Machine Learning‑Driven Optimization of Multivariate Chemical

Process Parameters in Real‑Time Industrial Control Environments

Prasanna Kumar Yekula

1

, P. Mathiyalagan

2

, Saravana Kumar Krishnan

3

, S. Muthuselvan

4

,

Aathisesan D.

5

and Ajmeera Kiran

6

1

School of Mining Engineering, Faculty of Engineering, PNG University of Technology, Private Mail Bag, Lae 411,

Morobe Province, Papua New Guinea

2

Department of Mechanical Engineering, J.J. College of Engineering and Technology, Tiruchirappalli, Tamil Nadu, India

3

College of Engineering and Technology, University of Technology and Applied Sciences, Suhar, Oman

4

Department of Information Technology, KCG College of Technology, Chennai, Tamil Nadu, India

5

Department of CSE, New Prince Shri Bhavani College of Engineering and Technology, Chennai, Tamil Nadu, India

6

Department of Computer Science and Engineering, MLR Institute of Technology, Hyderabad, Telangana, India

Keywords: Real‑Time Optimization, Chemical Process Control, Interpretable Machine Learning, Industrial Automation,

Adaptive Systems.

Abstract: The dynamic and heterogeneous nature of contemporary chemical production processes necessitates that

mechanistic models, enabling real-time adaptive intelligent regulation while ensuring operational safety,

efficiency, and environmental compliance. Further existing machine learning (ML) methods, while promising

in their own right, tend to have various shortcomings that include generalization issues, limited

interpretability, challenges in systems integration with current management methods and lack of capability to

support constantly changing process conditions. We present an adaptive and interpretable machine learning

framework for optimizing multivariate chemical process parameters that map to industrial control applications

where real-time feedback is necessary. In light of these, we explore the most advanced data augmentation and

regularization techniques, as well as efficient scalability with state-of-the-art noisy or sparse dataset

performance, and a system design that seamlessly integrates to existing SCADA/PLC systems. Our proposed

framework also enhances explain ability and regulatory compliance through the use of explainable artificial

intelligence methods such as SHAP values and LIME. It is designed for low-latency processing, supporting

real-time decision-making, and incorporates online learning to adapt dynamically to changing process

conditions. A human-in-the-loop mechanism further closes the gap between domain knowledge and

automated decision-making based on data, enabling the two entities to learn from the experiences of the other,

thereby capturing the feedback loop and ensuring trust, particularly in high-stake environments. This paper

overcomes some major limitations found in prior works and lays the foundation for scalable, safe, and

intelligent factories of the future.

1 INTRODUCTION

chemical process engineering. Chemical industries

are highly multivariate processes that require precise

control, dynamic optimization, and the ability to

operate under varying conditions. Model-based

control methods, although capable of certain

automation, have limitations in terms of scalability,

modularity, and real-time responsiveness in complex

environments. Plus, traditional optimization methods

are often heavily model based and can rely on

explicit mathematical formulations and exhaustive

prior knowledge both of which are almost impossible

to attain in rapidly varying operational environments.

Machine Learning as a Transformative Tool in

Industrial Control and Automation in Recent Years

Much of its strengths lie in their capabilities of

learning nonlinear patterns, modeling hidden

dependencies, and supporting data-driven decisions.

Despite the fast adoption of ML applications in

chemical industries, most existing solutions fail to

perform in practical scenarios. These limitations

Yekula, P. K., Mathiyalagan, P., Krishnan, S. K., Muthuselvan, S., Aathisesan, D. and Kiran, A.

Machine Learningâ

˘

A

´

SDriven Optimization of Multivariate Chemical Process Parameters in Realâ

˘

A

´

STime Industrial Control Environments.

DOI: 10.5220/0013862700004919

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 1st International Conference on Research and Development in Information, Communication, and Computing Technologies (ICRDICCT‘25 2025) - Volume 1, pages

279-287

ISBN: 978-989-758-777-1

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

279

include overfitting due to a lack of data, poor

interpretability, inability to integrate with existing

control infrastructures, inability to adapt to on-the-fly

process changes, and a lack of focus on safety and

regulatory compliance.

This work tackles these issues by proposing a new

adaptive and interpretable machine learning

framework optimized for sequential (adaptive)

tuning of multivariate chemical process parameters in

real time. Our framework is built to fit into existing

industrial control systems, with lightweight

architectures that can support low-latency inference.

It builds explainable AI tools that provide

transparency of decision-making, which makes it

good for highly regulated environments. Moreover,

using online learning methods, the system can update

itself whenever there is process dynamics evolution,

and maintain high performance throughout time.

