Impact of Digital Transformation on Corporate Value Creation: A

Case of Airbus

Mingwu Han

a

Surrey International Institute, Dongbei University of Finance and Economics,217 Jianshan Street, Dalian 116025, China

Keywords: Digital Transformation, Value Creation, Aviation Manufacturing, Technological Empowerment, Business

Model.

Abstract: In the context of the global digital economy, digital transformation has become the core path for enterprises

to break through the traditional value boundary and build new competitiveness. This paper takes Airbus as

the research object to explore the impact mechanism of digital transformation on the value creation of aviation

manufacturing enterprises. Through case studies and literature research, it is found that Airbus has

reconfigured its value chain by integrating technologies such as digital twins and the industrial Internet of

Things. This integration significantly enhances its R&D agility and production efficiency and drives the

company's expansion from equipment manufacturing to service ecology. The findings indicate that digital

transformation enables cross-chain collaboration, optimizes resource allocation, and reshapes competitive

barriers through technological empowerment, the core of which lies in the systematic reconfiguration of

business processes and business models and the transformation of technological value into commercial

benefits. The practice of Airbus demonstrates that enterprises need to be customer demand-oriented, balancing

technological innovation and ecological synergy. This provides theoretical references for the systemic impact

of the digital transformation value chain, injecting sustainable growth momentum into the core industry chain,

and providing replicable strategic paths for high-end manufacturing.

1 INTRODUCTION

Under the wave of global digital economy, digital

transformation has become an important engine for

sustained global economic growth. Digital

transformation is a strategic process of reconfiguring

the core architecture of an enterprise through the

integration of digital technologies, the essence of

which is to develop a market-driven capacity for

continuous and rapid innovation through the

systematic optimisation of production processes,

technologies and operations (Westerman, G et al,

2014). Therefore, enterprise digital transformation

has become a key way to improve the core

competitiveness of enterprises. According to

McKinsey & Company's 2023 report on the

digitisation of the global manufacturing industry,

although more than two thirds of manufacturing

enterprises have begun to implement a digital

strategy, less than 20 per cent of them have achieved

financial efficiency gains through the vertical

a

https://orcid.org/0009-0005-0560-2777

integration of core technologies (McKinsey &

Company, 2023). In the field of aviation

manufacturing, digital transformation not only

implies the intelligence of the production process and

the specialisation of the management mode, but also

involves the reconstruction of the value distribution

matrix of the industrial chain, as well as the in-depth

optimisation of the efficiency of research and

development and financial efficiency, and the

enhancement of user satisfaction, thus forming a new

transmission mechanism between technological

inputs and capital returns. As one of the two giants in

the global aviation manufacturing industry, Airbus

occupies an important position in the global market.

Since 2017, Airbus has been comprehensively

promoting digital transformation, covering a number

of cutting-edge fields including smart manufacturing,

artificial intelligence, quantum technology, etc., and

is gradually building up a full-chain digital ecosystem

from design to service. According to Airbus's annual

report for 2023 (Airbus, 2024), Airbus's full-year

102

Han, M.

Impact of Digital Transformation on Corporate Value Creation: A Case of Airbus.

DOI: 10.5220/0013834300004719

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on E-commerce and Modern Logistics (ICEML 2025), pages 102-109

