Research on the Impact of Digital Transformation on the Operational

Performance of Contemporary Amperex Technology Co. Limited

Siyu Tian

a

School of Accounting, Nanjing University of Finance and Economics, 210023, Xianlin Street, Nanjing, China

Keywords: Digital Transformation, Corporate Performance, Business Operations.

Abstract: In the context of the accelerated development of the global digital economy, digital transformation has become

the core driving force for enterprises to improve their business performance. This paper takes Contemporary

Amperex Technology Co. Limited (CATL), a leading enterprise in the power battery industry, as an example,

and systematically analyzes its digital transformation path and its impact on business performance. The study

shows that CATL has significantly optimized production processes and management efficiency, reduced

operating costs, and enhanced product innovation capabilities and market competitiveness through a phased

digital transformation strategy, including system upgrades, Internet of Everything, data empowerment, and

AI assistance. In addition, digital transformation has strengthened its global industry leadership position by

strengthening supply chain management and expanding into international markets. This study provides

theoretical and practical enlightenment for manufacturing enterprises to achieve high-quality development

through digitalization, emphasizing the need to promote transformation in stages based on enterprise

capabilities, and focusing on technological innovation and ecological synergy.

1 INTRODUCTION

In the context of a new round of global scientific and

technological revolution and industrial

transformation, digital transformation is reshaping

the competitive landscape and value creation model

of enterprises. Digital transformation is a systematic

change in which enterprises reshape business

processes and reconstruct value systems through the

integration of digital tools and intelligent

technologies, and it is the operation of enterprises to

apply a new generation of information and

communication technology to various fields of

business. Digital transformation is a comprehensive

project, and transformation covers multiple levels and

a wide range of dimensions (Yan, 2024). Through

digital transformation, enterprises can capture market

demand in real time, optimize business structure, and

improve resource allocation efficiency. This

transformation not only improves the information

integration ability of enterprises, but also realizes

efficient innovation through Internet analysis, and

builds sustainable competitive barriers in the era of

digital economy. China's 14th Five-Year Plan clearly

a

https://orcid.org/0009-0001-1504-1193

puts forward the strategic orientation of "promoting

the deep integration of digital technology and the real

economy", and the digital transformation of

enterprises has changed from an "optional" to a

"must-have" for survival and development. As a core

player in the global new energy industry chain,

Contemporary Amperex Technology Co. Limited

(CATL) has ranked first in the global market share of

power batteries for six consecutive years (37% in

2023) with the digital transformation path of "system

upgrade, Internet of Everything, data empowerment,

and AI assistance", and its development trajectory

provides a valuable research sample for exploring the

digital transformation of the new energy

manufacturing industry.

By building the world's first benchmark factory

for battery intelligent manufacturing (lighthouse

factory) and building a full-life cycle digital platform

covering R&D, production and recycling, CATL

achieved a countercyclical myth of a 9.3% drop in

revenue and a 17% increase in net profit during the

price war in the new energy industry. In the context

of digital transformation, this paper combines the

development of CATL, extracts the underlying logic

234

Tian, S.

Research on the Impact of Digital Transformation on the Operational Performance of Contemporary Amperex Technology Co. Limited.

DOI: 10.5220/0013842100004719

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on E-commerce and Modern Logistics (ICEML 2025), pages 234-239

ISBN: 978-989-758-775-7

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

and practical experience of CATL's digital

transformation through the study of its digital

evolution path, and studies the impact of the value

created by digital transformation on the business

performance of enterprises, which is of great practical

significance for promoting the high-quality

development of the new energy industry and

accelerating the process of new industrialization.

