Digital Transformation of the Nuclear Industry:

Leveraging Robotics, AI, and Digital Twins for Standardised,

Safe, and Efficient Operations

Abdenour Benkrid

a

, Omar Zahra

b

, Réka Szőke

c

, Ankur Shukla

d

and István Szőke

e

Institute for Energy Technology, OS alle 5, 1777 Halden, Norway

Keywords: Digital Transformation, Nuclear Back-end, Robotics, Artificial Intelligence (AI), Digital Twins (DT), Safety,

Building Information Modelling (BIM), Decommissioning, Waste Management, Security, Cybersecurity.

Abstract: The nuclear back-end is experiencing a pivotal digital transformation driven by the integration of robotics,

artificial intelligence (AI), and digital twin (DT) technologies. These innovations hold strategic potential to

enhance safety, efficiency, and standardisation across decommissioning, waste management, and site

remediation. Using the Technical, Economic, Commercial, Organisational, and Political framework (TECOP)

and Five Case Models, this paper critically assesses the value, deployment readiness, and integration barriers

of these digital tools across technical, organisational, and regulatory domains. Emphasis is placed on robotics

in 5D contexts, the nuclearization challenge, and the role of DT and Building Information Modelling (BIM)

in scenario planning and compliance. Persistent obstacles, including fragmented certification, cybersecurity

vulnerabilities, limited interoperability, and resistance to change, are analysed using data from expert surveys

and project experience. Targeted strategies are proposed to address these issues and accelerate technology

readiness and regulatory harmonisation. The contributions of EU-funded initiatives such as HARPERS,

DORADO, and XS-Ability are highlighted as catalysts for safe and scalable digital innovation. By providing

actionable recommendations, this paper supports policymakers, industry leaders, and technology developers

in advancing the digital evolution of the nuclear back-end.

1 INTRODUCTION

The nuclear back-end encompassing decommissioning,

radioactive waste management, and site remediation

represents some of the most technically demanding,

hazardous, and stringently regulated domains within

the energy sector (IAEA, 1992). Traditional

operational approaches frequently fall short in

delivering the scalability, efficiency, and

transparency required to address contemporary safety

and sustainability objectives, particularly in the

context of aging infrastructure and increasing

regulatory oversight (Bogue, 2011). In response,

industry stakeholders are progressively embracing

digital transformation strategies, including the

a

https://orcid.org/0000-0001-7217-4040

b

https://orcid.org/0000-0003-1644-6480

c

https://orcid.org/0009-0000-8992-5031

d

https://orcid.org/0000-0002-6737-2031

e

https://orcid.org/0000-0001-5438-7552

deployment of robotics, artificial intelligence (AI),

and digital twin (DT) technologies (Smith et al.,

2020; Benkrid et al., 2025).

These advanced tools are reshaping the landscape

of monitoring, maintenance, and dismantling

activities in nuclear facilities. Robotic systems

facilitate remote interventions in high-radiation or

structurally compromised environments (Michel et

al., 2025), AI-driven analytics support predictive

maintenance and complex decision-making (Arhouni

et al., 2025; Selvam et al., 2025), while DT and

Building Information Modelling (BIM) enable

advanced scenario simulation, regulatory

compliance, and enhanced stakeholder engagement

(Virando et al., 2024; Oti et al., 2022). Despite their

potential, the integration of these technologies

526

Benkrid, A., Zahra, O., Szõke, R., Shukla, A. and Szõke, I.

Digital Transformation of the Nuclear Industry: Leveraging Robotics, AI, and Digital Twins for Standardised, Safe, and Efficient Operations.

DOI: 10.5220/0013820700003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 526-535

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

remains hampered by persistent technical,

organisational, and regulatory challenges, including

the “nuclearization” of commercial solutions,

cybersecurity vulnerabilities, interoperability

limitations, and fragmented certification pathways

(Skilton et al., 2023; Wong et al., 2024).

This paper critically examines the implementation

and integration of robotics, AI, and digital solutions

in the nuclear back-end. Leveraging the TECOP and

Five Case Models, it analyses their strategic value,

maturity levels, and principal barriers to adoption.

Drawing on insights from recent EU-funded

initiatives, such as HARPERS, DORADO, and XS-

Ability, the study offers evidence-based

recommendations to support policymakers and

industry stakeholders in advancing safe,

standardized, and future-proof digital innovation.

2 ROBOTIC TECHNOLOGIES IN

THE NUCLEAR BACK-END

This section examines the role of robotics in the

nuclear back-end, focusing on their operational value

in hazardous and restricted-access environments.

Applying the TECOP framework, it analyses both the

strategic benefits and the persistent integration

challenges facing robotic technologies in

decommissioning and waste management.

Key barriers include the absence of harmonised

certification schemes, insufficient testing

infrastructure, and uncertainty surrounding first-of-a-

kind (FOAK) systems. Robotics are particularly

relevant for “5D” tasks Dirty, Dangerous, Difficult,

Dull, and Dear, where they enhance safety and

efficiency. However, broader deployment is

constrained by infrastructural gaps, organisational

risk aversion, fragmented knowledge sharing, and

complex regulatory pathways. These factors continue

to shape the pace and scale of robotics adoption

across the sector.

