Experimental Validation of Load Attitude Estimation Using Computer

Vision and IMU-Based Approaches for

Slung-Load Aerial Robots

Shlok Panchal

1

, Barbie Sharma

2

, Yash Dadheech

2

, Darshil Shah

3

, Ayush Agnihotri

1

, Kalash Jain

2

,

Parth S. Thakar

1,∗

a

and Anilkumar Markana

4 b

1

Department of Electronics and Communication Engineering, PDEU, Gandhinagar, Gujarat, India

2

Department of Computer Science and Engineering, PDEU, Gandhinagar, Gujarat, India

3

Department of Mechanical Engineering, PDEU, Gandhinagar, Gujarat, India

4

Department of Electrical Engineering, PDEU, Gandhinagar, Gujarat, India

Keywords:

Aerial Robot, Slung Load, Load Attitude, Computer Vision, IMU.

Abstract:

With the rise of the drone industry, there has been a surge in demand for its applications. One such critical

application is using drones to transport suspended cargo, which requires minimal swing of the load. To achieve

this, designing a robust control strategy plays a vital role. Such systems while in operation have critical issue

of maintaining stability due to the interacting multi-body dynamics. Furthermore, a quadrotor with a slung

load showcases coupled underactuated dynamics that complicates the control design problem. To effectively

execute control implementation for such systems accurate feedback of load attitude becomes essential. For

that matter, this study proposes two different approaches to determine the load attitude, namely, the computer

vision (CV) based method using ArUco markers and the inertial measurement unit (IMU) based approach. The

study investigates the real-time feasibility of these approaches through their response frequencies and tracking

accuracies by comparing the experimental plots with their simulation counterpart, considering that as an ideal

scenario. We also provide the implementation algorithms for both the methods proposed here. Finally, we

conclude the findings by throwing light on their suitability to various slung load scenarios with variable swing

angle ranges, also dwelling into the steady state behaviour comparisons in both the cases.

1 INTRODUCTION

Unmanned Aerial Vehicles (UAVs) are autonomously

operating aircrafts, which has found numerous appli-

cations over the years. Amongst those, the load trans-

portation using UAVs have increasingly attracted the

attention of the researchers over the last decades. For

aerial load transfer, from their initial application in the

military, the usages have expanded to serve various

purposes, for instance, as a last mile delivery solution

(Garg et al., 2023) enabling socio-economic growth

and for the humanitarian purposes as in (Mugala et al.,

2020), etc. Drones come in various configurations

and geometry, among which one is the quadrotor,

which is widely used due to its simple geometry. It

is a rigid body with six degrees of freedom (DOF),

a

https://orcid.org/0000-0003-3700-7559

b

https://orcid.org/0000-0002-2273-5839

three translational and three rotational but having only

four independent inputs (Palunko et al., 2012). This

makes it an underactuated system with complex cou-

pled dynamics. With the inclusion of a suspended

load on a taut string underneath the quadrotor, there

is an increase in the number of uncontrolled degrees

of freedom due to the load swing (Z

´

uniga et al., 2018).

These include two angles in the 3-D space of the load

on a taut string, which define the load attitude. To

control the swing of the suspended load, there is a

need for an effective feedback mechanism measuring

the load attitude, which can be used to control its be-

havior. An effective feedback mechanism consists of

one that can provide accurate data points in real-time

or at a very high frequency. These points become im-

portant benchmarks of testing before a mechanism is

deemed appropriate for the application.

There is a close connection between the motion of

the UAV and the swing of the load because the slung

Panchal, S., Sharma, B., Dadheech, Y., Shah, D., Agnihotri, A., Jain, K., Thakar, P. S. and Markana, A.

Experimental Validation of Load Attitude Estimation Using Computer Vision and IMU-Based Approaches for Slung-Load Aerial Robots.

DOI: 10.5220/0013784700003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 371-377

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

371

weight naturally alters the quadrotor’s center of mass

and applies time-varying torques. As a result, the load

swing causes oscillatory forces that might destabilize

the UAV and significantly disrupt its flight. Numer-

ous studies quantify the adverse effects of payload

swing, which researchers constantly find has a se-

vere impact on stability. For instance, to demonstrate

that only the feedback-aware law can actively attenu-

ate swing, (de Angelis and Giulietti, 2023) contrasts

two distinct control laws: one that explicitly accounts

for swing-angle feedback and another that does not.

