Strategies for Production Optimization in Non-Flow Production

Models in the Context of the Digital Economy

Yunchang Liu

a

College of Management and Economics, Tianjin University, Tianjin, China

Keywords: Data-Driven, Smart Manufacturing, Production Optimization, Data Analysis.

Abstract: This underscores the critical importance of enhancing production flexibility and intelligence. The extant

research primarily focuses on assembly line production models and has not extensively explored non-

assembly line production models. The present study focuses on the application of data empowerment to island

assembly models to optimize resource scheduling, production efficiency, and equipment utilization. The

research methods employed encompass theoretical modeling and case analysis. A mixed-integer

programming model is employed to analyze the role of data empowerment, and an intelligent warehouse

system is utilized to validate its effectiveness. A substantial body of research has demonstrated that the

empowerment of data leads to a considerable enhancement in the utilization of equipment and optimizes

inventory management. This approach contributes to the acceleration of production cycles and the

enhancement of process and task completion rates. Furthermore, it facilitates seamless production connections,

thereby enhancing system stability and response speed. Moreover, data empowerment enhances system

flexibility, thus enabling the system to respond more effectively to market fluctuations and uncertainties. This

article demonstrates the importance of data empowerment in manufacturing transformation and the potential

for further exploration of data technology integration in various fields.

1 INTRODUCTION

In recent years, the global manufacturing industry has

undergone a rapid transition from Industry 3.0 to

Industry 4.0. The traditional assembly line production

model plays a significant role in large-scale,

standardized production. It meets market demand for

standardized products with its efficient and scalable

characteristics. However, as consumer demand

diversifies and market uncertainty increases, the

traditional assembly line model is showing its

limitations in adapting to small-batch, multi-variety,

and personalized production. Traditional models

often prove ineffective when it comes to dealing with

market demand fluctuations, customized production,

and rapid resource allocation. Non-assembly line

production models have presented challenges in the

face of traditional assembly line models. Data-driven

technologies have advantages that make them a

potential solution to these problems. These

technologies have been adopted widely in

a

https://orcid.org/0009-0001-6754-1018

manufacturing, and there is immense potential for

them in non-assembly line production. It is critical to

conduct in-depth research on the application of these

technologies in non-assembly line production to drive

the transformation and upgrade of manufacturing and

enhance corporate competitiveness. Therefore, how

to enhance the flexibility and intelligence of

production systems while maintaining high efficiency

is a pressing issue that must be addressed in the

transformation and upgrading of manufacturing.

To address the challenges, data-empowered

technologies are increasingly being recognized as a

key method for enhancing production flexibility and

intelligence. Data-empowered technologies enable

real-time data collection, analysis, and optimization,

thereby improving the adaptive capabilities and

decision-making efficiency of production systems.

This assertion is especially valid in non-assembly line

production models, where the optimization of

resource scheduling, equipment utilization, and

production cycles can effectively address the

Liu, Y.

Strategies for Production Optimization in Non-Flow Production Models in the Context of the Digital Economy.

DOI: 10.5220/0013852200004719

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on E-commerce and Modern Logistics (ICEML 2025), pages 681-690

ISBN: 978-989-758-775-7

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

681

complexity and uncertainty inherent in production

environments (Li,2025). A significant body of

research was conducted by scholars and industry

experts on data-empowered technologies, with a

particular focus on their application in manufacturing.

For instant, the application of data empowerment in

flexible production systems can significantly improve

production response speed and resource utilization

(Zhang,2024). Wu et al. demonstrated through case

studies that data empowerment can help enterprises

quickly adjust production plans in highly uncertain

production environments, thereby maintaining

efficient operations (Wu,2025). However, despite the

myriad valuable explorations provided by extant

research on the application of data empowerment in

production systems, the majority of studies

concentrated on assembly line production models or

specific industries. These studies did not fully

consider the potential of data empowerment in non-

assembly line production models. Under island

assembly models, the question of how to achieve

intelligent and flexible production through data

empowerment remains a relatively under-researched

area. Therefore, filling this research gap and

exploring the specific applications and effects of data-

driven technologies in non-assembly line production

modes holds significant theoretical and practical

significance.

The focus of this study is to explore the

application of data empowerment in non-assembly

line production models, with an emphasis on how it

can enhance the flexibility and intelligence of

production systems through real-time data collection

and optimized decision-making, thereby addressing

issues such as uneven resource allocation, equipment

idling, and prolonged production cycles. The core of

the research lies in integrating the island assembly

mode with data empowerment technology, delving

into the underlying mechanisms of their combination,

and validating their effectiveness through case studies

in actual production settings.