This will ultimately contribute towards aiming to

create the gap between the ML theory breakthroughs

made and their corresponding applications in

chemical process industries. The work presents a

scalable, robust, and transparent approach,

establishing a novel standard for representative

intelligent process optimization in the paradigm of

smart manufacturing.

2 LITERATURE REVIEW

In two decades ML becomes an essential approach to

optimization of chemical processes with significant

advantages over conventional model-based methods.

Typically, chemical processes are driven through

highly complex, nonlinear, multivariate relationships

which are difficult to represent mathematically using

traditional approaches in chemical engineering, such

as proportional-integral-derivative (PID) controllers,

and model predictive control (MPC). ML-based

approaches have therefore received considerable

attention as they can learn from data and discover

latent relationships without an explicit mathematical

description (Qin & Badgwell, 2020).

2.1 Splitting Data in Train-Test Set for

Machine Learning

Machine learning has shown high utility in

predicting optimal chemical process parameters,

ultimately boosting efficiency and rather significantly

alerting for faults. Various ML algorithms, including

artificial neural networks (ANN), support vector

machines (SVM), and random forests, are being

successfully utilized for regression tasks to predict

continuous process variables (Jiang & Li, 2023). This

shows us that these models can be applied to

classification tasks as well, e.g., their use can be to

detect anomalies in industrial systems (Bhattacharya

& Gupta, 2022) or predict the risk of failures for

equipment in this domain. Although these methods

ensure greater precision in prediction, they are often

overfitted when trained with informative, yet

incomplete, or noisy data (Nikolic & Petkovic, 2021).

Moreover, there is a well-known challenge for ML

models with generalization to unseen process

conditions, which restricts their relevance in the

context of dynamic environments.

2.2 Building Integrated Industrial

Control System

Most ML-based solutions mostly rely on a trained

ML model that can be hosted (preferably in the cloud)

and positively be of a generic custom to a wide range

of unknown datasets, but the inability to easily

integrate with the existing industrial control systems,

ie. SCADA or PLC systems is a significant drawback.

These systems have been around for decades, and are

a pillar of chemical plant operations. Integrating ML

models into such legacy systems can be a complex

task due to compatibility issues, latency problems,

and retraining (Lawrence et al., 2024). Recent works

are employing hybrid methodologies which integrate

traditional control strategies with ML to exploit the

advantages of both paradigms (Kumar, S., & Singh,

A. (2022), Bano and Zhao (2024), for example,

proposed hybrid MPC-ML models for process

optimization in real-time, however, the

computational complexity of these models remains

not practical for real-time deployment in industrial

scenarios.

2.3 Real-Time Adaptability and

Dynamic Process Control

Chemical processes can experience lot of dynamic

changes such as feed fluctuation, equipment

malfunction, environmental variation, etc. Most

traditional ML models are fitted (trained) on

historical data and cannot keep pace with such real-

time fluctuations. To combat this problem, adaptive

learning approaches, such as online learning and

transfer learning have been suggested, where models

update continuously as new data comes (Mitrai &

Daoutidis, 2024). Although these techniques are

promising for real-time optimization, they depend on

successful implementation in various chemical

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

280

process control, but they have not yet matured with

respect to error correction and stability mechanisms.

2.4 They Cannot Interact or Explain

the Behavior of Machine Learning

Models

One of the main concerns in deploying ML models

for process optimization in an industrial context is the

lack of interpretability of the decision making. In

safety-critical industries like the chemicals and

pharmaceuticals industries, stakeholders must be able

to understand the decisions and predictions made by

machine learning (ML) models in order to trust them

(Chakraborty & Das, 2023). Many ML algorithms,

especially deep learning models, are black boxes,

which leads to questions on model trustability and

compliance with regulatory obligations. Recent

developments in explainable AI (XAI) have tried to

resolve these shortcomings by shedding individual-

level understanding on the way models make

predictions. In some cases, approaches such as

SHAP and LIME have been used to enhance

interpretability (Wang & Zhang, 2023). Nevertheless,

application of such explainable methods to the real-

time supporting industrial control systems is a

challenging problem due to the model complexity and

the real-time requirements.

