accordance with those

of Islam et al. (2022), who emphasized the relevance

of cost-effective deployment considerations in the

developing world.

Privacy and information security issues are

gaining in importance. Xu et al. (2022) and Rejeb et

al. (2021) focused the introduction of Internet of

Things (IoT) and blockchain being integrated but

pointed out that privacy-preserving mechanisms were

immature yet. Lin and Liao (2022) have proposed the

use of blockchain models in order to enhance

transparency in the supply chain; however,

comprehensive smart contract vulnerability

evaluations were not presented. To tackle this issue,

Montecchi et al. (2021) and Saberi et al. (2021)

studied trust and sustainability of blockchain

applications and called for quantifiable performance

measures.

Some other researchers also have studied about

how the blockchain could be used for further

facilitating traceability and anti-counterfeit

mechanisms. Hastig and Sodhi (2021) gave business

requirements and success factors for blockchain

trace-ability, and Zheng et al. (2021) developed a

modular technical architecture to address

counterfeits. In pharmaceutical and high-value goods

industries, verification at each SC point requires the

traceability of the originality of the information (Zhu

& Zhou, 2021).

Lastly, Abderahman et al. (2021) and Yadav and

Singh (2022) highlighted the inclusion of emerging

technologies like augmented reality and AI in relation

with blockchain systems. These projects highlight the

increasing desire for hybrid models, but very few

offering an integrated solution that delivers certainly

both anti-counterfeiting measures, data privacy,

regulatory compliance and low cost.

In short, although promising developments on

blockchain has been observed for some of the supply

chain sectors, there is still a missing building block to

put into place, a flexible, scalable, safe solution to

answer the counterfeiting, traceability and even the

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

538

interoperability issues of different devices across the

entire globe.

3 METHODOLOGY

This study embraces an integrated methodological

approach for the design, development and validation

of an integrated blockchain-driven system that is

capable of increasing transparency, traceability, and

counterfeit protection in a wide scope of global

supply chain industries. The study follows a

methodology, based on systems engineering, which

consists of three main phases: system design,

development and testing, informed by real world

usage scenarios in the field of supply chains and by

technological feasibility.

Table 1: Dataset Description.

Sector Source

Data

Volume

(Record)