2.1 Strategic Importance and

Advancing Robotic Capabilities

Over recent decades, robotic systems have progressed

from basic manipulators to advanced robotic systems

have evolved from basic manipulators to advanced

platforms capable of executing complex tasks in

hazardous nuclear back-end environments (Bogue,

2011; Szőke et al., 2023). In decommissioning

scenarios marked by intense radiation and limited

access, robotics improve safety by reducing worker

exposure (IAEA, 1992) and enhance operational

efficiency through remote inspection, sampling, and

dismantling (Kazemi et al., 2025; Shin et al., 2018).

Recent advances in AI, computer vision, and

sensor technologies enable semi-autonomous

navigation and perception. Mobile robots can now

map radiation zones and adapt in real time,

minimising human intervention and operational

delays (Benkrid et al., 2025; Fauquet-Alekhine &

Bleuze., 2023).

(

a

)

(

b

)

(

c

)

(

d

)

Figure 1: Representative Mobile Rovers and Manipulator

Arms Demonstrating Remote Robotic Operations in

Nuclear Decommissioning; Manipulator arms (a, b) and

mobile rovers (c, d) developed by Toshiba (a, d) and CEA

France (b, c) for nuclear remote operations.

2.2 Applications in 5D Environments

The adoption of robotic systems in nuclear operations

is fundamentally motivated by the so-called “5D”

criteria: Dirty, Dangerous, Difficult, Dull, and Dear.

These categories correspond to conditions where

direct human intervention is impractical, unsafe, or

economically prohibitive (IAEA, 1992). In the

nuclear back-end, such as decommissioning, waste

management, and contaminated facility inspection,

robotics have become indispensable. Routine

applications now include inspection, environmental

sampling, precision cutting, decontamination, and

waste segregation (Bogue, 2011).

These demands have led to diverse robotic

solutions, from standard ROVs for underwater

inspections to custom manipulators for hazardous hot

cells, such as those developed for Fukushima or by

CEA France (see Figure 1). Deploying such systems

requires multidisciplinary expertise and strict

adherence to nuclear qualification standards.

Digital Transformation of the Nuclear Industry: Leveraging Robotics, AI, and Digital Twins for Standardised, Safe, and Efficient Operations

527

Nevertheless, major technical and regulatory

hurdles remain, particularly around radiation

tolerance, remote operability, and system reliability

in complex nuclear environments.

2.3 Deployment Gaps and

Nuclearisation Challenges

While robotics are mature in aerospace and

manufacturing (Szőke et al., 2023; Smith et al., 2023),

their deployment in nuclear contexts is hindered by

the need for radiation-hardening and compliance with

strict safety standards (Bogue, 2011; IAEA, 1992).

Many components degrade under radiation and

require redesign, lowering their Technology

Readiness Level (TRL) when adapted for nuclear use

(Tugal et al., 2023; Swaminathan et al., 2025).

Additionally, nuclear sites pose complex

communication and control challenges (Fauquet-

Alekhine & Bleuze, 2023). The absence of

standardised procedures and diverse site conditions

further limit technology transfer and industrial uptake

(Benkrid et al., 2025; Michel & Amoyal, 2025).

2.4 Infrastructure for TRL

Advancement

Advancing robotic technologies from early concept to

operational deployment in the nuclear sector requires

dedicated infrastructures and systematic evaluation

frameworks (Michel & Amoyal., 2025). The NASA

Technology Readiness Level (TRL) scale

(Swaminathan et al., 2025) is commonly used to

assess maturity:

• TRLs 1–3: early research and proof of

concept,

• TRLs 4–6: validation in lab or relevant

environments,

• TRLs 7–8: prototype demonstration and

integration,

• TRL 9: proven systems in operational

conditions.

Notably, even mature technologies (TRL 8–9)

from other fields often require requalification and are

assigned lower TRLs for nuclear applications due to

strict safety and radiation requirements, a process

called “nuclearization” (Tugal et al., 2023).

Facilities like the UK National Nuclear User

Facility for Hot Robotics (NNUF-HR) enable

realistic testing, validation, and demonstration of

systems, facilitating technology advancement and

lowering barriers for SMEs (Bogue, 2011).

Surveys by groups such as the Expert Group on

Robotics in the Nuclear Back-end (EGRRS) (NEA-

EGRRS) indicate that challenges persist across

design, development, and integration phases,

particularly adapting to legacy infrastructure and

meeting certification standards.

Expanding dedicated testing infrastructures

across Europe is vital to accelerate technology

maturation and support widespread deployment

(Szőke et al., 2023).

2.5 Barriers Identified by Expert

Surveys

Recent expert surveys (Benkrid et al. 2025; Michel &

Amoyal, 2025; Szőke et al., 2023) have highlighted

that, despite improvements in technical

infrastructures and validation frameworks,

organizational and regulatory barriers persistently

impede the uptake of robotics in the nuclear sector.

The main challenges identified include:

• Risk aversion and reluctance to adopt

first-of-a-kind systems, often due to the

sector’s strong safety culture and strict

regulatory scrutiny.

• Limited cross-sector communication and

knowledge sharing, which restricts

awareness of available solutions and best

practices.

• Unclear or fragmented regulatory

requirements, making it difficult for

developers to navigate certification and

approval processes.

• Lack of sustained funding and

institutional support, especially for low-

and mid-TRL systems that require additional

demonstrations before deployment.