2 THE MOTIVATION AND

PROCESS OF CATL'S DIGITAL

TRANSFORMATION

2.1 Overview of the New Energy

Battery Industry

In the context of global energy transition, the new

energy battery industry has become the core track to

support the development of green economy. As an

emerging industry, the new energy vehicle industry

has entered a period of rapid growth in line with the

development goals of low-carbon emission reduction

in the new era (Hu, 2024). According to a report by

the International Energy Agency (IEA), global

electric vehicle sales are expected to reach 40 million

units by 2030, which will greatly boost battery

demand. The Ministry of Industry and Information

Technology of the People's Republic of China, the

National Development and Reform Commission, the

Ministry of Science and Technology, and the

Ministry of Finance jointly issued the Action Plan for

Promoting the Development of the Automotive

Power Battery Industry, aiming to accelerate the

development ability and level of China's automotive

power battery industry and promote the healthy and

sustainable development of the new energy battery

industry.

At present, the iteration of new energy battery

technology has achieved breakthroughs in many

aspects, such as the mass production of high-nickel

ternary cathode materials with a monomer energy

density of 300Wh/kg; CTP/CTC integrated

technology improves system energy efficiency by

15%; The solid-state battery has completed the

laboratory stage verification and is expected to enter

the mass production stage in the next 2-3 years.

Sodium-ion batteries have started the

industrialization process with resource advantages,

and initially built low-cost energy storage solutions.

2.2 Introduction to CATL

CATL is the world's leading supplier of new energy

batteries, founded in December 2011 in Ningde,

Fujian Province, mainly engaged in the R&D and

manufacturing of power batteries and energy storage

systems. In 2018, CATL successfully completed an

initial public offering of A-shares and listed on the

Shenzhen Stock Exchange (Gu, 2024). Since 2019,

CATL has been shortlisted as a "Lighthouse Factory"

by the World Economic Forum three times (Zhang

and Zhai, 2024). The company has been the global

champion in power battery loading for six

consecutive years, with a market share of more than

35% in 2023, and its customers include Tesla, BMW,

Mercedes-Benz and other international car

companies. Its self-developed CTP3.0 technology,

sodium-ion batteries and Kirin batteries and other

innovative products have promoted the energy

density of the battery system to exceed 250Wh/kg. By

the end of 2023, CATL has deployed 13 production

bases around the world, with an annual production

capacity of over 400GWh, and has built a closed-loop

industrial chain for lithium resource development and

battery recycling. The company's R&D investment

accounts for more than 20 billion yuan, holds more

than 10,000 patents, and leads the formulation of a

number of international standards, providing core

technical support for the global energy transition.

2.3 CATL's Digital Transformation

Drivers

In terms of green development and the promotion of

carbon peaking and carbon neutrality, digitalization

has become the key path to achieve green innovation

due to the current social situation of "carbon peak and

carbon neutrality". With the release of the dual carbon

policy, CATL, which is in the process of laying out

its digital transformation strategy, has continuously

deepened its digitalization process, reducing energy

consumption and optimizing resource utilization

through intelligent production (Xia, 2024).

From the perspective of industry competition and

market demand, the 2012 "Energy-saving and New

Energy Vehicle Industry Development Plan"

promoted the outbreak of the domestic new energy

vehicle market, and in the face of competition from

international competitors such as Panasonic and LG,

CATL, as a core supplier, needs to consolidate its

technological advantages through digital

transformation. In addition, after cooperating with car

companies such as BMW Brilliance, CATL's order

volume has surged, and it urgently needs digital

means to meet the challenges of large-scale

production and improve production capacity and

efficiency.

Research on the Impact of Digital Transformation on the Operational Performance of Contemporary Amperex Technology Co. Limited

235

In terms of production and equipment

collaboration requirements, because power batteries

are discrete manufacturing, the production process

involves multiple links, long processes and high

standardization difficulties, so it is difficult for the

traditional management mode to meet the

requirements of high-precision quality inspection.

For example, with a large amount of data on a single

battery and low detection efficiency, enterprises

urgently need to optimize the production process and

reduce the defect rate through technologies such as

the Internet of Things and big data. In addition, after

CATL introduced automation equipment in the early

days, it faced the problem of insufficient

compatibility between equipment, and needed to

realize the whole process through a unified platform

(such as MES system) to improve production

efficiency.