Theoretical modeling can reveal the intrinsic

mechanisms of data empowerment in non-assembly

line production modes from an abstract level, while

case studies can validate the effectiveness and

feasibility of these mechanisms through actual cases.

Therefore, this study comprehensively employs

theoretical modeling and case study methods.

Specifically, first, through theoretical modeling,

based on the characteristics of data empowerment

technology and island assembly mode, this study

proposes the key mechanisms of data empowerment

in non-assembly line production modes. Second, the

specific application effects of data empowerment in

resource scheduling, production efficiency, and

equipment utilization are explored using optimization

tools such as data analysis and mixed integer

programming models in combination with a specific

smart warehouse case.

The study aims to investigate how data

empowerment can optimize non-assembly line

production modes, focusing on addressing key

challenges such as unbalanced resource allocation,

equipment idling, and prolonged production cycles.

By systematically analyzing the core differences

between non-assembly line and traditional assembly

line modes, the study reveals the unique application

value and efficiency-enhancing pathways of data

empowerment in non-standard production scenarios,

and validates its effectiveness in improving

production efficiency and resource utilization

through actual case studies.

2 OVERVIEW OF

NON-ASSEMBLY LINE

PRODUCTION MODELS

2.1 Definition and Characteristics of

Non-Continuous Production Mode

Non-continuous production mode is a production

organization method that does not rely on traditional

assembly lines. It is widely used in scenarios

involving small batches, multiple varieties, and

customized production. This production organization

method, which does not rely on traditional assembly

lines, has the following notable characteristics: It

emphasizes that each unit in the production process

can operate independently, and production steps can

be flexibly arranged according to product

requirements and process characteristics, rather than

following a fixed sequence. Unlike traditional

assembly line production modes, non-assembly line

production modes offer significant advantages in

terms of production flexibility and the ability to

address diverse demands (Tang,2021), particularly in

industries with long production cycles, complex

products, and strong customization requirements,

such as aerospace manufacturing, shipbuilding, and

the production of special equipment.

Under the non-assembly line production model,

production tasks are not strictly constrained by fixed

ICEML 2025 - International Conference on E-commerce and Modern Logistics

682

processes, and production units operate

independently and flexibly, enabling effective

response to production environments characterized

by significant market demand fluctuations, diverse

product types, and strong personalized customization

requirements. This model possesses strong

adaptability and production flexibility (Zhang,2022).

However, this flexibility also presents challenges in

data management and resource allocation. The

complexity of non-assembly line production requires

enterprises to have more precise scheduling and

resource allocation capabilities, especially with the

support of intelligent and automated management

systems. It is necessary to effectively integrate and

optimize the massive amounts of data generated

during the production process to improve production

efficiency and resource utilization (Wang,2022).

Although non-assembly line production faces

greater challenges in resource allocation and

production rhythm control compared to assembly line

production, it demonstrates unique advantages in

handling customized and highly flexible production

tasks. By leveraging data-driven capabilities and

intelligent scheduling systems, non-assembly line

production can meet personalized production

demands while improving production efficiency and

resource utilization, thereby playing an increasingly

important role in modern manufacturing

(Chen,2021).

2.2 Data Characteristics in

Non-Assembly Line Production

Modes

2.2.1 Data Types and Sources

In non-assembly line production modes, intelligent

manufacturing systems rely on wireless local area

network (WLAN) technology to achieve device

interconnection and data collection. System data

primarily includes equipment operation, workstation

status, material flow, and production rhythm,

covering the entire production process.

Data sources primarily include production

information management systems, sensors, and

central control screens. Specific types include

equipment operating status, such as current operation,

shutdown, or fault conditions. Production

environmental data covers key parameters such as

production capacity, air pressure, temperature and

humidity, and noise levels. Information for each

workstation and unit includes location, power status,

material status, and task progress. Additionally,

warehouse location information provides detailed

data on storage status, material categories, and

storage duration. Through comprehensive monitoring

and management of these data, the efficiency and

reliability of the production process can be effectively

improved (Fang,2021).

Managers can use mobile terminals to monitor

workstation and task status in real time, while

electronic bulletin boards provide visual monitoring.

Digital twin technology enables real-time interaction

between the physical status of equipment and virtual

models, supporting digital mapping of the entire

production process and significantly improving

system efficiency and flexibility.