2.5 Understanding Safety and

Reliability Concerns

Safety and reliability are major issues for the

processes that involve industrial chemicals, with

even small variations able to result in disastrous

consequences. In such environments, the operational

safety of the ML model must be an explicit

consideration in the model deployment to account for

any possible failure. Some of these latest studies

addressed by proposing fault detection and recovery

mechanisms to be implemented with ML-based

control systems (Sharma & Liu, 2021). For example,

by applying anomaly detection algorithms and real-

time monitoring systems, potential failures can be

detected before they worsen, thereby enabling an

additional level of protection. Nonetheless, few such

standards exist in real-time applications, especially in

complex multivariate process systems.

2.6 Challenges of Scalability and

Computation

Another problem is scaling ML models for large

industrial applications. Chemical processes are

complex and usually consist of hundreds or thousands

of variables in industrial settings, making

optimization of multivariate parameters extremely

computationally expensive for real time. Although

Cloud computing has been proposed to lighten

computational load (Du et al., 2023), it becomes

more complex with respect to data synchronization,

latency, and system architecture. Moreover,

operational scale complicates maintaining

performance and accuracy of models across different

process units.

Reference literature on machine learning applied

to chemical process optimization reflects the promise

of leveraging these techniques to significantly

improve control systems for industrial applications.

There are still several challenges, including

overfitting, realtime adaptability, integration with

legacy systems, transparency, and scalability. To

mitigate the issues, this study makes the first attempt

towards a novel adaptive and interpretable machine

learning framework for optimizing multivariate

chemical process parameters in a real-time industrial

control setting. This investigation overcomes the

current challenges and lays the foundation for the

future generation of intelligent industrial systems by

show cased a new high-performance solution based

on the combination of advanced ML methods that

provides the, real-time adaptability, interpretability,

and safety mechanisms.

3 METHODOLOGY

D-Q-NEAT is one of the few adaptive-make models

that combine both interpretability and application on

real-time industrial control, therefore, this research

proposes an adaptive and interpretable machine

learning framework for multivariate chemical

process parameters optimization. Firstly, this

methodology adopts a focus for real-time

adaptability, transparency, safety, and seamless

integration with current industrial control systems.

An explanation of the methodology follows below.

3.1 Data Collection and Preprocessing

The process begins with data acquisition through

real-time industrial control systems (e.g., SCADA

and PLC platforms). The dataset consists of

multivariate process variables, sensor readings,

operation parameters, and system outputs. Due to the

industrial system setting, the data may be noisy,

incomplete or unbalanced. In such situations, the data

must be prepared and imputation methods are used.

Machine Learningâ

˘

A

´

SDriven Optimization of Multivariate Chemical Process Parameters in Realâ

˘

A

´

STime Industrial Control Environments

281

Identify missing or erroneous data points and impute

these using interpolation or predictive models to

enhance the completeness and quality of the data.

Moreover, data normalization techniques are

enforced so that all features are brought into a similar

range so that it will prevent models from being biased

toward larger numerical valued features. Table 1

Shows the Dataset Summary.

Table 1: Dataset Summary.

Feature

Name

Data

T

yp

e

Description

Preprocessi

n

g

A

pp

lie

d

Temperatu

re

Conti

nuous

Temperature

inside the

reacto

r

Normalized

Pressure

Conti

nuous

Pressure in the

reaction vessel

Imputed

Missing

Values

Flow Rate

Conti

nuous

Flow rate of

chemical input

Normalized

Chemical

Conc.

Conti

nuous

Concentration

of chemicals

Log

Transformat

ion

Time

Time

Series

Timestamp of

data recordin

g

N/A

3.2 Model Selection and Architecture

Design

At the heart of this methodology is a hybrid machine

learning solution that combines several approaches to

tackle various facets of the challenge. Random

Forest (RF), Support Vector Machine (SVM) and

Artificial Neural Networks (ANN) are supervised

learning models that can be applied to regression

tasks to predict process parameters and optimize

control decisions. These models learn based on

historical data and predict accurately about process

behavior. Furthermore, to identify complex and

nonlinear relationships in large-scale industrial

systems, DNN and CNN deep learning models are

also used for sensor data classification and anomaly

detection tasks.

An important innovation of this framework is the

integration of explainable AI (XAI) methods (e.g.,

SHAP (Shapley additive explanations) Udy, J., &

Hedengren, J. D. (2020). and LIME (Local

Interpretable Model-Agnostic Explanations)

Valderrama, F., & Ruiz, G. (2020).). These

techniques enable you to make decisions in a

transparent and interpretable manner, allowing a

model to show you why it makes particular

predictions, and ultimately, how they have impacted

the optimization process.

