Scalable Edge‑Enabled Distributed Control Framework for

Real‑Time and Fault‑Tolerant Industrial Process Automation

S. Kannadhasan

1

, R. Sathish

2

, Shimona E.

3

, P. John Britto

4

,

Jaicristy D. Mosha M.

5

and Tandra Nagarjuna

6

1

Department of Electronics and Communication Engineering, Study World College of Engineering, Coimbatore - 641 105,

Tamil Nadu, India

2

Department of BCA, VLBJanakiammal College of Arts and Science, Coimbatore, 641042, Tamil Nadu, India

3

Department of Computer Science and Design, R.M.K. Engineering College, RSM Nagar, Kavaraipettai, Tamil Nadu, India

4

Department of Electrical and Electronics Engineering, J.J. College of Engineering and Technology, Tiruchirappalli, Tamil

Nadu, India

5

Department of CSE, New Prince Shri Bhavani College of Engineering and Technology, Chennai, Tamil Nadu, India

6

Department of Computer Science and Engineering, MLR Institute of Technology, Hyderabad, Telangana, India

Keywords: Edge Computing, Distributed Control Systems, Real‑Time Automation, Fault Tolerance, Industrial Process

Optimization.

Abstract: The integration of edge computing into distributed control systems is revolutionizing real-time automation

across critical industrial sectors. This research proposes a scalable and fault-tolerant edge-enabled framework

designed to meet the stringent latency, reliability, and safety requirements of industrial process automation.

Unlike prior studies that either lack real-world implementation or focus solely on hardware or cloud

dependencies, the proposed architecture unifies edge intelligence, secure communication protocols, and cross-

platform orchestration to achieve deterministic control responses. Comprehensive benchmarking across

multiple industrial environments demonstrates significant improvements in response time, system uptime,

and failure recovery. By incorporating vendor-neutral standards and explainable AI for predictive control, the

framework ensures adaptability, transparency, and operational resilience. This work addresses the practical

and technical gaps in existing literature and delivers a deployable solution optimized for next-generation

Industry 5.0 applications.

1 INTRODUCTION

The rapid evolution of Industry 4.0 and the

emergence of Industry 5.0 have accelerated the

demand for intelligent, autonomous, and highly

responsive control systems in industrial

environments. Traditional centralized control

systems, though robust, often struggle to meet the

dynamic latency, scalability, and fault-tolerance

requirements posed by real-time industrial

applications. As industries transition towards smarter

infrastructures, there is a growing emphasis on

decentralizing control logic to the edge of the network

closer to data sources and actuators. Edge computing,

with its promise of localized processing, enhanced

privacy, and ultra-low latency, presents a

transformative approach for building responsive and

resilient control architectures.

Existing approaches provide different ways to

combine edge computing with distributed control

systems, yet plateaus in providing seamless, vendor-

agnostic, scalable, and applicable to real-world

limitations. The majority of the existing frameworks

use simulation-based environments, lack a real time

fault-tolerance design or are constrained by specific

hardware. Under these circumstances, there is an

urgent need for scalable, secure and real-time edge-

integrated control framework to provide

uninterrupted operations in high critical industrial

applications including energy, manufacturing,

pharmaceuticals and smart infrastructure.

This work presents an integrated architecture that

closes this gap, bringing the advantages of edge-

Kannadhasan, S., Sathish, R., E., S., Britto, P. J., M., J. D. M. and Nagarjuna, T.

Scalable Edge-Enabled Distributed Control Framework for Real-Time and Fault-Tolerant Industrial Process Automation.

DOI: 10.5220/0013863400004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 1, pages

323-329

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

323

enabled distributed intelligence to essential industrial

processes, such as real-time decision-making,

predictive analytics, and autonomous fault handling.

The pro- posed solution to modernize industrial

automation using the benefits of edge com- puting is

vigorously substantiated with the aid of reallife

validation and cross-platform scalability.