ISBN: 978-989-758-775-7

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

revenue reached 65.4 billion euros, with digital

transformation-related projects contributing about

12% of profit growth, which is representative of its

effectiveness (Airbus, 2024). In addition, existing

research on digital transformation in the aerospace

manufacturing industry is still insufficiently

analysed. Most of the cases only focus on local

technology application, and lack of systematic

research on the synergistic mechanism of the whole

industry chain. AlNuaimi, B. K. et al (2022) stated

that current digital innovation focuses more on

technological tools than on systematic business

model and organisational reconfiguration, which

leads to a disconnect between technological inputs

and corporate strategy. There is a significant lack of

research on the correlation between value creation

and financial metrics. Given that most existing

research focuses on a single technology application

and lacks a systematic exploration of the impact of

digital transformation across the value chain, there is

an urgent need to explore this issue through case

studies. Therefore, this paper takes Airbus as the

research object, adopts the method of combining case

analysis and literature research, and through

systematically sorting out the motives and pathways

of Airbus' digital transformation and its specific

mechanism of value creation, it aims to reveal the

internal logic of the synergy between digital

technological empowerment and corporate strategy,

and to provide a double inspiration for the theoretical

construction and practical application. By analysing

its digital transformation system and approach, and

studying the impact and effect of transformation on

enterprise value creation, it provides certain

inspiration and reference for the aviation

manufacturing industry and similar enterprises to

achieve digital transformation and healthy operation.

2 THE DRIVERS OF AIRBUS'

DIGITAL TRANSFORMATION

2.1 Company Overview

Founded in December 1970 in France, Airbus is the

world's leading civil aircraft manufacturer and

Europe's largest aerospace company. In 2024, Airbus

was ranked 183rd on the Fortune 500 list with

revenues of $70.751 billion (Fortune, 2024). Its

business covers aircraft design, manufacturing,

supply chain management, customer service, etc., and

its influence on the industry is significant. Airbus has

set as its development goal to create a new chapter in

sustainable aerospace and to commit to building a

safe and harmonious world. By the beginning of

2024, Airbus had 147,893 employees and assets

totaling US$131.2 billion (Airbus, 2024). Airbus has

more than 180 locations in more than 150 countries

and territories and is supported by 18,000 direct

suppliers around the world, covering most of the

world (Airbus, 2024).

In addition, Airbus is committed to leading the

transformation and modernization of the aerospace

industry to drive its continued growth. Since 2017,

Airbus has been relying on advanced digital

technologies to completely revolutionize the way it

designs, manufactures, and operates its products

(Airbus, 2024). This digital transformation extends to

all levels of the company's operations, driving

innovation and excellence throughout the ecosystem.

The company is also actively promoting the use of

digital tools to streamline workflows, increase

efficiency, and completely transform traditional

production methods. After the transformation, Airbus

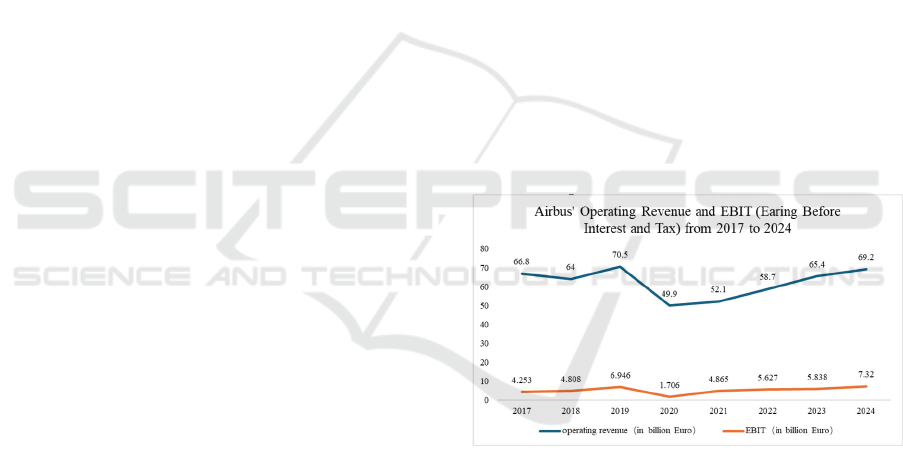

is doing well. According to the relevant data in Figure

1, although the company's operating performance

declined in 2020 due to the impact of the epidemic

and the global economic slowdown, it recovered

quickly after the epidemic and showed a continuous

and stable upward trend.

Figure 1: Airbus' operating revenue and EBIT (earing

before interest and tax) from 2017 to 2024 (Airbus, 2024).