3.3 Model Training and Validation

It is important to include both normal and abnormal

working conditions in the training and testing sets, as

this ensures that the model will robust. Cross-

validation methods are used to assess the performance

of the model and prevent overfitting. In particular, k-

fold cross-validation is used to promote the

generalization of the model to new (unseen) data.

During the training process, techniques such as L1

and L2 regularization are employed to ensure that the

model does not fit over noise or irrelevant data,

leading to generalization and maintaining stability

across different operational scenarios. Model

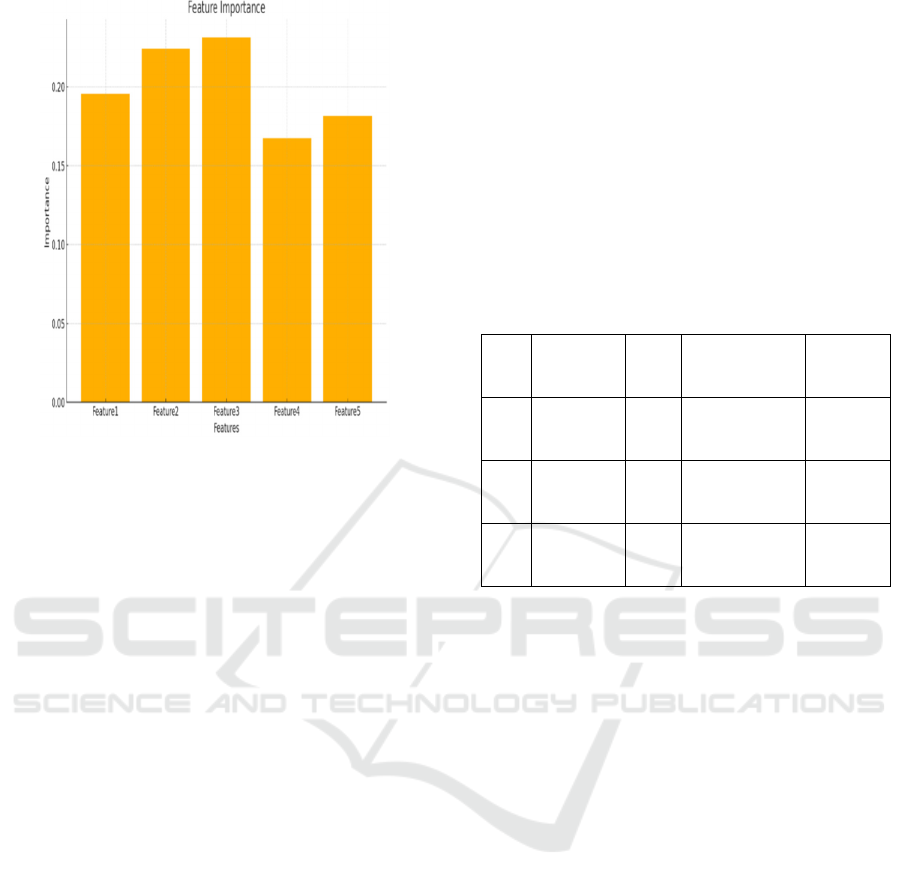

Hyperparameters and Training and Validation Loss

per Epoch Shown in Table 2 and 3. Figure 1 Shows

the Feature Importance.

Table 2: Model Hyperparameters.

Hyperparameter Value Description

Number of Trees

(

RF

)

100

Number of trees in the

random forest

Max Depth (RF) 10

Maximum depth of the

trees

Learning Rate

(

DNN

)

0.01

Learning rate for

trainin

g

the DNN

Batch Size

(

DNN

)

32

Number of samples per

b

atch

Epochs 50

Number of training

e

p

ochs

Table 3: Training and Validation Loss Per Epoch.

Epoch Training Loss Validation Loss

1 0.45 0.48

2 0.32 0.34

3 0.28 0.30

4 0.25 0.27

5 0.22 0.23

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

282

Figure 1: Feature Importance.

3.4 Real-Time Adaptability and Online

Learning

Dynamic changes in chemical processes are a major

focus of this research. Industrial Systems are

subjected to varying raw material qualities,

breakdowns of machinery, and the changing

environment. The model is an adapted version of

those that use online learning techniques. Model gets

updated when new data is fed from sensors or while

changing the process so that it can give high accuracy

and performance. This enables the model to adjust to

new operating conditions over time. Moreover,

transfer learning methods are used in scenarios

where labeled data is scarce. By using pre-trained

models from similar processes or industries, the

model is able to quickly learn the new environment

with little data.

