Research Progress of Crystalline Silicon Solar Cells

Muyang Jin

a

The College of Physics and Materials Science, Tianjin Normal University, Tianjin, China

Keywords: Crystalline Silicon, Solar Cells, Metal Oxides, Research Progress.

Abstract: Crystalline silicon solar cells have long dominated the photovoltaic market due to their high conversion

efficiency, stability, and mature industrial chain. This paper systematically reviews the research progress of

crystalline silicon solar cells, with a focus on analyzing the working principles and characteristics of

Passivated Emitter and Rear Contact (PERC) cells, Silicon Heterojunction (SHJ) cells, Tunnel Oxide

Passivated Contact (TOPCon) cells, and Metal Oxide Selective Contact cells. It is found that PERC

significantly reduces recombination losses through localized backside contacts. SHJ achieves full-area

passivation by utilizing amorphous silicon and crystalline silicon heterojunctions. TOPCon combines ultra-

thin oxide layers with doped polycrystalline silicon, offering both high passivation and process compatibility.

Metal oxide selective contact technology simplifies doping processes through band engineering, but interface

stability still needs improvement. Despite the efficiency improvements brought by these technologies, they

still face challenges such as the high purity requirement of n-type silicon substrates for SHJ, the uniformity

control of ultra-thin oxide layers in TOPCon, and the adhesion of metal oxide interfaces. High material costs,

process complexity, long-term reliability, and the consistency of large-scale production remain challenges.

Future research should further balance efficiency and cost, develop new passivation materials, optimize

interface engineering, and promote the efficient transition of technologies to industrialization, to support the

sustainable development of the photovoltaic industry.

1 INTRODUCTION

Crystalline silicon solar cells have a series of

advantages such as high efficiency, good stability and

low cost, and they occupy a dominant position in the

solar cell industry (Xiong & Zhu, 2009). The basic

principle of solar cells is the photovoltaic effect.

When incident light with energy greater than the band

gap width irradiates the p-n junction, electron-hole

pairs are excited in the junction area and the space

near the junction. Under the action of the junction

electric field, the electron-hole pairs separate and drift

to form photogenerated current. Through calculation,

it can be obtained that the theoretical conversion

efficiency limit of the solar spectrum of AM1.5 is

33%, and the corresponding optimal band gap is 1.4

eV.

Since the first single-crystal silicon solar cell with

an efficiency of 6% was developed by Bell Labs in

1954, crystalline silicon technology has undergone

multiple technological iterations (Zhang et al., 2021).

a

https://orcid.org/0009-0009-2254-941X

In the 1980s, the aluminum back surface field (BSF)

cell increased its efficiency to 17%-18% through a

full aluminum back electrode design. After 2000, the

passivated emitter and rear locally diffused contact

(PERC) cell broke through the efficiency bottleneck

with a rear point contact passivation technology,

achieving a laboratory efficiency of over 24% and

quickly becoming the mainstream commercial

technology. In recent years, silicon heterojunction

(SHJ) and tunnel oxide passivated contact (TOPCon)

technologies have further pushed the laboratory

efficiency above 26%, gradually approaching the

theoretical efficiency limit of crystalline silicon of

29% (Green et al., 2023; Yoshikawa et al., 2017;

Feldmann et al., 2019). Currently, high-efficiency

new crystalline silicon solar cells mainly include

passivated emitter solar cells, silicon heterojunction

solar cells, tunnel oxide passivated contact solar cells,

and metal oxide selective contact solar cells.

However, how to continuously improve

efficiency through material innovation and structural

optimization, while reducing manufacturing costs and

Jin, M.

Research Progress of Crystalline Silicon Solar Cells.

DOI: 10.5220/0013828900004708

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Innovations in Applied Mathematics, Physics, and Astronomy (IAMPA 2025), pages 529-533

ISBN: 978-989-758-774-0

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

529

ensuring long-term reliability, remains the core

challenge in current research. This article mainly

introduces the recent application research progress of

crystalline silicon solar cells. The aim is to focus on

the core principles, efficiency improvement strategies,

and industrialization bottlenecks of PERC, SHJ,

TOPCon, and metal oxide selective contact

technologies.

