Principles and Applications of Optical Temperature Measurement

Methods

Sicheng Xu

a

The School of Physical Science and Technology, Nantong University, Nantong, Jiangsu, 226000, China

Keywords: Optical Temperature Measurement, Radiation Thermometry, Fiber-Optic Temperature Measurement,

Non-Contact Temperature Sensing, Industrial Applications.

Abstract: Temperature measurement plays a vital role in industrial production, scientific research, and daily life.

Traditional contact temperature measurement methods face limitations such as restricted measurement range

and probe aging in extreme environments. Contact temperature measurement techniques offer high accuracy,

fast response, and strong adaptability, but still encounter challenges such as the uncertain emissivity of high-

temperature objects and interference from environmental reflections. This paper systematically reviews the

fundamental principles of optical temperature measurement, categorizes its methods, and elaborates on the

principles, characteristics, and applications of radiation thermometry and fiber-optic temperature

measurement. Case studies, including molten steel casting temperature monitoring, gas turbine blade

temperature measurement, and natural gas tank inspection, are analyzed to explore the applicable scenarios,

advantages, and disadvantages of different optical methods. Optical temperature measurement enables non-

contact, real-time, and long-distance temperature sensing, making it highly promising for applications in

industrial high-temperature monitoring and energy pipeline inspection. Research shows that combining

optical techniques with traditional methods, optimizing optical system design, and introducing advanced

signal processing technologies can enhance measurement accuracy and expand their applicability in complex

environments.

1 INTRODUCTION

The measurement of surface temperature and its

distribution is crucial and has a wide range of

applications in various fields. Traditional temperature

measurement methods mainly include pressure type,

RTD, thermocouple, liquid thermometer, etc., mostly

contact temperature measurement. Despite its high

accuracy and practicality, it is limited by temperature

range, linearity, probe aging, and response time in

extreme environments, with a long response time, and

cannot be used to measure very high temperatures and

the temperature of moving objects, and is gradually

being replaced by non-contact temperature

measurement methods.

The non-contact temperature measurement

method can measure the temperature of objects with

rapid temperature change without affecting their

status by simply aligning the optical receiving system

a

https://orcid.org/0009-0009-6587-9742

to the object to be measured, which can realize non-

destructive, real-time monitoring of temperature. By

optimizing the design of the thermometer's optical

system, it is also possible to measure the temperature

distribution in three-dimensional space (Xu & Yang,

2012). The method has the advantages of high

accuracy, high response, and adaptability. For

example, the infrared imager response speed,

response time up to microseconds, suitable for

measuring panoramic fast temperature field

measurement range of -30 ~ 2000 ° C, sensitivity up

to 0.05 ° C, and error of ± 0. 5% of the full scale.

Temperature measurement of small areas up to a few

microns can be simultaneously performed on the

point temperature, line temperature, and surface

temperature measurement, measurement results are

visualized in an image (Xie, 2017). Therefore, non-

contact temperature measurement has gradually

become an important method of modern industrial

temperature measurement.

Xu, S.

Principles and Applications of Optical Temperature Measurement Methods.

DOI: 10.5220/0013824500004708

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Innovations in Applied Mathematics, Physics, and Astronomy (IAMPA 2025), pages 295-302

ISBN: 978-989-758-774-0

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

295

Among them, photothermometry is a typical non-

contact temperature measurement method, which

mainly includes infrared radiation thermometry, fiber

optic thermometry, Raman spectroscopy,

phosphorescence thermometry, laser induced

fluorescence thermometry, and chromatic aberration

thermometry, etc. The purpose of this study is to

review in depth the research and progress of radiation

thermometry and fiber optic thermometry, as well as

their applications in various fields. The purpose of

this study is to review and summarize the research and

progress of radiation and fiber optic thermometry, as

well as their applications in various fields, and to look

forward to the future trends from the current

development, to contribute new insights and ideas to

theory and practice, and to make positive

contributions to the progress of related fields.