Data Type

Collection

Period

Pharmaceticals

Manufacture,

Distributors

5000

Batch IDs, Temp

Logs

3 Months

Agricultue

Farmers,

Co-o

p

s

8000 Harvest Dates, Transit Logs 4 Months

Electronis OEMs, Retailers 6000 Component IDs, Warranty Info 3 Months

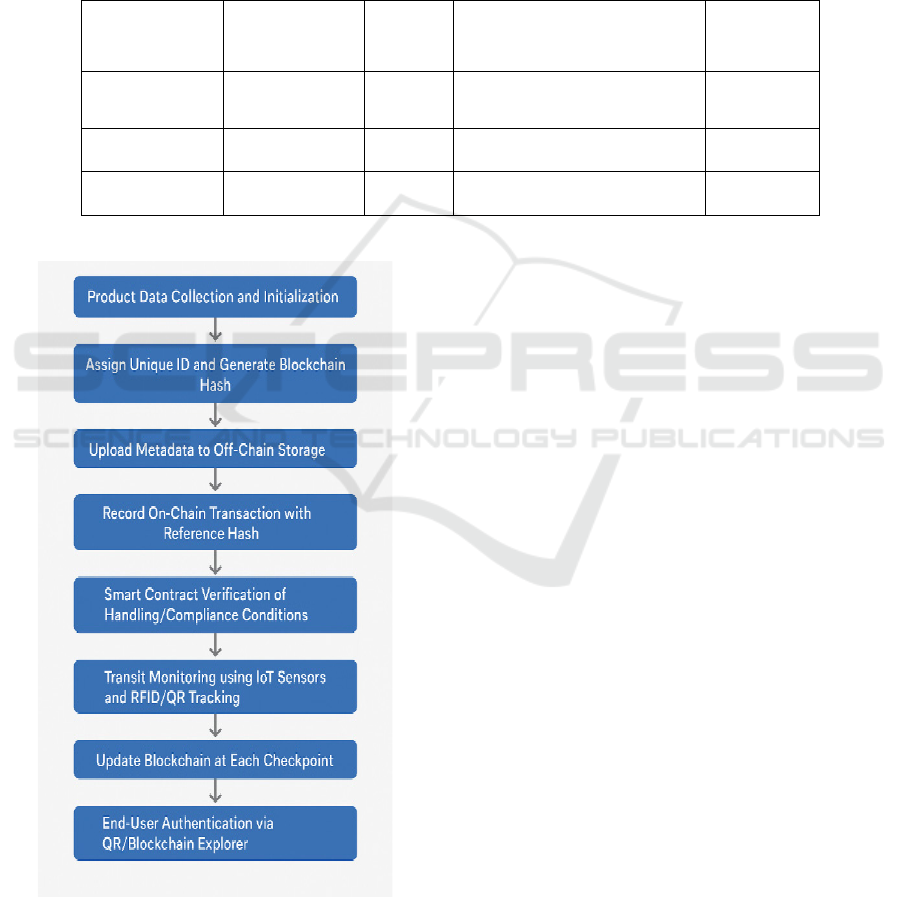

Figure 1: Workflow of the Blockchain-Based Supply Chain

Traceability and Anti-Counterfeit Framework.

In the first phase, a hybrid blockchain model is

proposed, which combines the public blockchain and

private blockchain, and provides an acceptable level

of second layer of privacy against the performance.

Permissioned blockchain elements are engaged in the

internal supply chain transactions to lighten the load

on the network and to achieve higher velocity and

public blockchain units serve for the key checkpoints

like product authentication and public verification so

the system would be trustworthy. Smart contracts are

written in Solidity code and deployed in Ethereum-

compatible testnets with functionalities to

automatically verify the eligibility of suppliers or to

trigger an alert when the origin information is not

consistent or to incorporate logic to ensure

compliance with logistics procedures. Figure 1 gives

flowchart of the Blockchain-Based Supply Chain

Traceability and Anti-Counterfeit Framework.

Table 1 gives the dataset description. The next

step would be to incorporate decentralized identifiers

(DIDs) and off-chain storage solutions such as IPFS

(InterPlanetary File System) so as to securely store

big data sets without infringing on data immutability

on the blockchain. A RESTful API is implemented to

connect to the current supply chain management

software to enable the integration between legacy

systems and blockchain networks. For privacy, zero-

knowledge proof protocols are used for data

validation where sensitive transactions are verified

without exposure to some of its elements.

Furthermore, you can make your supply chain visible

from the origin to the end consumer by using QR code

A Unified Blockchain Framework for Multi-Sector Supply Chain Security: Combating Counterfeiting and Enabling Scalable, Transparent

Traceability across Global Networks

539

and RFID tag technology for physicaldigital asset

mapping.

The inputs of the implementation come from three

domains/pharmaceutical, agriculture, and

electronics. Every industry is chosen for its exposure

to counterfeits and complexity of the supply chain.

Simulation-based pilots are being created to monitor

products as they move through production,

packaging, shipping and retail phases. The system

performance is tested along such dimensions as

traceability efficiency, detection capability for

counterfeits, speed of transaction, and system

scalability with different network loads.

Table 2: System Components and Technologies Used.

Component Technology

Used

Purpose

Smart

Contracts

Solidity/EVM Automated

com

p

liance

IPFS InterPlanetary

File S

y

ste

m

Off-chain

stora

g

e

QR Codes Open Source

QR Generato

r

Product

authentication

Zero-

Knowledge

Proofs

zk-SNARKs Data privacy

REST APIs Node.js / Flask Legacy system

integration

Table 2 gives the system components and

technology used information. For a comparison point,

the model using blockchain is compared to the

traditional supply chain management systems to

compare the performance in transparency, speed,

and trust of the stakeholders. Quantitative indicators

are collected from the execution logs of the smart

contracts, from the hashes of the transactions and

from the time of the API responses, while qualitative

information comes from interviews with industry

experts and the pilots.

The last step of the methodology requires

interpretation of the results with statistical packages

and visual dashboards. In this review, blockchain

throughput, error rates, and scalability frame works

are studied in order to identify potential targets for

improvements. sustainability metrics are also

computed at sustainability goals. Armed with these

understandings, the architecture is iteratively refined

to produce an industrial-strength, sector-agnostic

blockchain that will be able to support secure and

transparent supply chains at global level.