2 CHARACTERISTICS OF

CRYSTALLINE SILICON

Crystalline silicon is an indirect bandgap

semiconductor with a bandgap of 1.12 eV, which is

close to the optimal bandgap of 1.4 eV. The

theoretical conversion efficiency limit of its cells is

29% (Zhang et al., 2021). Among them,

monocrystalline silicon and polycrystalline silicon

are the two main types. Monocrystalline silicon is

composed of a single crystal, with a continuous and

ordered lattice, high carrier mobility, and excellent

photoelectric conversion efficiency. However, its

production cost is relatively high. Polycrystalline

silicon contains multiple grains, with increased

carrier recombination at grain boundaries, resulting in

slightly lower efficiency. However, its production

process is simple and the cost is low, making it

suitable for large-scale application. Both have their

own advantages, respectively meeting the

requirements of high efficiency and cost-

effectiveness.

Furthermore, crystalline silicon has high

mechanical strength and is suitable for large-scale

production. However, it is sensitive to impurities and

requires doping processes to optimize its electrical

properties. For example, n-type silicon with

phosphorus doping and p-type silicon with boron

doping. Typically, single-crystal silicon rods required

for solar cells are prepared using melt pull technology

and suspension zone melting technology.

The development of crystalline silicon solar cell

technology is leading the trend of photovoltaic power

generation. From the perspective of scientific

development, improving the photoelectric conversion

efficiency of crystalline silicon solar cells, reducing

light attenuation, and lowering the cost of power

generation are the directions for the future

development of crystalline silicon solar cells. The

continuous progress in the quality of crystalline

silicon materials and the design of battery structures

will be the key to achieving these goals. (Yang, 2014)

3 HIGH-EFFICIENCY

CRYSTALLINE SILICON

SOLAR CELLS

3.1 Passivated Emitters Solar Cell

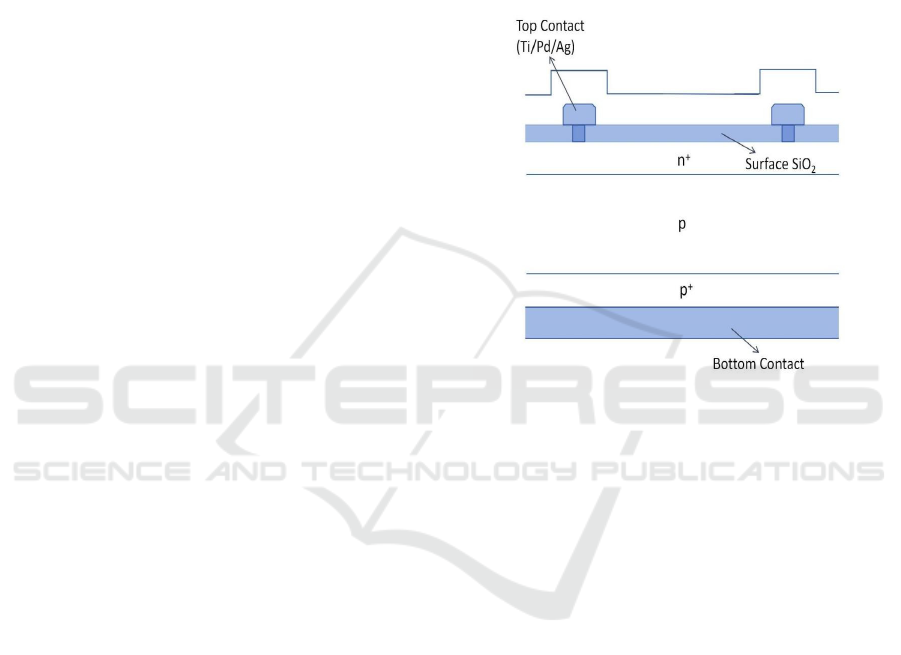

The Passivated Emitters Solar Cell (PESC) was

proposed in 1985. The structure of the cell is shown

in Figure 1.

