An Adaptive-Robust Strategy Design for Process Control

Dumitru Popescu

1,2

, Catalin Dimon

1

and Pierre Borne

3

1

Department of Automatic Control and Systems Engineering, University Politehnica of Bucharest,

Splaiul Independentei 313, Bucharest, Romania

2

Academy of Romanian Scientists, Strada Ilfov 3, Bucharest, Romania

3

Centre de Recherche en Informatique, Signal et Automatiqe de Lille, Ecole Centrale de Lille, Villeneuve d’Ascq, France

Keywords: Adaptive Control, Robust Control, Adaptive-Robust Control, Design Methodology, Model Degradation,

Optimal Control.

Abstract: The paper presents a new design strategy for industrial process control applications. The adaptive-robust

control approach considers both adaptive control advantages and robust control benefits; the connection

between the two concepts preserves the imposed performances for the closed loop nominal control system.

The combined adaptive-robust solution introduces the same integral criterion for parameters identification of

the process and for the control algorithm design. An optimal integral criterion and an appropriate robust

measure for degradation of the system performances due to variation of the model are introduced in an

iterative mechanism. The theoretical approach presented in this paper is validated on a close loop control

system, the application being developed in simulation. The proposed strategy is aiming to implement

adaptive-robust control in practical process applications.

1 INTRODUCTION

The 1960-1980s became the most important period

for the development of control theory and in

particular adaptive control. System identification and

parameter estimation played a crucial role in the

reformulation and redesign of adaptive control

(Astrom & Wittenmark, 2008; Landau, 1995).

Adaptive control systems can automatically adjust

its parameters to compensate variations in the process

ensuring imposed performances even when the

system's dynamics change or uncertainties are

present. This adaptive system identifies in closed loop

parameters in real time, adapting the controller's

action to the applications where process parameters

are unknown or time-varying (Popescu & Gentil,

1998; Foulloy et al., 2004; Popescu et al., 2008).

As a difference from an adaptive control strategy,

in robust control rather than relying on real-time

adaptation to measured variations, the controller is

designed a priori to maintain performance under the

assumption that certain system parameters are

uncertain, but within known bounds.

The start of the theory of robust control took shape

in the 1980s and is still active today. The modern

theory of robust control system began in the late

1990s and soon developed a number of techniques for

dealing with bounded system uncertainty.

Robustness is the ability to keep imposed

performance unchanged under external disturbances

and uncertainties. Robust control is a technique

focused on ensuring a control system's performance

despite uncertainties in the process or its

environment. It aims to maintain imposed

performance even when faced with disturbances,

parameter or dynamic model structure variations.

Robust control is crucial for applications with

parameters and structure uncertainties, where

stability and reliability are essential.

2 CONTROL STRATEGIES

2.1 Adaptive Control

The evolution of systems theory during the 70s-80s

allowed the growth of interest and progress in

adaptive control strategies. The rapid development of

numerical computing resources, programming and

simulation facilities contributed to the emergence and

development of numerical methods for data

acquisition and processing, modelling and

Popescu, D., Dimon, C. and Borne, P.

An Adaptive-Robust Strategy Design for Process Control.

DOI: 10.5220/0013838900003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 517-523

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

517

identification of processes and design of control

algorithms. Under these favourable conditions, the

possibility of transferring the performance of control

systems obtained in simulation to real applications in

processes appeared. As a result, for real-time control,

adaptive strategies were recommended and

implemented in industrial process automation.

The adaptive control strategy proposes for each

sampling moment, a re-identification of the process

and a re-design of the control system. It ensures the

maintenance of nominal imposed performances on

the physical system that drives the process, at each

sampling moment.

