Research on the Synergistic Effect of Global Supply Chain

Visualization and Data Technology

Zixing Wang

a

School of Economics, Qingdao University, Qingdao, China

Keywords: Global Supply Chain, Data Technology, Synergy Effect, Internet of Things, Blockchain.

Abstract: With the deepening development of globalization, global supply chains play a crucial role in connecting

production and consumption. However, the issue of transparency in the supply chain is becoming increasingly

prominent, and phenomena such as information asymmetry, data silos, and difficult traceability seriously

constrain the efficiency and security of the supply chain. This article focuses on the synergistic effects of

global supply chain visualization and data technology, aiming to explore how to use advanced technologies

such as the Internet of Things, blockchain, and augmented analytics to improve supply chain transparency,

reduce risks, and enhance overall performance. Based on the differences in digital practices in different

regions and their influence on supply chain performance, this study proposes a series of practical suggestions,

including developing targeted digital transformation strategies based on regional characteristics and market

demand, strengthening the application and promotion of advanced technologies in the supply chain, etc. These

suggestions aim to help enterprises better cope with challenges and seize opportunities in the process of digital

transformation, thereby enhancing the transparency and overall performance of the global supply chain.

1 INTRODUCTION

In the context of a globalized economy, the

importance of the supply chain as a key link between

production and consumption is becoming

increasingly prominent. The transparency of the

current global supply chain is facing many challenges.

These challenges mainly stem from the complexity of

the supply chain, the wide geographical distribution,

and the diversity of participating entities. These

factors work together to make information acquisition

and transmission exceptionally difficult (Sun,2025).

The complexity of the supply chain is one of the

important reasons for the decrease in transparency.

Global supply chains often involve multiple links and

numerous participants, from raw material

procurement to production, transportation, and

distribution, each link may generate a large amount of

data and information. The fragmentation and

dispersion of this information make it very difficult to

comprehensively and accurately grasp the overall

situation of the supply chain. At the same time,

different links in the supply chain may involve

different industries, countries, and regions, and their

a

https://orcid.org/0009-0004-1957-4618

operating models and regulatory environments are

also different, which further increases the difficulty of

information integration.

Regional distribution is also an important factor

affecting supply chain transparency. The various

links in the global supply chain are often distributed

in different countries and regions, even spanning

multiple time zones. This geographical dispersion not

only increases the cost of information communication

and coordination but may also lead to delays and

distortions in information. In addition, differences in

regulations, culture, language, and other factors

among different countries and regions may also pose

obstacles to the transmission and understanding of

information. By comparing and analyzing the

differences in supply chain digitalization practices in

different regions, enterprises can identify the gaps

between themselves and advanced regions and thus

learn from successful experiences in a targeted

manner, formulate supply chain visualization and

data technology application strategies that are more in

line with their actual situation, and enhance their

competitiveness in the global supply chain.

766

Wang, Z.

Research on the Synergistic Effect of Global Supply Chain Visualization and Data Technology.

DOI: 10.5220/0013860500004719

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on E-commerce and Modern Logistics (ICEML 2025), pages 766-771

ISBN: 978-989-758-775-7

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

The diversity of participants is also an undeniable

reason for the issue of supply chain transparency.

Participants in the global supply chain include

multiple roles such as suppliers, manufacturers,

distributors, and retailers, each with their own

interests and information needs. The existence of

such diversity makes the flow of information in the

supply chain more complex and difficult to control.

Meanwhile, due to the potential for information

asymmetry and conflicts of interest among

participants in the supply chain, this also increases the

likelihood of information fraud and risk.

This study aims to explore in depth the synergistic

effects of global supply chain visualization and data

technology to address the challenges of supply chain

transparency. By leveraging advanced technologies

such as the Internet of Things (IoT), blockchain, and

augmented analytics, this study highlights the

significant potential of these innovations in

enhancing supply chain transparency, mitigating risks,

and optimizing operational efficiency. This study will

also compare and analyze the differences in supply

chain digitalization practices in different regions, to

provide more targeted practical suggestions for

enterprises. By drawing on successful experiences

from advanced regions and combining them with the

actual situation of the enterprise, it can more

effectively promote the application of supply chain

visualization and data technology, thereby enhancing

its competitiveness in the global supply chain.