Figure 1: PESC solar cell structure(Xiong & Zhu, 2009)

Passivated emitter and rear local contact (PERC)

cells use back-point contact instead of the entire

aluminum rear field. The recombination on the back

surface decreases with the reduction of the back

electrode area, but the existence of "edge effect"

makes the recombination larger in small-pitch and

small-contact-point patterns under the same electrode

area ratio (Shen & Li, 2014).

Passivated emitter and rear surface localized

diffusion (PERL) cells are representative of high-

efficiency crystalline silicon cells. The substrate

material of this cell is a single-crystal silicon wafer

fabricated by zone melting, with low resistivity, p-

type boron doping, (100) crystal orientation, a

diameter of 5 ㎝, and a thickness of 280μm, and

double-sided polished (Li et al., 2019). Its core lies in

reducing carrier recombination through surface

passivation technology and combining selective

doping to improve contact performance. The front of

the PERL cell adopts a "inverted pyramid" textured

structure, reducing light reflection to below 5%, as

shown in Figure 2.

IAMPA 2025 - The International Conference on Innovations in Applied Mathematics, Physics, and Astronomy

530

Figure 2: PERL battery structure(Zhang et al., 2021)

The passivated emitter and rear surface full

diffusion (PERT) cell structure retains the

characteristics of PERL while adding a light boron

diffusion layer along the entire rear surface of the cell,

providing a low-resistance path. However, PESC

cells still have limitations such as complex high-

temperature processes, difficulties in fully

passivating metal oxides and silicon interface defects,

material stability affected by the environment, and

difficulties in controlling large-area uniformity,

which restrict their industrial application.