• Insufficient training and

expertise bridging robotics and nuclear

safety domains.

These non-technical barriers result in prolonged

pilot phases, slow market entry for emerging

solutions, and underutilization of available robotic

technologies.

Addressing these issues will require harmonized

regulatory approaches, dedicated funding and

demonstration programs, and stronger collaboration

between operators, industry, regulators, and research

organizations.

2.6 Regulatory and Organisational

Bottlenecks

Despite advances in robotics for the nuclear sector,

adoption remains limited by regulatory and

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

528

organisational challenges (Michel & Amoyal, 2025;

Swaminathan et al., 2025). Complex and fragmented

certification processes, coupled with inconsistent

regulatory frameworks, create significant hurdles for

developers, especially those new to nuclear

requirements (IAEA, 1992; Szőke et al., 2023).

Institutional risk aversion, rooted in the sector’s

strong safety culture, often leads to reluctance in

deploying novel or highly autonomous systems

without extensive validation, resulting in prolonged

pilot phases and slow operational uptake.

The integration of AI further complicates

certification due to issues around explainability, fail-

safes, and cybersecurity, which are not yet fully

addressed by existing regulations (Tugal et al., 2023).

Harmonisation of standards and regulatory processes

across Europe remains limited, increasing

development costs and barriers for SMEs.

Overcoming these bottlenecks requires regulatory

innovation, greater cross-sector collaboration, and

cultural shifts within organisations to embrace digital

and autonomous technologies. Initiatives such as the

European Expert Group on Robotics and projects like

CLEANDEM (Michel, M., et al. 2023) highlight the

need for coordinated efforts to facilitate robotics

deployment in the nuclear industry.

3 DIGITAL TECHNOLOGIES IN

NUCLEAR BACK END

Digital technologies such as Digital Twins (DT) and

Building Information Modelling (BIM) are

increasingly seen as strategic enablers for nuclear

back-end operations, particularly in

decommissioning and waste management (Szőke et

al., 2023). These tools support improved planning,

safety, and regulatory compliance through advanced

virtualisation and real-time data integration (Amin et

al., 2021).

This section applies the TECOP framework to

evaluate the deployment status of DT and BIM across

technical, economic, commercial, organisational, and

political dimensions. It outlines their core benefits,

identifies key barriers to adoption, presents

stakeholder insights, and concludes with targeted

recommendations to accelerate implementation and

digital innovation across the sector.

3.1 Strategic and Operational Benefits

DT and BIM technologies offer key advantages for

nuclear decommissioning and waste management. By

simulating dismantling scenarios, they enable

advanced planning, workflow optimisation, and early

anomaly detection, reducing safety risks and

enhancing decision-making. These tools also support

accurate waste estimation, material tracking, and

resource allocation throughout the decommissioning

lifecycle.

DT and BIM further improve remote and robotic

operations to limit human exposure in hazardous

zones (Szőke et al., 2023). Real-time data integration

enables condition monitoring and predictive safety

management, while simulations enhance emergency

preparedness (Amin et al., 2021).

From a regulatory standpoint, they streamline

compliance by facilitating data reporting and

supporting phased technology integration. DT/BIM

platforms also strengthen knowledge management,

training, and external communication by visualising

complex operations.

3.2 Barriers to Adoption and Emerging

Risks

Despite their advantages, DT and BIM face

cybersecurity vulnerabilities, sensor and data

limitations, and integration difficulties with legacy

systems. Many organisations lack adequate

infrastructure for secure data handling, and legacy

records remain largely non-digitised.

Financial uncertainty and organisational

resistance also constrain adoption, driven in part by

rapid technological change and insufficient

regulatory alignment. Without clear ROI and

consistent certification, decision-makers remain

hesitant to invest.

3.3 Stakeholder Insights and Priorities

According to the survey conducted in the context of

this analysis, stakeholders identified dismantling

scenario simulation as the highest-priority application

of DT and BIM. This was followed by their use in

regulatory review, project scheduling, site

monitoring, and strategy development. There was

also strong consensus around the usefulness of

DT/BIM for environmental risk modelling and waste

minimisation (Szőke et al., 2023).

However, these priorities are tempered by

persistent concerns around cybersecurity, lack of

interoperability, limited availability of commercial

off-the-shelf solutions, and insufficient regulatory

clarity (Szőke et al., 2023). These challenges were

echoed across responses from both internal and

external stakeholders .

Digital Transformation of the Nuclear Industry: Leveraging Robotics, AI, and Digital Twins for Standardised, Safe, and Efficient Operations