From the perspective of the needs of strategic

transformation, digital transformation aims to shift

from "scale expansion" to "quality growth", and build

core competitiveness through technology

empowerment. CATL uses the "cloud-edge-end" AI

defect detection technology to reduce the defect rate

and significantly improve product reliability.

2.4 CATL's Digital Transformation

Process

As a leading enterprise in the global power battery

industry, CATL's digital transformation process is a

model for upgrading traditional manufacturing to

intelligent manufacturing. Its transformation process

can be divided into four key stages, and gradually

realized the leap from "manufacturing" to "intelligent

manufacturing".

2.4.1 System Upgrade stage: Build a Digital

Management Base

In 2014, CATL launched an in-depth cooperation

with SAP, a global enterprise management software

giant, to officially launch its digital transformation.

Through the introduction of core systems such as

enterprise resource planning (ERP), supplier

relationship management (SRM) and customer

relationship management (CRM), the company has

built an integrated information management platform

with ERP as the core, covering three levels: core

business, business support and functional

management (Wang, 2022). This system realizes the

standardization and efficient collaboration of

business processes, such as order management,

supply chain collaboration and comprehensive

informatization of financial accounting. The

application of the SAP system not only improves the

efficiency of internal operations, but also lays the

foundation for subsequent data-driven decision-

making. At this stage, CATL integrated the upstream

and downstream resources of the industrial chain

through the ERP system, promoted the overall

digitalization process of the industry, optimized the

procurement process through data exchange with

suppliers, and enhanced the customer demand

response capability through the CRM system.

2.4.2 Internet of Everything Stage: The

Internet of Things Empowers the

Whole Production Process

In 2015, CATL ranked third in the world in terms of

installed power battery capacity, and began to

comprehensively promote the application of Internet

of Things (IoT) technology. In this stage, millions of

IoT terminal devices are deployed to cover more than

3,600 quality inspection points, and production data

is collected in real time and transmitted to the central

control system to achieve accurate control of the

entire production process. At the same time, the

Manufacturing Execution System (MES) was

introduced to integrate elements such as production

planning, equipment status, and energy consumption,

such as real-time monitoring of equipment failures

and early warnings to reduce downtime. In addition,

through PLM software, CATL has achieved

comprehensive and accurate control of product

design data, process data, manufacturing data, etc.

shortening the product iteration cycle and improving

market response speed (Wu, 2024). The technological

breakthrough at this stage has significantly improved

production efficiency and provided technical support

for the expansion of the global market.

2.4.3 Data Empowerment Stage: Big Data

Drives Decision Optimization

In 2017, CATL's installed power battery capacity

surpassed Panasonic and became the world's first.

With the explosion of data volumes, the company

began to build a comprehensive big data platform and

worked with many enterprises to solve the bottleneck

problem of data storage and analysis. By cooperating

with e Cloud to build an IoT data analysis platform, it

opens up the data channel between remote and local

data centers to achieve secure data transmission and

real-time analysis; At the same time, it cooperated

with Intel to upgrade the MES system and use high-

performance processor technology to increase the

processing power by 50%, supporting the expansion

ICEML 2025 - International Conference on E-commerce and Modern Logistics

236

of production capacity under the surge in market

demand. At this stage, the company was able to

reduce the product defect rate by 15% by analyzing

production data to optimize the process, such as

predicting equipment failures and adjusting

production parameters. This transformation marks

CATL's shift from "experience-driven" to "data-

driven", laying the data foundation for smart

manufacturing.

2.4.4 AI-Assisted Stage: Intelligent

Production is Fully Implemented

After being rated as an "Intelligent Manufacturing

Benchmarking Enterprise" by the Ministry of

Industry and Information Technology in 2019, CATL

began to apply artificial intelligence technology on a

large scale. In the field of quality control, CATL

worked with Intel to develop an AI battery defect

detection solution, combining computer vision and

deep learning technology to improve the accuracy of

defect detection to 99.9%; In terms of production

optimization, machine learning algorithms were

introduced to adjust parameters in real time to predict

equipment maintenance needs to reduce unplanned

downtime by 20%; At the same time, AGV unmanned

transport vehicles and intelligent warehousing

systems are deployed to increase inventory turnover

by 40% and reduce logistics costs by 25%. As of 2024,

among the company's 13 production bases around the

world, the German plant has obtained Volkswagen

battery cell certification with its intelligent

production line, and its overseas market share has

exceeded 32.7%. At present, CATL is deepening the

layout of AI and data platforms through the

establishment of Times Qiji Technology, and

continues to lead the intelligent upgrading of the new

energy industry.