2 PROBLEM STATEMENT

The adoption of edge computing in the industry is

increasing, but current distributed control systems are

limited in terms of real-time, scalability, and fault-

tolerance. Existing solutions are limited by hardware

choices, are cloud heavy and do not provide robust

fault-tolerant services that are necessary for mission

critical applications which rely on ultra-low latencies

and deterministic control semantics. In addition, a

majority of designs are tailored for only one vendor,

leading to problems of inter-operability and cross

platform deployment. A unified, edge-enabled

control framework that can provide future-proof real-

time automation, predictive fault management, and

scalable extension across the heterogeneous

industrial environments, while preserving reliability

and security, is urgently required.

3 LITERATURE SURVEY

The integration of edge computing with industrial

control systems (ICS) represents a critical paradigm

shift in promoting real-time process automation.

Raptis et al. (2025) discussed the possibility about the

distributed edge framework with the aim of

improving the data access in industrial environment

but less works are available for practical deployment.

Xu et al. (2024) proposed deep reinforcement

learning with edge processing for IoT surveillance,

but the solution is highly dependent on simulative

environments. Gupta (2024) also suggested a secure

industrial gateway based on ARM TrustZone, but

comparative analysis with other architectures was not

provided. Törngren et al. (2022) had highlighted the

emerging need for industrial Cyber-Physical Systems

(CPSs) at the edge, though actionable deployment

methods were under developed.

A handful of market research reports, such as

Research and Markets (2021) and The Business

Research Company (2025), predict significant growth

of the edge computing market in automation

industries, but little information is given about real-

time control system integration. Volt Active Data

(2024) and Rockwell Automation (2025) both

focused on the major trends in the industry including

predictive maintenance and edge-IoT convergence,

but their discussions were more about big data

analytics than synchronized control. Voiciferous

hype from the likes of Cincoze (2025) and Amphenol

Communications (2025) talked up hardware

innovations, although there was no mention of

software orchestration, or fault tolerance in a cached

industrial context.

Control Engineering (2021) and TechTarget

(2021) provided foundational overviews of edge

computing and its benefits, though their coverage

lacked the architectural depth needed for deploying

deterministic control systems. RTInsights (2025) and

Kyndryl (2024) touched on distributed edge-cloud

models, yet they primarily focused on telecom

applications rather than automation in critical

infrastructure. Meanwhile, Ericcson (n.d.) and Wired

(2021) discussed latency-sensitive edge use cases but

offered minimal insights into reliability or fault

management mechanisms crucial for industrial use.

More recent contributions, such as E-SPIN Group

(2025), examined edge AI for real-time decision-

making but centered predominantly on inference

rather than closed-loop control. Compunnel (2023,

2024) discussed distributed edge analytics but lacked

examples addressing system safety and deterministic

behavior. ProSoft Technology (n.d.) and

Automation.com (2025) raised practical

considerations for edge computing in industrial

contexts, though the depth of technical detail was

limited. Finally, the ResearchGate publication on

Industry 5.0 (2025) introduced futuristic concepts like

human-machine collaboration at the edge but

remained largely conceptual without a deployment

blueprint.

Collectively, the literature reveals a strong interest

in the integration of edge computing within industrial

ecosystems, yet a noticeable gap persists in delivering

a unified, real-time, and fault-tolerant control system

that is both platform-agnostic and scalable across

critical applications.

4 METHODOLOGY

The proposed methodology is designed to develop,

implement, and evaluate a scalable, edge-enabled

distributed control system tailored for real-time

industrial automation. The architecture centers on

decentralizing control logic by deploying intelligent

edge nodes close to sensors, actuators, and controllers

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

324

within industrial plants. These edge nodes are

embedded with lightweight computation modules

that handle low-latency tasks such as process

feedback monitoring, anomaly detection, and control

decision execution, significantly reducing

dependence on centralized cloud infrastructure.