529

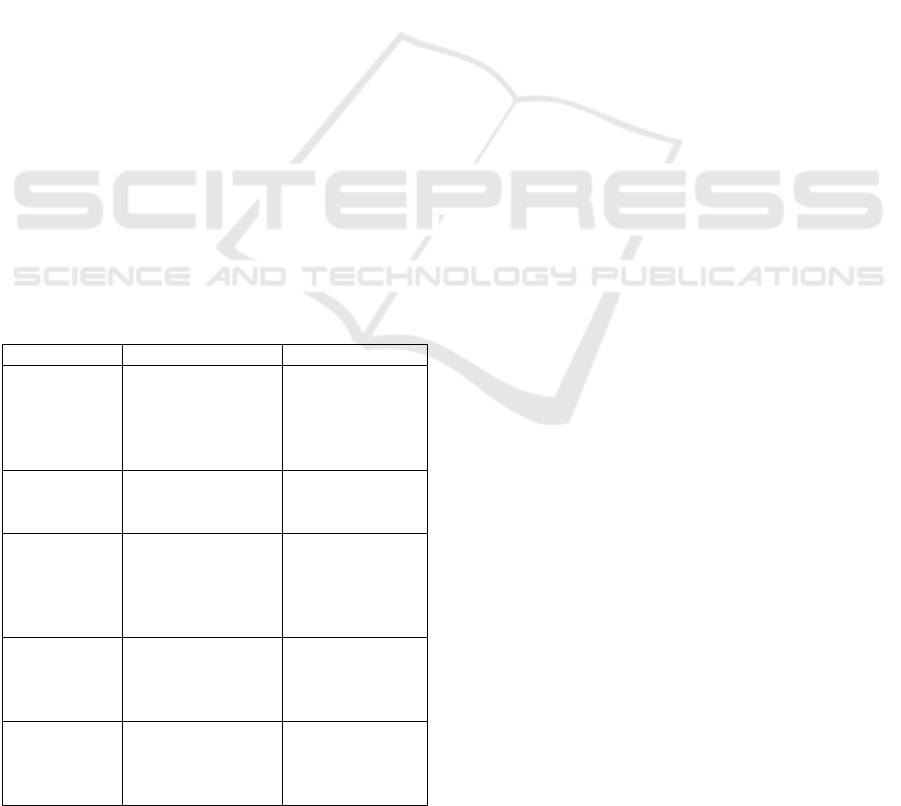

Table 1: Mapping of identified enablers and blockers for

DT/BIM implementation across TECOP dimensions.

TECOP

Dimension

Enablers /

O

pp

ortunities

Blockers /

Challen

g

es

Technical

Scenario

simulation,

safety

monitoring,

real-time data

integration,

robotics

support

Sensor limitations,

Legacy data, Low

interoperability,

Cybersecurity

vulnerabilities

Economical

Lifecycle cost

reduction

High initial

investment, Lack of

ROI evidence

Commercial

Technology-

provider

collaboration

Limited COTS

solutions, Unclear

b

usiness models

Organisational

Training and

knowledge

management,

Change

leadershi

p

Skills gaps,

Organisational

resistance

Socio-Political

Improved

transparency,

public

engagement,

Modern

image for

young

p

rofessionals

Public trust deficit,

Regulatory

misalignment, Lack

of global standards

Table 1 summarises the key enablers and barriers

to DT and BIM adoption in nuclear decommissioning

using the TECOP framework. It highlights the most

frequently cited opportunities, such as scenario

simulation, enhanced safety monitoring, and

improved public engagement, as well as major

challenges including cybersecurity risks, high initial

costs, limited interoperability, and regulatory

misalignment. This structured overview supports the

targeted recommendations provided in the following

section by clarifying the interplay between

technological promise and real-world constraints.

3.4 Recommendations for Effective

Implementation

To unlock the full potential of DT and BIM

technologies in nuclear decommissioning, several

measures are recommended: (i) Invest in enabling

infrastructure: Develop site-specific sensor systems

and secure data platforms tailored to the nuclear

context. (ii) Launch targeted pilot projects: Focus

on use cases with high strategic relevance, such as

dismantling scenario analysis and operator training to

generate early value and build internal support.

(iii) Develop integration standards: Promote

interoperability through shared data formats,

cybersecurity protocols, and implementation

frameworks. (iv) Promote cross-sector

collaboration: Strengthen ties between nuclear

stakeholders, technology providers, and regulatory

agencies to accelerate knowledge exchange and

regulatory harmonisation. (v) Build workforce

capacity: Offer continuous training and establish

change management strategies to reduce resistance

and foster digital culture.

4 REGULATORY CHALLENGES

AND STRATEGIES FOR

ENABLING INNOVATION

The integration of advanced technologies such as

autonomous robotics and artificial intelligence (AI)

into nuclear decommissioning and waste

management introduces not only technical but also

profound regulatory challenges. Unlike incremental

innovations, these emerging technologies often do not

align with existing regulatory assumptions or

categories (Szőke et al., 2023; Skilton et al., 2023).

Their disruptive nature, combined with the high-risk

profile of nuclear operations, demands regulatory

frameworks that are adaptable, harmonized, and

forward-looking.

4.1 Disruption of Established

Regulatory Paradigms

The nuclear sector is governed by conservative

regulatory regimes prioritising deterministic models

and validated practices (Szőke et al., 2023). Emerging

technologies especially AI and autonomous robotics,

often fall outside existing validation frameworks,

leading to uncertainty and delayed deployment.

Projects like SHARE and HARPERS call for

adaptive, risk-informed regulations to match the pace

of innovation while maintaining public trust (Michel

et al., 2023).

4.2 Fragmentation and Lack of

Harmonized Standards

One of the most significant barriers to adoption lies

in the absence of internationally harmonized

standards for the certification and deployment of

robotics and AI technologies in sensitive sectors

(Benkrid et al., 2025; Szőke et al., 2023). Regulatory

requirements vary considerably across jurisdictions,

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

530

leading to fragmented certification pathways and

increased complexity for multinational projects

(Michel & Amoyal, 2025; Tugal et al., 2023).