2.2 Airbus Digital Transformation

Motivation

2.2.1 Industry Competition

Global competition in the aviation manufacturing

industry has expanded from individual product

performance to digital service capabilities across the

value chain. According to Boeing's forecast, the size

of the global aviation services market will exceed $14

trillion by 2041, prompting Airbus to accelerate its

digital transformation to compete in emerging

markets (Boeing, 2022). For example, by building the

Impact of Digital Transformation on Corporate Value Creation: A Case of Airbus

103

Skywise platform, Airbus has achieved real-time

monitoring of globally connected aircraft, increasing

predictive maintenance accuracy to 98 percent and

helping airlines reduce unscheduled downtime by a

quarter (Boeing, 2022). This strategy not only

consolidates Airbus' strength in aircraft

manufacturing but also extends its business

boundaries into a high value-added digital services

ecosystem.

2.2.2 Technological Innovation

Industry 4.0 and artificial intelligence technology are

driving innovation in the manufacturing process. The

wave of industrial digitalization has led to the

transformation of the manufacturing process system.

Through the integration and application of Industrial

Internet of Things and artificial intelligence

technology, Airbus has realized the integration of

cross-factory data chains and the intelligent iteration

of production processes. It has significantly improved

the efficiency of supply chain collaboration and the

precision of composite material processing and built

a differentiated technological competitive advantage.

The digital factory can increase the efficiency of

aircraft assembly by 30% and reduce the quality

defect rate by 40%. It also proves that digital

innovation contributes significantly to productivity

improvements (Airbus, 2024).

2.2.3 Market Demand

Global air travel demand continues to recover in the

post-epidemic era, with total airport passenger traffic

expected to return to pre-epidemic levels by the end

of 2023 (Qianqian Pendulum & Li Zhi, 2022). As a

result, customer demand for lead time and

customization has increased. For example, Airbus

launched its "Digital Twin First" strategy to increase

the response time for customized configurations to

within 72 hours on the A220 program, directly

supporting its premium terms in the competition for

orders from Qatar Airways (Airbus, 2024). Market

demand has thus redefined digital technology and

opened a new chapter in the application of digital

transformation to manufacturing processes and

technologies.

2.2.4 Policy Compliance

In response to the European Union's (EU)

sustainability needs to implement the EU's Clean

Skies 2.0 framework (2021-2027), which sets dual

targets for airframe weight reduction and carbon

emissions, Airbus has been prompted to increase the

proportion of its investment in Digital Thread

technology (European Commission, 2018). The

European Union Aviation Safety Agency (EASA) has

mandated that aircraft manufacturers reduce fuel

consumption by 50% by 2035, as outlined in the 2050

Aviation Carbon Neutral Roadmap (Royal, N. L. R.,

& Economics, 2024). Airbus is relying on digital twin

technology to complete the ZEROe hydrogen-

powered aircraft program, accelerating its goal of

commercializing a zero-carbon aircraft by 2050

(Sacchi, R. et al., 2023). Consequently, a strategic

alignment of digital transformation to support the EU

aviation emissions reduction milestones is imminent.

3 PATHWAYS AND

MECHANISMS FOR AIRBUS'