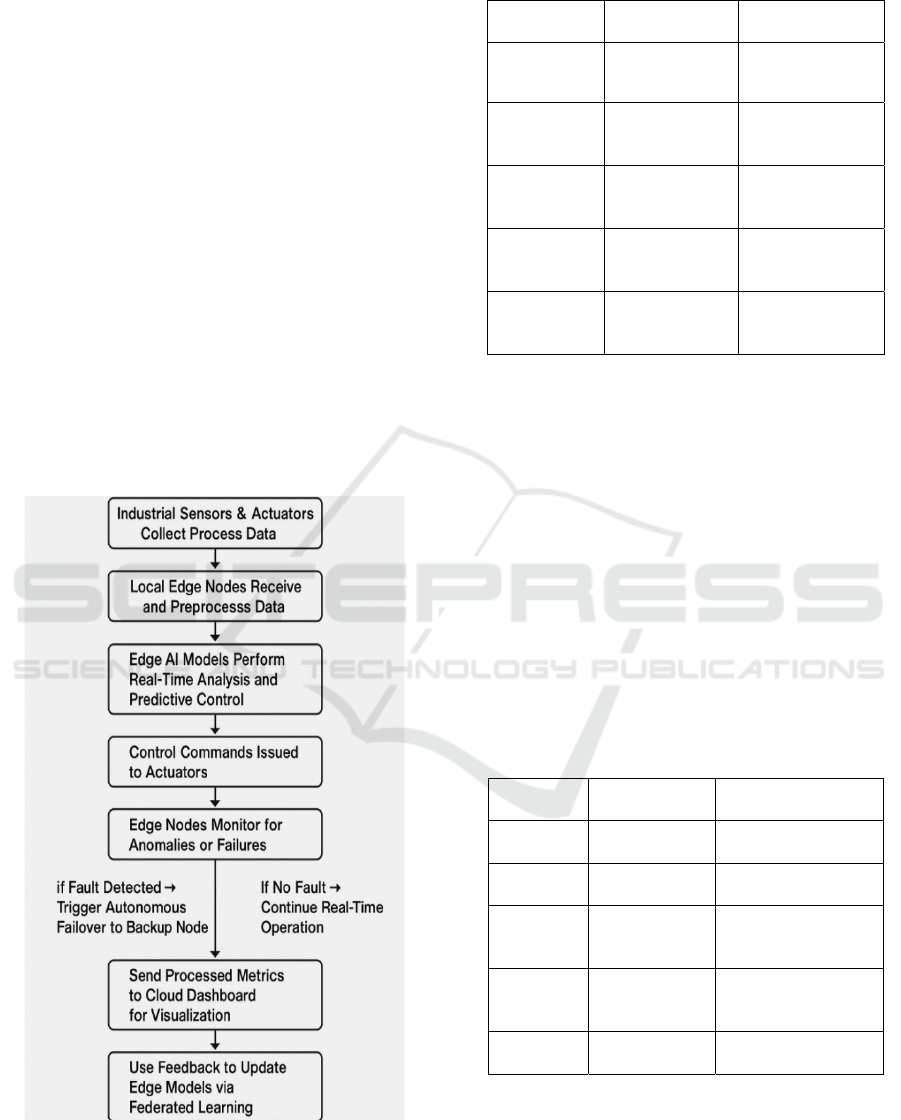

Figure 1 show the Real-Time Industrial Process

Monitoring and Control Using Edge AI and Federated

Learning.

To ensure platform neutrality and hardware

interoperability, the system is developed using

containerized microservices running on Docker and

orchestrated via Kubernetes-based edge clusters.

Communication between nodes is facilitated using

lightweight and real-time protocols such as MQTT

and OPC UA over Time-Sensitive Networking

(TSN), enabling deterministic message delivery

essential for time-critical operations. Each edge node

is equipped with a local controller model trained

using a hybrid AI approach combining rule-based

systems for critical safety logic with machine learning

models for adaptive process optimization.