2 GLOBAL SUPPLY CHAIN

TRANSPARENCY

CHALLENGES AND CORE

PAIN POINTS

The challenges faced by global supply chain

transparency are multifaceted, with information

asymmetry and traceability difficulties being the core

pain points. These pain points not only compromise

the efficiency and flexibility of the supply chain but

also escalate the operational risks and costs for

enterprises.

Asymmetric information is due to the

involvement of multiple links and numerous

participants in the supply chain, which often hinders

the acquisition and transmission of information. For

example, in the procurement process, suppliers may

provide incomplete or false information, which may

prevent the purchaser from accurately assessing the

supplier's capabilities and reputation, thereby

affecting procurement quality and cost control; In the

sales process, distributors may exaggerate market

demand to seek high profits, which in turn leads to

overproduction and inventory accumulation by the

production side, increasing the operating costs and

risks of the enterprise; During the consumption

process, consumers may choose low-quality and low-

priced products based on limited information, which

may affect the promotion of high-quality products.

Traceability difficulty is another important issue

in the global supply chain. In the supply chain, the

production and circulation of products involve

multiple links and participants. Once a problem arises,

it is often difficult to quickly identify the cause and

the responsible person. This difficulty in tracing not

only increases the quality risk and cost of the

enterprise but also reduces consumers' trust in the

product. Especially in the fields of food safety, drug

quality, etc., traceability difficulties may lead to

serious social problems and legal consequences.

3 PATH OF DATA-DRIVEN

SUPPLY CHAIN

VISUALIZATION

TECHNOLOGY

3.1 Internet of Things and Edge

Computing

The combination of the Internet of Things and edge

computing has brought significant advantages to

supply chain management. Firstly, this combination

enables enterprises to monitor the status of their

supply chain in real-time. Whether it is the inventory

situation in the warehouse, the transportation progress

of goods, or even the quality status of products, they

can be tracked in real time through IoT devices.

Secondly, through real-time analysis of the collected

data through edge computing, enterprises can quickly

find problems in the supply chain, such as inventory

backlog, transportation delay, or abnormal product

quality, to take timely measures to correct them. This

real-time monitoring and instant response capability

is crucial for improving the transparency and

efficiency of the supply chain. The improvement of

transparency means that enterprises can more

accurately understand the actual situation of the

supply chain and make wiser decisions. The

improvement of efficiency is directly reflected in

reducing unnecessary waste, speeding up the flow of

goods, and ultimately improving the competitiveness

of enterprises. The combination of the Internet of

Things and edge computing has laid a solid

Research on the Synergistic Effect of Global Supply Chain Visualization and Data Technology

767

foundation for supply chain visualization, while

blockchain and data sharing further promote the

development of supply chain visualization from

another angle (Lin,2025).

3.2 Blockchain and Data Sharing

In supply chain management, blockchain technology,

with its decentralized nature, means that data no

longer relies on a single central institution or server

for storage and verification, thereby reducing the risk

of data tampering or forgery. Every transaction and

flow of information is permanently recorded on the

blockchain, forming an immutable data chain that

greatly enhances the authenticity and credibility of

the data (Wang,2025).

The data sharing mechanism of blockchain

technology enables various links in the supply chain

to obtain and update information in real time. This not

only includes basic information such as product

production, transportation, and sales, but may also

cover more dimensions of data such as quality

inspection, certification, tariffs, etc. In this way,

blockchain helps eliminate information silos,

allowing all stakeholders to work collaboratively in a

shared and transparent environment, with real-time

updates and verification of information at each stage,

thereby reducing unnecessary intermediate links and

improving the operational efficiency and adaptability

of the supply chain (Yin,2022).

For example, in the automotive supply chain, data

sharing is achieved between different component

suppliers, vehicle manufacturers, and dealers through

blockchain technology, eliminating information silos,

improving the collaborative efficiency of the supply

chain, and reducing production delays and cost

increases caused by information opacity.

Furthermore, the data traceability function of

blockchain is also of great significance for addressing

issues in the supply chain. Once problems arise, such

as product quality issues or transportation delays,

companies can quickly trace the source of the

problem through blockchain and take timely

measures to correct them. This ability not only helps

companies improve the speed and accuracy of

problem response but also prevents similar problems

from happening again to a certain extent (Feng,2020).

3.3 Augmented Analytics

Augmented analytics play a crucial role in visualizing

global supply chains. By utilizing advanced

algorithms such as machine learning and natural

language processing, this technology can deeply

explore the potential value in supply chain data,

providing enterprises with more accurate and

comprehensive operational insights (Alghamdi,2022;

Prat,2019).