DIGITAL TRANSFORMATION

3.1 Airbus Digital Transformation

Pathway

Airbus is using digital technologies to revolutionize

the way it designs, produces, and operates its products

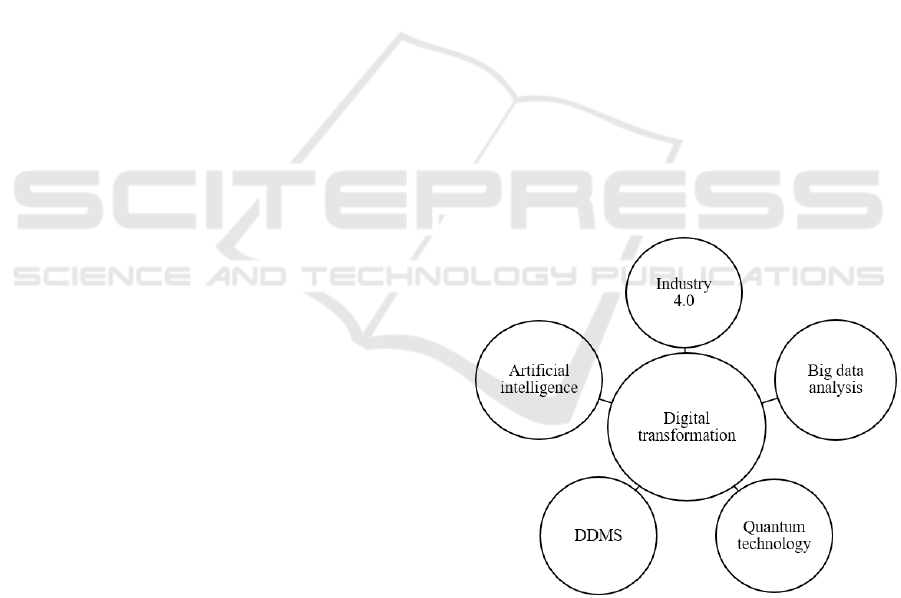

(Airbus, 2024). As shown in Figure 2, its digital

transformation encompasses the following five

different aspects of the pathway.

Figure 2: Airbus digital transformation relationship map

(Airbus, 2024).

3.1.1 Industry 4.0

Changing market demands and customer

expectations are profoundly affecting aircraft design

and manufacturing. Airbus is following the pace of

Industry 4.0 and exploring advanced manufacturing

technologies. It is Applied the latest advanced

ICEML 2025 - International Conference on E-commerce and Modern Logistics

104

manufacturing technology achievements, such as

robotics, virtual reality, digitalization, and 3D

printing, to the factory of the future, to promote the

industrial ecology towards intelligence and

digitalization, and to fully open the path of digital

transformation of the product lifecycle (Sigov, A.et

al, 2022).

3.1.2 Artificial Intelligence (AI)

AI is at the heart of future technologies and has a

profound impact on all areas of society. For Airbus, it

is the key to competitive advantage. The Skywise

platform, which relies on AI technology to identify

potential problems and delays in a timely manner, is

an innovation that is disrupting the aviation industry.

The platform enables connectivity capabilities to ease

real-time information propagation within the airline’s

digital ecosystem, applying AI and Machine Learning

(ML) engineering to advance predictive and health

monitoring (Bernard & Hoffmann, 2023). AI is

therefore fully integrated into corporate governance

to ensure responsible and sustainable technological

development.

3.1.3 Quantum Technology

Quantum technology has the potential to transform

the way aircraft are built and flown. Airbus fully

recognizes the importance of this technology in

enhancing the performance of its products and

services and is using it to address complex aerospace

challenges.

3.1.4 Digital Design, Manufacturing, and

Services (DDMS)