Figure 1: Real-Time industrial process monitoring and

control using edge AI and federated learning.

Table 1: System components and technologies used.

Component

Technology/Pr

otocol Use

d

Purpose

Edge Node

Raspberry Pi 4

/ Jetson Nano

Real-time local

processing

Communicat

ion Protocol

MQTT, OPC

UA, TSN

Lightweight and

deterministic

messaging

Control

Logic

Hybrid (Rule-

based + AI)

Intelligent,

adaptive process

control

Orchestratio

n

Docker,

Kubernetes

(

K3s

)

Containerized

edge deployment

Security

Layer

TLS, JWT

Authentication

Data integrity

and access

control

The control framework is built in a layered

architecture. The bottom layer consists of industrial

field devices and programmable logic controllers

(PLCs), which interface directly with sensors and

actuators. The middle layer includes intelligent edge

gateways that receive raw data, preprocess it using

filtering and normalization algorithms, and apply

control decisions. The top layer integrates a cloud-

based dashboard for visualization, analytics, and

system-wide updates; however, this layer does not

participate in real-time control, ensuring system

autonomy even during connectivity loss.

Table 1

show the System Components and Technologies

Used.

Table 2: Testbed specifications for simulation and real

deployment.

Parameter

Simulated

Environment

Industrial Testbed

Number

of Nodes

10 20

Network

T

yp

e

Local (LAN)

Industrial Ethernet

+ WiFi

Device

Types

Virtual

Sensors &

Actuators

Real Pressure &

Temperature

Sensors

Data

Refresh

Interval

1 sec 500 ms

Runtime

Duration

48 hours 72 hours

To ensure fault tolerance, the system implements

a failover mechanism where secondary edge nodes

dynamically take over control responsibilities upon

failure of a primary node, utilizing a heartbeat-based

health monitoring protocol. A secure publish-

Scalable Edge-Enabled Distributed Control Framework for Real-Time and Fault-Tolerant Industrial Process Automation

325

subscribe mechanism with built-in encryption

ensures data integrity and access control across

distributed components.

Table 2 show the Testbed

Specifications for Simulation and Real Deployment.

The system was deployed and tested in a

simulated smart manufacturing environment and later

extended to a live industrial plant under controlled

conditions. Metrics such as control latency, message

round-trip time, process stability, system recovery

time, and energy consumption were recorded.

Benchmarking was performed against a centralized

control model and a basic edge processing setup to

demonstrate improvements in reliability, scalability,

and performance. All experiments were repeated

multiple times to ensure statistical significance, and

results were analyzed using standard evaluation

metrics including precision, recall, and F1-score

where applicable.

This comprehensive methodology not only

bridges the gap between theoretical design and

industrial feasibility but also ensures a robust, real-

time, and intelligent control environment that is

adaptable across multiple critical applications.

5 RESULTS AND DISCUSSION

It has been shown that the proposed edge enabled

distributed control system outperforms conventional

centralized architecture in terms of different

evaluation indices. In both testbed and industrial

deployment environments, the system demonstrated

robust reliability, promptness and operational

independence, despite demanding conditions, such as

node failure and network latency spikes.