2 RADIOMETRIC

THERMOMETRY

2.1 Principle of Radiometric

Thermometry

The basic principle underlying radiometric

thermometry is the blackbody radiation law, which

states that the radiation spectrum of a blackbody is

determined by the thermodynamic temperature of the

blackbody. This usually includes Planck's blackbody

radiation law, Wien's displacement law, and the

Stefan-Boltzmann law. On this basis, the total

radiation law, the peak Wien displacement law, and

the brightness thermometry law can be derived (Xu &

Yang, 2012).

2.1.1 Venn's Method of Peak Displacement

Wien's displacement law, which can be derived from

Planck's formula, describes the relationship between

the wavelength and frequency corresponding to the

maximum brightness in blackbody radiation. i.e.

(1)

where

is the value of the wavelength

corresponding to the maximum radiance at that

temperature in m.

For a blackbody the relation between

monochromatic radiance and temperature and

wavelength is given by Planck's equation:

(2)

where

is the irradiance of the blackbody;

is the wavelength;

=

is the absolute temperature;

is the first Planck coefficient and m is the second

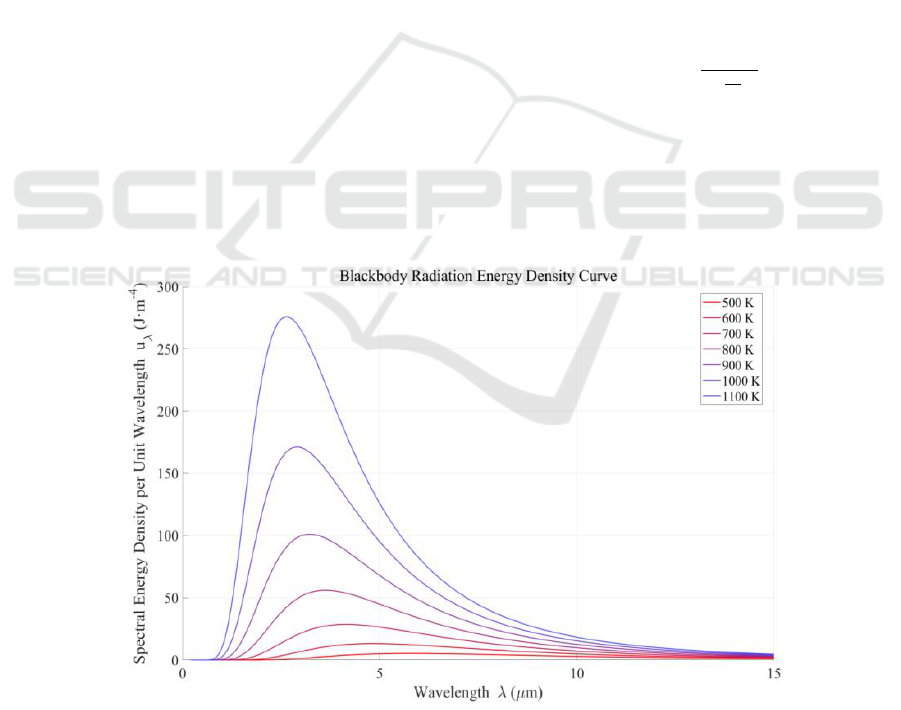

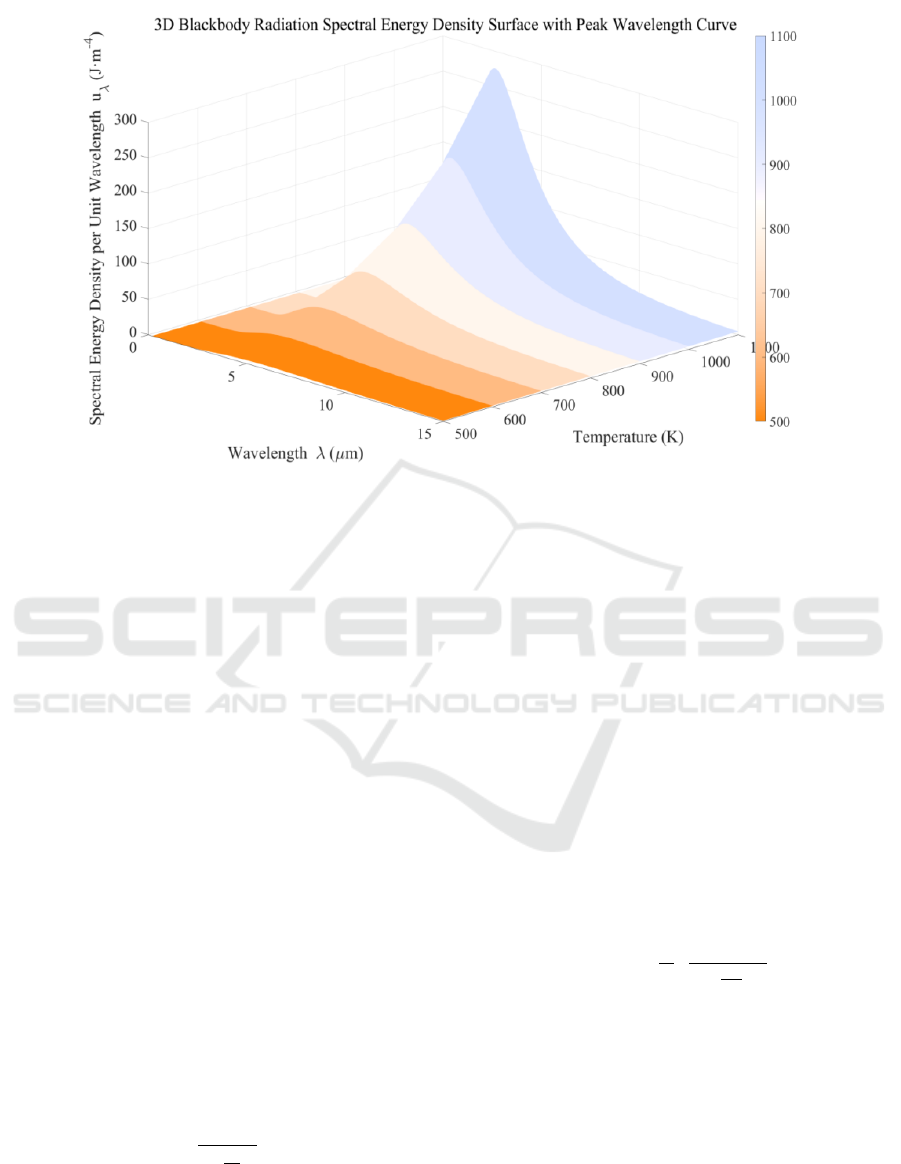

Planck coefficient. Figures 1 and 2 are the images

drawn according to Planck's formula.

Figure 1: Spectral energy density curves of blackbody radiation at different temperatures (Original).

IAMPA 2025 - The International Conference on Innovations in Applied Mathematics, Physics, and Astronomy

296

Figure 2: 3D surface of blackbody radiation spectral energy density as a function of wavelength and temperature (Original).

