A Web-Controlled, Modular 3D-Printed Exoskeleton for Upper Limb

Stroke Recovery

Crina B

˘

arbieru

a

and Isabela Dr

˘

amnesc

b

Department of Computer Science, West University of Timis¸oara, Romania

Keywords:

Robotic Hand Exoskeleton, Stroke Rehabilitation, 3D-Printed Exoskeleton, Remote Monitoring, Web-Based

Rehabilitation Platform.

Abstract:

Stroke survivors often experience partial or complete loss of hand function, significantly affecting their ability

to perform everyday tasks. Current rehabilitation methods can be resource intensive and require significant

human intervention. This paper aims to develop a portable, modular, 3D-printed robotic hand exoskeleton that

provides targeted repetitive exercises designed to enhance motor recovery. This exoskeleton is controlled via

a web application, which includes progress-tracking functionalities for both patients and physical therapists,

enabling remote monitoring. Preliminary testing was conducted with one patient to evaluate the usability

and efficacy of the device. Feedback was collected from a physical therapist to assess the feasibility of the

exoskeleton. The proposed system offers a scalable, cost-effective solution for post-stroke hand rehabilitation.

Further studies with larger cohorts are needed to validate efficacy.

1 INTRODUCTION

Stroke is one of the leading global causes of death

and long-term disability, with nearly 12 million new

cases every year (Feigin et al., 2025). Approxi-

mately 25.3% of patients develop post-stroke spas-

ticity (Zeng et al., 2021), a condition in which mus-

cle stiffness and abnormal muscle contractions affect

movement, limiting their ability to perform daily tasks

and regain independence.

The development of innovative therapeutic tools,

such as robotic exoskeletons, holds promise for im-

proving the rehabilitation process, particularly for

those with limited mobility due to spasticity. Some

studies found robot-assisted therapy in acute and sub-

acute stroke patients more effective than traditional

therapy (Masiero et al., 2007; Sale et al., 2014; Taka-

hashi et al., 2016), although others found no signif-

icant differences between the two approaches if ex-

ercises were performed at a similar intensity (Kahn

et al., 2006; Hesse et al., 2014).

In the last three decades, a wide range of upper-

limb robotic exoskeletons have been developed for

patients to perform independent and repeatable exer-

cises remotely, allowing for a more personalized ap-

a

https://orcid.org/0009-0004-1794-6510

b

https://orcid.org/0000-0003-4686-2864

proach to rehabilitation. However, many existing sys-

tems rely on minimal control interfaces, with little ca-

pability for progress tracking or therapist supervision.

The aim of this paper is to address some of the gaps in

existing solutions and design a portable, 3D-printed,

modular exoskeleton controlled via a web application,

enhancing the patient’s rehabilitation experience and

streamlining the progress supervision process.

2 RELATED WORK

Finding a balance between design simplicity and

portability constitutes a significant challenge when

designing a robotic hand exoskeleton. We can dis-

tinguish a category of exoskeletons that actuate the

fingers via cable systems placed on the palmar side

of the hand. While it is relatively straightforward,

this approach can prevent patients from fully sensing

and grasping objects during rehabilitation exercises.

The device described in (Selvaraj Mercyshalinie et al.,

2023) uses fishing lines attached to distal inter-

phalangeal (DIP) joint hooks and guided through

metacarpophalangeal (MCP) joint hooks. The mod-

ular exoskeleton developed by (Chirinos and Vela,

2021) assists with the flexion and extension of the

thumb, index, and middle fingers using a pulley con-

nected to a direct current (DC) motor. Teflon tubes

150

B

ˇ

arbieru, C. and Dr

ˇ

amnesc, I.

A Web-Controlled, Modular 3D-Printed Exoskeleton for Upper Limb Stroke Recovery.

DOI: 10.5220/0013835400003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 150-157

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

guiding the wires allow for better object-grasping ca-

pabilities, although they still remain limited.

This issue can be solved by placing cables on the

sides of the fingers, as can be observed in (Chiri et al.,

2009). Extension is actively achieved via Bowden ca-

bles pulled by a slider connected to the DC motor.

DC motors are commonly used in robotic applica-

tions due to their precise control and compact size.

Their rotational torque can be adapted to simulate the

movement generated by a linear actuator, which is the

mechanism leveraged by (Chiri et al., 2009). Flexion

is achieved passively, with cables attached to linear

compression springs.