2.2.2 Data Complexity and Correlation

In non-assembly line production modes, the island-

based assembly model achieves decoupling and

flexible reorganization of assembly processes

through modular work units called “islands.” Each

‘island’ is responsible for completing one or a group

of relatively independent assembly operations and

possesses certain autonomous operations and local

optimization capabilities. Under the unified

management of the central scheduling system, the

“islands” collaborate to complete complex assembly

tasks and can dynamically adjust the content and

execution order of operations based on real-time

production status. It is precisely because of this

characteristic of the island assembly model that the

data in the production process is highly complex and

interrelated.

To achieve this flexible and efficient coordination

mechanism, each “island” relies extensively on data-

driven analysis methods during operation. First, by

collecting real-time data on equipment status and

process execution, the system uses correlation

analysis to identify resource conflicts, process

dependencies, and bottlenecks, guiding dynamic

adjustments to assembly rhythms. Second, leveraging

mixed-integer programming (MIP) algorithms, the

system integrates multiple constraints such as process

priorities, resource utilization, and time windows into

a unified scheduling model to optimize production

scheduling strategies across multiple islands,

ensuring globally optimal resource allocation. Third,

based on predictive models (such as time-series-

based order trend forecasting and inventory demand

forecasting), the system can anticipate future

production capacity loads and material requirements,

Strategies for Production Optimization in Non-Flow Production Models in the Context of the Digital Economy

683

enabling proactive adjustments to assembly plans to

mitigate the impact of sudden orders or inventory

shortages.

Additionally, some “islands” utilize edge

computing devices to locally process high-frequency

data such as equipment operational status, sensor

feedback, and work-in-progress information,

reducing reliance on the central system and

accelerating response times. These data analysis and

processing mechanisms support the independent

operation of “islands” and ensure the entire assembly

system maintains high adaptability and robustness in

response to dynamic changes in orders, processes,

and material conditions.

3 APPLICATION OF DATA

EMPOWERMENT IN

NON-ASSEMBLY LINE

PRODUCTION MODELS

3.1 Role and Mechanism of Data

Empowerment

3.1.1 Enhancing Production Efficiency

Through Data Empowerment

In a Smart Warehouse environment, the demand for

resources among different work islands is highly

uncertain, requiring real-time scheduling systems to

effectively resolve potential conflicts during frequent

resource calls. At the same time, the diversity of data

types, such as equipment operating status, material

location information, and process progress,

significantly increases the complexity of the decision-

making process. Faced with constantly changing

order demands, the assembly system must have a

highly flexible, dynamic adaptation capability to

minimize material waste and avoid process delays. To

effectively address these issues and enhance the

dynamic adaptability of assembly systems, data

decomposition has emerged as a critical approach. By

decomposing complex data, heterogeneous data can

be transformed into basic elements that can be

independently identified and analyzed, thereby

providing a reliable foundation for analyzing resource

requirements and optimizing decision-making

processes. Data decomposition helps systems better

identify potential conflicts, optimize resource

scheduling, reduce material waste, and avoid process

delays.