Technologies may require redundant testing and

approval in each country, resulting in higher costs,

procedural delays, and ultimately deterring

investment and cross-border collaboration.

Moreover, this regulatory fragmentation hinders

interoperability and slows down the development of

common safety protocols. For developers and

operators, navigating this patchwork of national

requirements imposes a substantial administrative

and financial burden that inhibits innovation.

4.3 Knowledge Gaps and Regulatory

Grey Zones

Many tech developers lack familiarity with nuclear

regulatory frameworks, leading to under- or over-

designed solutions and unpredictable review

processes (Smith et al., 2020; Szőke et al., 2023).

FOAK systems face long approval timelines due to

the absence of established categories and evaluation

criteria (Michel & Amoyal, 2025).

Clarifying certification requirements and building

cross-sector expertise are essential to de-risk

innovation and reduce development costs.

4.4 Validation and Emerging Solutions

Validation of robotics and AI systems intended for

hazardous environments is a complex, yet essential,

step toward acceptance (Smith et al., 2020). Unlike

conventional industrial tools, these systems must

demonstrate robustness, reliability, and safety across

a wide range of operational scenarios, including

exposure to high radiation, limited accessibility, or

degraded sensing environments. Current validation

protocols, however, often fall short of addressing

these extreme-use conditions (IAEA, 1992).

In response, innovative regulatory tools such as

regulatory sandboxes are gaining attention (Michel

& Amoyal, 2025). These controlled environments

allow early collaboration between technology

developers and regulators, enabling real-world testing

of novel systems under limited scope and risk. By

facilitating iterative feedback, sandboxes help refine

both technology design and regulatory expectations

(Smith et al., 2020). They offer a pragmatic path

toward the development of realistic, risk-informed

standards that can accelerate the safe deployment of

advanced technologies.

4.5 Continuous Validation, Post-

Market Surveillance, and Trust

Building

Beyond initial certification, the long-term safety and

reliability of deployed robotic and AI systems must

be ensured through continuous validation and post-

market surveillance mechanisms (Szőke et al.,

2023). These mechanisms are critical in a high-risk

sector such as nuclear decommissioning, where even

minor system failures can have severe consequences.

Real-time performance monitoring, incident

reporting, and software updates must be integrated

into regulatory expectations, allowing technologies to

evolve while remaining within a validated operational

envelope (IAEA, 1992).

These feedback loops not only enhance safety but

also contribute to building regulatory trust. When

regulators, operators, and technology providers share

data and lessons learned from real-world use, future

assessments become faster and more robust.

Importantly, such processes help address the

limitations of initial FOAK (first-of-a-kind)

validations, enabling dynamic improvement of both

technologies and regulatory practices over time.

4.6 Capacity Building and

Collaborative Governance

The complexity and novelty of digital and

autonomous technologies require regulatory bodies

themselves to evolve (IAEA, 1992). Traditional

expertise may no longer suffice to assess the nuanced

behaviour of AI systems, the cybersecurity

vulnerabilities of connected platforms, or the

functional resilience of autonomous robots in

radioactive environments. As such, capacity

building within regulatory authorities is essential.

Dedicated training programmes, collaborative

working groups, and participation in international

standardisation efforts are all necessary to enhance

regulators' ability to keep pace with innovation.

Initiatives such as the OECD Working Group on new

technologies demonstrate the value of cross-border

dialogue and harmonised policy development.

Collaboration across sectors between nuclear

operators, research institutions, digital technology

providers, and regulators is another key enabler.

Shared pilot projects, co-developed testing protocols,

and transparent communication channels support

mutual understanding and accelerate the co-creation

of practical, innovation-friendly regulatory

frameworks.

Digital Transformation of the Nuclear Industry: Leveraging Robotics, AI, and Digital Twins for Standardised, Safe, and Efficient Operations

531

4.7 Clarifying Regulatory

Requirements vs.

Misinterpretations

In many cases, the perceived rigidity of regulatory

frameworks stems not from actual legal constraints,

but from misinterpretation of requirements (Smith

et al., 2020). Differentiating clearly between what is

truly mandated by regulation, what is a technical

necessity, and what is an organisational habit is

critical. This clarity can prevent overengineering,

reduce unnecessary costs, and avoid project delays

caused by conservative overcompliance.

Efforts should therefore include guidance

documents, case studies, and knowledge exchange

platforms to clarify how existing regulations apply

to new technologies (2021 Szőke et al., 2023). These

tools will help both developers and operators focus

their efforts on genuine compliance priorities and

avoid wasting resources on irrelevant or

misunderstood constraints.

5 VALUE PROPOSITION OF

ADVANCED TECHNOLOGIES

The integration of advanced technologies AI,

robotics, and digitalisation is increasingly shaping

nuclear back-end activities such as decommissioning,

waste management, and site remediation (IAEA,

1992). These tools offer the potential to enhance

safety, improve efficiency, and reduce long-term

costs (Wong et al., 2024). Digital twins, autonomous

systems, and analytics support smarter decision-

making and risk mitigation.

However, adoption requires more than a cost-

saving argument. A robust business case must address

strategic alignment, operational feasibility, and long-

term sustainability (Swaminathan et al., 2025). The

Five Case Model provides a structured framework

across five dimensions:

Strategic alignment, particularly with goals

such as enhanced safety and modernization.