3 THE IMPACT OF CATL'S

DIGITAL TRANSFORMATION

ON BUSINESS PERFORMANCE

3.1 Digital Transformation Promotes

Technology R&D and Profitability

Improvement

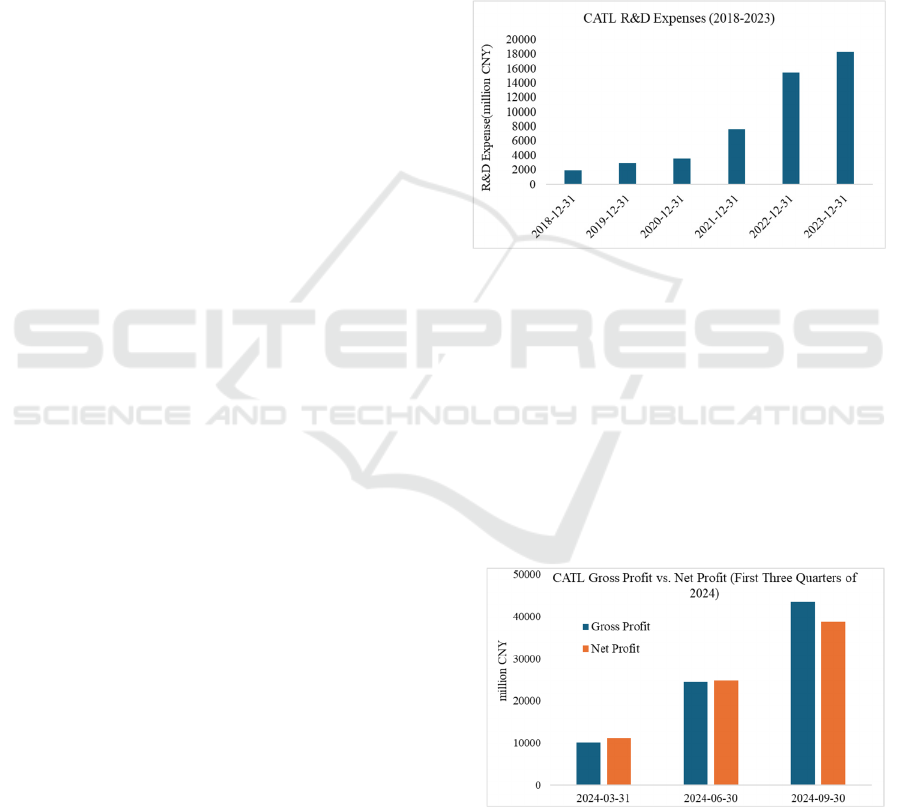

As shown in Figure 1, CATL has continued to

increase R&D investment since 2015, with R&D

expenses of nearly 8.6 billion yuan in the first half of

2024 and a cumulative number of more than 36,000

patents. The high R&D investment has been

translated into technological advantages, such as the

Shenxing Plus battery (the world's first lithium iron

phosphate battery with a range of 1000km and 4C

supercharging) and Kirin high-power batteries, which

will be launched in 2024, which have significantly

improved the competitiveness of products. CATL's

technological advantages are directly reflected in the

gross profit margin: the gross profit margin reached

31.17% in the third quarter of 2024, an increase of

4.53 percentage points quarter-on-quarter. This

highlights the profitability of technology R&D

brought about by digital transformation.

Figure 1: CATL R&D expenses from 2018 to 2023 (Photo

credit: Original).