According to the Figures. 1, 2, it can be seen that

the monochromatic radiance has a unique extreme

value, and the product of its corresponding peak

wavelength and temperature is a definite constant

. That is, the temperature of the radiating body

can be determined simply by determining this value.

2.1.2 Total Radiometric Thermometry and

Luminance Thermometry

The total radiation method is based on the Stefan-

Boltzmann law, which integrates the spectral radiance

over the entire wavelength to obtain the full-wave

radiant energy flux per unit area. This means that the

temperature of the radiating body is determined by

measuring the total radiation:

(3)

Where

is the total amount of radiation

radiated per unit time from a unit area of a blackbody

at a temperature of , called the total radiance;

is the Stefan-

Boltzmann constant, and is the temperature of the

object. The temperature of the radiating body can be

determined as long as

is measured.

If Planck's formula is written in the form of

luminosity, i.e (Fan, 2016).

(4)

where

is the monochromatic radiance

measure of the spectrum. That is, the temperature of

the radiator is determined by measuring the radiant

luminance

of the radiator.

2.1.3 Multispectral Pyrometry

Multispectral thermometry, in contrast to total

radiometric thermometry, which collects the total

radiant energy in the infrared band (where the object

to be measured is approximated as an ideal

blackbody, i.e., the surface emissivity ε(λ) is

approximated to be 1), collects the intensity of

radiation at multiple wavelengths to derive the

temperature based on a mathematical model.