The computational effort is significant and

demanding for processes with rapid evolution and

these limitations were cancelled by the robust control

strategy. The adaptive control mechanism is

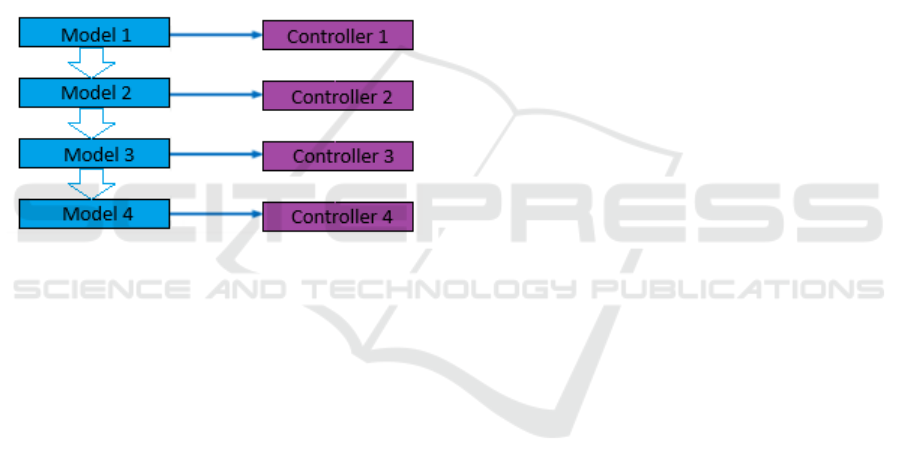

illustrated in Figure 1.

Figure 1: Adaptive control scheme.

The adaptive control mechanism is based on the

recursive relationship for repeated estimation of

model parameters and design of the control

algorithm, after the relation:

()( )

11

,,

kk k k

CM C M

++

→

(1

)

where

k

C

and

1k

C

+

are the controllers at step k and

k+1,

k

M

and

1k

M

+

are the models at step k and k+1.

Adaptive control remains a recommended

solution for processes with model parametric

uncertainty (invariant structure and variable

parameters) and for slowly variable processes

described by low-order models (Astrom, 1983;

Chalam, 1987; Anderson, et al., 1986).

Successes after the 1980s, however, were soon

followed by controversies over the practicality of

adaptive control concerning the computational effort

for the reidentification of model parameters and the

redesign of the controller in real-time closed loop

system. Thus, the robust control alternative began

(Ogata, 1990; Lewis et al., 2012; Wang et al., 2013;

Doelman et al., 2009).

2.2 Robust Control

Robust control is a field of automatic control theory,

recommended for preserving the stability and

performance of systems with parametric and/or

structural model uncertainty. Robust design methods

ensure a maximum uncertainty region through

robustness corrections, in order to attenuate the

effects of disturbances. The robust controller is

tolerant to the action of disturbances and to the

nonlinearities in the system for a collection of models

associated with different operating regimes of the

process (Dullerud & Paganini, 1999).

Duncan McFarlane and Keith Glover of

Cambridge University propose a design method for a

robust H-infinity loop-shaping system in the

frequency domain by minimizing the disturbance-

output sensitivity function (McFarlane & Glover,

1992). The optimal-robust controller guarantees that

the system ensures an invariance of the performance

under the action of disturbances.

An important approach for the design of robust

systems in input-output representation is presented in

(Popescu et al., 2017). Robustness indicators in the

frequency domain (robustness margin and

disturbance-output sensitivity function) are

introduced to evaluate the robustness of the system

and a design method based on the remarkable

properties of the disturbance-output sensitivity

function is proposed. The nominal control system is

adjusted so that the sensitivity function respects, in

the frequency domain, a template imposed by

successive calibration techniques.

From an application-oriented perspective, sliding

mode control (SMC), represents an emerging area

within robust control. Its inherent robustness to

uncertainties, combined with its relative design

simplicity, has led to its widespread adoption across

a range of practical applications (Bojan-Dragos et al.,

2024). Other areas of application concern power

control for renewable sources of energy (Ghalem et

al., 2018).

