Research on Green Supply Chain Management in New Energy

Vehicle Industry: A Case Study of BYD

Yuxuan Lou

a

Business College, East China University of Science and Technology, Shanghai, China

Keywords: New Energy Vehicles, Green Supply Chain, BYD, Green Development.

Abstract: Nowadays, the environmental awareness of society as a whole is constantly improving, and the new energy

industry is also developing rapidly. The development and demand for green supply chains in various industries

are increasing daily. To achieve sustainable development, the automotive industry, as a high-energy-

consuming and polluting industry, has gradually changed its products and production methods. Based on the

purpose of green development, it not only embodies the concept of green environmental protection in terms

of energy use, but also undergoes green transformation in the industrial chain and supply chain, aiming to

achieve low-carbon emission reduction and minimize environmental harm as well as full-chain costs. As a

trailblazer in China's new energy vehicle industry, BYD has paved the way for the exploration of green and

sustainable development by making significant contributions. The purpose of this study is to investigate the

construction and management of a green supply chain system in the new energy vehicle industry, using BYD

as an example.

1 INTRODUCTION

Due to the advancement of industry and human

society, the global economic pattern has been deeply

reconstructed. The global climate is undergoing

drastic changes, and resource and environmental

problems are becoming prominent. The climate crisis

cannot be delayed (Liu & Yan, 2025). The

international community is adopting various

sustainable development plans and means to

implement emission reduction and ecological

civilization construction. How to improve the ability

to manage the climate crisis from all dimensions and

achieve green development has also become a key

issue in the meantime. The green supply chain

represents the cross-integration of environmental

consciousness, efficient resource utilization and all

supply chain links. It constitutes a significant

mechanism for realizing green manufacturing and

promoting sustainable development. The goal is to

achieve maximum resource efficiency across the

supply chain ecosystem through systematic

management, all while reducing environmental

impact to the lowest feasible level. The traditional

supply chain system cannot be compared to the green

a

https://orcid.org/0009-0003-3679-6653

supply chain system, which integrates the concept of

the whole life cycle of products and the extension of

producer responsibility with the traditional supply

chain. It uses the huge power of the government,

enterprises and public consumption to drive the green

transformation. The development of green supply

chains has become unstoppable and has become a key

driving force for global supply chains and industrial

chains (Liu & Yan, 2025). As the low-carbon

economy continues to improve, China has set the

Dual Carbon Goals of reaching carbon peaking by

2030 and carbon neutrality by 2060.The CO2

emissions of the automotive industry are significantly

higher than those of other industries, so new energy

vehicles have emerged. Meanwhile, the global energy

system is undergoing a profound revolution and the

electric vehicle industry is gradually occupying an

important strategic position in green development.

The global new energy vehicle industry has

experienced rapid growth in recent years, driven by

factors such as increasing environmental awareness,

technological advancements, and supportive

government policies and is expected to dominate the

automotive market in the coming years. The

technological innovation of eco-friendly vehicles is

Lou, Y.

Research on Green Supply Chain Management in New Energy Vehicle Industry: A Case Study of BYD.

DOI: 10.5220/0013852600004719

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on E-commerce and Modern Logistics (ICEML 2025), pages 705-710

ISBN: 978-989-758-775-7

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

705

constantly advancing. Battery technology is gradually

maturing, and autonomous driving is constantly

developing. Governments around the world are

increasingly investing in the construction of charging

facilities for new energy vehicles. The upstream and

downstream enterprises of the industrial chain

cooperate more closely. Various parts enterprises and

vehicle enterprises develop together. However,

within the supply chain, carbon emissions and

resource waste from logistics operations have become

major environmental concerns. From production to

sales, manufacturing and processing time constitutes

merely 10%, with nearly 90% of the total time

attributed to logistics processes, including

warehousing, transportation, loading/unloading, sub-

packaging, distribution processing, and information

handling. Upstream energy consumption is high, and

carbon emissions are huge, so supply chain emission

reduction actions deserve more research. For the

purpose of achieving sustainable development and

reducing operational costs, the new energy vehicle

(NEV) industry places emphasis on building a green

supply chain system. Consumers are more likely to

select companies that have environmental

responsibility for their product selection due to the

growing awareness of environmental protection

throughout society.