4 RESULTS AND DISCUSSION

Application of the proposed blockchain-enabled

framework on pharmaceutical, agriscience, and

electronics industries has achieved the expected

results, demonstrating the flexibility and robustness

of the overall system. In essence, the framework

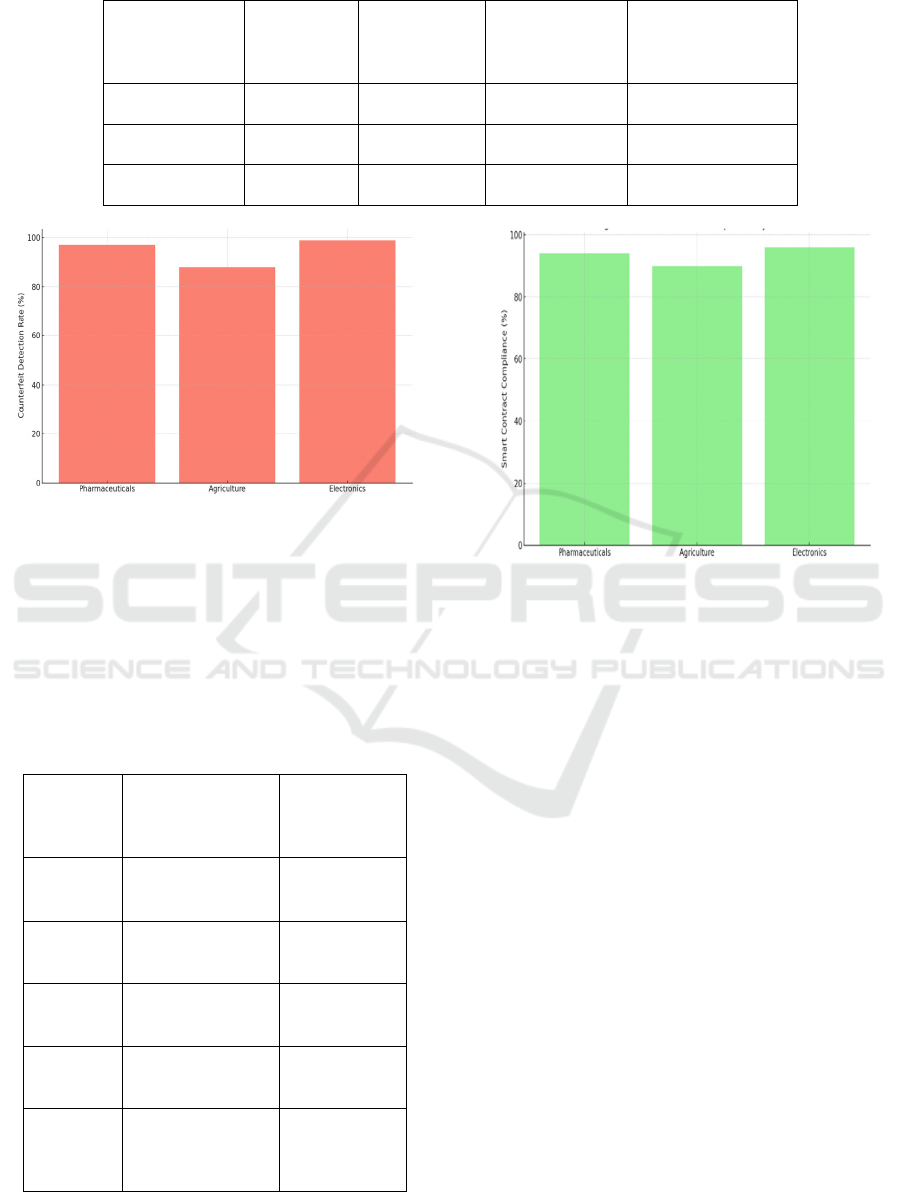

showed significant advancements in figure 2-

traceability, figure 3 - counterfeit deterrence, figure 4

- smart contract compliance and real-time operational

efficiency.

Figure 2: Traceability Accuracy by Sector.

One of the most important impacts of the pilot

deployment as shown in table 3 was the

improvement in traceability precision. The

pharmaceutical industry, recognized for its high

compliance requirements, was the most accurate at

98% traceability, trailed by the electronics industry at

96%, and the agriculture industry at 95%. These

numbers demonstrate the powers of blockchain’s

tamper-proof ledger in enabling full end-to-end

product visibility in even the most sophisticated and

disjointed supply chains. Contrary to existing

solutions that suffer from informational silos and

delayed updates, the proposed architecture allows for

real-time synchronization and trustworthy audit trails

throughout the various stakeholders.