Consider general object surface emissivity

(5)

A system of equations can be constructed for the

intensity of radiation

measured at multiple

wavelengths

:

(6)

The temperature T and the unknown emissivity

ε(λ) can be solved for using numerical fitting.

2.2 Radiation Thermometry

Characteristics

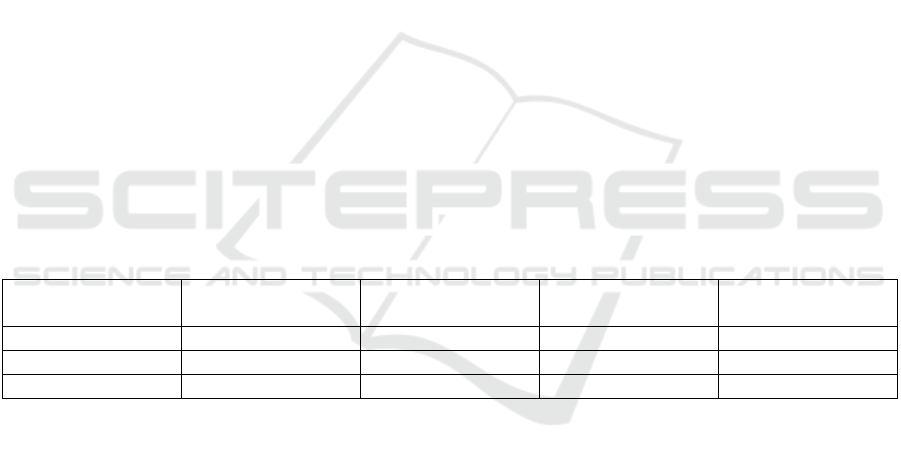

As shown in Table 1, a comparison of the advantages

and disadvantages of the different methods is

demonstrated.

Principles and Applications of Optical Temperature Measurement Methods

297

Table 1: Comparison of different methods.

Temperature

measurement method

Main principle

Vantage

Drawbacks

Venn's method of

peak displacement

Calculation of temperature

by determining the peak

wavelength of radiation

The method is intuitive and simple

to calculate

Susceptible to background

noise and large measurement

errors

Luminance

thermometry

Measuring the brightness

of monochromatic

radiation to derive

temperature

Simple equipment, fast

measurement

Limited measurement

accuracy by relying only on

single-wavelength

information

Total radiometric

thermometry

Measurement of the total

radiant energy of the target

in all wavelength ranges

Wide coverage and high

temperature measurement

accuracy

Need to consider the spectral

response characteristics of

the detector, interference

from background radiation

Multispectral

pyrometry

Detects infrared radiation

in multiple wavelength

ranges to obtain spectral

information.

Reduces emissivity variations and

environmental interference errors,

making it suitable for high-

precision measurements.

Complexity of equipment

and calculations

2.3 Radiometric Thermometry

Applications

The radiation method of temperature measurement is

applicable to the temperature measurement of solid

surfaces such as blast furnace walls, workpiece

surfaces, cooling walls, etc.; the spectral line

broadening method and the molecular spectral line

rotation light intensity distribution method are

applicable to the measurement of the temperature and

its distribution in the furnace chamber. In the

industrial field, the application of optical temperature

measurement technology to the real-time monitoring

of blast furnace temperature is of great significance to

extend the life of the furnace, improve product

quality, and reduce energy consumption (Xu & Yang,

2012).

When smelting new steel grades, the first

steelmaking plant of Tianjin Tiangang Group Co.,

Ltd. needs to accurately determine the casting

temperature of steel when it is cast into ingot molds.

Due to the interference of smoke on site, the

measurement result of a conventional infrared

thermometer or optical pyrometer is more than 300

degrees lower than the actual value. If a thermocouple

thermometer is used for the measurement, the

thermocouple will be lost.