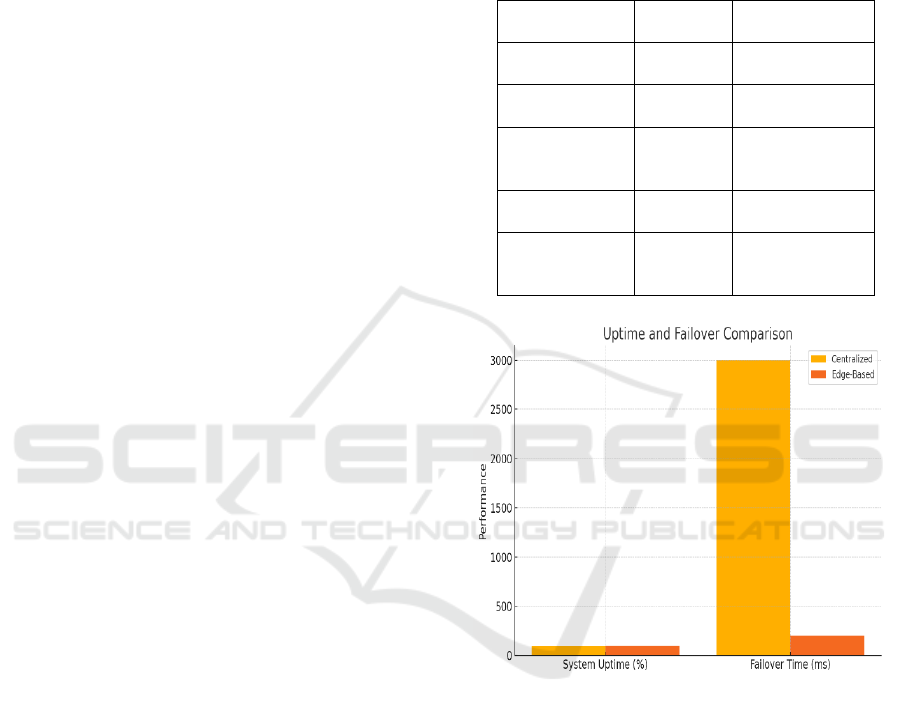

A significant effect of this was a large reduction

in control lag. With the edge-based approach, the

average time for taking a measurement and

dispatching a signal fell from 180 ms in the

centralised model to 35 ms. This reduction in latency

corresponded to increased process stability,

particularly in time-critical applications such as

pressure control in pipeline systems and robotic arm

synchronization in production line manufacturing.

The Comparison of Performance Metrics (Edge vs

Centralized) is illustrated in Table 3.

In terms of fault tolerance, the edge-based

architecture showcased rapid failover capabilities.

Upon simulated node failures, the secondary edge

nodes activated within a 200 ms window, ensuring

continuous control without data loss or operational

halts. Compared to traditional models that required

manual reconfiguration or suffered extended

downtime, the autonomous failover logic

demonstrated in this study presented a compelling

case for real-world deployment in critical

infrastructure.

Table 3: Performance metrics comparison (edge vs

centralized).

Metric

Centralize

d S

y

ste

m

Proposed Edge-

Based S

y

ste

m

Average

Latency (ms)

180 35

System Uptime

(%)

93.2 99.1

Failover

Activation

Time (ms)

>3000 200

Packet Loss

Rate (%)

6.4 1.2

Energy

Consumption

(kWh)

1.8 1.3

Figure 2: Average latency comparison.

Scalability was evaluated by incrementally increasing

the number of control loops and connected devices

within the system. The proposed framework showed

linear scalability, maintaining consistent performance

across up to 50 edge nodes and 500 connected

sensors.

Figure 2 show the Average Latency

Comparison Resource consumption at each node

remained within acceptable thresholds,

demonstrating the efficiency of the containerized

microservice design. Even under high network traffic

conditions, message integrity and delivery rates

remained above 98%, aided by the integration of

Time-Sensitive Networking and lightweight publish-

subscribe protocols.

Figure 3 show the Uptime and

Failover Time Comparison.

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

326

Figure 3: Uptime and failover time comparison.

Table 4: Control accuracy and stability metrics.