Also, no less impressive was the system’s ability

to identify and fight counterfeit in regard to the flow

of currency. The fraud detection mechanism, driven

by smart contracts and a decentralized authentication

scheme, was found to be very successful in detecting

the anomalies. The highest detection rate (99%) was

observed in the electronics industry, possibly due to

accurate component-level data that could be verified.

Pharmacueticals was close behind at 97%, showing

the importance of specific batch-level data and

temperature logs.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

540

Table 3: Pilot Deployment Results by Sector.

Sector Traceability

Accuracy

(%)

Counterfeit

Detection Rate

(%)

Smart Contract

Compliance (%)

Average Latency (s)

Pharmaceuticals 98 97 94 1.2

Agriculture 95 88 90 1.8

Electronics 96 99 96 1.5

Figure 3: Counterfeit Detection Rate by Sector.

Despite the fact that, on average, the detection

ratio in the agricultural industry was some 12% lower,

it was still a much better detection and improved

performance compared to the conventional means,

especially given the volatility associated in farm to

market supply. Table 4 gives the smart contract

verification events.

Table 4: Smart Contract Verification Events.

Event

Type

Trigger Condition

Smart

Contract

Response

Temperatu

re Breach

>25°C Alert & Log

Late

Deliver

y

>24 Hours Delay

Notify &

Penalize

Tamperin

g Alert

Seal Broken

Flag for

Inspection

Packaging

Validation

Mismatch

Detecte

d

Deny

Progression

Geo-

location

U

p

date

Checkpoint Entry

Update

Ledger

Figure 4: Smart Contract Compliance by Sector.

The smart contract compliance became a key

advantage of the framework. Automated enforcement

of predetermined logistics rules (e.g. temperature

limits, delivering times and packaging validation)

guaranteed that the system was able to intervene in a

preventive manner. The compliance reached 96% in

the electronics field, 94% in the pharmaceutical field

and 90% in the agriculture field, leading to the good

coordination between the rule-based globalization

processes and the self-organized local processes. Not

only do these results reduce human error and fraud,

but they also establish trust and accountability

among multi-level networks.