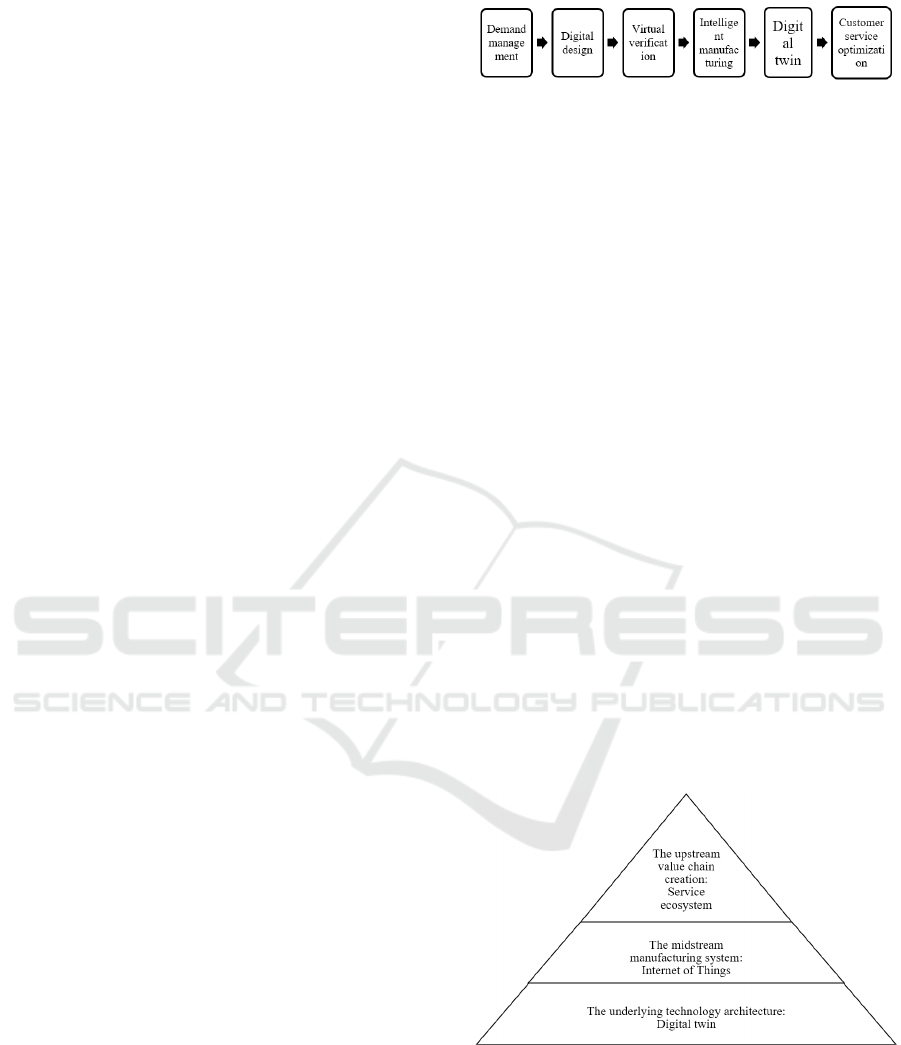

The DDMS initiative, shown in Figure 3, uses end-to-

end digital methods and tools to optimize business

processes. The goal is to increase the capability

readiness level (CRL) of various modeling and

simulation functions, including multidisciplinary

analysis and optimization (MDAO) capabilities

(Sarda, N. et al., 2023). In addition, Airbus' use of the

Dassault Systèmes 3DEXPERIENCE platform

provides digital continuity from design to operations,

enabling Airbus to achieve enterprise-wide digital

design, manufacturing, and services (Courtney, M,

2015). This results in lower costs, faster time to

market, and meets the high standards of quality,

safety, and environmental performance demanded by

customers (Courtney, M ,2015).

Figure 3: Airbus DDMS programme core processes and

tools framework diagram (Airbus, 2024).

3.1.5 Big Data Analytics

Making the right business decisions depends on big

data analytics and insights. Airbus deals with

complex, unstructured data and uses advanced

analytics to ensure that the right information is

available to the right people at the right time to make

decisions.

3.2 Mechanisms for Airbus Digital

Transformation

The essence of Airbus' digital transformation is to

reconstruct the value creation system of the aviation

manufacturing industry by means of digital

capabilities. This transformation is evident in a

sequential progression from the innovation of

technical tools to the enhancement of the industrial

ecosystem. Through the in-depth integration of digital

technology and aviation manufacturing elements,

Airbus has built a value-added network throughout

the entire life cycle of its products, forming a new

type of competitiveness with “digital continuity” at its

core. Therefore, Airbus' digital transformation is

based on a three-dimensional value chain system of

“digital twin, intelligent manufacturing and

ecological synergy” (Figure 4).

Figure 4: The three-dimensional value chain system of

“Digital Twin - Intelligent Manufacturing - Eco-

Collaboration” (Photo credit: Original).

At the level of the underlying technical

architecture, digital twin technology constitutes the

cornerstone of transformation. Airbus has extended

the two-way connection between physical aircraft and

Impact of Digital Transformation on Corporate Value Creation: A Case of Airbus

105

virtual models to the whole process of R&D,

manufacturing, and operation, and most of the design

verification process has been moved to the digital

space. The A350XWB pro

ject has used the

multidisciplinary collaborative simulation system to

compress the development cycle of the prototype by

up to 25%, which is a breakthrough marking the

transformation of the aviation product R&D

paradigm from physical iteration to virtual

verification (Airbus, 2024). This innovative model of

blending the real and the virtual has reduced the R&D

cost of a single aircraft by $760 million and

empowered the product to respond quickly to market

demands (Airbus, 2024).