This study seeks to evaluate the current state of

green supply chain management and investigate the

creation of a green supply chain system in the new

energy vehicle market. BYD is the market leader

when it comes to new energy vehicles. Its green

supply chain is integral to the automotive industry

process and its business encompasses the entire

industrial chain of new energy vehicles, with a

complete system and typical characteristics. Taking

BYD as an example, this study examines the current

state of BYD's supply chain and proposes

development suggestions for the advancement of

green supply chain management in NEV.

2 THE STATUS QUO OF GREEN

SUPPLY CHAIN

MANAGEMENT IN NEV

2.1 Industrial Policy Environment

Driven by technological breakthroughs, the NEV

industry has become a trailblazer for innovation in the

global automotive sector, providing new

development opportunities for China to transform

from a Big Country of Imitation to a Strong Country

of Automobile Manufacturing. To promote the early

achievement of the national carbon peak goal, the

Ministry of Industry and Information Technology

(MIIT) issued the Measures for the Parallel

Management of Corporate Average Fuel

Consumption and New Energy Vehicle Credits for

Passenger Vehicles in September 2017. Among these,

the Double Credit carbon emission management

model and national subsidy policies have driven the

transformation of the traditional automotive industry

toward new energy vehicles. China's NEV production

climbed from 84,000 units in 2014 to 9.587 million

units in 2023, indicating significant progress in

China's transition to a green and electrified

automotive industry (Sun, 2025). In the context of

phased NEV development , the upstream raw

material manufacturers of green energy vehicles

account for a huge proportion of carbon emissions

(Yang & Xuan, 2025). According to McKinsey,

emissions from the production of materials for

electric vehicles are expected to account for 45% of

total vehicle life cycle emissions by 2025 and about

85% by 2040 (Yang & Xuan, 2025). Although the

carbon emissions of new energy vehicles relying on

electric vehicles in the process of driving are zero all

carbon emissions are transferred to the production

end (Chen , 2018). Qiao ( Qiao, Zhao, Liu, Jiang &

Han, 2017) et al. compared the carbon emissions of

pure electric vehicles and traditional fuel vehicles in

China from three aspects: different materials,

components and energy consumption, and the results

showed that the carbon emissions of pure electric

vehicles were 15.0~15.2t, about 50% higher than that

of traditional fuel vehicles (Yang & Xuan, 2025).