Some of the existing solutions flex the fingers by

pushing rather than pulling them, allowing the pal-

mar side of the hand to remain free. The portability

of devices in this category is influenced by the choice

of hardware components. In (Wang et al., 2020) the

palm is positioned in an upward position and braces

support it to prevent fatigue. The system flexes one

finger at a time via pneumatic muscles attached to

plates and wheels of different radii. This setup sig-

nificantly limits the range of rehabilitation exercises

which can be performed. (Ho et al., 2011) uses a

linear actuator and a dual arch guide mechanism to

actuate the MCP and proximal interphalangeal (PIP)

joints. Electromyography (EMG) sensors are inte-

grated to detect movement intent and a wireless con-

trol unit allows the therapist to choose from different

training modes. The exoskeleton described in (San-

dison et al., 2020) achieves a 90

◦

range of motion

(ROM) at the MP and 100

◦

at the PIP. The elastic dis-

tal segment is user dependent and can be avoided to

achieve tactile sensation when grasping objects.

The integration of 3D-printing technology in

robotic exoskeletons has enabled more innovative,

customizable designs and has lead to the development

of new actuation mechanisms. (Yap et al., 2015) uses

3D-printed molds to create accordion-like, elastomer

actuators. Actuators in (Ridremont et al., 2024) are

pressurized to flex the joints and vacuumed to extend

them, while those in (Yap et al., 2017) use the oppo-

site mechanism. Other devices (Fiorilla et al., 2009;

Sandison et al., 2020; Selvaraj Mercyshalinie et al.,

2023) use 3D-printed parts as components of the ex-

oskeleton to lower the cost, reduce the weight, and

more easily adapt the exoskeleton to diverse patient

needs.

Although most robotic exoskeletons are con-

trolled via hardware components, some implement

mobile or Web applications to personalize rehabil-

itation sessions and improve user experience. In

(Fiorilla et al., 2009), the application developed

in Microsoft Visual C++ and National Instruments

LabView

TM

communicates with the robot’s con-

troller, reads the input from sensors and encoders to

reconstruct the MCP angle and monitors the device

during rehabilitation exercises. The Android mobile

application in (Selvaraj Mercyshalinie et al., 2023)

contains buttons for each individual finger. Flexion

is done gradually, in three stages, and the fingers are

relaxed by pressing dedicated buttons.

3 EXOSKELETON DESIGN

The proposed solution utilizes the advantages of 3D-

printed components to design a modular robotic ex-

oskeleton. The current system is comprised of a

single-finger module, with the possibility to connect

multiple such modules to achieve a full-hand ex-

oskeleton.

3.1 Hardware Components

The robotic exoskeleton is controlled by an Arduino

Nano ESP32 board, chosen for its integrated Wi-Fi,

enabling communication with the web-based client

interface. Thus, users are able to remotely select ex-

ercise modes and intensity.