In order to solve this problem, the plant uses fiber

optic infrared thermometer, on-site temperature

measurement, the probe and fiber optic cable installed

in a metal protective tube with insulation, manipulate

the protective tube to the probe end of the steel close

to the steel (from the steel only 300mm) for

measurement. When the steel was ready to be

discharged, the fiber optic infrared thermometer was

calibrated alternatively with a consumable tungsten-

molybdenum thermocouple thermometer (the

consumable thermocouple thermometer was

calibrated at 1663°C and the fiber optic infrared

thermometer was calibrated at 1637°C, and the fiber

optic infrared thermometer was adjusted from 1637°C

to 1663°C). In the casting site, each ladle can be cast

eight groups of ingot molds, each group of about 8min

minutes. At the initial trial, eight casting temperatures

were measured, in chronological order: 1574°C,

1602°C, 1651°C, 1643°C, 1631°C, 1617°C, 1596°C,

1568°C. The measurement results correctly reflect the

law of casting temperature change with time, which

provides a reference for the development of the

smelting process for new varieties of steel. After a

number of casting temperature measurements, the

reproducibility of the program is good (Cao, 1998).

This composite scheme combines radiation

thermometry with traditional thermocouple

thermometry, and calibrates the fiber-optic infrared

thermometer with a consumable thermocouple of

higher accuracy to compensate for the initial

deviation of the instrument. According to the

measurement data, the scheme has better repeatability

and higher stability, and the loss is much lower than

the traditional thermocouple temperature

measurement scheme, and the accuracy is higher than

that of the scheme using only infrared temperature

measurement.

In addition, Zhan Chunlian et al. from the No. 205

Research Institute of China's weapon industry

proposed a high-speed multispectral real-time

temperature measurement technology program for

gas turbine blades, which solves the technical

problem that the high-speed and high-temperature

blades of domestic gas turbines cannot be monitored

IAMPA 2025 - The International Conference on Innovations in Applied Mathematics, Physics, and Astronomy

298

in real time. By constructing a comprehensive system

integrating high-speed multispectral detection, optical

decomposition, signal processing, and software

monitoring, Chunlian Zhan effectively solved the

limitations of traditional temperature measurement

methods in high temperature and high-speed

environments, and realized the goal of online real-

time temperature measurement and fault warning for

turbine blades (Zhang et al., 2018).

3 OPTICAL FIBER

THERMOMETRY

3.1 Principle of Distributed Fiber Optic

Thermometry

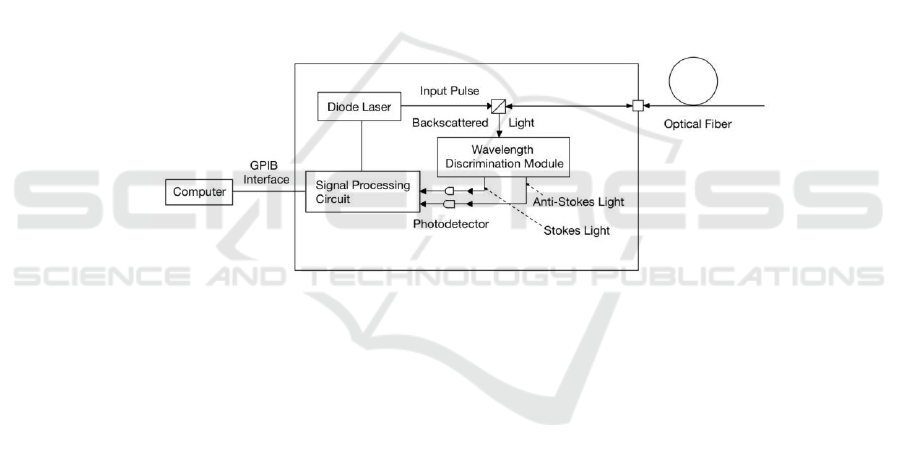

A distributed fiber optic temperature sensor obtains

spatial temperature distribution information by using

the principle of using light transmission in the optical

fiber can produce backward scattering. Injected into

the fiber with a certain energy and width of the laser

pulse, it is transmitted in the fiber at the same time

constantly produce backward scattering light waves,

the state of these light waves by the fiber where the

temperature of the scattering point and change the

scattering back to the light waves by wavelength

division multiplexing, detection and demodulation,

sent to the signal processing system can be real-time

display of temperature signals and by the optical fiber

light wave transmission speed and the backward light

return time can be on the These information can be

localized. The principle and structure of the block

diagram are shown in Figures 3 and 4 (Bo, 2024).