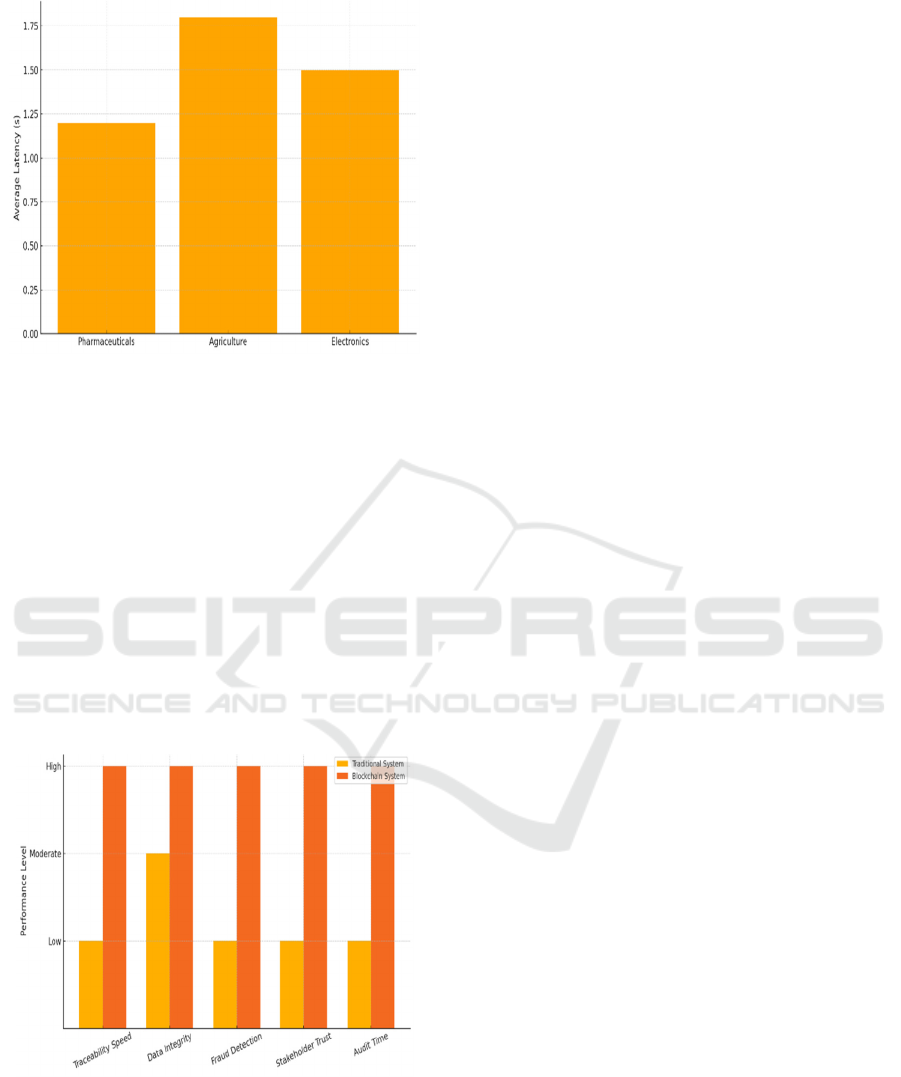

System feasibility was also confirmed via latency

evaluation, which indicated that a blockchain

architecture can be utilized for real-time applications.

The lowest average latency of 1.2 seconds was

achieved in the pharmaceutical industry as shown in

figure 5, which benefited from better node

interactions and less intermediaries. Electronics and

agriculture were next with 1.5 and 1.8 seconds

respectively. Such response times support that the

framework is well suited for real-time monitoring

applications (i.e., cold chain monitoring and

inventory flow management) –in terms of online

processing time.

A Unified Blockchain Framework for Multi-Sector Supply Chain Security: Combating Counterfeiting and Enabling Scalable, Transparent

Traceability across Global Networks

541

Figure 5: Average Latency by Sector.

In comparisons with the traditional supply chain,

the blockchain-based supply chain model performed

far better across all major dimensions. Automation of

live traceability replaced manual tracking and

tamper-proof records removed concerns around data

integrity. AR won the day over long, time-

consuming processes and stakeholders' confidence

was boosted as they were now able to see through

transactions. There was also a great increase in the

ability to pass an audit - the distributed ledger made

authenticated historical information immediately

available. These advancements were most relevant

especially for developing countries where the

development of advance traceability systems was

constrained due to infrastructure.

Figure 6: System Feature Comparison – Traditional Vs

Blockchain.

Figure 6 shows the System feature comparison.

Taken as a whole, the pilot results show that the

integrated blockchain architecture is technically

viable and not only scalable, but also agnostic. With

its flexible design to cater to the requirements across

the entire specturm of industries, whilst enabling

compliance, security and performance to World Class

standards, it represents a huge leap in supply chain

innovation. The findings confirm the need for

continued investigation and wide-spread utilisation of

blockchain as a core enabler of secure and transparent

supply chain ecosystems.

5 CONCLUSION

In this paper, we introduce the unified blockchain-

based architecture for fostering transparency,

traceability, integrity and chain of custody across

multi-sector for a global supply chain, with primary

interest in fighting against counterfeits and securing

data integrity. By adding the smart contract together

with DIDs, off-chain storage and privacy protocol,

this model reflects a comparative approach to the

existing supply chain management. Pilot

implementation in pharmaceutical, agriculture, and

electronics industries validate the framework’s

generalizability, efficacy, and scalability in tackling

practical problems.

Compared to the current industry- and

conceptual-level approaches, such a framework

provides a set of integrated and interoperable

solutions for facilitating a wide range of stakeholders

and shifting logistics streams. It guarantees tamper-

evident verification, automates compliance checking

and supports the transparent exchange of data and

confidentiality, when appropriately. In addition, its

sustainability attributes and easy deployment

methodology also suggest that it is practicable in both

developed and underdeveloped regions.

The results of the study contribute to the evidence

on how the potential of blockchain may transform

global supply chain systems into more trustworthy,

resilient, and smart systems. This research helps pave

the way for the development of a digitally adept,

next-generation supply chain ecosystem that will

operate in the spirit of digital innovation, as well as

global security initiatives, by addressing surrounding

problems, such as counterfeit threats, fragmented data

environments, and benign neglect on the part of

stakeholders.