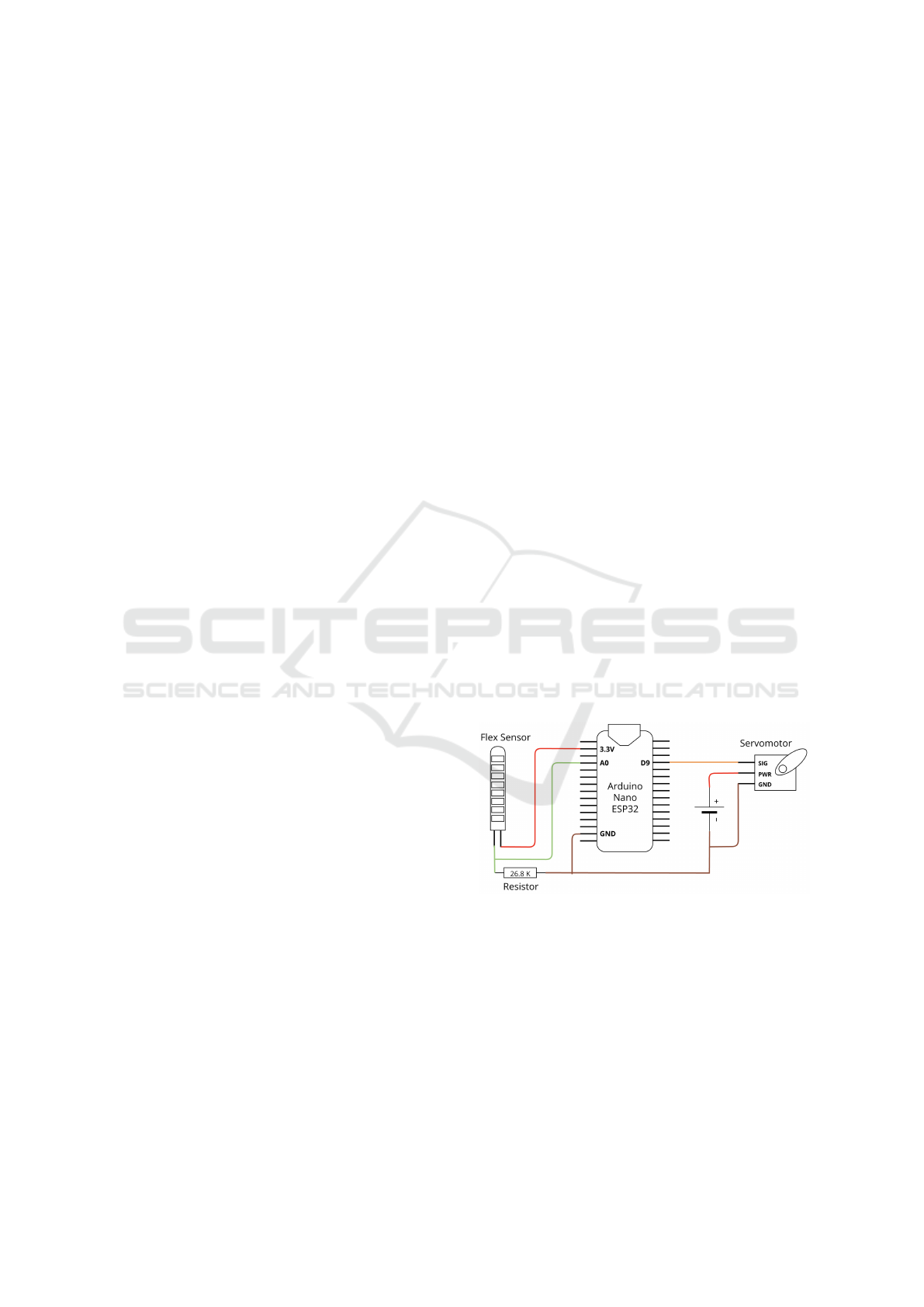

Figure 1 illustrates the wiring configuration of the

exoskeleton’s electronic components. The MG90S

servomotor interfaces with the Arduino via the D9

digital pin, utilizing Pulse Width Modulation (PWM)

for precise control.

Figure 1: Circuit Diagram of the System.

Due to the Arduino Nano ESP32’s 3.3V logic

level, the 5V servomotor cannot be directly powered

by the board. Instead, an external power source is

employed, consisting of a power bank module. This

module supplies 5V at 2A, sufficient to drive multiple

servomotors if needed. To ensure a common refer-

ence voltage, the grounds of the Arduino, servomotor,

and power bank are interconnected.

The flex sensor input is measured using a volt-

age divider circuit, a configuration which reduces the

A Web-Controlled, Modular 3D-Printed Exoskeleton for Upper Limb Stroke Recovery

151

voltage to a lower value while maintaining constant

current flowing through the resistors. In this setup,

the input voltage spans the entire resistor network.

The output voltage is measured from the junction be-

tween two resistors, with its magnitude dictated by

their resistance ratio. The flex sensor has a nominal

resistance of 10KΩ(±30%), and when paired with

a 26.8KΩ fixed resistor, the resulting voltage divi-

sion ensures analog readings remain below the mid-

point of the Arduino’s 12-bit analog to digital con-

verter (ADC) range (2047). The sensor is powered

directly from the Arduino’s 3.3V pin, which serves as

the voltage divider’s supply source, ensuring compat-

ibility with the board’s analog input range.

3.2 3D-Printed Components

The components of the exoskeleton are designed us-

ing Autodesk Tinkercad (Autodesk Inc., 2025), a

web-based computer-aided design (CAD) platform

that simplifies 3D modeling through an intuitive,

primitive-based approach. CraftWare Pro is used to

slice the components with fine layer resolution, which

are then printed using the Craftbot Flow 3D printer.

The distal and metacarpal components use a thermo-

plastic polyurethane (TPU) 95A filament. This semi-

flexible, rubber-like material allows the exoskeleton

to fit more comfortably on different finger sizes. The

other components, involved in the actuation mecha-

nism, are printed using a polylactic acid (PLA) fila-

ment. This material is selected for its strength, as it

needs to withstand repeated mechanical stress.