The Guiding Opinions of the General Office of the

State Council on Actively Promoting Supply Chain

Innovation and Application issued by the General

Office of the State Council in October 2017 shows

that new development is a defining characteristic of

the supply chain concepts , such as innovation,

coordination, green, openness and win-win, thereby

fostering supply chain innovation and growth. This

approach facilitates mutually beneficial collaboration

and synchronized development among upstream and

downstream enterprises in the supply chain, while

promoting the establishment of a green industrial

system covering all links. Green supply chain

management is promoted throughout the product life

cycle and the demonstration is carried out in the

automobile and other industries, which will

strengthen supervision, establish a harmonized green

standard, certification and labeling regime , support

green industries and facilitate the construction and

sustainable development of green supply chain

ICEML 2025 - International Conference on E-commerce and Modern Logistics

706

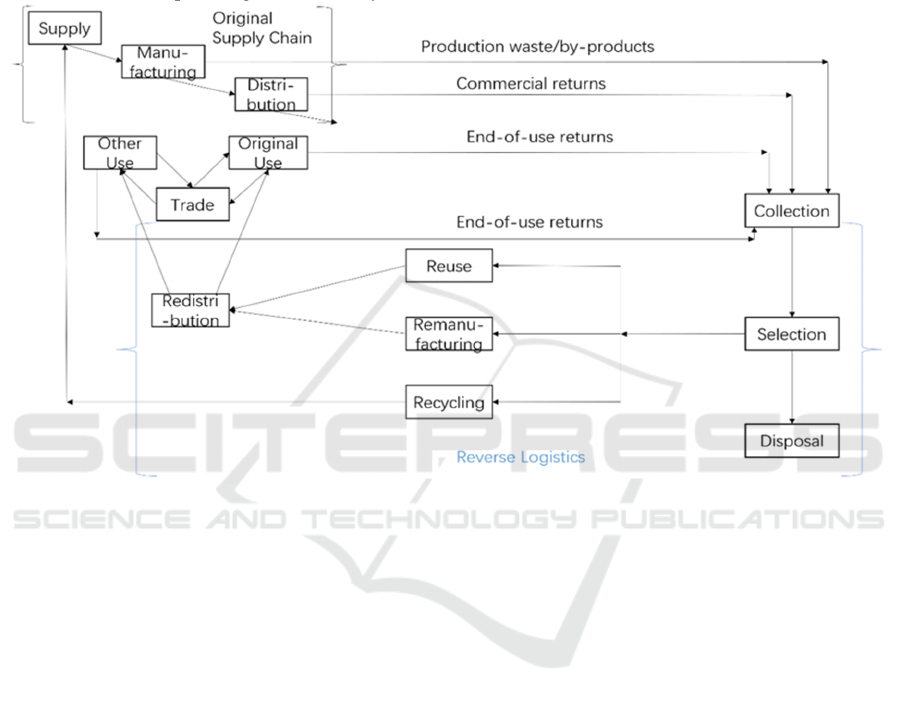

systems. Reverse logistics is encouraged to be

constructed based on the supply chain,as shown

Figure 1. Reverse logistics distinguishes itself from

the traditional supply chain. Its extension part realizes

the improvement of resource utilization in the chain,

focusing on the recycling and reuse of products from

multiple parties in the automobile, electronics and

other industries and optimizing the network layout of

reverse logistics. The supply chain of new energy

vehicles encompasses vehicle manufacturers, parts

producers, suppliers, retailers, and other enterprises.

Across the entire industry, low-carbon innovation in

the NEV supply chain has emerged as an unavoidable

trend and a critical pathway to drive the transition

toward low-carbon emission reduction.

Figure 1: Reverse logistics. (Picture credit: Original)

2.2 Industrial Chain Structure and Key

Links

With regard to the new energy vehicle industry, the

supply chain spans multiple stages, including the

procurement, production, and distribution of critical

components such as power batteries, motor drives,

electronic control units, and body structural parts. In

recent years, the price fluctuations of key raw

materials have been obvious, which has increased the

difficulty of cost control. The inventory turnover of

various production bases needs to be improved and the

planning of logistics and distribution links is not good.

The arising of various issues has led to an increase in

supply chain costs. Therefore, the improvement and

resolution of existing problems is made possible

through the improvement of the supply chain

management system. Unlike the linear flow of

traditional supply chains, reverse logistics introduces

a return-and-recycle mechanism, thus transforming

the supply chain into a closed loop. Based on

traditional supply, production and marketing, the

recyclable materials in the process are re-put into the

industrial chain for use, improving resource

utilization, while reducing carbon emissions and costs.

The Ministry of Industry and Information

Technology's Green Supply Chain Management

Evaluation Requirements pointed out that the green

supply chain will run through the concept of

environmental protection and resource conservation

throughout the whole process of enterprises from

product design to raw material procurement,

production, transportation, storage, sales, use,

scrapping and recycling, so that enterprises can

achieve environmental protection while carrying out

economic activities. Integrated green supply chain

activities include green procurement, logistics, design,

products, packaging, sales, and waste recycling. Its

specific performance in the new energy vehicle

industry chain can be manifested in the supply of

sustainable raw materials and environmentally

friendly parts (green procurement), the substitution of

clean energy for the use of non-renewable energy and

production quality control (green production), low-

carbon transportation modes such as railway

transportation and water transportation as well as

Research on Green Supply Chain Management in New Energy Vehicle Industry: A Case Study of BYD

707

intelligent physical management (green logistics),

power battery recycling and recycling of waste parts

(waste recycling), etc.

3 CASE STUDY OF BYD's GREEN

SUPPLY CHAIN

MANAGEMENT

3.1 Company Profile of BYD

BYD stands as a globally leading integrated

enterprise in the new energy and technology domains.

Originating from the production of rechargeable

batteries, it first ventured into the lithium-ion battery

industry in 1997, and became Nokia's first Chinese

lithium-ion battery supplier in 2002. The business

scope of the BYD brand covers four major fields:

electronics, automobiles, new energy, and rail transit.

With over 30 industrial parks worldwide, it has

completed a strategic deployment across six

continents. BYD takes battery technology as the core

to promote the iteration of new energy vehicles,

energy storage systems and other technologies. It has

rich experience in research and development in the

field of new energy vehicles and strong technical

strength. Its products also have high visibility and

competitiveness in the global market. BYD has made

a series of important achievements in the field of

NEV. The industrial chain layout is strengthened and

R&D technology is continuously developed, BYD

will continue to strive to advance new energy vehicle

technology innovation and foster the sustainable

development of the global NEV industry. It will

continue to be committed to helping achieve the Dual

Carbon goal through zero-emission solutions (Yang,

2024).