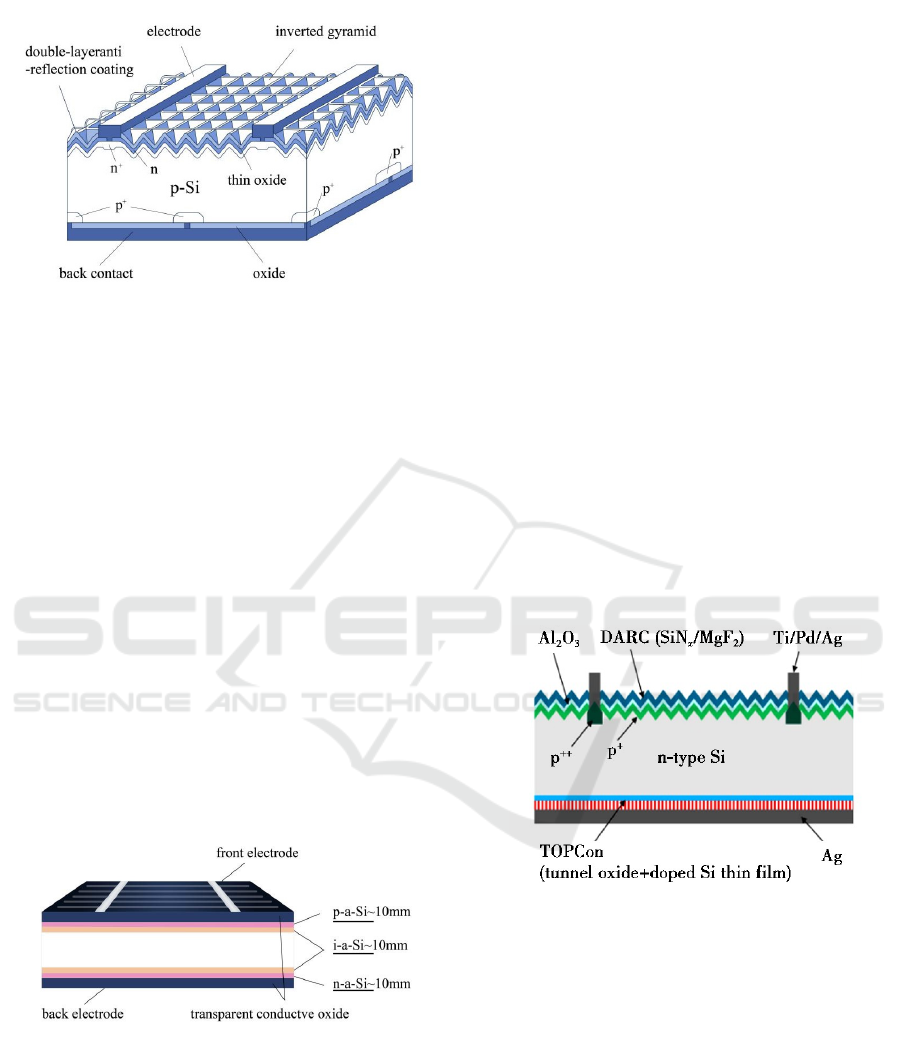

3.2 Silicon Heterojunction Solar Cells

In 1991, Sanyo Corporation of Japan first proposed a

structure that combines monocrystalline silicon and

amorphous silicon films and inserts a thin intrinsic

layer in the middle, namely the silicon-based hetero

junction solar cell SHJ (silicon hetero junction) with

an intrinsic layer, as shown in Figure 3.

Figure 3: SHJ battery structure(Zhang et al., 2021)

SHJ batteries have the advantages of full-area

passivation characteristics, low-temperature process

compatibility, and double-sided power generation.

By using high-quality N-type silicon substrates, both

bulk recombination and interface recombination of

the battery have been effectively controlled. As a

result, the open-circuit voltage of SHJ batteries is

much higher than that of conventional batteries, and

a higher photoelectric conversion efficiency can be

achieved (Li et al.,2019). In addition, the temperature

rise coefficient of SHJ batteries is low, making them

suitable for high-temperature environments. In recent

years, SHJ batteries have made remarkable progress

in efficiency improvement, process optimization and

industrial application. In 2023, domestic research

teams increased the efficiency to 26.8% by

optimizing the interface passivation and the

transparent conductive oxide (TCO) layer (Li X et

al.,2023).

Despite significant progress, SHJ batteries still

face multiple challenges. For example, high

manufacturing cost, photoinduced attenuation (LID),

and the need for optimization of the TCO layer, etc.

3.3 Tunnel Oxide Passivated Contact

(TOPCon) Solar Cells

The tunneling oxide layer passivation contact

(TOPCon) technology has been a research hotspot in

recent years. Firstly, a layer of ultrathin silicon oxide

is prepared on the back of the battery by chemical

methods, and then a thin layer of doped silicon is

deposited, as shown in Figure 4.

Figure 4: TOPCon solar cell structure(Chen et al., 2019)

According to the doping type of the silicon thin

layer, it is divided into p-TOPCon and n-TOPCon.

Silicon oxide reduces the surface state and lowers the

tunneling resistance. Doped polycrystalline silicon

provides field-induced passivation. Together, the two

form a passivation contact structure, providing good

surface passivation for the back of the silicon wafer

(Fu et al., 2012).

Tunneling oxide passivated contact (TOPCon)

solar cells have advantages such as high passivation

performance, process compatibility, and material

optimization. In recent years, atomic layer deposition

(ALD) technology has been used to prepare uniform

Research Progress of Crystalline Silicon Solar Cells

531

and dense silicon oxide layers with thickness control

accuracy reaching the sub-nanometer level.

Meanwhile, the in-situ doping of polycrystalline

silicon technology has improved the carrier mobility

(Ding et al.,2021). In 2023, a Chinese research team

further increased the efficiency to 26.5% by

optimizing the doping concentration of polysilicon

and the interface passivation process (Wang et

al.,2023). The TOPCon structure combines excellent

surface passivation effect with low contact electricity.

Its process is compatible with existing production

lines and is regarded as the mainstream direction of

the next-generation high-efficiency batteries.

With the advancement of technology, there are

still some challenges. For instance, enhancing the

uniformity of the oxide layer, improving the doping

process of polysilicon, and controlling costs, etc.

3.4 Selective Contact of Metal Oxides

Metal oxides achieve efficient and stable selective

carrier transport through band engineering, interface

passivation and optical synergy. Efficient carrier

selective contact is the key to improving the

efficiency of solar cells, but heavy doping can have

adverse effects on the open-circuit voltage, short-

circuit current and blue light response of the cells.