Uncontrolled swinging can result in significant tran-

sients and even crashes. The payload may experi-

ence severe degradation by collisions or induced vi-

brations, which may result in an unstable application

with delicate contents (e.g., liquids) if uncontrolled,

as in (Guerrero-S

´

anchez et al., 2017). Consequently,

stability and payload safety are severely compromised

if swing is disregarded. Thus, for safe, steady, and

effective quadrotor operations, the swing angle feed-

back of a suspended load is essential.

In the literature, a few studies ((Palunko et al.,

2012), (Prajapati et al., 2022) ) are report that cal-

culate the swing angle for control design in a slung

load scenario. However, the emphasis on accurate

load attitude feedback during implementation was not

addressed. In (Lee and Kim, 2017), the authors have

calculated the swing angle from the estimated force

components and IMU. A method for estimating an-

gle using visual algorithms and the difference in sky-

infrared emissivity, the ability of a surface to emit in-

frared radiation, through an infrared camera has been

proposed in (Deng et al., 2024). In (Huang et al.,

2022), the authors proposed a method to measure

swing angle using the minimum area circular method

along with the Mean Shift (MS) algorithm. In (Tang

et al., 2018), the authors suggested payload state es-

timation with a downward-facing camera and an Ex-

tended Kalman Filter (EKF). For the quadrotor with

a slung load system, in order to estimate cable atti-

tude, a Cable Attitude Measurement (CAM) device

that functions similarly to a joystick was created in

(Prajapati et al., 2022). Despite these advancements,

there remains a gap of the study of load attitude feed-

back mechanisms, particularly from the perspective

of a quadrotor with slung load systems.

1.1 Contributions

In this paper, a comparative study is presented to

evaluate the load attitude feedback performance of

two mechanisms, one CV-based and the other IMU-

based, tested under identical experimental conditions

for slung-load systems with simplified planar as-

sumptions. The CV-based approach makes use of

monocular vision and geometric principles, while the

IMU-based approach relies on accelerometer read-

ings. The performance, advantages, and limitations

of both mechanisms are analyzed to aid in the ex-

perimental validation of slung load dynamics control.

Both systems consist of components that are straight-

forward to integrate with the experimental platform,

allowing them to be deployed easily in either indoor

or outdoor scenarios. Owing to their computational

simplicity and minimal hardware requirements, they

do not interfere with the primary drone operations

during experimentation. As such, they are well-suited

as feedback mechanisms for use in an already com-

plex experimental setup. The proposed CV algorithm

was implemented on a single-board computer paired

with a webcam, with an ArUco marker employed to

estimate the pose of the load. Experimental validation

involved plotting the measured angles and comparing

them with those obtained from real-time video pro-

cessing. For inertial sensing, an IMU sensor was used

to capture the load’s attitude. The validation was car-

ried out on a planar setup as described in Section 3.

2 PROBLEM SETUP

The quadrotor with a slung load is an underactuated

system (Thakar et al., 2014), characterized by hav-

ing fewer control inputs than degrees of freedom,

which introduces significant challenges in stabilizing

the load’s swing. In the context of a quadrotor with

suspended loads, the underactuated nature arises from

the complex coupling between the quadrotor motion

and the load’s dynamics, leading to oscillatory behav-

ior that complicates control. To validate the proposed

methods, we use a simple planar setup explained in

detail in Section 3. The planar assumption simplifies

the system to a 2D model, focusing on the swing an-

gle α only in a vertical plane.

2.1 CV-Based Method

In this approach, we use a standard artificial ge-

ometric pattern fiducial marker, namely ArUco, to

accurately and efficiently measure the load attitude.

ArUco markers (Garrido-Jurado et al., 2014) are 2D

square fiducial markers. Each marker encodes a

unique ID using the white and black square pattern.

At the detection end, a dictionary of unique identifi-

cation numbers, which are encoded into the markers,

is stored. As a marker is detected in the camera frame,

its unique ID is decoded, and the marker is identified.

Based on the dimensions of the square patterns, orien-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

372

tation, and position of the marker in the field of view

of a calibrated camera, we can derive the exact orien-

tation and position of the marker in the image frame.