Economic value, emphasizing public

benefits and cost-effectiveness.

Commercial viability, ensuring market

readiness and industrial uptake.

Financial assessment, balancing initial

investment against expected returns.

Managerial readiness, focusing on

regulatory compliance, project governance,

and workforce capacity.

Despite growing interest, deployment remains

constrained by fragmented regulation, limited

standardisation, and integration gaps (Wong et al.,

2024). The HARPERS project proposes a structured

methodology combining the Five Case Model with

the TECOP framework to assess not only financial

outcomes but also technical feasibility, regulatory

alignment, and socio-political impact.

5.1 The Need for Change

Current decommissioning and waste handling

practices rely heavily on outdated, manual methods

that are not only cost-intensive but also pose health

and environmental risks. Inconsistent technology

qualification processes, especially across

jurisdictions, result in delayed innovation uptake and

inefficiencies in waste processing. Robotics and

automation remain underutilized, with challenges in

reliability, cost justification, and regulatory

acceptance hindering wider deployment (Michel &

Amoyal, 2025).

Similarly, digital twin and BIM technologies,

despite their planning and simulation benefits-face

barriers such as poor interoperability, cybersecurity

concerns, and lack of certification standards.

These systemic limitations underscore the urgent

need for harmonization and international cooperation

to standardize practices, accelerate innovation

adoption, and improve operational outcomes.

5.2 Building the Economic Case

The HARPERS framework guides the development

of a robust economic case through four key steps:

identifying evaluation criteria (TECOP attributes),

analysing impacts and risks, comparing change

scenarios, and making informed go/no-go decisions

(Szőke et al., 2023). The evaluation spans safety

improvements, cost reductions, time efficiencies, and

sustainability considerations.

Each technological area, waste management,

robotics, and digital twins, has been assessed via

high-level TECOP analyses. These reveal that:

• Technical: Standardization enhances

reliability and scalability but requires robust

integration with legacy systems and

advanced safety features (IAEA, 1992).

• Economic: While upfront costs can be high,

lifecycle savings from improved efficiency

and reduced waste volumes justify

investment (Michel & Amoyal, 2025).

• Commercial: Unified standards can

stimulate market growth and reduce

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

532

investment risks through predictable

qualification pathways (Wong et al., 2024).

• Organizational: Success depends on

workforce training, internal acceptance, and

change management strategies (Oti et al.,

2022).

• Socio-Political: Public trust and regulatory

alignment are critical; these can be improved

through stakeholder engagement and

transparency (Kolditz et al., 2023).

5.3 Insights from Practical

Applications

The framework was applied to real-world use cases

(e.g., Centraco Melting Unit, Studsvik inDRUM,

NNL’s EASD, Magnox DT, and Fukushima

robotics). Across all, benefits such as enhanced

worker safety, cost savings, and improved timelines

were observed (Michel & Amoyal, 2025). However,

challenges persist around capital costs, workforce

resistance, and regulatory complexity.

Interactive discussions at DigiDECOM 2024

further highlighted the need to adopt a broader view

of return on investment (ROI), considering not only

direct cost savings but also long-term strategic gains

such as risk reduction, regulatory resilience, and skill

development (Szőke et al., 2023).

Table 2: Summary of key challenges and levers identified

in the HARPERS project for successful adoption of

robotics, digital tools, and advanced decontamination

technologies in the nuclear back-end.

Dimensions Barriers Enablers

Technical

Fragmented

qualification

protocols,

interoperability

g

a

p

s

Standardized

frameworks,

digital

integration

Economic

High upfront costs,

uncertain ROI

Lifecycle

savings, pooled

R&D fundin

g

Commercial

Market hesitation,

lack of certified

products

Cross-sector

partnerships,

shared

procurement

mechanisms

Organizational

Workforce

resistance, limited

skills

Training

programs,

leadership

en

g

a

g

ement

Socio-

Political

Regulatory

fragmentation,

public scepticism

International

harmonization,

early stakeholder

involvement

5.4 Recommendation for Policy

Markers

The findings present a compelling case for policy-led

harmonization in three critical domains:

• Waste treatment and decontamination

technologies

• Robotics and automation in dismantling and

waste operations

• Digital twin and advanced BIM integration

Policymakers are urged to lead the establishment

of international standards, develop collaborative

regulatory testing environments, and promote data

interoperability (IAEA, 1992). Addressing societal

concerns, such as job displacement or data privacy

requires transparency, community engagement, and

inclusive governance mechanisms.

By adopting a standardized and collaborative

approach, the nuclear sector can overcome systemic

barriers and unlock the full value of advanced

technologies, ensuring a safer, more efficient, and

sustainable future for nuclear back-end operations.

6 SAFETY AND SECURITY IN

DIGITAL NUCLEAR

OPERATIONS

Digital transformation, driven by the integration of

robotics, artificial intelligence (AI), and digital twins

(DT), presents major opportunities to strengthen

safety and security in the nuclear operation while

enhancing operational efficiency (Smith et al., 2020;

Virando et al., 2024). Safety requirements in this

domain are exceptionally stringent, not only due to

radiological hazards but also the persistent threats of

malicious attacks and cyber intrusions.