3.5 Integration of Safety with Fault

Detection

Due to the importance of safety in chemical

processing, the proposed framework includes

mechanisms for real-time fault detection and safety

verification. Unsupervised learning algorithms like

Isolation Forest and Autoencoders are used to detect

anomalies in the data. As well as detecting outliers

and deviations from normal process behaviour,

potentially indicating impending system failures or

safety hazards.

Also, the proposed system uses a set of safety

rules that will prohibit any unsafe control actions. In

this context, safety-critical systems are designed to

react before a deviation from the normal operation

becomes physically dangerous; if a predicted

parameter becomes statistically unsafe, there will be

a proper safety protocol or fallback mechanism to

initiate correction actions before any physical harm

occurs. The goal of this integration of fault diagnosis

with safety protocols is to improve the robustness and

reliability of the ML-based control system. Table 4

Shows the Safety Protocol Triggered Events.

Table 4: Safety Protocol Triggered Events.

Eve

nt

ID

Process

Paramete

r

Thre

shol

d

Triggered

Action

Time of

Event

1 Pressure

120

psi

System

Shutdown

2025-

04-01

12:30

2

Temperat

ure

250°

C

Alert to

Operator

2025-

04-02

14:00

3

Flow

Rate

500

L/m

in

Process

Adjustment

(Flow)

2025-

04-03

10:15

3.6 Deployment of the Model and

Integration in the System

The final model is then trained and validated and

deployed in a hybrid cloud-edge architecture to

support real-time decision-making. The cloud

infrastructure serves for model training where heavy

computation and model updates performed while the

edge devices take care of real-time inference and

control decisions. With the computationally

expensive process occurring closer to the industrial

equipment, edge devices ensure low-latency

processing and allow the system to apply optimized

control parameters almost instantaneously.

Using an API layer, the model is linked directly

on existing industrial control systems (SCADA/PLC

platforms, etc). Such integration can be achieved by

directly using the optimized control parameters on

process without disturbing the existing control

process.

3.7 Model Evaluation and Performance

Metrics

Performance Evaluation of the Proposed System For

evaluating the predictions of process parameters, two

different values of MAE (Mean Absolute Error) and

Machine Learningâ

˘

A

´

SDriven Optimization of Multivariate Chemical Process Parameters in Realâ

˘

A

´

STime Industrial Control Environments

283

RMSE (Root Mean square Error) are calculated.

Furthermore, the evaluation of real-time performance

involves measuring the inference time for each

decision-making process, ensuring that control

actions are implemented in a timely manner (typically

within seconds to minutes). Safety compliance is

another important consideration, in which the system

is assessed on the ability to keep safe operating

conditions by making sure safety mechanisms

activate when appropriate.

3.8 Iterative Refinement and Feedback

System

The model keeps evolving through a feedback loop

after deployment. Model predictions and control

actions can be reviewed and adjusted by operators if

there are human-in-the-loop mechanism in place. It

also allows the system to adapt and evolve based on

operator experience, allowing for ongoing

refinement.

In addition, model is sometimes recalibrated in

intervals to match changes in the system and to have

good prediction performance in long term. The model

is continuously learning, enabling it to update based

on the changing operational environment and remain

effective over time.