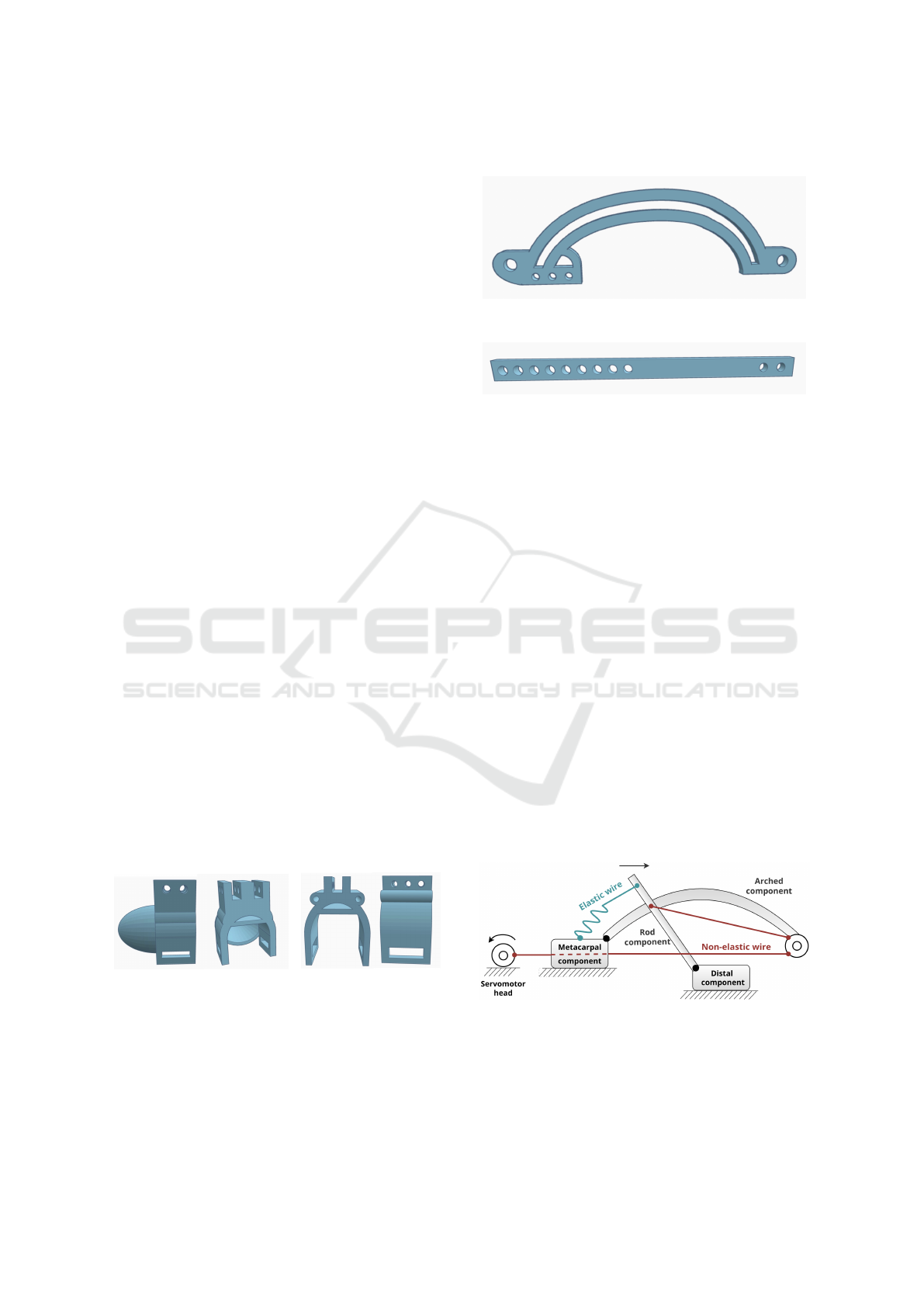

The fingertip interface (Figure 2a) positioned on

the distal phalanx, supports the attachment of two

guide rods, which are designed to follow an arched

channel. The metacarpal component (Figure 2b) pro-

vides structural support and serves as the mounting

point for the arched component. Two tubular exten-

sions on either side of mounting channel guide the

wires used by the actuation mechanism.

(a) Distal Element. (b) Metacarpal Element.

Figure 2: 3D Models of Exoskeleton Components.

The arched component (Figure 3) guides the rod-

shaped components (Figure 4) placed laterally, which

slide and convert the curved trajectory into a con-

trolled flexion movement. This movement simulta-

neously bends the DIP and PIP joints, mimicking the

natural movement of a finger.

Figure 3: 3D Model of Arched Component.

Figure 4: 3D Model of Rod-Shaped Component.

3.3 Actuation Mechanism

Actuation is achieved via a system of wires attached

to a servomotor. A non-elastic wire is attached to

the rod-shaped components, passes through the guide

components mounted distally on the arch compo-

nent and then through the guides integrated into the

metacarpal component before terminating at the ser-

vomotor head.

During flexion, the servomotor’s torque is trans-

formed into the linear movement of the rods along

the arched trajectory, as shown in Figure 5. Due to

pulley-like elements guiding the non-elastic wire at

the distal end of the arched component, the rotational

movement of the servomotor head leads to a transla-

tional movement of the rods along the arched trajec-

tory. The finger extension mechanism is achieved pas-

sively, through an elastic wire positioned between the

proximal end of the arched element and the extremi-

ties of the rods. While the servomotor releases tension

on the wires, the elastic wire provides the force nec-

essary to pull back the rods and bring them into their

initial position.

Figure 5: Kinematic Diagram of the System.