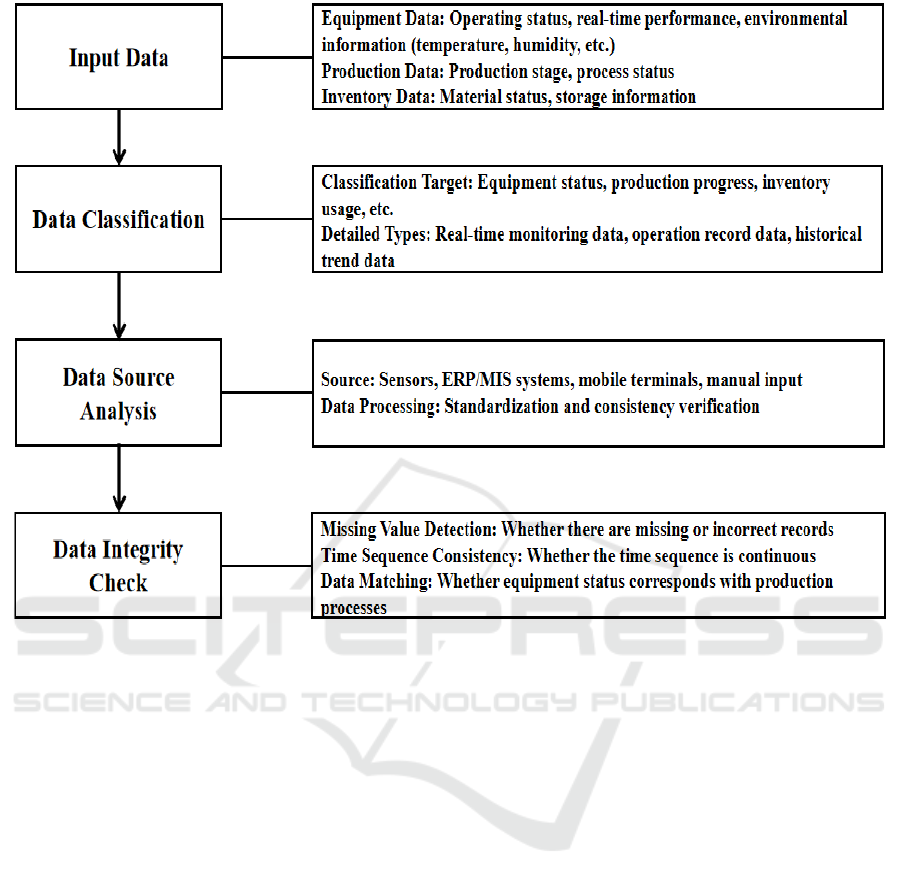

Initially, the data types involved must be

identified and classified. According to the preceding

analysis, the present study encompasses the following

data types. The initial category is equipment data,

encompassing the operational status of equipment,

including power status (i.e., on, off, and malfunction),

as well as real-time production capacity and

environmental parameters such as air pressure,

temperature, and humidity. The second category is

production data, which encompasses production

rhythm, the number of work-in-progress items, and

the input and output quantities of materials. The third

category is job unit data, which includes the real-time

operating status of each job unit, the material

information involved, power consumption, and task

execution progress. The fourth category is inventory

data, which encompasses information regarding

temporary storage location, material status, storage-

related information, and material storage time. The

fifth category is real-time monitoring data, which is

primarily obtained through sensors and central

control screens to gather real-time information on

equipment operation and environmental conditions.

Additionally, it encompasses the execution status of

tasks, which are ascertained through the utilization of

mobile handheld devices.

Following the identification of the data types, it is

imperative to undertake a subsequent analysis of the

data sources to ensure data completeness and

accuracy. Sensors installed on-site enable real-time

monitoring of equipment operating status and

environmental parameters, thereby ensuring the

timeliness and authenticity of the data. The

production information management system provides

comprehensive production data support and statistical

analysis functions, helping to systematically

understand production status. Central control screens

and electronic bulletin boards are utilized to display

the status of equipment and key production indicators

in a centralized manner, thereby enhancing the

efficiency of information transmission. The

implementation of digital twin technology facilitates

the real-time mapping of equipment operation within

a virtual environment, thereby enabling dynamic

simulation and interaction with the status of the

equipment. This, in turn, enhances perception and

control capabilities over the production process. The

overall process is shown in Figure 1.

ICEML 2025 - International Conference on E-commerce and Modern Logistics

684

Figure 1: Data decomposition process (Picture credit: Original)