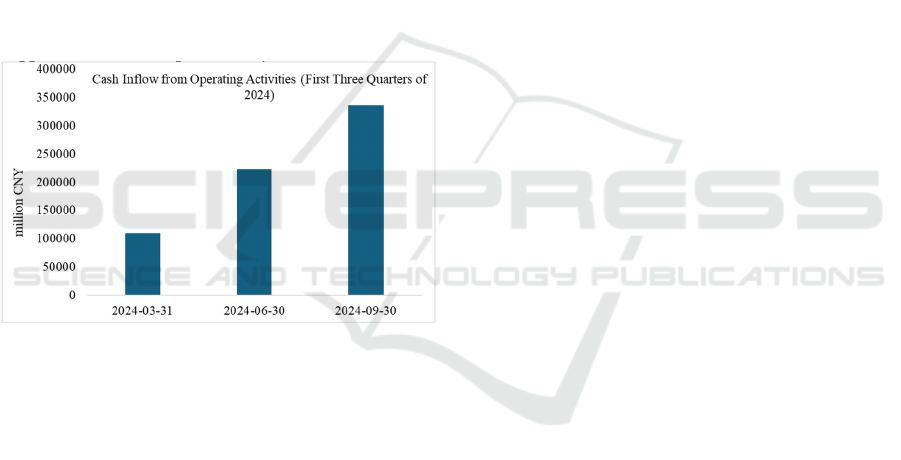

Although the revenue in 2024 is expected to

decline by 8.71%-11.2% year-on-year due to product

price adjustment due to the decline in lithium

carbonate prices, through cost optimization, product

upgrades and market share expansion, the double

growth of gross profit and net profit as shown in

Figure 2 has been achieved, and net profit is expected

to increase by 11.06%-20.12% against the trend to

reach 49 billion to 53 billion yuan (Global Network,

2025).

Figure 2: CATL gross profit vs. net profit (first three

quarters of 2024) (Photo credit: Original).

Research on the Impact of Digital Transformation on the Operational Performance of Contemporary Amperex Technology Co. Limited

237

3.2 Digital Transformation Optimizes

Costs and Operational Efficiency

Through intelligent production and supply chain

management, CATL has achieved cost reduction and

efficiency increase. For example, as shown in Figure

3, the operating cash flow in the first three quarters of

2024 reached 66.977 billion yuan, the net profit was

36.001 billion yuan, a year-on-year increase of

15.59%, and the ratio of free cash flow to revenue was

5.43% on average, showing the optimization effect of

digital transformation on cash flow. In addition, the

company will integrate its global production capacity

layout through a digital platform, add a new joint

venture plant in Spain in Europe in 2024, and deepen

cooperation with Stellantis and other car companies,

driving the proportion of overseas revenue to increase

to more than 35%. The high gross margin in overseas

markets (about 5 percentage points higher than that in

the domestic market in the first half of 2024) further

supported the overall profitability.

Figure 3: Cash inflow from operating activities (first three

quarters of 2024) (Photo credit: Original).

3.3 Digital Transformation

Consolidates the Market

Competitiveness and Share of

Enterprises

Digital transformation has helped CATL stay ahead

of the fierce competition. In 2024, its domestic power

battery market share will reach 45.08%, an increase

of 1.89 percentage points year-on-year, and the

shipment of energy storage batteries will rank first in

the world for three consecutive years. Through the

Lithium Resource Service (LRS) authorization model

and battery chassis integration (CTC) technology, the

company not only reduces its dependence on

upstream resources, but also expands the energy

storage and commercial vehicle markets, and in 2024,

the commercial vehicle brand "Tianxing" will cover

the logistics and public transportation fields, further

expanding the application scenarios. In addition,

digitally-driven customer collaboration, such as

battery swap cooperation with FAW and SAIC,

strengthened customer stickiness, driving the

installed volume to increase by 28.6% year-on-year

to 246.01GWh (Electric Zhijia, 2025).