Midstream manufacturing system innovation

focuses on the Industrial Internet of Things (IIoT) to

reconfigure the logic of production. The ‘factories of

the future’ in Hamburg and Toulouse are

interconnected with more than 3,500 intelligent

devices, capturing more than 28,000 production data

streams in real time and building a dynamic

scheduling system with autonomous decision-making

capabilities (Airbus, 2024). Relying on this system,

the total assembly efficiency of the A320 series has

increased by 30 percent, setting a new industry record

of one narrow-body airliner off the production line

every minute (Airbus, 2024). This flexible production

capacity supports Airbus in winning aircraft orders.

At the top of value creation, Airbus is breaking

through the traditional boundaries of hardware sales

to build a new data-driven service ecosystem. Its

Skywise aviation big data platform has accessed real-

time flight data from 12,000 aircraft worldwide and

developed nine types of service products, including

predictive maintenance and fuel efficiency

optimization. Through subscription models such as

‘pay by the hour,’ the company's digital service

revenue will reach 1.9 billion euros in 2022 (Airbus,

2024).

The deeper significance of Airbus' digital

transformation lies in breaking down the physical

boundaries of traditional aircraft manufacturing

through digital continuity. This practice provides a

triple revelation for the global high-end equipment

manufacturing industry: the digital main line through

is the technical premise of realizing the optimization

of the whole value chain, data assetization is the key

lever to break through the industrial value ceiling, and

open ecological synergy is the strategic choice to

cope with the challenges of the complex market.

The transformation drive mechanism is shown in

Figure 5:

Figure 5: Airbus digital transformation mechanisms map

(Photo credit: Original).

4 ANALYSES OF THE IMPACT

OF DIGITAL

TRANSFORMATION ON

VALUE CREATION

4.1 R&D Efficiency and Costs

Airbus has gradually restructured its R&D system

recently and consolidated its technological barriers

with digital transformation at its core. Figure 6 shows

that from 2017 to 2023, its R&D expenditure will

increase from 3.68 billion euros to 4.83 billion euros,

and its investment intensity (R&D expenditure as a

proportion of operating revenue) will remain stable at

5-6 percent and gradually increase to more than 7

percent, which is significantly higher than the average

level of the aviation manufacturing industry. This

continuous investment and the deep integration of

digital tools have created synergies: the introduction

of the ‘digital twin’ technology in 2017 has enabled

the design verification cycle of the A320 family of

models to be compressed from 33 months in the

traditional model to 24 months in 2023, resulting in

significantly faster R&D efficiency and delivery

(Airbus 2024). The efficiency gains also extend to

production and delivery. In addition, the average

aircraft delivery cycle has also been reduced from 33

months in 2017 to 24 months in 2023, according to

the data, with digitalized assembly lines and

predictive maintenance systems driving a return to

pre-outbreak levels of capacity and delivery numbers.

Airbus has demonstrated that its R&D investment

is not simply a matter of scaling up but of digitization

to achieve ‘precision efficiency.’ This model

strengthens short-term resilience (rapid recovery in

operating income and cash flow) and lays the

foundation for long-term technological leadership.

According to the Airbus website, the proportion of

digital technology-related patents has exceeded 25%

(Airbus, 2024). This value creation logic of data-

driven efficiency is reshaping the competitive

paradigm of aviation manufacturing.

ICEML 2025 - International Conference on E-commerce and Modern Logistics

106

Figure 6: Airbus data on R&D efficiency and costs (Airbus,

2024).

4.2 Operations and Financial

Performance

The movement of Airbus' gross margin and net profit

confirms its ability to balance external shocks and

management efficiency. As shown in Figure 7,

Airbus' gross margin stabilized at 14-16% in 2017-

2019 on the strength of delivery of high-value-added

models such as the A350 and supply chain synergies.