Rayleigh scattering, Raman scattering, and

Brillouin scattering are mainly involved in distributed

fiber optic temperature sensors.

Figure 3: This diagram illustrates the basic working principle and signal processing flow of a fiber-optic distributed

temperature sensing system based on Raman scattering (Original).

3.1.1 Rayleigh Scattering

Rayleigh scattering refers to the elastic scattering

phenomenon that occurs when an incident

electromagnetic wave (e.g., visible light) encounters

a tiny particle that is much smaller than its

wavelength, due to the excitation of the particle by an

external electric field that exhibits an electric dipole

radiation effect. Rayleigh scattering occurs when light

is incident into an optical fiber, where the

backscattered light can be used to monitor the

temperature distribution.

The backscattered optical power per unit length is:

(7)

Here, it is assumed that the fiber is homogeneous

and absorption is neglected. Where

, i.e.,

the time experienced by the optical pulse front from

injection to return to the injection end from the L point

on the optical fiber, different t corresponds to

different positions of the sensing fiber;

is the

speed of light in the optical fiber;

is the injected

optical pulse energy; is the backward scattering

factor; is the Rayleigh scattering coefficient

(proportional to the temperature), the change of the

temperature causes the change of the numerical

aperture of the optical fiber and the Rayleigh

scattering coefficient, thus affecting the backward

intensity of the scattered light. Based on this property,

the temperature distribution along the fiber can be

deduced by analyzing the intensity of the

backscattered signal returned at different times during

the transmission of light pulses in the fiber.