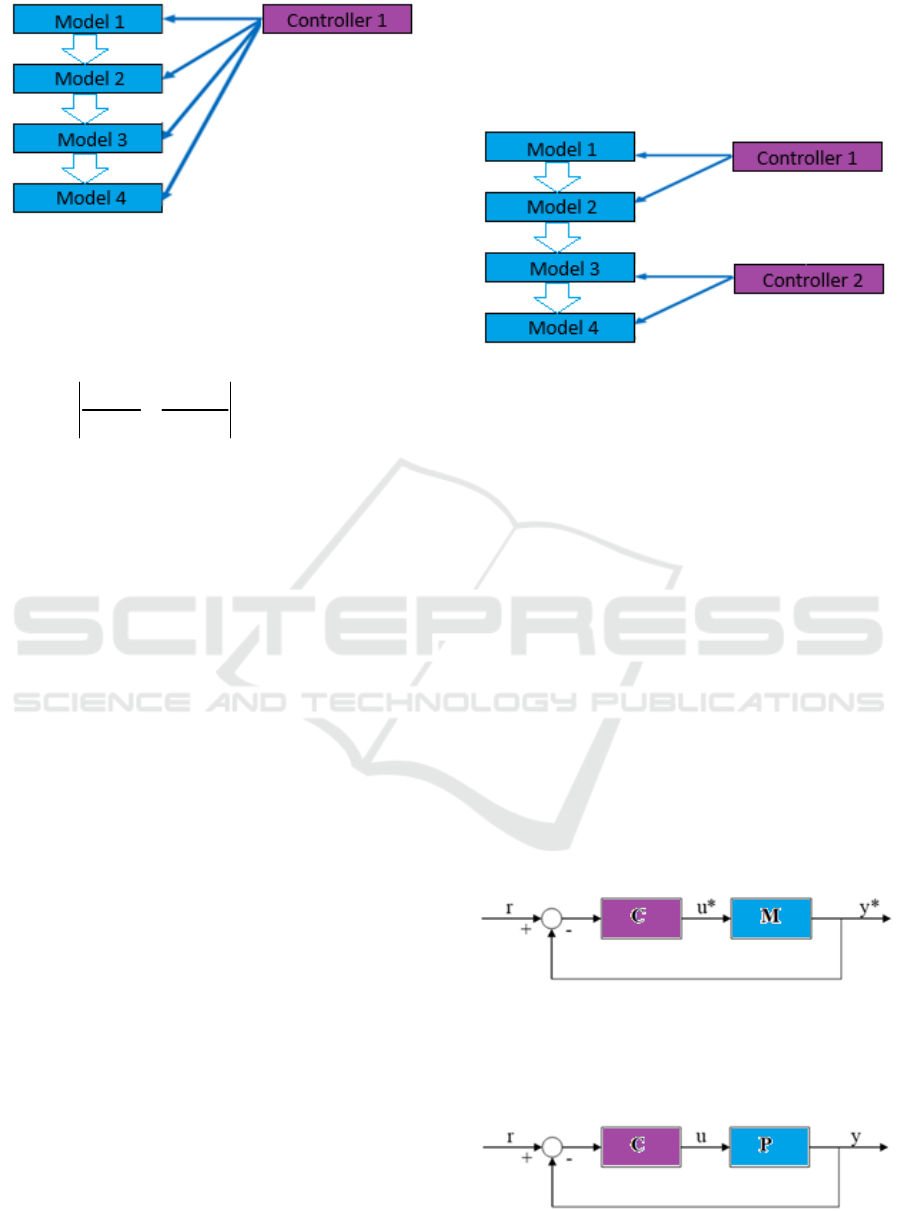

The robust control strategy is represented in

Figure 2 and remains recommended for models with

parametric and/or structural uncertainty and for

nonlinear process models. Robust control preserves

system stability of the system and tolerates model

uncertainties caused by the action of disturbances or

process nonlinearities. The robust controller

preserves system performance for a class of models

associated with possible process operating regimes

(Popescu et al., 2017; Green & Limebeer, 2012;

Popescu et al., 2008).

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

518

Figure 2: Robust control scheme.

The robustness reported to system performance is

expressed by relation (2), which expresses the

performance difference between the physical system

and the nominal system:

11

CP CM

s

mall

CP CM

−→

++

(2

)

where

C

is the controller computed for process

P

,

estimated by model

M

.

2.3 Adaptive-Robust Control

By the middle 1980s, several new redesigns and

modifications were proposed and recommended,

leading to a series of work known as robust adaptive

control.

The efficiency of integrated control systems in

automation solutions dedicated to technological

processes is determined by the process identification

and the system control design, two extremely

important concepts that ensure the performance of the

system. The behaviour of control systems in

industrial applications depends directly on the quality

of the mathematical model that expresses the process

dynamics and the control algorithm and therefore the

interdependence between the two concepts to ensure

the required performances is obvious. For a high level

of performance, the model must adapt when it

becomes uncertain for the process, and the control

algorithm must be tolerant to the action of

disturbances. Thus, starting with the 1990s, a new

concept was highlighted under the name of

identification for robust control, a concept that later

supported the adaptive-robust control strategy

(Athans et al., 2005; Ioannou & Sun, 2013; Narendra

& Annaswamy, 1986).

Important results on adaptive-robust control

strategies are obtained after 1990s and involved the

understanding of the various robust modifications and

their unification under a more general framework.