3.1.2 Data Dimensions and Key

Performance Indicators

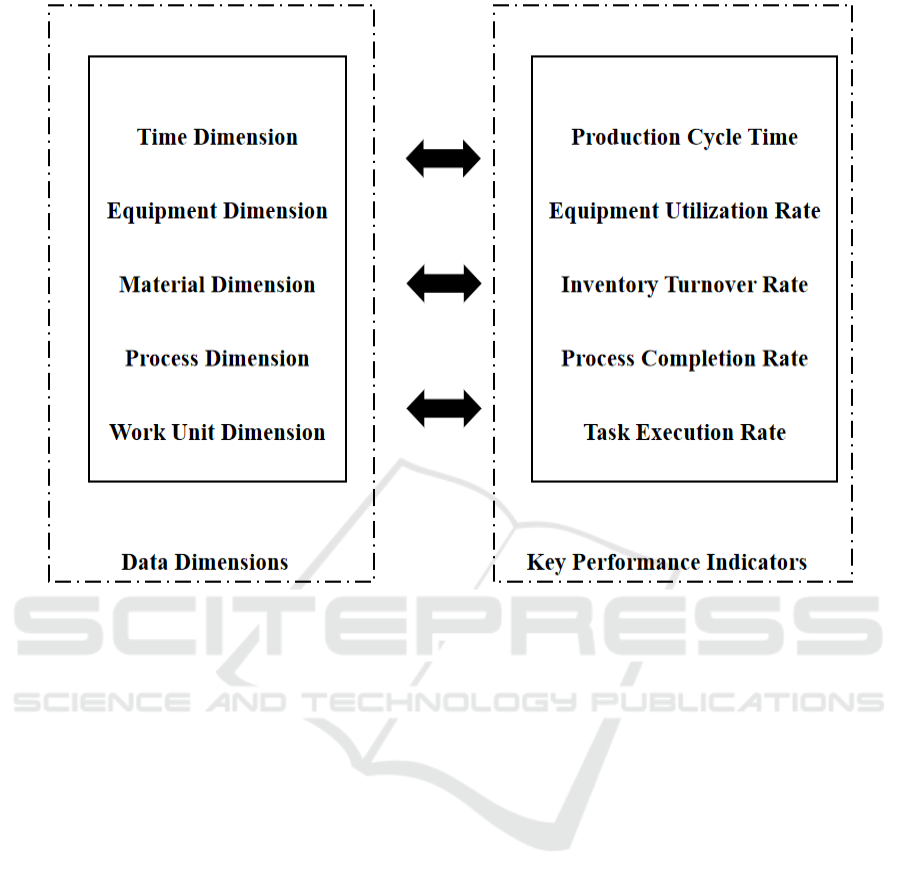

Effective application of data dimensions, and key

performance indicators (KPIs) is critical to improving

production efficiency in the management and

optimization of smart warehouses. Data dimensions

offer a thorough analytical view of the production

process. They include the time dimension, which

identifies time-based patterns to support production

decision-making; the equipment dimension, which

monitors equipment utilization rates and failure

frequencies to mitigate risk; the material dimension,

which ensures material flow and supply align with

production demands to reduce waste (Fang,2021); the

process dimension, which monitors progress to

optimize production workflows; and the work unit

dimension, which coordinates resources between

workstations to enhance flexibility and adaptability.

However, data dimensions alone are insufficient for a

comprehensive assessment of production efficiency.

Thus, key performance indicators (KPIs) have

emerged as essential tools for quantifying the

performance of each dimension. Production cycle

time measures processing time to help identify

bottlenecks and optimize processes. Equipment

utilization assesses usage to help identify issues with

inefficient use. Inventory turnover rate measures

material flow efficiency to avoid inventory buildup.

Process completion rate reflects production task

execution to help adjust plans. Task execution rate

focuses on execution efficiency to ensure the

coordinated operation of all production links.

Comprehensive utilization of data dimensions and

key performance indicators (KPIs) enables

companies to enhance production transparency,

improve flexibility and efficiency, and make more

precise decisions in complex production

environments (Zheng,2022). This optimization

extends to their overall warehouse management

system.

Strategies for Production Optimization in Non-Flow Production Models in the Context of the Digital Economy

685

Figure 2: Data dimension and key performance indicator correspondence chart (Picture credit: Original)

A close intrinsic relationship exists between data

dimensions and key performance indicators. As

shown in Figure 2. Each data dimension provides the

necessary contextual data for calculating KPIs. For

instance, the level of equipment utilization is directly

influenced by the operational status within the

equipment dimension. Frequent equipment

malfunctions result in a significant decrease in

equipment utilization, potentially indicating

underlying resource scheduling issues. Concurrently,

the length of the production cycle time is closely

related to the processing time of each process in the

time dimension, which can reveal bottlenecks in the

production process. Furthermore, the integration of

inventory turnover rate with real-time data from the

material dimension can facilitate the formulation of

rational material replenishment and allocation

strategies by management, thereby enhancing the

overall efficiency of the production system

(Zheng,2022). Through meticulous examination of

these dimensions and indicators, smart warehouses

can attain more efficient resource scheduling and

decision support.

To further enhance the operational efficiency of

smart warehouses, effective correlation analysis is

imperative. The objective of correlation analysis is to

explore the interrelationships between data

dimensions and key indicators, thereby providing a

scientific basis for real-time decision-making

(Ren,2022). Through the implementation of

statistical analysis and machine learning

methodologies, researchers can identify the pivotal

factors influencing production efficiency and discern

potential interdependencies among data elements.

This methodological approach facilitates a

comprehensive understanding of how disparate data

dimensions interact with one another, thereby

providing a foundational framework for optimizing

resource allocation and enhancing production

flexibility.

3.2 Smart Warehouses and Production

Scheduling

3.2.1 Application of Mixed-Integer

Programming Models in Scheduling

Optimization

In the context of a Smart Warehouse environment,

correlation analysis frequently entails the

management of resources, including scheduling and

allocation. For instance, alterations in equipment

ICEML 2025 - International Conference on E-commerce and Modern Logistics

686

status, process priorities, and material inventory can

directly influence the execution of tasks on an

assembly line. MIP is an optimization algorithm

capable of handling models with both integer and

continuous variables, making it highly suitable for

addressing complex scheduling problems in smart

warehouses, particularly those involving resource

conflicts and priority allocation. MIP methods can

represent these variables and their interdependencies

as a set of mathematical constraints and an objective

function. By optimizing these constraints, the

algorithm attains a globally optimal schedule.