The selective contact technology of metal oxides

achieves efficient separation and collection of carriers

through band engineering. Transition metal oxides

(MoOx, WOx, V2Ox, CrOx, CuOx), graphene,

carbon nanotubes, etc. All materials with high work

functions and hole transport capabilities can be

attempted as hole transport layers (HTL), which can

passivate the interface and reduce the contact

resistance (Yu,2019). The core of the selective

contact technology of metal oxides lies in material

innovation and the improvement of interface stability.

Take MoO₃ as an example. As a hole transport layer,

it can replace the traditional doping process, simplify

the production steps and improve the mechanical

reliability of the components. Studies have shown

that MoO₃ has a wide band gap (3.0-3.6 eV) and a

high work function (5.3-5.7 eV), which enables it to

exhibit excellent hole selectivity in perovskite and

silicon heterojunction solar cells (Wang et al., 2019).

However, the interface adhesion and long-term

stability still need to be further optimized.

4 DEVELOPMENT DIRECTIONS

Passivated emitter batteries, as the current

mainstream technology, have an efficiency close to

the industrialization limit of 24%. In the future, the

focus will be on suppressing photoinduced decay

(LID) and further reducing costs. The development of

new hydrogen passivation processes (such as laser-

assisted hydrogen injection) can reduce the center

density of boron-oxygen recombination and extend

the service life of components (Chen Z et al.,2021).

The future of silicon heterojunction cells (SHJ)

lies in cost reduction, efficiency improvement and

enhanced adaptability to multiple scenarios. The cost

can be reduced by adopting low-purity N-type

silicon-based and amorphous silicon coating process

optimization (Masuo et al.,2022). SHJ and perovskite

tandem technology demonstrated an efficiency

potential of over 30%. In 2023, the research team

achieved a laboratory efficiency of 28.5% through

interface band engineering (Al-Ashouri et al.,2020)

The development direction of tunneling oxide

passivated contact cells (TOPCon) lies in process

simplification and breaking through the efficiency

limit. Research in 2022 showed that double-sided

passivated contact could increase laboratory

efficiency to 26.8%(Wang et al.,2022). The core of

selective contact technology for metal oxides lies in

material innovation and the improvement of interface

stability, reducing carrier recombination by

optimizing the band structure and interface

passivation. In recent years, the contact technology of

undoped metal oxides has become a research hotspot.

For example, the WO3 layers prepared by the all-

solution method not only exhibit excellent hole

selectivity and high light transmittance, but also can

avoid the high-temperature doping process,

significantly simplify the preparation process and

reduce the production cost (Zhang et al., 2022). In

addition, new binary oxides and ternary oxides (such

as MoOx, VOx and NiOx) have achieved battery

efficiency of more than 20% through band regulation,

while the application of atomic layer deposition

technology (ALD) has further enhanced the accuracy

of interface passivation. In the future, the

development of metal oxide materials that can be

processed at low temperatures and are

environmentally stable will become the key to

promoting industrialization.

5 CONCLUSION

Crystalline silicon solar cells enhance their

conversion efficiency by reducing the reflection of

incident light by the cells and minimizing the

recombination loss of photogenerated carriers within

the cells. On this basis, solar cells have developed

IAMPA 2025 - The International Conference on Innovations in Applied Mathematics, Physics, and Astronomy

532

types such as passivated emitter cells, silicon

heterojunction solar cells, and TOPCon solar cells.

Through passivation optimization, structural

innovation and material engineering, the laboratory

efficiency has been pushed up to 26%-28%.

Despite significant progress, there are still

challenges such as the balance between cost and

efficiency, material and process innovation, and

consistency in large-scale production. Selective

contact of undoped metal oxides has become a new

development direction. PERC is limited by

photoinduced attenuation and the reliability of the

thinning process. SHJ needs to reduce the cost of N-

type silicon-based coatings and the complexity of

amorphous silicon coating. TOPCon needs to solve

the uniformity of the oxide layer and the accuracy of

the doping process. Metal oxide technology needs to

break through interface stability and consistency in

scale.