2020 saw its gross margin plummet to an all-time low

of 10.4% on the back of major factors such as

epidemic shocks and idle capacity, as well as a 40%

increase in the cost of raw materials such as titanium

alloys. However, after 2021, through the

strengthening of supply chain resilience and digital

transformation of production, its operating capacity

improved significantly, and its gross margin

rebounded to 15.6% in 2023, reaching the pre-

epidemic level.

In contrast to the volatility in gross margins, net

profit and free cash flow have shown more resilience

and positive development, stabilizing at around €3

billion in the pre-epidemic period. Despite a severe

shock in 2020, when both were negative, an all-time

low, they turned positive instantly a year later and

recovered quickly to grow to record highs of over €4

billion from 2022 onwards. This phenomenon reflects

the fact that digital transformation is driving Airbus

to be a thriving and resilient company and a source of

value creation for the company. At the same time, it

is a sign that the company's digital transformation

strategy is paying off.

Figure 7: Airbus data on operations (Airbus, 2024).

4.3 Customer Satisfaction

Digital transformation significantly improves

customer satisfaction by building a proactive service

system, and predictive maintenance and full-process

optimization form a closed loop of value. The

Skywise system deployed by Airbus, based on the

analysis of real-time data of 7,000 aircrafts

worldwide, achieves 92% fault prediction accuracy,

enabling the airline to reduce unplanned downtime by

30%, increase on-time performance by 23%, and

increase customer retention rate by 15% (Airbus,

2024). The upgraded service efficiency is further

reflected in the digital delivery system: the e-signing

process is 70% faster, and the delivery cycle time is

22% shorter, driving incremental orders of €460

million from airlines in 2024 (Airbus, 2024). With a

spontaneous overall satisfaction index of 84.9

percent, Airbus has an advantage in terms of fleet

versatility, operational flexibility, training

requirements, etc., and the A320's cabin comfort and

width are better than that of Boeing's 737 model

(Flight School USA ,2024). As a result, the digital

service network established by Airbus is restructuring

the customer value model of the aviation

manufacturing industry through accurate insights and

rapid response.

5 CONCLUSIONS

The practice of Airbus shows that the digital

transformation strategy through the dual path of

technological empowerment and ecological

reconstruction has profoundly reshaped the logic of

value creation in the aviation manufacturing industry.

At the technological level, the deep integration of

digital twins, the Industrial Internet of Things, and

artificial intelligence has promoted the improvement

Impact of Digital Transformation on Corporate Value Creation: A Case of Airbus

107

of R&D efficiency, production process optimization,

and service model innovation, forming a

differentiated competitive chain of ‘accurate R&D -

agile manufacturing - data-driven service’; on the

ecological level, digital transformation has broken the

industrial boundaries and built a new competitive

chain based on data assets and services. On the

ecological level, digital transformation has broken the

industrial boundaries, built a value network with data

assets as the core and multi-party collaboration, and

promoted the transformation of enterprises from

traditional equipment suppliers to comprehensive

service providers.

In summary, the application of digital tools has

the potential to drive value creation by improving

operational efficiency and financial resilience.

Furthermore, these tools can provide long-term power

for enterprises by upgrading customer experience,

sharing ecological value, and building strategic

barriers. The case of Airbus demonstrates that the

logic of digital transformation empowering enterprise

value creation is not purely a superimposition of

technology but rather lies in the systematic

reconstruction of business processes and optimization

of the resource allocation model, which ultimately

realizes the transformation of technological dividends

into sustainable business value. Its experience reveals

that digital transformation is a systematic innovation

of strategic thinking and business model, and

enterprises need to be based on long-term value

objectives, take customer demand as the traction, and

deeply integrate digital capabilities into the core value

chain so as to seize the first opportunity in the

industrial change.

Despite the systematic exploration of the impact

of digital transformation on value creation, as

exemplified by the Airbus case study, the study is not

without its limitations. Firstly, the research focuses on

top enterprises that have specificity. As a result, the

research conclusions lack universality for small and

medium-sized enterprises. Secondly, the long-term

economic effects and social impacts (e.g., changes in

the employment structure, technological and ethical

risks) of digital transformation have not yet been

sufficiently discussed. Thirdly, there is insufficient

empirical analysis of the value transformation paths

of quantum computing and other technologies. In the

future, it is necessary to expand the research on the

transformation paths of enterprises in multiple

industries and of different scales and, at the same

time, pay attention to the impact of technological

iteration on the governance model of the industrial

chain, as well as the synergistic mechanism between

digital transformation and the goal of carbon

neutrality. The purpose of this theoretical research is

to provide support for the construction of a more

inclusive and sustainable transformation paradigm.