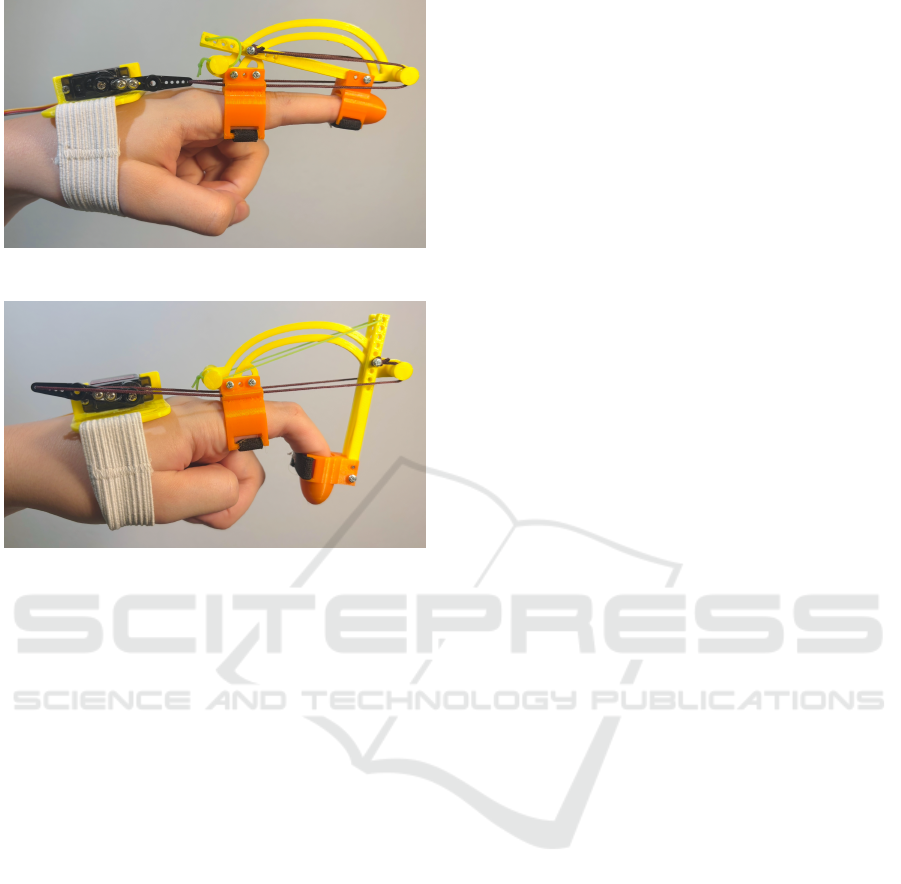

Figures 6a and 6b showcase the position of the fin-

ger when the exoskeleton assists with extension, and

flexion respectively.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

152

(a) Exoskeleton-Assisted Extension.

(b) Exoskeleton-Assisted Flexion.

Figure 6: Finger Position During Exoskeleton-Assisted Ex-

ercises.

3.4 Sensors

The distal and metacarpal components of the ex-

oskeleton have slots designed to accommodate the

movement of the flex sensor during finger flexion and

extension. The sensor is secured at the metacarpal

component and passes freely through the fingertip’s

slot. This allows it to slide slightly as the distance

between the two components increases when the fin-

ger is bent and decreases when the finger is fully ex-

tended.

When measuring the movement of the finger, the

system first establishes a baseline reading with the fin-

ger fully extended. In this situation, the resistance of

the flex sensor is minimum, while the voltage reaches

its maximum value. During flexion, the resistance of

the flex sensor increases, causing a proportional volt-

age drop. The system thus captures the combined

bend of the DIP and PIP joints by tracking the voltage

change.

4 SOFTWARE DESIGN

The robotic hand exoskeleton is controlled via a web

application, which communicates with the robot us-

ing the controller’s Wi-Fi module. The web applica-

tion serves two distinct user roles: patients and super-

visors. An intuitive and responsive interface improves

the patient’s experience, which not only serves as the

control interface for the exoskeleton, but as a tool

for recording exercise sessions and tracking progress.

Furthermore, physical therapists are able to monitor

the activity of their patients, essential for the safety

and efficacy of remote rehabilitation.

The Client Layer is built with React, serving as the

user interface patients and supervisors interact with.

The Application Layer is a Spring Boot application,

enforcing role-based access via Spring Security. Ad-

ditionally, sensitive information, such as user pass-

words, is encrypted through BCrypt hashing. For per-

sistent data storage, the system employs MySQL as

its relational database management system. The re-

lational model is suitable for the structured nature of

the application’s data, including user accounts and in-

formation related to exercise sessions.

The patient Graphical User Interface (GUI) pro-

vides a control interface in the Active Exercises screen

(Figure 7a), where they are able to select the level of

intensity on a 1-10 scale and perform exoskeleton-

assisted, repeated movements. Level 1 represent a

slight movement of the exoskeleton, and corresponds

to a 18

◦

rotation of the servomotor head, while level

10 ensures full exoskeleton movement and a 180

◦

ser-

vomotor head rotation. In Passive Mode (Figure 7b),

the patient attempts independent flexion and the appli-

cation screen displays the flex sensor input as a per-

centage of the total range of movement of the DIP and

PIP joints. All robot-assisted or passive sessions are

recorded automatically and displayed in the Patient

Progress component (Figure 7c). Patients view statis-

tics related to their rehabilitation journey, such as the

number of assisted exercise sessions completed in the

current week, and a calendar containing both assisted

and passive sessions.