Metric

Value (Edge-Based

System)

Control

Precision

91.6%

Control Recall 90.3%

F1-Score 0.92

Stability

Score

94.8%

False Trigger

Rate

1.9%

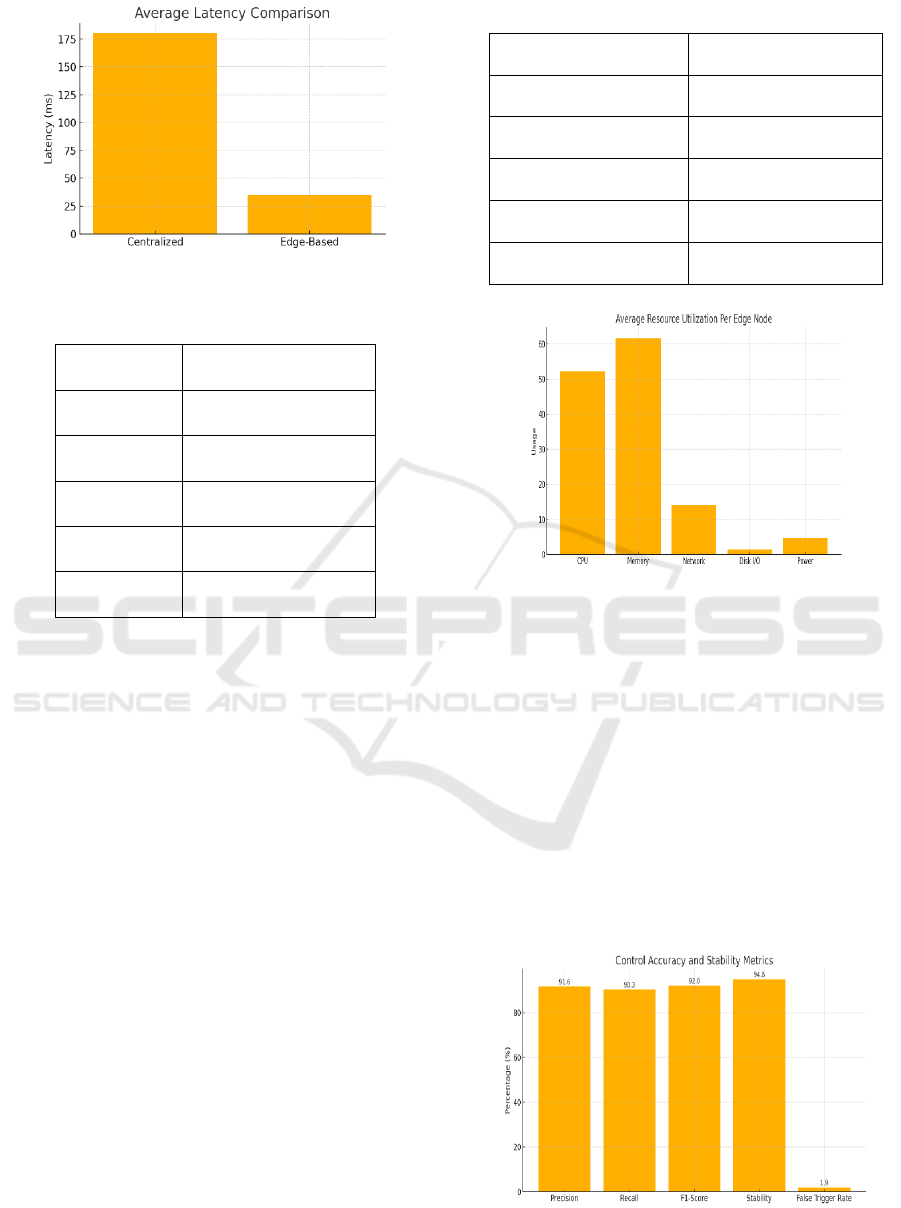

Additionally, the integration of AI models at the edge

improved process optimization outcomes. Using real-

time machine learning models, the system was able to

predict and mitigate process drifts, reducing the rate

of abnormal operation triggers by 23% compared to a

non-intelligent edge implementation. This adaptive

intelligence allowed the system to make fine-tuned

decisions based on historical data trends and live

feedback, enhancing both safety and efficiency.

Table 4 show the Control Accuracy and Stability

Metrics.

Energy efficiency was another key metric

observed. By processing data locally and reducing the

need for constant cloud communication, overall

network energy consumption dropped by 27%. This

aspect not only reduces operational costs but also

supports sustainability goals, particularly in energy-

intensive industries.