The adaptive–robust control strategy, proposed in this

paper, combines the advantages of adaptive control

and robust control respectively, by minimizing the

computational effort and by increasing the transfer of

simulation results in real time applications. This

strategy is shown in Figure 3.

Figure 3: Adaptive-robust control scheme.

3 ADAPTIVE-ROBUST

CONTROL METHODOLOGY

The main objective for this strategy is to combine

resources offered by adaptive and robust control in a

complementary manner to obtain high-performance

results in the automation of industrial processes.

The identification mechanism must be integrated

into an automatic control system and therefore a set

of models attached to the process dynamics must be

considered, if the nominal performances from the

simulation are to be maintained for the operation of

real processes. It is therefore proposed to perform an

identification and calculate a real-time command, for

the regulation of the process subjected to

disturbances.

Let us consider the nominal system (NS) with the

nominal performances (NP) validated in simulation,

represented in Figure 4:

Figure 4: Nominal control system (NS).

and the physical real system (RS) with performances

to be achieved (RP) on the physical process,

represented in Fig. 5:

Figure 5: Real control system (RS).

An Adaptive-Robust Strategy Design for Process Control

519

It is desired that the performances obtained in the

simulation are found as achieved performances, under

the conditions in which the process changes its

nominal operating point under the action of

disturbances.

In practice, the identification problem is solved by

minimizing the criterion constructed with the

estimation error and separately the optimal command

is calculated by minimizing another optimality

criterion depending on the regulation error system, as

follows:

• if a compensator

C

is known, the optimal

identification model

M

can be determined using an

identification criterion

I

J :

()

arg min ,

I

M

M

CM= J

(3

)

• if an identification model

M

is known, the

optimal compensator

C

can be determined using a

control criterion

C

J :

()

arg min ,

C

C

CCM= J

(4

)

The complementary relationship between the

problems of identification and control design is

supported by an iterative process (Gliga et al., 2008;

Levreetsky & Wise, 2024; Pham et al., 2025). The

two problems above can be defined in a unified

manner, which once again emphasizes the

complementarity between the two optimization

problems within the general problem of designing

automatic control systems.

Our approach is based on the idea that

identification should be carried out for the purpose of

control design and not separately. For this reason, a

single criterion remains important, for example

C

J

.

Given an optimization criterion

J

(for example,

J ≡ J

) and a corresponding norm, its optimal value

is obtained by minimizing

‖

J

‖

on the set of model-

compensator pairs associated with the process.

In practice, the compensator built from an

estimated model must lead to similar performances in

simulation and on the operating process. There are

thus two additional types of restrictions imposed by

the criterion

J

:

‖

J

𝐶, 𝑀

‖

< 𝛿

(5)

‖

J

𝐶, 𝑃

−J

𝐶, 𝑀

‖

≪

‖

J

𝐶, 𝑀

‖

(6)

where

δ

is the degradation error. The norms in the

above inequalities have natural interpretations, such

as:

•

‖

J

𝐶, 𝑀

‖

represents the nominal

performance;

•

‖

J

𝐶, 𝑃

‖

represents the performance

achieved during operation;

•

‖

J

𝐶, 𝑃

−J

𝐶, 𝑀

‖

measures the

degradation of the nominal performance, while the

compensator was built starting from the estimated

model

M

and not from the real model P .

Constraint (5) ensures good nominal

performance, while constraint (6) refers to

robustness. The value of

‖

J

𝐶, 𝑀

‖

being

sufficiently small, the performance degradation will

also be reduced.

We should also point out that this constraint does

not necessarily have to be verified if the nominal

performance

‖

J

𝐶, 𝑀

‖

is close to the realized

performance

‖

J

𝐶, 𝑃

‖

.

As this is difficult to test, the

robustness constraint (6) is imposed. If this is

verified, then the nominal and realized performances

are close.

The criterion

J

can be used to trigger an iterative

calculation process aiming to obtain a model-

compensator pair as close as possible to the optimal

pair. It is sufficient to use the performance

degradation measure for both the optimization and

identification criterion of the nominal performance

I

J

and for the optimization function in the

evaluation of the command

‖

J

‖

(Borne et al., 2013;

Stefanoiu et al., 2014).