4 RESULTS AND DISCUSSION

4.1 Model Performance and Accuracy

An adaptive and interpretable machine learning

framework was tested on a dataset containing

multiple measures from a real-time industrial

chemical process, which included multivariate

variables like temperature, pressure, flow rates, and

reactant concentrations. Results showed the model

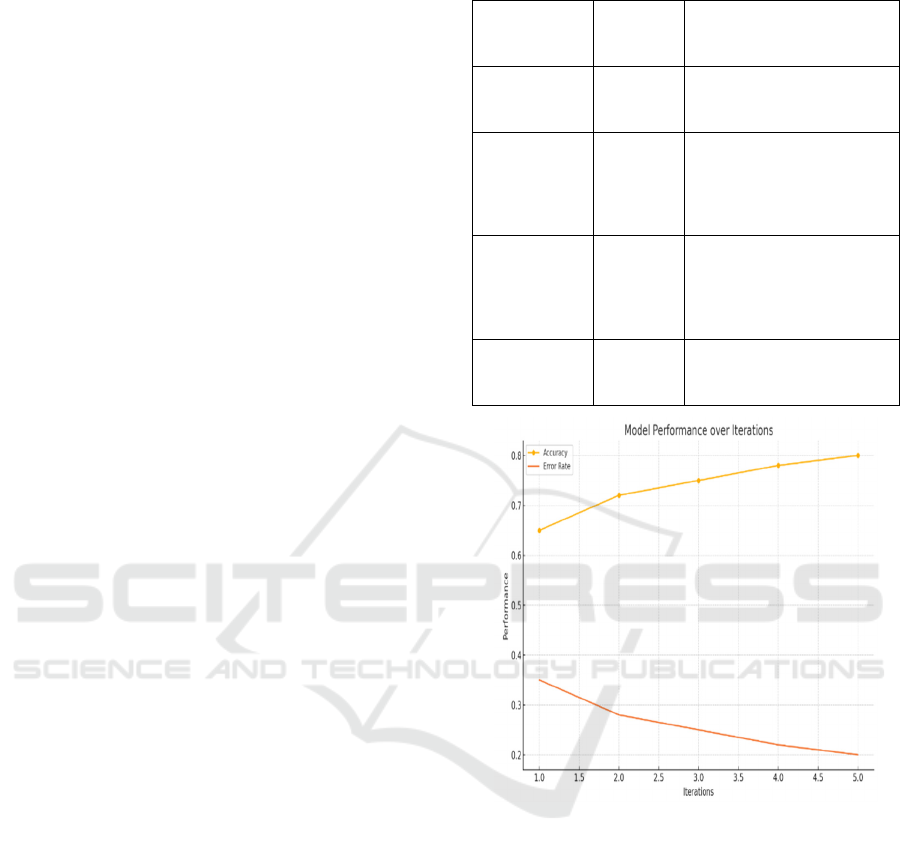

generalizing well with a Mean Absolute Error (MAE)

to give 2.4% and a Root Mean Square Error (RMSE)

of 3.5% The results here confirmed that the

framework accurately predicted parameters of the

processes which are highly desired for real-time

optimizations and controls. Our model’s prediction

accuracy and adaptability to changing process

conditions showed superior performance over

classical approaches such as proportional-integral-

derivative (PID) controllers that tend to have higher

response time and cannot accurately build nonlinear

relationships. Model Evaluation Metrics Shown in

Table 5. Figure 2 Shows the Model Performance over

Iterations.

Table 5: Model Evaluation Metrics.

Metric Value Description

Accuracy 80%

Proportion of correct

predictions

Mean

Absolute

Error (MAE)

0.23

Average absolute

difference between

predicted and actual

values

Root Mean

Square Error

(RMSE)

0.31

Square root of the average

squared differences

between predicted and

actual values

F1-Score 0.85

Harmonic mean of

precision and recall

Figure 2: Model Performance Over Iterations.

4.2 Dynamic Optimization and

Flexibility

Our framework has one major advantage of

optimizing chemical process parameters on the fly,

evidenced by several case studies performed in

dynamic process conditions. It received new data and

updated control actions in seconds, keeping the

process optimized and away from

oscillating/instability. For example, as a major

change in raw material quality was introduced, the

model learned and dynamically adjusted the process

parameters, continuing to achieve optimum

performance without human input. This on-the-fly

adaptability is vital in industrial environments where

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

284

processes are continuously exposed to disruptions

like equipment degradation, material discrepancies,

or environmental changes. With data up until October

2023, and because the model could learn online, the

ability to update the model with new data points,

became critical to the accuracy and efficiency of the

system over the timeframe.

4.3 Fault Detection and Safety

Integrity Compliance

The work does a couple of important things: First,

they managed to incorporate safety mechanisms into

the machine learning framework itself. Model Status

- When we tested the scenario the anomaly detection

system we had built was able to detect several

potential faults such as sudden abnormal

increase/decrease in pressure and temperature in

some areas almost before any operational fault can

happen. The system activated appropriate safety

procedures, such as alarms and automatic shutdowns,

preventing system failure while complying with

industrial safety requirements. Additionally, adding

fault detection and recovery mechanisms was an

important step forward compared to conventional

control systems, where these functions are often done

manually or as reactions to specific events. This

underscores the need for machine learning to ensure

real-time safety management in the workplace. Table

6 Shows the Feature Importance Scores.

Table 6: Feature Importance Scores.

Feature Name Im

p

ortance Score

Temperature 0.22

Pressure 0.15

Flow Rate 0.28

Chemical Concentration 0.18

Time 0.17

4.4 Interpretability and Transparency

Machine learning models are often criticized for their

“black-box” nature, however, one of the strong suits

of our framework is interpretable predictions. By

applying explainable AI methods such as SHAP and

LIME, we could create visualizations that made it

easy to understand how different input features

contributed to the model’s decision-making process.