3.2.2 Model Definition

Within the MIP model, it is imperative to delineate

the objective function and constraints.

The objective of optimization is to be established,

and it may pertain to the minimization of production

cycle time, inventory costs, or equipment utilization.

In the context of intelligent warehouses, the objective

is to enhance equipment utilization and resource

dynamic adaptability by minimizing completion time

and inventory costs.The parameters are defined as

shown in Table 1 and Table 2.

Table 1: Core Parameter Table

Decision

variables

Meaning

X

ijt

Indicates whether task j is assigned to device i at time t. If so, X

ijt

=1; otherwise,

X

ijt

=0

S

jt

Indicates the start time of task j at time t

C

jt

Indicates the completion time of task j at time t

I

kt

Indicates the quantity of inventory material k at time t

Table 2: Core Parameter Table

Parameters Meaning

T

ij

Processing time of task j on device i

M A sufficiently large constant to ensure task order

D

j

Deadline for task j

P

k

Inventory cost per unit of material k

R

k

Material quantity required for task

K

i

Maximum processing capacity of device i

Objective function: Minimize the total completion

time and inventory cost

minimize Z = C

+P

,

⋅I

(1)

where Cj is the completion time of task j, and

Pk·Ikt is the inventory cost of each material in each

time period.

Resource allocation constraint: Each task can only

be assigned to one device.

X

=1 ∀j,t

(2)

Device capacity constraint: The task load of each

device cannot exceed its processing capacity.

X

≤

K

∀i,t

(3

)

Task start and end time constraints:

S

+T

⋅X

≤C

∀i,j,t

(4

)

Process priority constraint: Task j can only start

after task k is completed.

S

≥C

+M⋅1−X

∀i,j ≠ k,t

(5

)

Inventory update constraint: The inventory level

at each time period is updated based on production

and consumption.

I

=I

+R

⋅X

−D

∀k,t

(6

)

Strategies for Production Optimization in Non-Flow Production Models in the Context of the Digital Economy

687

3.3 Model Results Analysis

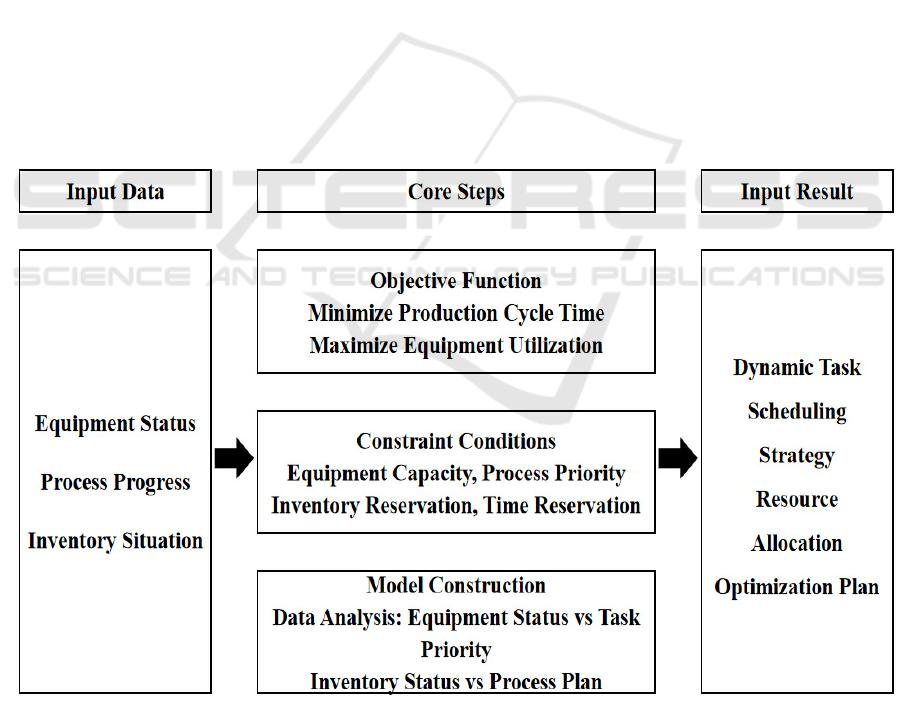

3.3.1 Results Interpretation

Following the resolution of the model, a systematic

analysis was conducted, with a focus on the specific

task allocation and the operational status of the

equipment associated with each task. A comparison

of the model solution results with actual production

data allows for an effective evaluation of the model's

performance and its applicability in practical

applications. This analysis suggests that managers

can adjust their scheduling strategies promptly,

thereby enhancing resource allocation efficiency.