Supervisors have a similar view over their pa-

tients’ progress in the Supervisor Progress screen

(Figure 7d), where the same data is aggregated and

shown in the form of patient progress cards. The

progress cards contain metrics about the patients med-

ical information, such as: the number of days since

the stroke occurred, the number of days in rehabili-

tation, and exercise sessions, like the number of ses-

sions in the current week and average session dura-

tion. Furthermore, for better data visualization, the

cards contain a similar calendar to that of the patients,

but with exercise sessions and passive mode data sum-

marized.

A Web-Controlled, Modular 3D-Printed Exoskeleton for Upper Limb Stroke Recovery

153

(a) Active Exercises Screen. (b) Passive Mode Screen.

(c) Patient Progress Screen. (d) Supervisor Progress Screen.

Figure 7: GUI Screens of the Web Application.

5 EXPERIMENTS AND RESULTS

The finger joint angles were analyzed using a custom

Python script that combines computer vision track-

ing with geometric angle calculations. The OpenCV

library is used to load a side-view recording captur-

ing one full flexion movement of the exoskeleton.

Three joint locations (MCP, PIP, DIP) and an addi-

tional point representing the finger tip (TIP) are man-

ually selected on the first video frame. This is used for

joint angle calculation, by applying the scalar product

formula:

θ

PIP

= cos

−1

(PIP − MCP)· (DIP − PIP)

|PIP − MCP| · |DIP − PIP|

(1)

θ

DIP

= cos

−1

(DIP − PIP) · (TIP − DIP)

|DIP − PIP| · |TIP − DIP|

(2)

Initially, we attempted to automate joint detection

and angle computation entirely through the CSRT al-

gorithm (Channel and Spatial Reliability Tracking)

OpenCV. However, due to interference from the ex-

oskeleton’s distal component, the TIP point could not

be accurately identified, leading to incorrect DIP an-

gle calculations (Figure 8a). To resolve this, we modi-

fied the program to allow periodic manual corrections,

allowing us to reselect joint positions at fixed inter-

vals. We tested three different scenarios, manually

positioning the MCP, PIP, DIP and TIP points every

5, 8, and 10 frames respectively, to balance tracking

accuracy with manual intervention.

The results revealed that the PIP joint reached

a maximum angle of 110–115 degrees, correspond-

ing to a flexion of 65–70 degrees from full exten-

sion. The DIP joint reached a peak flexion of approx-

imately 65 degrees, although this decreased slightly

to around 60 degrees towards the end of the move-

ment. To ensure robustness, we applied a smoothing

filter (3-frame moving average) to the raw angle data,

thus filtering out noise and tracking errors between

manual corrections. To contextualize our results, we

consulted a physical therapist

1

with experience in the

field of hand rehabilitation. We learned that similar

1

The physical therapist consented to the use of their

feedback in this paper.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

154

(a) Automatic Detection.

(b) 5-frame Correction.

(c) 8-frame Correction.

(d) 10-frame Correction.

Figure 8: Experiment Results: PIP and DIP Angles During

Exoskeleton-Assisted Flexion.

robotic technologies, particularly pneumatic-actuated

gloves, tend to lose precision after 3–4 weeks as mate-

rials stretch and deform, limiting their clinical utility.

While our 3D-printed PLA exoskeleton takes a dif-

ferent approach, similar wear-and-tear issues might

eventually emerge with prolonged use. Since PLA

isn’t commonly used in clinical exoskeletons, or its

use is limited and does not constitute a significant pro-

portion of exoskeleton components, durability studies

should be conducted to evaluate the performance of

this material.

We conducted additional experiments to measure

the load on the elastic component of the exoskeleton,

which not only assists in passive extension, but in-

fluences the flexion mechanism as an opposing force

to the one generated by the torque of the servomo-

tor. In this scenario, the chosen elastic component

was latex wire with a diameter of 1 millimeter and

≈ 700% elasticity. The exoskeleton was tested with a

dynamometer to record applied forces. We measured

that a force of about 0.8N was required to stretch the

wire efficiently to enable full exoskeleton movement.