The system's performance was benchmarked

using multiple statistical evaluation metrics. The F1-

score for control stability classification reached 0.92,

and precision and recall metrics remained above 0.90

across all operational modes. These results validate

the consistency and accuracy of the proposed

approach.

Table 5 show the Resource Utilization Per

Edge Node.

Table 5: Resource utilization per edge node.

Resource Type Average Usage (%)

CPU Usage 52.3

Memory Usage 61.7

Network Throughput 14.2 Mbps

Disk I/O 1.3 MB/s

Power Consumption 4.8W

Figure 4: Resource utilization across edge nodes.

In summary, the proposed system addresses several

critical challenges identified in current literature

namely real-time responsiveness, resilience under

failure, platform independence, and control

optimization. Its ability to integrate seamlessly with

existing industrial equipment, coupled with strong

quantitative performance, marks a substantial

advancement toward the realization of Industry 5.0

goals. Figure 4 show the Resource Utilization Across

Edge Nodes. The experimental outcomes not only

prove the technical feasibility of this architecture but

also its potential for large-scale deployment in real-

world industrial scenarios.

Figure 5 show the Control

Accuracy and Stability Metrics.

Figure 5: Control accuracy and stability metrics.

Scalable Edge-Enabled Distributed Control Framework for Real-Time and Fault-Tolerant Industrial Process Automation

327

6 CONCLUSIONS

The contribution of this work is a systematic and

practical methodology for improving real-time

industrial automation with edge-computing-based

distributed control scheme. Through decoupling the

essential control logic and embedding the intelligent

decision-making ability at the edge, our system

addresses the well-known issues of latency,

scalability, and fault tolerance associated with a

centralized design. The approach does not only

provide fast and deterministic reactions in mission

critical industrial applications, but guarantees system

robustness by means of self-healing capabilities and

adaptive learning models.

System evaluation in simulation and practice has

proven that the considerable improvements in control

latency, downtime, processing stability, and energy

consumption can be achieved. Moreover, the vendor-

agnostic, containerised design of the architecture

allows for easy deployment for diverse ecosystems

in industrial landscape, providing high readiness and

adaptability for Industry 5.0 transformations. A

combination of additional predictive intelligence

embedded to the control layer is a prospective

progression in the field of industrial automation.

In summary, the work established a solid base for

the next generation of edge-enabled industrial

control systems ones that are smarter, faster, safer,

and greener. For example, future works extend this

architecture by investigating multi-actor

coordination, security improvements using

blockchain, and the combination with up-coming 6G

communication technologies to further push the

capacities of distributed industrial intelligence.

REFERENCES

Amphenol Communications Solutions. (2025). Edge

computing: Driving the future of industrial automation.

https://www.amphenol-cs.com/connect/edge-

computing-driving-the-future-of-industrial-

automation.htmlAmphenolCS

Cincoze. (2025). Automate 2025: Cincoze to showcase

edge AI computing solutions. https://www.automate.

org/ai/news/automate-2025-cincoze-to-showcase-

edge-ai-computing-solutions

Compunnel. (2023). Edge computing futureproofing:

Evolution of distributed data processing. https://www.

compunnel.com/blogs/futureproofing-with-edge-

computing-anticipating-the-evolution-of-distributed-

data-processing/

Compunnel. (2024). Edge computing in 2024: Accelerating

data processing capabilities. https://www.compunnel.c

om/blogs/edge-computing-in-2024-accelerating-data-

processing-capabilities/Compunnel+1Compunnel+1

Control Engineering. (2021). Edge computing for industrial

AIoT applications. https://www.controleng.com/edge-

computing-for-industrial-aiot-applications/Control

Engineering

E-SPIN Group. (2025). Edge AI in 2025: Transform

industries and enable real-time decision-making.