Robotics significantly reduces operator exposure

by performing hazardous tasks such as inspection,

maintenance, and decontamination, thereby

contributing substantially to on-site physical safety

(Smith et al., 2020; Wong et al., 2024). Autonomous

robots further bolster physical protection through

surveillance and intrusion detection.

AI plays a critical role in nuclear back-end safety,

enabling predictive maintenance by identifying

failures early through sensor data analysis, and

enhancing cybersecurity via anomaly detection and

the protection of information networks (IAEA, 1992).

Digital twins are essential for real-time

monitoring and risk assessment. They facilitate the

simulation of incidents, cyber-physical attacks, and

Digital Transformation of the Nuclear Industry: Leveraging Robotics, AI, and Digital Twins for Standardised, Safe, and Efficient Operations

533

technical failures, supporting the continual testing

and refinement of safety and security protocols

(Virando et al., 2024; Eckhart & Ekelhart, 2019).

However, the adoption of these technologies also

introduces new risks, such as cybersecurity

vulnerabilities, software/ hardware failures, and

human–machine interface challenges. Robotic

systems must therefore be designed with redundancy,

fail-safe mechanisms, and subjected to rigorous

validation protocols (Smith et al., 2020; Wong et al.,

2024). Robust cybersecurity measures are vital for

both AI and networked robotics, including

encryption, access controls, behavioral monitoring,

and compliance with relevant standards (Wen et al.,

2025).

For digital twins, the reliability and accuracy of

models and data are critical; any compromise may

result in improper responses to incidents.

Consequently, these systems require continuous

updates, real-world validation, and architectures that

are resilient to intrusions (Holmes et al., 2021).

Ultimately, the success of this transformation also

depends on human expertise, continuous operator

training, compliance with regulatory frameworks

(such as ISO 27001, ISO 42001, GDPR, and the EU

AI Act), and a proactive approach to emerging safety

and cybersecurity challenges throughout the lifecycle

of digital solutions (Wen et al., 2025; Holmes et al.,

2021).

7 EU-FUNDED SOLUTIONS:

DORADO AND XS-ABILITY

Two EU-funded projects, XS-Ability and DORADO,

are addressing major technical and organisational

barriers that hinder the deployment of robotics and

digital solutions in nuclear decommissioning.

The XS-Ability project (Michel & Amoyal,

2025), funded by EURATOM, focuses on the

development of modular, autonomous robotic

systems for in-situ characterisation in hard-to-access,

highly radioactive nuclear environments. XS-Ability

platforms are designed to operate with minimal

human intervention in environments that present

radiological, spatial, and logistical constraints. The

robotic systems incorporate radiation-tolerant sensors

(e.g., gamma spectrometers, LiDAR, structured light

scanners), onboard AI for data fusion and

autonomous decision-making, and wireless

communication for remote supervision. The project

also emphasises modular payload architecture to

allow rapid adaptation to mission-specific needs.

Technical validation is carried out through lab-based

mock-ups and real-world testing campaigns in

partnership with end users (e.g., EDF, CEA). XS-

Ability directly targets Technology Readiness Level

(TRL) progression by embedding safety and

nuclearization requirements from the design phase

onward.

The DORADO project (Benkrid et al. 2025)

focuses on enabling the integration of digital tools,

especially digital twins, into robotic

decommissioning workflows through semantic

interoperability and regulatory traceability. At its

core, DORADO is developing a digital framework

based on ontologies to formally structure knowledge

across tools, actors, and assets involved in

dismantling operations. This includes: (i) BIM-based

mission control; (ii) linkage between digital twins and

robotic mission planning systems; and (iii)

standardised data models for knowledge transfer

across decommissioning stages. The framework is

designed to support explainable AI for safety-critical

decisions and provide visual dashboards that enhance

operator understanding and oversight.

8 CONCLUSIONS

Digital transformation is fundamentally reshaping the

nuclear back-end, offering unprecedented

opportunities to enhance safety, operational

efficiency, and regulatory compliance through the

integration of robotics, artificial intelligence (AI), and

digital twin (DT) technologies. This paper has

examined the strategic relevance of these innovations

within the decommissioning and waste management

domains, using the TECOP and Five Case Models to

provide a structured analysis of their benefits and

barriers.

While robotics extend operational reach in

hazardous 5D environments, and DT/BIM systems

improve simulation, training, and regulatory

traceability, their deployment remains constrained by

nuclearization requirements, fragmented certification

processes, cybersecurity risks, and institutional

inertia. These challenges must be systematically

addressed to ensure scalable and sustainable

adoption.

EU-funded initiatives such as XS-Ability and

DORADO demonstrate the critical role of

coordinated research in bridging the gap between

technological development, field deployment, and

regulatory integration. By targeting TRL

advancement, semantic interoperability, and safety-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

534

oriented design, these projects provide blueprints for

future digital innovation in the nuclear sector.

Looking ahead, the successful digital

transformation of the nuclear back-end will depend

on sustained cross-sector collaboration, adaptive

regulatory frameworks, and investments in digital

infrastructure. Such efforts are essential to ensure the

long-term safety, efficiency, and resilience of nuclear

operations across Europe and beyond.

REFERENCES

Arhouni, F. E., Abdo, M. A. S., Ouakkas, S., Bouhssa, M.

L., & Boukhair, A. (2025). Artificial intelligence-

driven advances in nuclear technology: Exploring

innovations, applications, and future prospects. Annals

of Nuclear Energy, 213, 111151.