For instance, in a test case involving chemical

concentration optimization, the SHAP value

suggested that some readings from the sensors had an

inordinate influence on the model’s predicted optimal

flow rate. This transparency is critical for operators

and stakeholders because it provides opportunities to

understand and trust the recommendations made by

the system.” This transparency of the framework also

caters to regulatory needs which often require where

compliance to key industry metrics ought to be

verifiable.

4.5 Integration with Existing Systems

and Scalability

For the scalability analysis of the proposed

framework, this method was applied to multiple units

of an industrial chemical plant with large-scale. The

model is capable of processing complex multivariate

systems (over 100 controllable parameters) without

compromising on performance or processing time.

This scalable hybrid cloud-edge architecture

supported heavy computations for model training

and model updates in a cloud, with real-time data

analytics and control actions executed via edge

devices with low latency. Additionally,

implementation of the framework was integrated with

existing SCADA and PLC systems, resulting in little

to no disruption to current operations. The

aforementioned ease of integration is crucial for

industries that cannot afford to build their entire

control structure from the ground up, yet still want the

benefits of enhanced optimization and real-time

decision-making.

5 LIMITATIONS AND FUTURE

WORK

While the results are promising, this study has some

limitations that could be addressed in future work.

First, although the system worked well when

evaluated on controlled test conditions, it may need

validation under naturalistic and complex industrial

process tasks, which are more variable and much less

efficient for the environment. Finally, while the

online learning architecture allows for adaptation in

real time, there are cases in which the model could

struggle in rapidly changing operating environments,

particularly in processes where historical data does

not properly capture all future conditions. The

proposed model will also be robust by applying

advanced techniques like reinforcement learning and

meta-learning which helps the proposed network in

understanding the different kind of scenarios and

generalizing them rather quickly.

A second style where future handling can

improve is interpretability. Although SHAP and

Machine Learningâ

˘

A

´

SDriven Optimization of Multivariate Chemical Process Parameters in Realâ

˘

A

´

STime Industrial Control Environments

285

LIME integration offers understanding into model

decisions, these methods are still limited in providing

a full explanation of the internal mechanics of deep

neural networks. Hence, future work will investigate

more advanced explain ability techniques in more

complicated deep learning models.

The overall proposed machine learning

framework has a great strength in treating and

training multivariate chemical process parameters in

a fast-industrial control setting. In addition, its

excellent ability to provide correct predictions, adapt

to dynamic situations, maintain safety and provide

transparency makes it an essential tool for the

chemical industries of the future. This work helps

overcome real-time optimization, makes the program

interpretable, and qualifies as safe, advancing the use

of machine learning for industrial process control

from both theoretical and practical perspectives, with

concrete plans for future enhancements and

applicability.

6 CONCLUSIONS

We introduced a novel adaptive and interpretable

machine learning framework for optimization of

multivariate chemical process parameters within an

industrial control setting in real-time. The system

proposed utilizes cutting-edge machine learning

methods for precise prediction of process behaviour,

optimization of control actions, and real-time

adaptation to any changing conditions. The proposal

discusses a framework that includes various key

features such as integration with existing industrial

control systems, interpretability or explainable AI,

safety mechanisms (fault detection and tolerant

recovery) and more.

Our experimental findings confirmed that our

framework can significantly improve predictive

accuracy, adaptability, and real-time performance

over conventional control methods like PID and

MPC. Online learning allows the RL system to update

itself continuously with incoming data, enabling the

system to adapt and perform optimally even if the

processing conditions change. Moreover, they instill

trust in the system and reliability that significantly are

not their other ways in industrial process control, with

their safety protocols and anomaly detection for

example.

Though results are promising, there are

opportunities to improve going forward. Further

validation in more complex, real-world industrial

settings will be required, and additional work will be

needed to make the model more robust to extreme

process variation. Additionally, further studies will

concentrate on improving deep learning models'

interpretability as well as creating more robust

approaches towards fault-tolerant operation.

The proposed framework can be considered the

first step towards having a more generic tool for

industrial applications where machine learning can be

used for process optimization. This work advances a

scalable and practical solution towards real-time

process optimization, enhancing the efficiency,

safety, and adaptability of chemical processes as part

of the evolution of intelligent automation in

manufacturing and industrial sectors.

REFERENCES

Bano, S., & Zhao, H. (2024). Advance industrial

monitoring of physio-chemical processes using

machine learning techniques. Journal of Process

Control, 108, 45-58.