The generic stage of this mecanism is described

below (for all

𝑖∈ℕ):

𝑀

= 𝑎𝑟𝑔𝑚𝑖𝑛

‖

J

𝐶

, 𝑃

−J

𝐶

, 𝑀

‖

𝐶

= 𝑎𝑟𝑔𝑚𝑖𝑛

‖

J

𝐶

, 𝑀

‖

(7

)

For each iterative step, the constraints (5) and (7)

must be verified, expressed in the form:

‖

J

𝐶

, 𝑀

‖

< 𝛿

(8)

‖

J

𝐶

, 𝑃

−J

𝐶

, 𝑀

‖

≪

‖

J

𝐶

, 𝑀

‖

(9)

Relations (7), (8) and (9) constitute the core of the

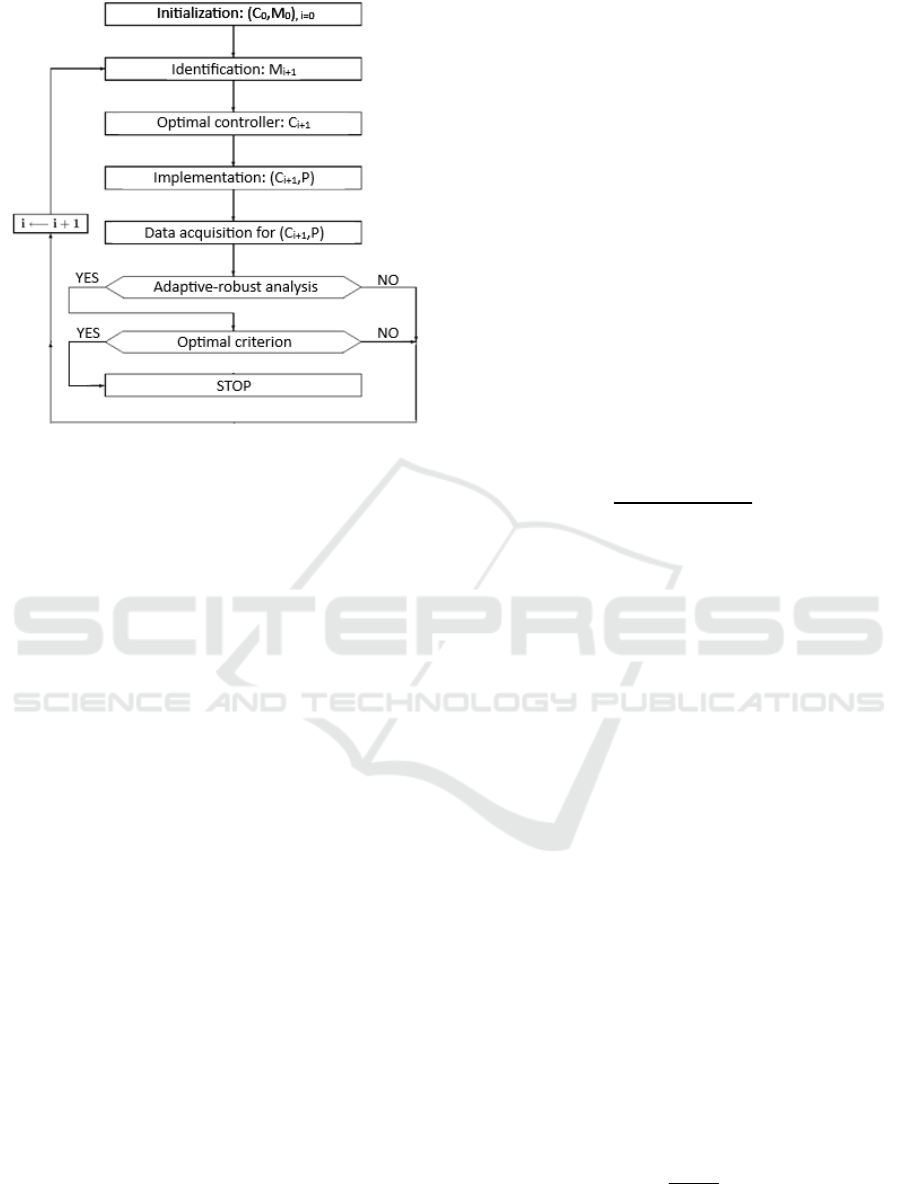

iterative process. The recursive algorithm is shown in

the diagram in Figure 6.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

520

Figure 6: Recursive adaptive-robust algorithm.

The recursive algorithm will stop while the

conditions (8) and (9) are verified, otherwise it goes

to the identification of the model, and the algorithm

starts again. The controller that satisfies condition (8)

is the robust adaptive controller implemented on the

real system structure (RS).