REFERENCES

Airbus. (2024). Financial results (2017-2024), Airbus Offi

cial Website, https://www.airbus.com/en/investors/fina

ncial-results,last accessed 2025/3/20.

Airbus. (2024). Digital transformation, Airbus Official

Website, https://www.airbus.com/en/innovation/digital

-transformation,last accessed 2025/3/20.

AlNuaimi, B. K., Singh, S. K., Ren, S., Budhwar, P., &

Vorobyev, D. (2022). Mastering digital

transformation: The nexus between leadership, agility,

and digital strategy. Journal of Business Research, 145,

636-648.

Bai, Q. Q., & Li, Z. (2022). Houyiqing shiqi duo jichang

lüke tunuliang fenlei yuce [Classification prediction of

multi-airport passenger throughput in the post-

epidemic period]. Journal of Transportation

Technology and Economy, 24(6), 9–15.

Bernard, W., & Hoffmann, A. (2023). SKYWISE-Big data

platform as a foundation of airlines predictive and

health monitoring. In PHM Society Asia-Pacific

Conference, 4 (1).

Boeing. (2022). Commercial Market Outlook 2022. Retrie

ved from https://www.boeing.com/commercial/market

/commercial-market-outlook/,last accessed 2025/3/20.

Courtney, M. (2015). The future of flight is

green. Engineering & Technology, 10(6), 38.

European Commission. (2018, April 17). Clean Sky 2 - the

largest research programme for aviation ever launche

d in Europe. Projects. https://projects.research-and-inn

ovation.ec.europa.eu/en/projects/success-stories/all/cle

an-sky-2-largest-research-programme-aviation-ever-la

unched-europe,last accessed 2025/3/20.

Flight School USA. (2024). Operator feedback analysis: B

oeing vs. Airbus customer satisfaction. Flight School U

SA. https://www.flightschoolusa.com/zh-CN/%E6%B

3%A2%E9%9F%B3%E4%B8%8E%E7%A9%BA%E

5%AE%A2/#operator-feedback-analysis-boeing-vs-air

bus-customer-satisfaction, last accessed 2025/3/20.

Fortune. (2024). Global 500 rankings 2024. Fortune

Magazine, 2024(8), 56-73.

McKinsey & Company. (2023). Digital transformation in

global aviation manufacturing: Challenges and

opportunities. Aviation Technology Review, 47(3), 45-

60.

Grande, R., & Tang, H. K. (2023). Emerging digital

technologies in the workplace. 3d printing, work

organization and job quality at the airbus spain case

study. International Journal of Innovation &

Technology Management, 20(6).

Sacchi, R., Becattini, V., Gabrielli, P., Cox, B.,

Dirnaichner, A., Bauer, C., & Mazzotti, M. (2023).

How to make climate-neutral aviation fly. Nature

Communications, 14(1), 3989.

ICEML 2025 - International Conference on E-commerce and Modern Logistics

108

Sarda, N., Estanguet, R., & Ernadote, D. (2023, June).

Model-based approach to support Multi-Disciplinary

Analysis and Optimization capability governance at

enterprise level: preliminary results. In 2023 18th

Annual System of Systems Engineering Conference

(SoSe) (pp. 1-6). IEEE.

Sigov, A., Ratkin, L., Ivanov, L. A., & Xu, L. D. (2022).

Emerging enabling technologies for industry 4.0 and

beyond. Information Systems Frontiers, 1-11.

Westerman, G., Bonnet, D., & McAfee, A. (2014). Leading

digital: Turning technology into business

transformation. Harvard Business Press.

Impact of Digital Transformation on Corporate Value Creation: A Case of Airbus

109