In supply chain management, data is the

foundation of decision-making. Augmented analytics

technology can automatically screen, integrate, and

analyze large amounts of data, simplify the data, and

present clear results. Users can get rid of subjective

opinions and biases, gain true insights, and quickly

and accurately act based on the data, providing

powerful support for enterprise decision-making

(Andriole, 2019).

More importantly, augmented analytics not only

focus on historical data, but also reveals possible

future market changes and supply chain risks through

predictive analysis. By predicting key factors such as

future demand changes and price fluctuations,

companies can prepare in advance, adjust production

and operational strategies to address potential market

challenges.

In practical applications, augmented analytics has

demonstrated its powerful potential. For example, in

terms of inventory management, by analyzing

historical sales data and combining it with market

trends and consumer behavior predictions, companies

can more accurately develop inventory plans to avoid

inventory backlog or stockouts. In terms of risk

management, enhancing analytical techniques can

help companies detect abnormal situations in the

supply chain promptly, such as supplier instability,

transportation delays, etc., and take timely measures

to respond.

3.4 Synergistic Effects of Technological

Paths

When exploring the synergistic effects of

technological paths such as the Internet of Things,

blockchain, and augmented analytics in supply chain

visualization, cannot help but mention how these

technologies complement and promote each other to

jointly promote the improvement of global supply

chain transparency.

As a pioneer in supply chain data collection, IoT

technology captures raw data from each link in real

time, providing basic support for subsequent links.

Blockchain technology ensures the openness,

transparency, and immutability of data, greatly

enhancing its credibility and establishing a

foundation of trust for analysis and application.

Augmented analytics technology utilizes AI to deeply

mine data, predict demand, optimize operations, and

warn of risks. Its insight value highly depends on the

ICEML 2025 - International Conference on E-commerce and Modern Logistics

768

quality and credibility of the data provided by the first

two.

When the three are closely combined, the

synergistic effect becomes apparent: the Internet of

Things provides real-time data sources; Blockchain

ensures its authenticity and security; Enhanced

analysis involves deep processing and prediction

based on trustworthy data, producing high-value

insights. This closed-loop, trustworthy intelligent

analysis system significantly improves the efficiency,

visualization level, and risk response capability of

supply chain management.

4 COMPARISONS OF THE

IMPACT OF REGIONAL

DIGITALIZATION LEVEL ON

SUPPLY CHAIN

PERFORMANCE

4.1 EU Compliance-Oriented Digital

Practices

In the EU region, the digitalization of supply chains

is heavily influenced by compliance orientation.

While pursuing supply chain efficiency and cost

optimization, enterprises must strictly comply with

various regulatory standards, including

environmental protection, safety, and data protection.

To satisfy various compliance requirements,

enterprises are increasingly adopting IoT technology

to enable real-time monitoring across the supply

chain. Through the installation of sensors and RFID

tags, organizations can continuously track the

location, status, and transportation environment of

goods. This capability ensures adherence to relevant

regulatory standards throughout the supply chain

process. Beyond ensuring compliance, real-time

monitoring also enhances supply chain transparency

and responsiveness, thus improving overall supply

chain performance.

Chinese battery company Sunwoda is responding

to the EU's battery regulations by collecting real-time

data on the entire lifecycle of batteries (such as raw

material traceability and carbon emissions) through

IoT sensors and using blockchain technology to

ensure that the data is tamper proof, meeting the EU's

mandatory requirements for supply chain

transparency. At the same time, integrate production,

recycling, and other full chain data to generate

automated compliance reports, avoiding market

access risks; Analyze supply chain bottlenecks and

optimize production scheduling to increase partner

inventory turnover by 15%. This transformation

transforms the initial compliance investment into a

competitive barrier, shortens the order response cycle

by 20%, and supports the expansion of overseas

markets. EU policies force companies to tilt their

digital resources towards building auditable data trust

chains (such as blockchain traceability), converting

compliance costs into long-term market access

advantages (Zhou,2025).

4.2 Efficiency-Oriented Digital

Practices in China

In China, efficiency-oriented digital practices have

become an important trend in supply chain

management. By deeply mining and analyzing the

massive data generated in the supply chain,

enterprises can more accurately understand market

demand, optimize inventory management, improve

logistics paths, and predict future market changes.

This not only helps companies make wiser decisions

but also significantly improves the responsiveness

and flexibility of the supply chain.