The MG90S servomotor has a 1.8kg/cm stall torque

at 4.8V . The non-elastic wire is fixed at 4cm from

the servomotor shaft, therefore a maximum force of

≈ 4.4N can be applied before the servomotor stalls, in

ideal conditions. Additional factors such as resistance

from the elastic wire and the finger, friction between

exoskeleton components and voltage drops could pro-

vide an explanation for the need of patient interven-

tion when performing exoskeleton-assisted rehabili-

tation exercises, as the servomotor is not able to gen-

erate enough force for passive finger flexion. This is

beneficial in situations where patient intervention is

required during rehabilitation exercises, and the de-

gree of intervention can be increased by choosing a

thicker, less elastic wire.

Furthermore, we conducted preliminary testing

with a patient

2

(Figure 9), who reported that the de-

vice was comfortable and lightweight.

Although we originally designed and tested the

device for the index finger, the patient required reha-

bilitation for the little and ring fingers. This demon-

strates an advantage of the modular exoskeleton, as

it can be adapted and reused based on patient needs.

During assisted flexion trials, the exoskeleton demon-

strated measurable improvement, although the ROM

was constrained by the patient’s capability to initiate

movement. The device augmented flexion by a small

but consistent margin beyond the patient’s indepen-

dent effort, suggesting its potential as a training aid

for motor recovery.

2

The patient consented to the use of their feedback and

photo in this paper.

A Web-Controlled, Modular 3D-Printed Exoskeleton for Upper Limb Stroke Recovery

155

Figure 9: Patient During Preliminary Testing.

A demonstration video showcasing the main fea-

tures of our developed system can be accessed at

https://youtu.be/LA84F36UVH4.

6 CONCLUSIONS AND FUTURE

WORK

The developed system successfully integrates a 3D-

printed finger exoskeleton with a web-based control

interface. Similarly to (Chiri et al., 2009), it is a mod-

ular exoskeleton that uses active and passive mecha-

nisms to flex and extend the fingers, though inverted

(passive flexion and active extension). Where their

design uses a system of 6 pulleys, 2 for each joint,

the device described in this paper achieves simulta-

neous DIP and PIP flexion and extension via a set of

servomotor-driven cables. This improvement reduces

mechanical complexity while maintaining a compara-

ble range of motion.

The arched trajectory mechanism is similar to that

developed by (Ho et al., 2011), but with some opti-

mization. The linear actuators are replaced with a ser-

vomotor cable system. (Ho et al., 2011) design fea-

tures two arched components for the PIP and MCP

joints, while this exoskeleton employs a single arch

to simultaneously guide PIP and DIP movements.

Furthermore, 3D-printed PLA and TPU compo-

nents increase portability and allow adjustments to ac-

commodate a wider range of hand proportions. How-

ever, a key trade-off remains: the design’s ability to

withstand repetitive mechanical forces and maintain

efficiency is uncertain and requires further testing.

The web application developed in this paper is an

important improvement to previous systems. In ad-

dition to exoskeleton control and sensor feedback, it

enhances the user’s experience by providing relevant

metrics related to the recovery process. Furthermore,

it streamlines the supervision process and it offers a

web interface for physical therapists to monitor their

patients’ activity.

While the current finger module demonstrates

the system’s core functionality, several improvements

could be made to enhance its clinical utility.

The cable-driven actuation system presents limita-

tions, as wire tension must be constantly maintained,

requiring fixed-length cables or patient-specific ad-

justments. Transitioning to an alternative actuation

mechanism would improve adaptability and reduce

maintenance demands. Furthermore, incorporating

MCP joint support would enable comprehensive fin-

ger rehabilitation, which is essential for restoring

grasping functionality.

Expanding the exoskeleton to accommodate mul-

tiple fingers would be a critical step towards a full-

hand exoskeleton. The expansion would require hard-

ware upgrades, including a servomotor shield to sup-

plement the Arduino Nano’s limited I/O capabilities.

Before widespread adoption, the exoskeleton effi-

cacy must be evaluated through controlled trials with

stroke patients. These studies should quantitatively

measure progress, and comparing the recovery rates

in exoskeleton-assisted patients versus patients who

undergo traditional therapy regimens. Additionally,

feedback from physical therapists and patients could

be collected to improve the user interface design of

the web application, ensuring functionalities align

with real-world rehabilitation needs.

ACKNOWLEDGMENTS

This work is co-funded by the European Union

through the Erasmus+ project AiRobo: Artificial

Intelligence-based Robotics, 2023-1-RO01-KA220-

HED-000152418.

REFERENCES

Autodesk Inc. (2025). Tinkercad. Online 3D design and

modeling platform.

Chiri, A., Giovacchini, F., Vitiello, N., Cattin, E., Roccella,

S., Vecchi, F., and Carrozza, M. C. (2009). HAN-

DEXOS: Towards an exoskeleton device for the reha-

bilitation of the hand. In 2009 IEEE/RSJ International

Conference on Intelligent Robots and Systems, IROS

2009, pages 1106–1111.

Chirinos, S. and Vela, E. (2021). A Modular Soft Robotic

Exoskeleton for Active Hand Rehabilitation after

Stroke. In 2021 IEEE Engineering International Re-

search Conference (EIRCON), pages 1–4.