Specifically, the MIP model optimized the

allocation of equipment and tasks, thereby effectively

reducing equipment idle time in a non-flow

production mode. The model demonstrated a

substantial enhancement in equipment utilization,

leading to a notable reduction in resource waste

stemming from equipment idling (Ni, 2022). This

improvement was achieved through the dynamic

allocation of tasks to the most appropriate equipment,

thereby optimizing resource usage. Furthermore, the

model meticulously scheduled the commencement

and conclusion of each production task, ensuring that

tasks were executed by their relative priorities. This

approach not only reduced waiting times within the

production process but also enhanced the production

system's capacity to adapt to evolving market

demands. Consequently, this methodology

contributed to a reduction in the overall production

cycle and an improvement in delivery efficiency,

Figure 3 shows the correlation analysis process.

In the context of material management, the MIP

model can dynamically adjust real-time material

demands and inventory status, thereby reducing

inventory backlogs. The model can automatically

identify and determine the optimal replenishment

timing and quantity for materials. This capability

effectively reduces unnecessary inventory costs and

further optimizes material management (Huang,

2019). In the context of island production models, the

implementation of the MIP model enables the system

to achieve efficient coordination between production

units, thereby avoiding resource conflicts and

bottlenecks. This coordination mechanism has been

demonstrated to enhance overall production

efficiency while ensuring production flexibility.

Figure 3: Correlation analysis process (Picture credit: Original)

ICEML 2025 - International Conference on E-commerce and Modern Logistics

688

3.3.2 Application Analysis

The MIP model exhibits considerable adaptability in

responding to fluctuations in production demand,

particularly in cases of variable order demand. The

model's capacity for expeditious reallocation of

resources is pivotal in ensuring the prioritized

execution of critical tasks, a feature that is particularly

salient in contexts characterized by the fulfillment of

bespoke and limited production volumes. The

model's scheduling optimization has been shown to

improve the production system's responsiveness and

adaptability to market changes, enhancing its

flexibility and efficiency.

Furthermore, the MIP model provides accurate

decision support by leveraging real-time data to

optimize production planning and scheduling

decisions. The integration of data analysis enables

management to make more precise decisions,

informed by real-time feedback. This approach

effectively mitigates production deviations and

reduces resource wastage, thereby enhancing overall

production efficiency(Ren,2022). This process

exemplifies the merits of data empowerment in

decision-making, thereby enhancing the scientific

rigor and efficiency of production scheduling.

The MIP model has been demonstrated to play a

dual role in terms of quality and cost improvement.

The model's efficacy is demonstrated by its ability to

optimize equipment utilization and inventory

management, thereby reducing inventory costs while

enhancing quality control levels. The model

incorporates a priority allocation function for critical

equipment and materials, thereby averting quality

issues stemming from material shortages or

equipment failures and ensuring effective cost control

during production. This optimization not only ensures

product quality but also further improves production

economics.

The MIP model establishes a sustainable feedback

optimization mechanism. The model provides data

support for future scheduling optimization through

continuous feedback on execution results, thereby

forming a cycle of continuous improvement. The

production management team can use this feedback

to continuously adjust resource allocation plans,

thereby improving the adaptability and scalability of

the model. This mechanism enables the MIP model to

continuously optimize in a dynamic production

environment, providing enterprises with long-term

production management advantages.

4 CONCLUSIONS

The primary conclusions of this study emphasize the

substantial influence of data empowerment on

numerous pivotal indicators within non-assembly line

production models. Firstly, the enhancement in

equipment utilization is indicative of the optimization

of resource scheduling that is driven by data. The

implementation of real-time data collection and

intelligent task allocation is instrumental in

enhancing the operational efficiency of production

equipment. This, in turn, leads to a reduction in

equipment idle time and ensures the optimal

utilization of overall production capacity. Secondly,

the enhancement in inventory turnover rate

substantiates the efficacy of data empowerment in

inventory management. Conventional inventory

management is characterized by substantial expenses

and protracted lead times. Conversely, data

empowerment employs dynamic integration of

production, inventory, and order data to optimize

replenishment strategies and storage routes, thereby

effectively mitigating inventory buildup and shortage

risks. About the production cycle time, the

empowerment of data results in a reduction of said

cycle through the optimization of task allocation and

resource configuration. Intelligent algorithms

circumvent traditional production issues, such as

process queuing and resource conflicts, by

prioritizing processes and considering resource

constraints. This renders the production process more

efficient and seamless. Furthermore, the

enhancement in process completion and task

execution rates underscores the pivotal role of data

empowerment in facilitating effective production

coordination. The real-time dissemination of pivotal

production data facilitates seamless coordination

among processes, mitigates production delays, and

enhances the stability of the production rhythm.