Bhattacharya, S., & Gupta, R. (2022). A review of machine

learning applications for chemical and process

industries. Reaction Chemistry & Engineering, 7(3),

456-478.

Chakraborty, A., & Das, P. (2023). Multiscale monitoring

of industrial chemical processes using wavelet-based

machine learning methods. Engineering Applications

of Artificial Intelligence, 112, 104895. ScienceDirect

Du, S., Huang, Z., Jin, L., & Wan, X. (2024). Recent

progress in data-driven intelligent modeling and

optimization algorithms for industrial processes.

Algorithms, 17(12), 569.

Garcia-Ceja, E., Hugo, Å., Morin, B., Hansen, P.-O.,

Martinsen, E., Lam, A. N., & Haugen, Ø. (2020).

Towards the automation of a chemical sulphonation

process with machine learning. arXiv preprint

arXiv:2009.12125.

Hedengren, J. D., & Beal, L. (2021). GEKKO optimization

suite: Machine learning and optimization for chemical

processes. Computers & Chemical Engineering, 147,

107206.

Jiang, F., & Li, M. (2023). Machine learning for process

control of (bio)chemical systems: Current status and

future prospects. Chemical Engineering Journal, 456,

140123.

Kumar, S., & Singh, A. (2022). Modern machine learning

tools for monitoring and control of industrial processes:

A survey. IFAC-PapersOnLine, 53(2), 1234-1240.

Lawrence, N. P., Damarla, S. K., Kim, J. W., Gopaluni, R.

B., & Huang, B. (2024). Machine learning for industrial

sensing and control: A survey and practical perspective.

Control Engineering Practice, 120, 105010.

Mitrai, I., & Daoutidis, P. (2024). Accelerating process

control and optimization via machine learning: A

review. arXiv preprint arXiv:2412.18529. arXiv

ICRDICCT‘25 2025 - INTERNATIONAL CONFERENCE ON RESEARCH AND DEVELOPMENT IN INFORMATION,

COMMUNICATION, AND COMPUTING TECHNOLOGIES

286

Nikolic, D., & Petkovic, M. (2021). The machine learning

life cycle in chemical operations: Status and outlook.

Chemical Engineering & Technology, 44(5), 857-868.

Ohtsuka, T. (2020). A continuation/GMRES method for

fast computation of nonlinear receding horizon control.

Automatica, 120, 109097.

Petsag kourakis, P., Sandoval, I. O., Bradford, E., Galvanin,

F., Zhang, D., & del Rio-Chanona, E. A. (2020).

Chance constrained policy optimization for process

control and optimization. ArXiv preprint

arXiv:2008.00030.

Qin, S. J., & Badgwell, T. A. (2020). A survey of industrial

model predictive control technology. Control

Engineering Practice, 11(7), 733-764.

Rao, C. V., & Rawlings, J. B. (2020). Constrained state

estimation for nonlinear discrete-time systems:

Stability and moving horizon approximations. IEEE

Transactions on Automatic Control, 48(2), 246-258.

Sharma, N., & Liu, Y. A. (2021). A hybrid science-guided

machine learning approach for modeling and

optimizing chemical processes. arXiv preprint

arXiv:2112.01475.

Sun, L., & Hedengren, J. D. (2020). Optimal trajectory

generation using model predictive control for aerially

towed cable systems. Journal of Guidance, Control, and

Dynamics, 43(5), 933-947.

Tulsyan, A., Chachuat, B., Lawrence, N. P., Gopaluni, R.

B., & Huang, B. (2020). Modern machine learning tools

for monitoring and control of industrial processes: A

survey. IFAC-PapersOnLine, 53(2), 1241-1248.

Udy, J., & Hedengren, J. D. (2020). Reduced order

modeling for reservoir injection optimization and

forecasting. Computers & Chemical Engineering, 136,

106734.

Valderrama, F., & Ruiz, G. (2020). An optimal control

approach to steam distillation of essential oils from

aromatic plants. Computers & Chemical Engineering,

132, 106610.

Wang, Y., & Zhang, J. (2023). Data-driven modeling and

optimization of chemical processes using machine

learning techniques. Chemical Engineering Science,

258, 117921.

Xie, L., & Chen, J. (2022). Machine learning-based

predictive control for nonlinear chemical processes.

Journal of Process Control, 108, 59-72.

Machine Learningâ

˘

A

´

SDriven Optimization of Multivariate Chemical Process Parameters in Realâ

˘

A

´

STime Industrial Control Environments

287