Intelligent management is another key to

improving supply chain efficiency. With the help of

IoT, big data, and AI, enterprises can achieve real-

time monitoring and intelligent scheduling of various

links in the supply chain. For example, by using IoT

technology to track goods in real-time, companies can

ensure the safe transportation of goods and respond

promptly to emergencies; By optimizing warehouse

management through artificial intelligence

technology, enterprises can increase inventory

turnover and reduce warehousing costs. At the same

time, in digital practice, these enterprises also focus

on introducing quality management systems and risk

assessment tools to ensure the stability and

sustainability of the supply chain.

Taking Guizhou Fengmao Chemical Logistics

Enterprise as an example, its independently

developed intelligent logistics system (RMS)

embodies the logic of efficiency priority: by

monitoring the transportation status of hazardous

chemicals through on-board sensors, AI dynamically

schedules thousands of vehicles, achieving a 40%

increase in order matching efficiency and a 25%

reduction in empty driving rate. Integrate warehouse

and transportation data into the dashboard operation,

automate financial processes with robots, and save

1.5 million yuan in labor costs annually; A 50%

decrease in accident rate indirectly reduces insurance

expenses. This system increases daily transportation

volume by 30%, achieves a 98% order fulfillment rate,

Research on the Synergistic Effect of Global Supply Chain Visualization and Data Technology

769

and achieves a dual reduction in operating costs and

risks (Wang,2025).

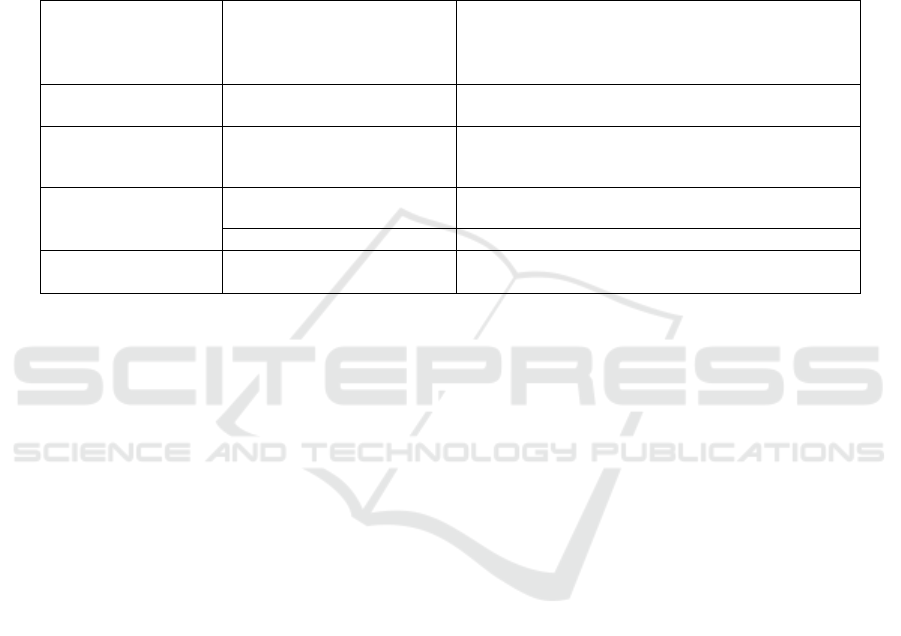

4.3 Comparative Analysis

To clearly present the essential differences in the

impact of digital practices on supply chain

performance under the EU compliance orientation

and China efficiency orientation, this study extracts

key comparative dimensions based on the practices of

Sunwoda (EU compliance case) and Guizhou

Fengmao (China efficiency case), as shown in Table

1.

Table 1. A comparison of the impact of digital Practices on Supply Chain Performance under the EU Compliance Orientation

and China Efficiency Orientation (Zhou,2025; Wang,2025).