In summary, the application of data empowerment

in non-assembly line production models can

effectively improve key production indicators,

optimize resource allocation, enhance production

efficiency, and strengthen system flexibility and

responsiveness. Enterprises can enhance their

responsiveness to market demand changes and

production environment uncertainties by leveraging

accurate data analysis, intelligent scheduling, and

resource optimization. This, in turn, can lead to

improvements in overall competitiveness. Data

empowerment has been shown to improve production

efficiency and provide enterprises with more efficient

decision-making support and operational capabilities

in a dynamic market environment. Consequently, this

Strategies for Production Optimization in Non-Flow Production Models in the Context of the Digital Economy

689

can drive the non-assembly line production model

toward greater efficiency and flexibility.

The findings of this study offer novel insights for

future research, particularly in the domains of

production process optimization and intelligent

scheduling. The findings suggest that data

empowerment has a substantial impact on equipment

utilization, inventory management, and production

cycle acceleration. This prompts numerous avenues

for future research, particularly about the

enhancement of system intelligence, the

augmentation of data accuracy and real-time

performance, and the adaptation to more intricate and

evolving production environments.

Subsequent research endeavors should

concentrate on investigating methodologies for the

dissemination of data-empowered technologies

across diverse industry sectors, with a particular

emphasis on those domains characterized by intricate

resource scheduling and considerable demand

fluctuations. Furthermore, cross-industry

applications and system integration will be pivotal in

the development of data-empowered technologies.

Research must explore the profound integration of

data technologies with conventional manufacturing

industries and the innovative application of intelligent

algorithms.

REFERENCES

Chen, L., & Wu, M., 2021. Design of an intelligent

workshop quality data integration and visualization

analysis platform. Computer-Integrated Manufacturing

Systems, 27(06), 1641-1649.

Fang, W., Guo, Y., Huang, S., Liu, D., Cui, S., Liao, W., &

Hong, D., 2021. Research on intelligent control

methods for production processes in discrete

manufacturing workshops driven by big data.

Transactions of the Chinese Society of Mechanical

Engineering, 57(20), 277-291.

Huang, S., Guo, Y., Cha, S., Fang, W., & Wang, F., 2019.

Research and application of IoT in discrete

manufacturing workshops and its key technologies.

Computer-Integrated Manufacturing Systems, 25(02),

284-302.

Li, X., Tong, Y., & Cao, F., 2025. Enterprise digital

transformation and participation in global value chains.

Journal of Management Engineering, 39(01), 15-31.

Ni, Y., Cai, G., Zhao, Y., & Wang, Z., 2022. A pricing

model for a one-stop service platform for technology

transactions under dual objectives and multiple

stakeholders. Journal of Industrial Engineering and

Management, 27(03), 24-32.

Ren, L., Jia, Z., Lai, L., Zhou, L., Zhang, L., & Li, B., 2022.

Data-driven industrial intelligence: Current status and

future prospects. Computer-Integrated Manufacturing

Systems, 28(07), 1913-1939.

Tang, J., Ren, Y., Yu, Y., & Han, Y., 2021. Comparison and

simulation analysis of SERU production and classic

production methods. Nankai Management Review,

24(02), 126-136.

Wang, M., Wang, L., Xu, X., & Qin, Y., 2022. Real-time

scheduling model for high-speed trains under severe

initial delays and interval speed limits. Journal of

Railway Engineering, 44(01), 8-16.

Wu, L., & Zhen, L., 2025. Research on mathematical

programming algorithms for optimizing production

operations management. Chinese Journal of

Management Science, 33(01), 345-355.

Zhang, C., & You, M., 2022. A supply chain coordination

model based on credit payment under retailers' fairness

preferences. Industrial Engineering and Management,

27(03), 44-53.

Zhang, M., & Zhao, H., 2024. A study on the mechanism of

industrial internet empowering enterprise green

development from a value chain perspective. Science

and Industry, 24(06), 1-9.

Zheng, S., & Sha, J., 2022. Research on container allocation

and container handling coordination optimization

considering synchronous entry and exit of containers.

Industrial Engineering and Management, 27(03), 33-43.

ICEML 2025 - International Conference on E-commerce and Modern Logistics

690