Let us consider:

2

min ( )

J

etdt=

(10)

the optimal integral criterrion for designing the

controller, where

()et is the control error of the

closed loop system.

The expression (10) becomes:

𝐽

= 𝑚𝑖𝑛

𝑒

(𝐶, 𝑀)𝑑𝑡

(11)

which accepts a direct representation of the criterion

as follows:

𝐽

= 𝑚𝑖𝑛

(

𝐶, 𝑀

)

(12)

For a fixed model

M

, identified from the

measure the robustness degradation, we can compute

the new controller:

𝐽

= 𝑚𝑖𝑛

(

𝐶

)

(13)

The main steps of the proposed algorithm are the

following:

- A closed-loop control system

(𝐶

, 𝑀

), which

ensures performance at a nominal operating point of

the process

0

P , is considered.

- If the perturbed process changes the operating

point

i

P driven by the system (𝐶

, 𝑀

) to the new

point

1i

P

+

, a new model

1i

M

+

is re-identified by

minimizing the performance degradation due to the

model parametric uncertainty.

- A new controller

𝐶

is recomputed using the

optimality criterion

J

.

- The recursive procedure ends if the performance

degradation becomes insignificant.

As mentioned earlier, the following optimal

integral criterion

J

is considered:

𝐽

=

𝑒

(𝑡)𝑑𝑡

∞

(14

)

After some mathematical transformations,

detailed in (Calin et al., 1979), the direct expression

of the integral criterion is obtained as follows:

2(1 )

ir

rr

TKk

J

Kk Kk

+τ

=

+

(15

)

The unique optimality criterion

J

is used to

identify the process model by minimizing the

degradation measure and respectively to recompute

the controller by minimizing the same criterion. After

estimating the new model, the new controller is

designed to preserve the system performance using

the relations (7). Thus, the limitations of the closed-

loop model adaptation strategy given by the redesign

of the control algorithm at each sampling moment are

reduced by the effect of the robust strategy.

4 STUDY-CASE AND

SIMULATIONS

A simple study case for understanding the adaptive-

robust approach is presented considering a first order

process model and a PI controller for the system. For

higher order systems, the design methodology

remains the same, just the number of mathematical

calculations increases with the order of the process

model and of the controller complexity.

Let us consider a process expressed using a first

order transfer function:

()

1

k

Ps

s

τ

=

+

(16

)

An Adaptive-Robust Strategy Design for Process Control

521

and the PI control algorithm which will be used for

the system:

1

() 1

r

i

Cs K

Ts

=+

(17)

Let us consider the process from (16) given by the

parameters

2k =

and

10τ=

. We can initialize the

controller by using a poles placement method,

considering as performances: zero overshoot and 40

sesonds response time. The computed controller is

given by the parameters

,0

0.5

r

K =

and

,0

10

i

T =

.