Dimension

EU Compliance Orientation

(Xinwangda Case)

China Efficiency Orientation (Case Study of

Fengmao, Guizhou)

Core objective

Meet regulatory audits (such

as batter

y

p

ass

p

orts

)

Reduce transportation/warehousing costs

Technical weight

Blockchain>Internet of

Things>Augmented analytics

Internet of Things=AI>Blockchain

Performance Focus

Avoid the risk of fines/bans Vehicle/warehouse utilization rate

Full chain traceability Order response speed

Benefit cycle

Breaking through long-term

market barriers

Significant decrease in short-term costs

5 CONCLUSIONS

This article systematically studies the collaborative

mechanism between data technology and supply

chain visualization through literature analysis, case

studies, and comparative analysis. Research has

found that global supply chains are facing core

challenges of insufficient transparency: complexity

and globalization lead to frequent information gaps,

data silos, and traceability difficulties. The

technology triangle, consisting of the Internet of

Things, blockchain, and augmented analytics, is

restructuring the supply chain management model -

the Internet of Things enables real-time data

collection throughout the entire chain, blockchain

establishes a decentralized trust network, and

augmented analytics optimizes inventory turnover

through machine learning. The collaborative

application of the three promotes the supply chain to

enter an intelligent closed loop of "perception

analysis decision-making". Based on research

findings, enterprises implementing digital

transformation need to follow three core paths:

Construction of technology integration

architecture: Establish an integrated database of IoT

and blockchain technology, realize real-time data

collection and dynamic monitoring of the entire

supply chain through IoT, and synchronously use

blockchain to build a decentralized and tamper-proof

data sharing network. The architecture needs to be

compatible with 5G, edge computing, and other new

infrastructures, ensure the security and timeliness of

the whole link of data from acquisition, storage

transmission, and provide high-quality data input for

intelligent decision-making.

Deployment of intelligent decision-making

center: Build a data processing platform with

enhanced analysis as the core, integrating technology

modules such as machine learning and natural

language processing. The system needs to have multi-

dimensional data analysis, real-time risk warning, and

adaptive optimization functions, and achieve

intelligent demand forecasting, inventory

optimization, and logistics scheduling through deep

mining of data correlations, forming a closed-loop

decision-making mechanism from data insight to

execution feedback.

Regional adaptation strategy design: Develop

differentiated technology application plans, deploy

data traceability and transparency systems in

compliance-oriented markets, build a digital

governance framework that complies with ESG

standards, strengthen the integration of IoT and

intelligent algorithms in efficiency priority areas, and

develop agile, responsive supply chain models. At the

same time, establish a dynamic learning mechanism

ICEML 2025 - International Conference on E-commerce and Modern Logistics

770

and continuously absorb international advanced

practices for localization transformation.

In future implementation, attention should be paid

to the three core dimensions of technology

aggregation, data liquidity, and organizational agility.

Through systematic engineering such as building a

technology platform, optimizing data governance,

and reshaping business processes, the supply chain

can be continuously upgraded from visualization to

predictability and adjustability. Enterprises should

establish a collaborative mechanism between

technological iteration and organizational change to

enhance supply chain resilience in dynamic balance.

REFERENCES

Alghamdi, N. A., & Al-Baity, H. H., 2022. Augmented

analytics driven by AI: A digital transformation beyond

business intelligence. Sensors, 22(20), 8071.

Andriole, S. J., 2019. Artificial intelligence, machine

learning, and augmented analytics. IT Professional,

21(6), 56-59.

Feng, H., Wang, X., Duan, Y., Zhang, J., & Zhang, X., 2020.

Applying blockchain technology to improve agri-food

traceability: A review of development methods,

benefits and challenges. Journal of Cleaner Production,

260, 121031.

Lin, J., Yin, X., Huang, X., Li, M., Duo, B., & Sun, H., 2025.

TD3 based resource scheduling and energy efficiency

optimization for air mobile edge computing. Internet of

Things Technology, 15(10), 56-62+66.

Prat, N., 2019. Augmented analytics. Business &

Information Systems Engineering, 61, 375-380.

Sun, Z., 2025. Research on risk management strategies in

supply chain management modernization of shopping

malls, (11), 63-65.

Wang, J., & Liang, J., 2025. The application and challenges

of blockchain in various fields of supply chain

management. Logistics Technology, 48(09), 120-123.

Wang, Y., 2025. Guizhou Fengmao: Digitalization

empowers efficient management of transportation

capacity. https://rb.gywb.cn/epaper/gyrb/html/2024-

10/18/content_14378.htm#.

Yin, W., & Ran, W., 2022. Utilizing blockchain technology

to manage the dark and bright sides of supply network

complexity to enhance supply chain sustainability.

Complexity, (1), 7734580.

Zhou, Z., 2025. Sunwoda leads the new revolution of

battery passports and jointly explores the path to

upgrading the core competitiveness of the industry.

https://news.solarbe.com/202505/23/389532.html.

Research on the Synergistic Effect of Global Supply Chain Visualization and Data Technology

771