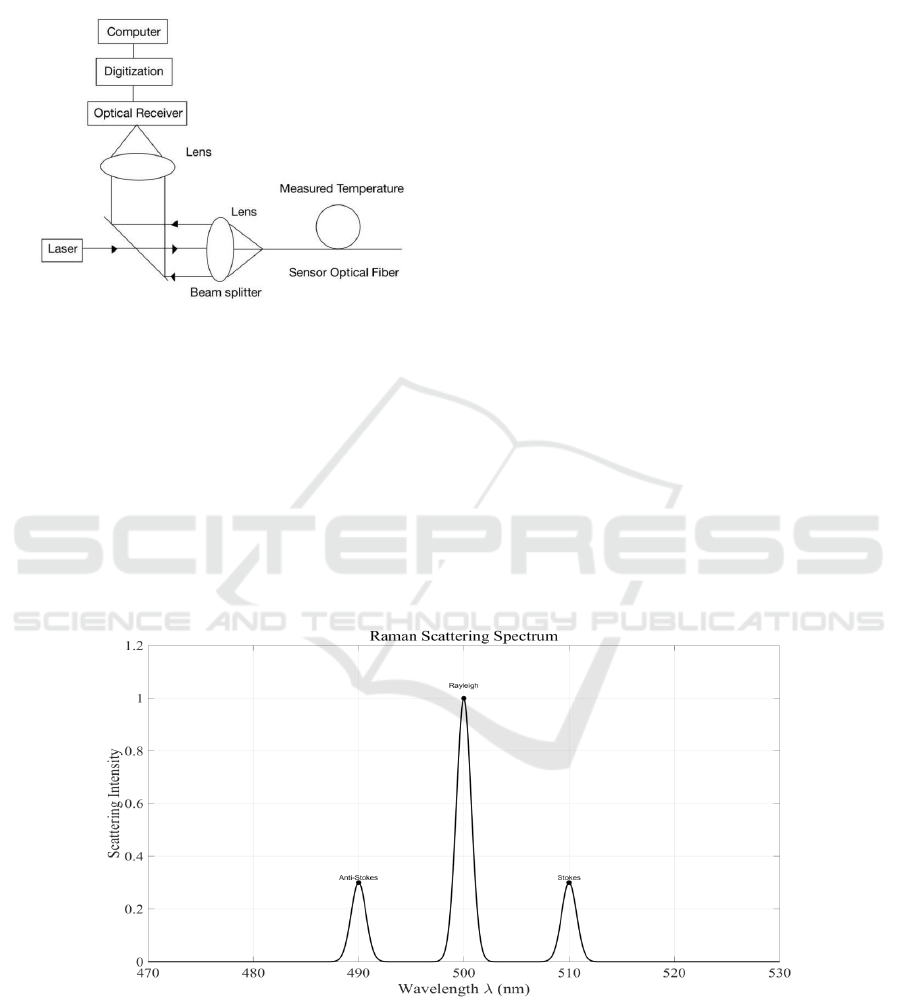

Rayleigh scattering temperature measurement

usually uses a pulsed laser light source and a beam

splitter between the laser and the fiber. When the

backscattered light returns to the injection end of the

optical pulse, the beam splitter reflects it back into the

detection optical path. The light signal is then

detected by an optical receiver system consisting of

an avalanche photo diode (APD) and a mutual

Principles and Applications of Optical Temperature Measurement Methods

299

impedance amplifier, and transmitted to a computer

for display after signal processing (Shi et al., 1997).

The structure of the device is shown in Figure 4.

Figure 4: This diagram shows a fiber-optic temperature

sensing system using a laser source, beam splitter, lenses,

and an optical receiver for temperature measurement and

digitization. (Original).

In distributed fiber optic temperature

measurement systems that use Rayleigh scattering,

the insensitivity of Rayleigh scattered light to

physical quantities of temperature leads to a lower

temperature resolution in systems that use this

scheme. Therefore, the technology of the distributed

fiber optic temperature measurement system based on

Rayleigh scattered light is gradually being eliminated.

When Brillouin scattering is used in the distributed

fiber-optic temperature measurement system, the

distributed temperature measurement system using

Brillouin scattering is not considered for the time

being because the corresponding variable physical

quantities in the Brillouin-scattered signals and the

changes in the temperature are sensitive to the

changes in the temperature, which are prone to cross-

influence. While in the distributed fiber optic

temperature measurement system based on Raman

scattering, its Raman scattering signal is only

sensitive to the temperature change around the fiber,

not easy to be interfered by other signals, and the

theoretical knowledge is relatively rich and perfect,

there is no special requirement for the type of optical

fiber, which is easier to realize and more practical

value compared to the above two techniques (Xia et

al., 2019).

3.1.2 Raman Scattering

Raman scattering is an inelastic light scattering

phenomenon, i.e., after the incident photon interacts

with matter, the frequency of the scattered photon

changes due to molecular vibration or lattice

vibration, resulting in Stokes and anti-Stokes

scattering, and its intensity is much lower than that of

Rayleigh scattering, which is about as much as that of

Rayleigh scattering as shown in Figure 5.

Figure 5: This graph shows the Raman scattering spectrum with Rayleigh, Anti-Stokes, and Stokes peaks used for temperature

sensing (Original).

The following is the ratio (R) of anti-Stokes light

to Stokes light intensity for Raman scattering as a

function of temperature.

(8)

Where,

,

are the anti-Stokes and Stokes

light intensities of Raman scattering, respectively;

,

are the anti-Stokes and Stokes light

wavelengths of Raman scattering, respectively, which

IAMPA 2025 - The International Conference on Innovations in Applied Mathematics, Physics, and Astronomy

300

are only related to the fiber material: h is Planck's

constant; c is the speed of light;γis the Raman

frequency-shift wave number, which is only related to

the fiber material; k is Boltzmann's constant; and T is

the absolute temperature.

It can be seen that the optical intensity ratio R is

not affected by the incident laser power, injection

conditions and stress, and thus has good temperature

response characteristics. Therefore, the temperature

distribution along the fiber can be accurately

determined by analyzing the backward Raman

scattering intensity ratio of light pulses returned at

different times when they are transmitted in the fiber

(Hu, 2014).

3.2 Fiber Optic Thermometry in

Industry

Due to the distributed Raman temperature

measurement technology has the advantages of

intrinsic safety, easy to use, low maintenance cost,

strong anti-interference ability, large measurement

range, in the long-distance application scenarios can

be achieved Continuous and uninterrupted

temperature detection, can be quickly demodulated in

real time temperature, and can be arranged in the

environment of the complex and harsh environments,

and therefore is often used in oil and gas transmission

pipelines, large warehouses, large machinery,

Therefore, it is often used in oil and gas pipelines,

large warehouses, large machinery, power supply and

other scenarios.