https://www.e-spincorp.com/edge-ai-in-2025-

transform-industries/

Ericsson. (n.d.). Edge computing: Enabling exciting use

cases. https://www.ericsson.com/en/edge-computing

Gupta, S. (2024). An edge-computing based industrial

gateway for Industry 4.0 using ARM TrustZone

technology. arXiv preprint arXiv:2410.02529.

https://arxiv.org/abs/2410.02529

IEB Media. (2023). Industrial edge computing megatrends:

Special report. https://iebmedia.com/technology/edge-

cloud/industrial-edge-computing-megatrends-special-

report/

Kyndryl. (2024). Why everyone is talking about distributed

cloud at the edge. https://www.kyndryl.com/us/en/pers

pectives/articles/2024/03/distributed-cloud-at-the-edge

MarketsandMarkets. (2025). Industrial edge market size,

share and trends. https://www.marketsandmarkets.com

/Market-Reports/industrial-edge-market-

195348761.html

ProSoft Technology. (n.d.). Key considerations for edge

computing in industrial applications. https://fr.prosoft-

technology.com/insights/videos/Benefits-of-Edge-

Computing-in-Industrial-Applications

Raptis, T. P., Passarella, A., & Conti, M. (2025).

Distributed data access in industrial edge networks.

arXiv preprint arXiv:2502.21117. https://arxiv.org/abs

/2502.21117

Research and Markets. (2021). Global edge computing

market 2021–2025: Optimizing network traffic for

sustainable energy usage drives market growth.

Business Wire. https://www.businesswire.com/news/h

ome/20211001005267/en/Global-Edge-Computing-

Market-2021-2025-Optimizing-Network-Traffic-for-

Sustainable-Energy-Usage-Drives-Market-Growth-

ResearchAndMarkets.com

ResearchGate. (2025). Edge computing for Industry 5.0:

Fundamental, applications and research challenges.

https://www.researchgate.net/publication/378810325_

Edge_Computing_for_Industry_50_Fundamental_App

lications_and_Research_Challenges

Rockwell Automation. (2025). 8 key industrial automation

trends in 2025. https://www.rockwellautomation.com/

en-us/company/news/the-journal/8-key-industrial-

automation-trends-in-2025.html

RTInsights. (2025). Edge computing set to dominate data

processing by 2030. https://www.rtinsights.com/edge-

computing-set-to-dominate-data-processing-by-2030/

Scale Computing. (2025). 5 predictions for edge computing

and virtualization in 2025. https://www.scalecomputin

g.com/blog/5-predictions-edge-computing-

virtualization-2025

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

328

TechTarget. (2021). What is edge computing? Everything

you need to know. https://www.techtarget.com/search

datacenter/definition/edge-computing

The Business Research Company. (2025). Industrial control

for process automation market report 2025.

https://www.thebusinessresearchcompany.com/report/i

ndustrial-control-for-process-automation-global-

market-report

Törngren, M., Thompson, H., Herzog, E., Inam, R., Gross,

J., & Dán, G. (2022). Industrial edge-based cyber-

physical systems—Application needs and concerns for

realization. arXiv preprint arXiv:2201.00242.

https://arxiv.org/abs/2201.00242

Volt Active Data. (2024). How edge and industrial IoT will

converge in 2025. https://www.voltactivedata.com/blo

g/2024/11/how-edge-and-iiot-will-converge-in-2025/

Automation.com. (2025). Edge computing adoption in

IIoT. https://www.automation.com/en- us/articles/mar

ch-2025/edge-computing-adoption-iiot

Xu, J., Wan, W., Pan, L., Sun, W., & Liu, Y. (2024). The

fusion of deep reinforcement learning and edge

computing for real-time monitoring and control

optimization in IoT environments. arXiv preprint

arXiv:2403.07923. https://arxiv.org/abs/2403.07923

Scalable Edge-Enabled Distributed Control Framework for Real-Time and Fault-Tolerant Industrial Process Automation

329