By breaking through the efficiency limit through

layering technology, green manufacturing and

intelligent process innovation have become new

development directions. Through multi-technology

collaborative innovation and vertical integration of

the industrial chain, crystalline silicon cells are

expected to achieve a balance among efficiency, cost

and sustainability, accelerating the progress of the

global photovoltaic industry.

REFERENCES

Al-Ashouri, A., Köhnen, E., Li, B., Magomedov, A.,

Hempel, H., Caprioglio, P., ... & Albrecht, S. 2020.

Monolithic perovskite/silicon tandem solar cell with>

29% efficiency by enhanced hole extraction. Science,

370(6522), 1300-1309.Chen, J., Zhao, S., Gao, T., 2019.

Latest Progress and Development Trends of High-

Efficiency Monocrystalline Silicon Solar Cells.

Materials Review, 33(1), 110-116.

Ding, K., Aeberhard, U., Bivour, M., Köhler, M., Hermle,

M., Glunz, S. W., 2021. In-situ doped poly-Si for high-

performance TOPCon solar cells. IEEE Journal of

Photovoltaics, 11(1), 2-8.

Feldmann, F., Simon, M., Bivour, M., Reichel, C., Hermle,

M., Glunz, S. W., 2019. Tunnel oxide passivated

contacts as key technology for high-efficiency silicon

solar cells. Nature Energy, 4(10), 884-891.

Fu, M., Yuan, P., Fan, L., 2012. Performance Analysis of

Several High-Efficiency Crystalline Silicon Solar Cells.

Materials Review, 5(1), 1-5.

Green, M., Dunlop, E., Hohl-Ebinger, J., Yoshita, M.,

Kopidakis, N., Hao, X., 2023. Solar cell efficiency

tables (Version 62). Progress in Photovoltaics, 31(7),

651-663.

Li, X., Zhang, C., Wang, Z., Shen, W., 2023. 26.8%

efficiency silicon heterojunction solar cell via advanced

interface passivation. Advanced Energy Materials,

13(5), 2203015.

Li, Z., Yang, L., Shen, W., 2019. New Progress in Silicon-

Based Heterojunction Solar Cells. Progress in Physics,

39(1), 1-22.

Shen, W., Li, Z., 2014. Physics and Devices of Silicon-

Based Heterojunction Solar Cells. Beijing: Science

Press, 11-204.

Wang, Y., Zhang, C., Shen, W., 2022. 26.8% efficiency

bifacial TOPCon solar cell. Nature Energy, 7(2), 123-

130.

Wang, Y., Zhang, C., Shen, W., 2023. 26.5% efficiency

TOPCon solar cell via interface engineering. Advanced

Energy Materials, 13(15), 2203001.

Xiong, S., Zhu, M., 2009. Fundamentals and Applications

of Solar Cells. Beijing: Science Press, 67-149.

Yang, S., 2014. Research on Light-Induced Degradation of

Crystalline Silicon Solar Cell Efficiency. Hebei

University of Technology.

Yoshikawa, K., Kawasaki, H., Yoshida, W., Irie, T.,

Konishi, K., Nakano, K., Uto, T., Adachi, D.,

Kanematsu, M., Uzu, H., Yamamoto, K., 2017.

Exceeding conversion efficiency of 26% by

heterojunction interdigitated back contact solar cell.

Nature Energy, 2(5), 17032.

Yu, J., 2019. Research on Silicon-Based Heterojunction

Solar Cells with Metal Oxides as Carrier Selective

Transport Layers. University of Chinese Academy of

Sciences.

Zhang, Q., Wang, Z., Shen, W., 2022. Solution-processed

WO₃ for low-cost carrier-selective contacts. Advanced

Science, 9(5), 2104562.

Zhang, Y., Chen, X., Zhou, Z., 2021. Research Progress of

Crystalline Silicon Solar Cells. Acta Energiae Solaris

Sinica, 42(10), 49-60.

Research Progress of Crystalline Silicon Solar Cells

533