Benkrid, A., Zahra, O., & Szőke, I. (2025). Digital Twin-

Enabled Multi-Robot Systems for Safe and Efficient

Nuclear Decommissioning.

Bogue, R. (2011). Robots in the nuclear industry: a review

of technologies and applications. Industrial Robot: An

International Journal, 38(2), 113-118.

Eckhart, M., & Ekelhart, A. (2019). Digital twins for cyber-

physical systems security: State of the art and outlook.

Security and Quality in Cyber-Physical Systems

Engineering: With Forewords by Robert M. Lee and

Tom Gilb, 383-412.

Fauquet-Alekhine, P., & Bleuze, J. (2023, July). Robot-

Assisted Nuclear Disaster Response: determinants of

performance. In 2023 3rd International Conference on

Electrical, Computer, Communications and

Mechatronics Engineering (ICECCME) (pp. 1-12).

IEEE.

Holmes, D., Papathanasaki, M., Maglaras, L., Ferrag, M.

A., Nepal, S., & Janicke, H. (2021, September). Digital

twins and cyber security–solution or challenge?. In

2021 6th South-East Europe Design Automation,

Computer Engineering, Computer Networks and Social

Media Conference (SEEDA-CECNSM) (pp. 1-8).

IEEE.

Nuclear Energy Agency (NEA) - Expert Group on the

Application of Robotics and Remote Systems in the

Nuclear Back-end (EGRRS)

International Atomic Energy Agency, Safety Aspects of

Nuclear Power Plant Automation and Robotics, IAEA-

TECDOC-672, IAEA, Vienna (1992)

Kazemi, S. (2025). Robotic Automation for Nuclear

Decommissioning: Development of a Tool Carrier

System with Milling and Clearance Measurement

Capabilities. Sensors & Transducers, 268(1), 28-36.

Kolditz, O., Jacques, D., Claret, F., Bertrand, J., Churakov,

S. V., Debayle, C., ... & Wendling, J. (2023).

Digitalisation for nuclear waste management:

predisposal and disposal. Environmental Earth

Sciences, 82(1), 42.

Kundavaram, R. R., Onteddu, A. R., Devarapu, K., &

Nizamuddin, M. (2025). Advances in autonomous

robotics for environmental cleanup and hazardous

waste management. Asia Pacific Journal of Energy and

Environment, 12(1), 1-16.

Michel, M., & Amoyal, G. (2025). From robots to drones,

the future of decommissioning operations–The

CLEANDEM and XS-ABILITY projects. EPJ Nuclear

Sciences & Technologies, 11, 15.

Michel, M., Amoyal, G., & Schoepff, V. (2023).

CLEANDEM, a cyber physical equipment for

unmanned nuclear decommissioning measurements. In

EPJ Web of Conferences (Vol. 288, p. 07004). EDP

Sciences.

Oti, A. H., Farrell, P., Abanda, F. H., McMahon, P.,

Mahamadu, A. M., Mzyece, D., ... & Prinja, N. (2022).

A BIM-driven framework for integrating rules and

regulations in the decommissioning of nuclear power

plants. Construction Innovation, 22(4), 809-830.

Selvam, D. C., Devarajan, Y., & Raja, T. (2025). Exploring

the potential of artificial intelligence in nuclear waste

management: Applications, challenges, and future

directions. Nuclear Engineering and Design, 431,

113719.

Smith, R., Cucco, E., & Fairbairn, C. (2020). Robotic

development for the nuclear environment: challenges

and strategy. Robotics, 9(4), 94.

Swaminathan, S., Wishart, J., Zhao, J., Russo, B., &

Rahimi, S. (2025). Adapting the Technology Readiness

Level (TRL) Framework to Automated Vehicle

Development (No. 2025-01-8671). SAE Technical

Paper.

Szőke, I., Hartmann, C., Szőke, R., Stephane, L., Zahra, O.,

& Benkrid, A. (2023, October). A holistic approach to

digitalisation and robotics in the nuclear back-end. In

International Conference on Radioactive Waste

Management and Environmental Remediation (Vol.

87530, p. V001T01A001). American Society of

Mechanical Engineers.

Tugal, H., Abe, F., Caliskanelli, I., Cryer, A., Hope, C.,

Kelly, R., ... & Skilton, R. (2023, June). The impact of

a haptic digital twin in the nuclear industry and

potential applications. In 2023 IEEE international

conference on advanced robotics and its social impacts

(ARSO) (pp. 134-139). IEEE.

Virando, G. E., Lee, B., Kee, S. H., & Yee, J. J. (2024).

Digital Twin Simulation and Implementation in Safety

Risk Management Process. IEEE Access.

Wen, S. F., Shukla, A., & Katt, B. (2025). Artificial

intelligence for system security assurance: A systematic

literature review. International Journal of Information

Security, 24(1), 43.

Wong, C., Chapman, H., Lawton, S., Szulik, M., Tuck, O.,

& Richardson, J. P. (2024). A Proposed Pathway to

Improve Reliability Claims for Robotic Systems in

Nuclear Decommissioning Safety Cases. ATW-

International Journal For Nuclear Power, 69(4), 38-44.

Digital Transformation of the Nuclear Industry: Leveraging Robotics, AI, and Digital Twins for Standardised, Safe, and Efficient Operations

535