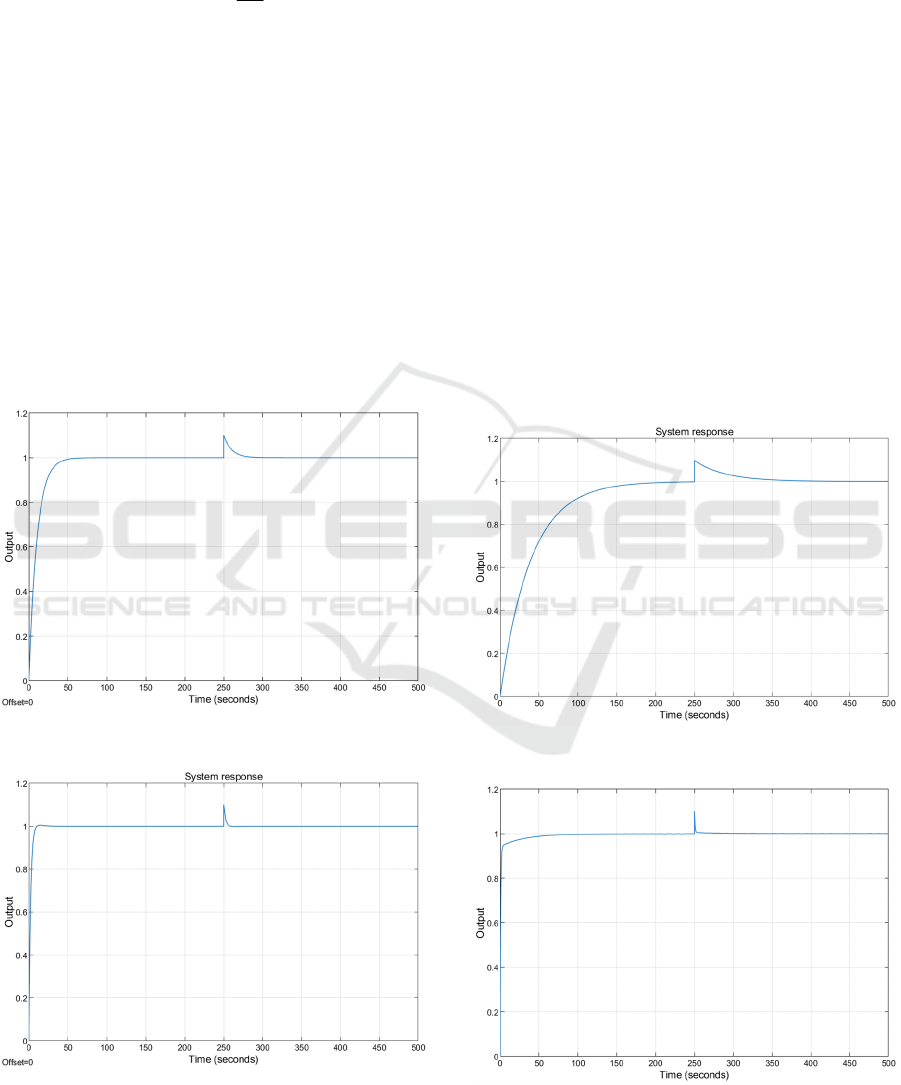

The system response is represented in Figure 7. A

10% disturbance is added to the output of the system

at time t=250s, which is rejected. It should be noted

that the computed controller will be maintained as

long as the degradation error criterion given by (8) is

verified. The degradation error in this case will be

𝛿 =J

(

𝐶

, 𝑀

)

=5.

Figure 7: System response for

(𝐶

, 𝑀

)

.

Figure 8: System response for

(𝐶

, 𝑀

)

.

By using the Cauchy gradient method with the

ceriterion function given by (15),

the algorithm will

compute a new controller only when necessary.

The optimum values for the controller at iteration i:

𝐾

,

*

= 10.592 and 𝑇

,

*

= 8.2574 . The degradation

error will be given by the new value

𝛿 =

J

(

𝐶

, 𝑀

)

= 1.0454

. The system response is shown

in Figure 8.

In time the model of the process will change, such

that the controller will not be able to assure the

nominal performances. Such a case is represented in

Figure 9, where the process is identified by a new

model

1i

M

+

. By applying the same principle, we

obtained the controller

1i

C

+

and the system response

is represented in Figure 10. The degradation error is

given by

𝛿 =J

(

𝐶

, 𝑀

)

= 0.3885

.

It can be noticed that the system performances are

verified; in fact, we obtained better response time

compared with the initial response (the response time

is about 33 seconds).

Figure 9: System response for

(𝐶

, 𝑀

)

.

Figure 10: System response for

(𝐶

, 𝑀

)

.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

522

5 CONCLUSIONS

The paper proposes a new adaptive-robust control

strategy for the development of industrial automation

applications.

The main objective for this strategy is to combine

the advantages offered by adaptive and robust control

in a complementary manner to obtain high-

performance results in the automation of

technological processes with parametric and/or

structural uncertainties.

Adaptive-robust control is recommended for

processes with parametric and/or structural

uncertainty, tolerant to the action of disturbances and

nonlinearities in the process.

Adaptive-robust control is based on the concept of

robust degradation measure and uses a recursive

calculation procedure, by using a single optimality

criterion that minimizes the degradation measure for

the identification operation, and which calculates the

optimal command.

The theoretical results validated in simulation can

be transferred as efficient solutions for the automation

of real technological processes and installations

guaranteeing superior performances in operation.

REFERENCES

Anderson, B.D.O., Bitmead, R.R., Johnson, C.R.,

Kokotovic, P.V., Kosut, R.L., Mareels, I., Praly, L.,

Riedle, B. (1986). Stability of Adaptive Systems, M.I.T.

Press, Cambridge, Massachusetts.