3.4 Digital Transformation Promotes

Enterprise Risk Resilience and

Long-Term Growth Potential

In the face of cyclical fluctuations in the industry

(such as lithium carbonate price fluctuations in 2023

and 2024), CATL optimized inventory management

and procurement strategies through digital

forecasting models, and provided for impairment

losses of RMB7.543 billion in Q3 2024 to divest

inefficient assets (Sina Finance, 2024), while

improving capacity utilization and reducing unit

depreciation costs. In the long run, the company's

integrated ecology of "photovoltaic storage, charging

and swapping" and overseas energy storage projects

(such as the RTC project in the United Arab Emirates)

will benefit from the global energy transition, and the

net profit is expected to exceed 60 billion yuan in

2025.

4 CONCLUSIONS

This study finds that CATL is evolving from a

"battery manufacturer" to a "new energy solution

service provider" by continuously deepening its

digital transformation, and its transformation path

provides a replicable Chinese solution for the

digitalization of the global manufacturing industry.

CATL's digital transformation is the result of policy

dividends, market expansion, technological

bottleneck breakthroughs, and internal efficiency

demands, laying the cornerstone for CATL to realize

the leap from "manufacturing" to "intelligent

manufacturing". With technology research and

development as the core, the digital transformation

has realized the transformation from "scale

expansion" to "quality growth" through intelligent

production, global layout and ecological chain

integration. Although short-term revenue fluctuates

due to the impact of raw material prices, net profit

continued to grow, gross profit margin increased and

market share was stable, confirming the far-reaching

impact of digital transformation on CATL's operating

performance. This study can provide guidance for

ICEML 2025 - International Conference on E-commerce and Modern Logistics

238

China's related industries to break through the

transformation dilemma.

Since this study does not conduct a specific

empirical analysis, it does not identify the specific

reasons that contributed to CATL's digital

transformation and improved business performance.

In the future, relevant variables can be found for

further refinement, so as to facilitate in-depth

research on this topic.

REFERENCES

Electric Zhijia. CATL made 53 billion yuan. January 22,

2025. Retrieved on March 30, 2025. Retrieved from:

https://news.qq.com/rain/a/20250122A03MWY00

Global Network. CATL: Net profit is expected to reach 49

billion to 53 billion yuan in 2024. January 22, 2025.

Retrieved on March 30, 2025. Retrieved from:

https://news.qq.com/rain/a/20250122A05VZJ00

Gu J. (2024). Performance evaluation of Contemporary

Amperex Technology Co., Ltd. in the context of digital

transformation. Nanjing Forestry University.

Hu Y. F. (2024). Research on the Path and Effect of Green

Innovation of Power Battery Enterprises in the Context

of Digital Transformation: A case study of CATL. Inner

Mongolia University of Finance and Economics.

Sina Finance. CATL (300750): Operational performance s

ignificantly exceeded expectations, impairment and re

bates increased. October 27, 2024. Retrieved on Marc

h 30, 2025. Retrieved from: http://stock.finance.sina.c

om.cn/stock/go.php/vReport_Show/kind/lastest/rptid/7

83382671304/index.phtml

Wang J. B., Jiang M. J., Sheng J. (2022). From

Manufacturing to Intelligent Manufacturing: The Road

to Digital Transformation in CATL. Tsinghua Business

Review, (09): 122-129.

Wu Z. P. (2024). Research on the Impact of CATL's Digital

Transformation on Enterprise Value Creation, Yangtze

University.

Xia Y. F. (2024). Study on the motivation, path and

performance of enterprise digital transformation--

taking Ningdeshidai as an example. Chongqing

Technology and Business University.

Yan S. Q. (2024). Dissertation for the Degree of Master A

Case Study on Performance Improvement in CATL

Based on Digital Transformation. Harbin University of

Commerce.

Zhang Q., Zhai J. Y. (2024). Reconstruction of the Value

Chain of Manufacturing Enterprises from the

Perspective of Digital Empowerment: A Case Study of

CATL. Finance and Accounting Monthly, 45(22),89-

95.

Research on the Impact of Digital Transformation on the Operational Performance of Contemporary Amperex Technology Co. Limited

239