Table 1: From January to November 2024,China's New Energy Vehicle Manufacturers will be Ranked TOP10 in Retail Sales

Rank The name of the business Sales volume(10,000) units Year-on-year growth Market share

1 BYD Auto 331.52 37.80% 34.50%

2 Geely Automobile 75.41 94.30% 7.90%

3 Tesla China 57.42 8.80% 6.00%

4 SAIC GM-Wuling 55.71 42.60% 5.80%

5 Changan Automobile 55.03 60.60% 5.70%

6 Ideal car 44.20 35.70% 4.60%

7 Cialis Motors 35.58 379.20% 3.70%

8 Chery Automobile 35.39 252.30% 3.70%

9 GAC Aion 33.08 -24.80% 3.40%

10 Great Wall Motors 25.33 21.30% 2.60%

As can be seen from Table 1, BYD is the new

energy vehicle manufacturer with the highest sales

volume and market share, which has great reference

value for other automobile companies in the same

industry when studying enterprise value. In addition,

BYD has repeatedly received an A ESG rating,

indicating that BYD is doing well in promoting its

sustainable development strategy. Therefore, BYD

was selected as the research object to explore its green

supply chain management (Sun, 2025).

3.2 BYD's Green Supply Chain

Management Strategy

By embedding green supply chain management into

its corporate strategy, BYD has set a benchmark for

the automotive industry to demonstrate how

environmental responsibility can be integrated with

business growth, aiming to achieve sustainable

growth through low-carbon procurement, eco-

friendly production, and responsible distribution. It

has built a low-carbon supply chain system covering

the whole life cycle of R&D, production, logistics and

recycling around the three major contents of

technological innovation, full-chain collaboration

and a standardization system. BYD has established a

carbon data management platform covering suppliers,

following ISO14067 unified data collection standards

and training suppliers to improve data quality to

ensure transparency and traceability of scope

emissions. For the procurement of materials, BYD

gives priority to low-carbon material suppliers,

incorporates environmental protection indicators into

the supplier assessment system and forces upstream

enterprises to upgrade their technology.

ICEML 2025 - International Conference on E-commerce and Modern Logistics

708

3.3 Green Supply Chain Management

Practices

BYD has invested more than 150 billion RMB in

technology R&D and innovation, covering battery

technology, photovoltaic energy storage, intelligent

logistics and other fields, providing underlying

support for carbon reduction in the supply chain.

BYD's independently developed blade battery has

initiated a new form of energy storage. Employing a

lithium -iron-phosphate (LFP) structure, the blade

battery has a milder environmental impact compared

to the common nickel-cobalt-manganese (NMC) and

nickel-cobalt-aluminum (NCA) compositions

utilized by the majority of other EV producers.

Additionally, it achieves a 30% boost in energy

density and a cumulative decrease of 65 million tons

in carbon emissions. LFP batteries also feature higher

recyclability at the end of their lifecycle, enhancing

environmental sustainability while cutting production

costs. (de Sousa, C., Daniel Morais, 2024). However,

the blade battery faces some problems, for example,

the discharge capacity of the blade battery is only

80% of the normal temperature in a low temperature

environment (-20°C), while the ternary lithium

battery can be maintained at 86%. This attenuation of

low-temperature endurance may weaken consumers'

confidence in lithium iron phosphate batteries and

affect the purchase decisions of users in the north.

BYD has deep technology accumulation and a

complete industrial chain layout in the field of

photovoltaic energy storage. Its technology covers

core links such as photovoltaic power generation,

energy storage batteries, energy management systems

(EMS), and intelligent inverters, forming an

integration of photovoltaic and storage. BYD's

photovoltaic module technology uses high-efficiency

monocrystalline silicon PERC cell technology, with a

conversion efficiency of more than 22%, supporting

bifacial power generation design and increasing

power generation per unit area. At the same time,

lightweight flexible components have been

developed, which are suitable for special scenarios

such as industrial and commercial roofs and carports,

reducing installation costs.

BYD set up China's first zero-carbon park

headquarters for an automaker in 2022, which has

become a model for other zero-carbon parks in the

country. At the Pingshan headquarters park, BYD has

achieved 100% utilization of new energy vehicles. In

the park, all production processes utilize its self-

developed pure electric forklifts, pallet trucks,

cleaning vehicles, etc., aiming to realize 100% green

logistics and achieve a cumulative reduction of

245,681.89 tons of carbon dioxide equivalent.

(Zhang, 2023).