In the field of liquefied natural gas (LNG) storage

tanks, the distributed fiber optic temperature

measurement and warning system is of great

significance in the safety management of the tank

area. Through the reasonable deployment of

distributed fiber optic temperature measurement can

be accurate measurement of the tank temperature, can

detect the temperature of the tank is too low point, in

order to achieve the LNG storage tank perlite filling

layer settlement of real-time online monitoring.

Distributed fiber optic temperature monitoring system

for LNG storage tank temperature monitoring and

early warning provides nearly perfect detection

performance (Bo, 2024). Table 2 shows the

evaluation results in three stages after application.

With the continuous improvement of the system, its

temperature measurement accuracy is significantly

improved, and the percentage of samples with error

within 5% is increased from 61.58% in stage 1 to

93.93% in stage 3. Meanwhile, the most negative

error and the most positive error are also reduced

significantly, indicating that the system error tends to

converge and the temperature measurement results

are more stable and reliable.

Table 2: Assessment results in the three phases (Xu, 2024).

Phase

Total number of

samples taken

Conformity (M

≤ 5%)

minuscule error

logarithmic

error

Phase 1

151

61.58%

-51.68%

75.58%

Phase 2

143

85.31%

-21.54%

17.50%

Phase 3

33

93.93%

-6.02%

1

4 CONCLUSION

Compared with the traditional contact temperature

measurement method, the optical temperature

measurement technology has the advantages of fast

response speed, good dynamic performance, and will

not destroy the surface temperature field of the

measured medium. Due to the uncertainty of the

emissivity of the surface of the object,

photothermometry may produce errors in the

temperature determination process. Therefore, the

relevant fields by combining the traditional

thermocouple calibration measurement, the

introduction of signal processing systems (including

APD and mutual impedance amplifier, etc.) to

achieve real-time display of temperature signals and

distribution of localization, combined with the

confocal measurement technology, but also to obtain

the temperature distribution of the three-dimensional

space, the computer automated control and other

programs. Thus, the optical temperature measurement

technology without interference, fast response, wide

measurement range of features to a greater extent to

benefit human production and life and scientific

research. In summary, the development trend of

optical temperature measurement technology is

toward higher accuracy, intelligence and automation,

multi-functional integration, better performance and

stronger environmental adaptability, the future will

bring more innovation and convenience for industrial

production and scientific research fields.

Principles and Applications of Optical Temperature Measurement Methods

301

REFERENCES

Bo, Z., 2024. Application of fiber optic temperature

measurement technology in engineering practice. Soda

Ash Industry, (05), 40–42.

Cao, B., 1998. Application of radiation temperature

measurement technology. Journal of Tianjin

Polytechnic Institute, (02), 58–60.

Fan, S., 2006. Infrared radiation temperature measurement

accuracy and error analysis. Changchun University of

Science and Technology.

Hu, Z., 2004. Principle and application of distributed fiber

optic temperature measurement system. China

Instrumentation, (07), 44–46.

Jianchun, X., Li, X., Wu, Y., Zhao, Y., Li, S., 2019.

Simultaneous measurements of distributed temperature

and discrete strain based on Hybrid Raman/FBG system.

Sensors and Actuators: A. Physical, 296.

Shi, W., Huang, D., Liu, D. 1997. Research and progress of

distributed fiber optic temperature sensors.

Semiconductor Optoelectronics, (04), 8–11.

Xie, Q., 2017. Comparison of several radiation temperature

measurement techniques. China Inspection and Testing,

25(04), 37–39+27.

Xu, X., Yang, X., 2012. Non-contact temperature

measurement technology. Science and Technology

Communication, (05), 159–160.

Xu, Z., 2024. Application of distributed fiber optic

temperature measurement system in monitoring of

perlite settlement in liquefied natural gas storage tanks.

Fluid Measurement and Control, 5(01), 31–34.

Zhan, C., Han, J., Lu, S. 2018. Research on multispectral

temperature measurement technology of ammunition

explosion flame temperature. Measurement Technology,

38(06), 48–52.

IAMPA 2025 - The International Conference on Innovations in Applied Mathematics, Physics, and Astronomy

302