Feigin, V. L., Brainin, M., Norrving, B., Martins, S. O.,

Pandian, J., Lindsay, P., Grupper, M. F., and Rautalin,

I. (2025). World Stroke Organization: Global Stroke

Fact Sheet 2025. International Journal of Stroke,

20(2):132–144. PMID: 39635884.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

156

Fiorilla, A., Tsagarakis, N., Nori, F., and Sandini, G. (2009).

Design of a 2-Finger Hand Exoskeleton for Finger

Stiffness Measurements. Applied Bionics and Biome-

chanics, 30:1–13.

Hesse, S., Heß, A., Werner C, C., Kabbert, N., and

Buschfort, R. (2014). Effect on arm function and cost

of robot-assisted group therapy in subacute patients

with stroke and a moderately to severely affected arm:

a randomized controlled trial. Clinical rehabilitation,

28(7):637–647.

Ho, S., Tong, R. K.-Y., Hu, X., Fung, K., Wei, X., Rong, W.,

and Susanto, E. (2011). An EMG-driven exoskele-

ton hand robotic training device on chronic stroke

subjects: Task training system for stroke rehabilita-

tion. IEEE International Conference on Rehabilita-

tion Robotics, 2011:5975340.

Kahn, L. E., Zygman, M. L., Rymer, W. Z., and Reinkens-

meyer, D. J. (2006). Robot-assisted reaching ex-

ercise promotes arm movement recovery in chronic

hemiparetic stroke: a randomized controlled pilot

study. Journal of neuroengineering and rehabilitation,

3(1):12.

Masiero, S., Celia, A., Rosati, G., and Armani, M. (2007).

Robotic-assisted rehabilitation of the upper limb after

acute stroke. Archives of physical medicine and reha-

bilitation, 88(2):142–149.

Ridremont, T., Singh, I., Bruzek, B., Jamieson, A., Gu,

Y., Merzouki, R., and Wijesundra, M. (2024). Pneu-

matically Actuated Soft Robotic Hand and Wrist Ex-

oskeleton for Motion Assistance in Rehabilitation. Ac-

tuators, 13:180.

Sale, P., Franceschini, M., Mazzoleni, S., Palma, E., Agosti,

M., and Posteraro, F. (2014). Effects of upper limb

robot-assisted therapy on motor recovery in subacute

stroke patients. Journal of NeuroEngineering and Re-

habilitation, 11(1):104.

Sandison, M., Phan, K., Casas, R., Nguyen, L., Lum, M.,

Pergami-Peries, M., and Lum, P. S. (2020). Hand-

MATE: Wearable Robotic Hand Exoskeleton and In-

tegrated Android App for At Home Stroke Rehabilita-

tion. In 2020 42nd Annual International Conference

of the IEEE Engineering in Medicine & Biology Soci-

ety (EMBC), pages 4867–4872.

Selvaraj Mercyshalinie, E. R., Ghadge, A., Ifejika, N., and

Tadesse, Y. (2023). NOHAS: A Novel Orthotic Hand

Actuated by Servo Motors and Mobile App for Stroke

Rehabilitation. Robotics, 12:169.

Takahashi, K., Domen, K., Sakamoto, T., Toshima, M.,

Otaka, Y., Seto, M., Irie, K., Haga, B., Takebayashi,

T., and Hachisuka, K. (2016). Efficacy of Upper

Extremity Robotic Therapy in Subacute Poststroke

Hemiplegia. Stroke, 47(5):1385–1388.

Wang, D., Wang, Y., Zi, B., Cao, Z., and Ding, H. (2020).

Development of an active and passive finger rehabili-

tation robot using pneumatic muscle and magnetorhe-

ological damper. Mechanism and Machine Theory,

147:103762.

Yap, H. K., Koh, T., Sun, Y., Liang, X., Lim, J., and Yeow,

R. C.-H. (2017). A Fully Fabric-Based Bidirectional

Soft Robotic Glove for Assistance and Rehabilitation

of Hand Impaired Patients. IEEE Robotics and Au-

tomation Letters, PP:1–1.

Yap, H. K., Lim, J., Nasrallah, F., Low, F.-Z., Cho, J., and

Yeow, R. C.-H. (2015). MRC-glove: A fMRI com-

patible soft robotic glove for hand rehabilitation ap-

plication. In 2015 IEEE International Conference on

Rehabilitation Robotics (ICORR), pages 735–740.

Zeng, H., Chen, J., Guo, Y., and Tan, S. (2021). Preva-

lence and Risk Factors for Spasticity After Stroke: A

Systematic Review and Meta-Analysis. Frontiers in

Neurology, 11:616097.

A Web-Controlled, Modular 3D-Printed Exoskeleton for Upper Limb Stroke Recovery

157