3.4 Digital Empowerment

BYD has built a full-chain digital system covering

R&D, production, supply chain, marketing and

service through the model of technology self-research

+ ecological integration to promote the digital

transformation of enterprises to intelligence. To

facilitate digital transformation, the company has

formed a steering committee for digital

transformation and a dedicated office, tasked with

ensuring its efficient advancement and practical

implementation (Zhou & Zhang, 2025). In terms of

technology manufacturing, BYD has realized the

digital upgrade of the whole process, introduced AI

visual inspection in the production process of

batteries and monitored the surface quality of battery

cells in real time with a detection accuracy of 99.99%,

reducing labor costs by 70%. BYD's Pingshan plant

uses an EMS system to visualize water, electricity and

gas consumption data, reducing unit energy

consumption by 18%. In the realm of integrating

photovoltaic (PV) power generation with energy

storage, BYD has linked its PV power generation and

energy storage system to an intelligent microgrid,

boosting the self-sufficiency rate of green electricity

to 45%.

4 CONCLUSIONS

There is a definite positive correlation between

BYD's green supply chain management and its

corporate value, which is not only the practice of

environmental responsibility, but also an important

source of its technical barriers and cost advantages,

establishing a reproducible model of mutual

commercial and social value for the global NEV

sector. Building on the above findings, NEV

companies can benchmark against BYD to

systematically enhance their supply chain

management capabilities. Enterprises are advised to

further strengthen the green supply chain

management standard system, ensuring that green

transformation can be implemented across the entire

supply chain. Enterprises should also take a leading

role in enhancing collaboration with suppliers,

distributors, and other upstream and downstream

enterprises. This involves optimizing procurement

strategies, strengthening the alignment of

environmental protection standards, achieving

efficient resource utilization and waste reduction, and

Research on Green Supply Chain Management in New Energy Vehicle Industry: A Case Study of BYD

709

jointly advancing the sustainable development of

green supply chains. Enterprises should continue to

strengthen the construction and management of the

green information platform, improve the level of

information transparency in the whole chain, create a

green image of enterprises, and enhance corporate

visibility and social recognition. In the long run,

although the company's R&D expenditure and

production costs may be increased in the early stage,

enterprises must reinforce their ability to innovate

independently, continuously improve the technology

level of new energy vehicles, and invest in green

production and logistics. Enterprises should improve

resource utilization, strive to reduce carbon emissions

in the production and transportation process and

maximize the market competitiveness of products by

reducing the environmental impact and optimizing

the production process. Enterprises need to

dynamically track green manufacturing policies and

actively participate in certification to enhance brand

premium. Enterprises should also proactively engage

in international environmental protection cooperation

and exchanges, draw insights from global practices,

and actively compete with international counterparts

to continuously enhance their green development

capabilities.

REFERENCES

Chen, X., 2018. Research on the Environmental Benefits of

Electric Vehicles Based on the Life Cycle of Coal

Power. Wuhan University of Technology.

de Sousa, C., & Morais, D., 2024. Electric vehicle

manufacturer BYD expansion into europe: A case

study. (Order No. 31902934). (3196617178).

Liu, X., & Yan, F., 2025. Accelerate the construction of a

green supply chain system. Party and Government

Cadres Forum, (03), 27-29.

Peng, W., 2025. Research on BYD's supply chain cost

control from the perspective of green development.

Automotive Knowledge, 25(05), 244-246.

Qiao, Q., Zhao, F., Liu, Z., Jiang, S., & Hao, H., 2017.

Cradle-to-gate greenhouse gas emissions of battery

electric and internal combustion engine vehicles in

China. Applied Energy, 204, 1399-1411.

Sun, W., 2025. The impact of green supply chain

management on the value of new energy vehicle

enterprises: A case study of BYD. World Journal of

Management Science, 3(1).

Yang, Q., & Xuan, F., 2025. Research on the development

of closed-loop supply chain of new energy vehicles

under the background of "dual carbon". Modern

Commerce & Trade Industry, (02), 73-76.

Yang, S., 2024. Research on Green Development and

Sustainable Development Strategy of Automobile

Industry: A case study of BYD Co., Ltd. Modern

Industrial Economics and Informatization, 14(08), 187-

188+191.

Zhang, J., 2023-03-23. BYD's ESG secret. Securities

Times, A05.

Zhou, Z., & Zhang, Q., 2025. Digital transformation path

and case study of automobile manufacturing industry:

A case study of BYD group. Times Automobile, (08),

25-27.

ICEML 2025 - International Conference on E-commerce and Modern Logistics

710