Astrom, K.J. (1983). Theory and applications of adaptive

control - a survey, In Automatica, vol.19, no.5, pp. 471-

486.

Astrom, K.J., Wittenmark, B. (2008). Adaptive Control,

Courier Corporation.

Athans, M., Fekri S., Pascoal, A. (2005). Issues on robust

adaptive feedback control. In Preprints of the 16th

IFAC World Congress, pp. 9-39.

Bojan-Dragos, C.A., Precup, R.E., Petriu, E., Tibre, R.A.,

Han, T. (2024). Sliding Mode and Super-Twisting

Sliding Mode Control Structures for Vertical Three-

Tank Systems. In Studies in Informatics and Control

Journal, Vol. 33, No. 3, 2024.

Borne, P., Popescu, D., Filip F.G., Stefanoiu, D. (2013).

Optimization in Engineering Sciences- Exact Methods,

J.Wiley Press, London.

Calin, S., Tertisco, M., Dumitrache, I., Popeea, C., Popescu,

D. (1979). Optimizations in industrial automation,

Tehnica Press, Bucharest.

Chalam, V. V. (1987). Adaptive Control Systems:

Techniques and Applications, New York.

Doelman, N., Fraanje, R., Houtzager, I., Verhaegen, M.

(2009). Adaptive and real-time optimal control for

adaptive optics systems. In ECC-European Control

Conference, Proceedings.

Dullerud. G.E., Paganini, F. (1999). A Course in Robust

Control, Springer-Verlag, Berlin.

Foulloy, L., Popescu, D., Dauphin-Tanguy, G. (2004).

Modelisation, Identification et Commande des

Systemes, Romanian Academy Press, Bucharest.

Ge, S.S., Wang, C., Li, Y., Lee, T.H., Ang, M.H. (2013).

Adaptive optimal control for linear discrete time-

varying systems. In IEEE Conference on Cybernetics

and Intelligent Systems, Proceedings.

Ghalem, A., Tayeb A., Attallah, S., Abdeldjabbar, K.M.

(2018). Robust and modern control of VSC-HVDC. In

U.P.B. Sci. Bull., Series C, vol. 80(2).

Gliga, L., Cosmin, M., Lupu, C., Popescu, D. (2008).

Adaptive–Robust Control, a computational efficient

real time simulation. In EMES International

Conference, Oradea.

Green, M., Limebeer, D.J.N. (2012). Linear Robust

Control, Courier Corporation.

Ioannou, V.P., Sun, J. (2013). Robust Adaptive Control,

Courier Corporation.

Landau, I.D. (1995). Identification et Commande des

Systemes, Hermes Publishing, Paris.

Levreetsky, E., Wise, K. (2024). Robust and Adaptive

Control: With Aerospace Applications (Advanced

Textbooks in Control and Signal Processing),

SpringerPress.

Lewis, F.L., Vrabie, D., Syrmos, V.L. (2012). Optimal

Control, John Wiley and Sons.

McFarlane, D., Glover, K. (1992). A loop-shaping design

procedure using H/sub infinity / synthesis. In IEEE

Transactions on Automatic Control, vol. 37, no. 6, pp.

759-769.

Narendra, K.S., Annaswamy, A.M. (1986). Robust

Adaptive Control in the Presence of Bounded

Disturbances. In IEEE Transactions on Automatic

Control, vol. 31, no. 4, pp. 306-315.

Ogata, K. (1990). Modern Control Engineering, Practice

Hall, New Jersey.

Pham, D.A., Han, S.H., Kong, K.J. (2025). Time-Specified

Adaptive Robust Control Framework for Managing

Nonlinear System Uncertainties. In Appl.Sci., 16(6).

Popescu, D., Gentil, S. (1998). Commande Numerique et

Intelligence Artificielle en Automatique, Tehnica Press,

Bucharest.

Popescu, D., Stefanoiu, D., Lupu, C., Petrescu, C.,

Ciubotaru, B., Dimon, C. (2008). Industrial

Automation, Agir Press, Bucharest.

Popescu, D., Stefanoiu D., Borne, P. (2017). Process

Control Design for Industrial Applications, John Wiley

Press, London.

Stefanoiu, D., Borne, P., Popescu, D., Filip, F.G. (2014).

Optimization in Engineering Sciences- Metaheuristic,

Stochastic Methods and Decision Support, J.Wiley

Press, London.

An Adaptive-Robust Strategy Design for Process Control

523