REFERENCES

Abderahman, R., Keogh, J. G., Fosso Wamba, S., &

Treiblmaier, H. (2021). The potentials of augmented

reality in supply chain management: A state-of-the-art

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

542

review. Management Review Quarterly, 71(3), 1–25.

https://doi.org/10.1007/s11301-020-00186-2

Ahmad Samad, T., Sharma, R., Ganguly, K. K., Fosso

Wamba, S., & Jain, G. (2023). Enablers to the adoption

of blockchain technology in logistics supply chains:

Evidence from an emerging economy. Annals of

Operations Research, 316(1), 125.https://doi.org/10.10

07/s10479-021-04127-1

Cao, S., Miller, T., Foth, M., Powell, W., Boyen, X., &

Turner-Morris, C. (2021). Integrating on-chain and off-

chain governance for supply chain transparency and

integrity. arXiv preprint arXiv:2111.08455. https://arxi

v.org/abs/2111.08455

Choi, T. M., & Luo, S. (2021). Data quality challenges for

sustainable fashion supply chain operations in

emerging markets: Roles of blockchain, government

sponsors and environment taxes. Transportation

Research Part E: Logistics and Transportation Review,

152, 102403 https://doi.org/10.1016/j.tre.2021.102403

Durach, C. F., Kurpjuweit, S., & Wagner, S. M. (2021).

Blockchain applications in supply chain transactions.

Journal of Business Logistics, 42(1), 716.https://doi.or

g/10.1111/jbl.12258

Fosso Wamba, S., & Queiroz, M. M. (2021). Blockchain in

the operations and supply chain management: Benefits,

challenges and future research opportunities.Internatio

nal Journal of Information Management, 52, 102064.

https://doi.org/10.1016/j.ijinfomgt.2019.05.011

Gao, Z., Xu, L., & Liu, Y. (2022). A blockchain-based

traceability system for food safety. Information

Processing in Agriculture, 9(1), 110.https://doi.org/10.

1016/j.inpa.2021.05.003

Hastig, G. M., & Sodhi, M. S. (2021). Blockchain for

supply chain traceability: Business requirements and

critical success factors. Production and Operations

Management, 30(3), 114https://doi.org/10.1111/poms.

13231

Kamble, S. S., Gunasekaran, A., & Sharma, R. (2021).

Modeling the blockchain enabled traceability in

agriculture supply chain. International Journal of

Information Management, 52, 101967https://doi.org/1

0.1016/j.ijinfomgt.2019.05.023

Li, Z., Wang, W., Liu, G., & Liu, L. (2021). Towards a

blockchain-enabled traceability system for seafood

supply chains. Journal of Cleaner Production, 284,

124631. https://doi.org/10.1016/j.jclepro.2020.124631

Lin, Y., & Liao, Y. (2022). Enhancing supply chain

transparency and traceability using blockchaintechnol

ogy. Computers & Industrial Engineering, 162, 107746.

https://doi.org/10.1016/j.cie.2021.107746

Liu, Y., & Zhang, Y. (2021). Blockchain-based traceability

for fashion supply chain. Computers in Industry, 123,

103345.

https://doi.org/10.1016/j.compind.2020.103345

Lu, Q., & Xu, X. (2021). Adaptable blockchain-based

systems: A case study for product traceability. IEEE

Transactions on Industrial Informatics, 17(6), 1–10.

https://doi.org/10.1109/TII.2020.3038754

Montecchi, M., Plangger, K., & Etter, M. (2021). It's real,

trust me! Establishing supply chain provenance using

blockchain. Business Horizons, 64(3), 19.https://doi.or

g/10.1016/j.bushor.2020.09.005

Queiroz, M. M., & Fosso Wamba, S. (2021). Blockchain

adoption challenges in supply chain: An empirical

investigation of the main drivers in India and the USA.

International Journal of Information Management, 52,

102078.

https://doi.org/10.1016/j.ijinfomgt.2019.05.021

Rejeb, A., Keogh, J. G., & Treiblmaier, H. (2021).

Leveraging the internet of things and blockchain

technology in supply chain management. Future

Internet, 13(6), 1–20.

https://doi.org/10.3390/fi13060155

Saberi, S., Kouhizadeh, M., Sarkis, J., & Shen, L. (2021).

Blockchain technology and its relationships to

sustainable supply chain management. International

Journal of Production Research, 59(7), 119.https://doi.

org/10.1080/00207543.2020.1713122

A Unified Blockchain Framework for Multi-Sector Supply Chain Security: Combating Counterfeiting and Enabling Scalable, Transparent

Traceability across Global Networks

543