This information can be utilized to calculate load at-

titude. To get accurate results from this method, the

camera needs to be calibrated properly. The detailed

load attitude estimation algorithm using this method

is articulated in Section 3.

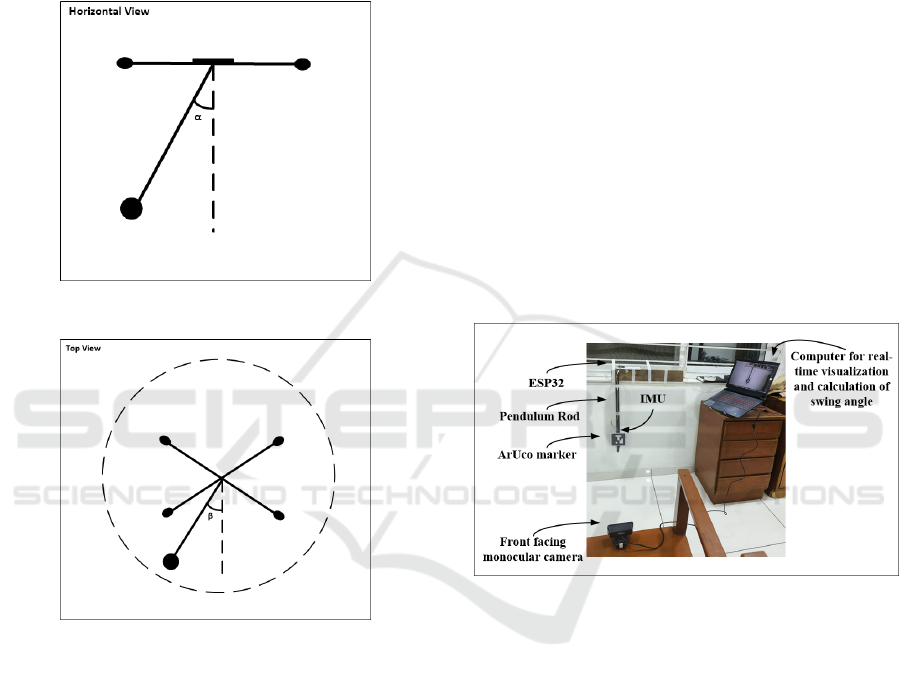

Figure 1: In-plane (vertical) swing angle, α.

Figure 2: Out-of-the-plane swing angle, β.

Figures 1 and 2 illustrate the in-plane angle, α

seen in the vertical plane in 2D motion of the drone

and β-represents the out-of-the-plane swing angle.

2.2 IMU-Based Method

In this approach, we use a Micro-Electro-Mechanical

System (MEMS) based IMU to determine the load at-

titude, specifically the planar angle α in 2D. While

many control systems estimate load attitude indirectly

using the carrier platform’s IMU and dynamic mod-

els (Nguyen and Caverly, 2021), recent studies have

explored the direct measurement of suspended load

attitude using dedicated IMUs mounted on the pay-

load. For instance, (Gao et al., 2014) developed

a wireless dual-IMU system to monitor swing an-

gles in crane operations with 0.6

◦

(max 2

◦

) accu-

racy. Thus, these approaches demonstrate that com-

pact, low-power IMUs can reliably capture the 3-DOF

orientation of suspended loads in dynamic environ-

ments. Following this, we propose the IMU-based

load attitude determination method for the suspended

load on a quadrotor system.

3 LOAD ATTITUDE ESTIMATION

AND EXPERIMENTAL

VALIDATION

The methods in this study are experimentally vali-

dated based on a simple pendulum apparatus, which

emulates the behavior of the suspended load on the

quadrotor using a fixed-length, rigid string.

The experiment has been conducted for two meth-

ods, namely, the CV-based method and IMU-based

method for the simple pendulum-like test setup as dis-

played in Figure 3.

Figure 3: Experimental setup for load attitude measurement

combining both - CV-based and IMU-based methods.

3.1 CV-Based Load Attitude Estimation

and Setup

The experimental setup of this method consists of a

Fingers 1080p webcam. It was connected to a com-

puter to capture the real-time video feed. For the im-

age processing OpenCV in Python was used. Initially,

the camera was calibrated using the checkered board

calibration technique, and the respective camera ma-

trix and distortion coefficients were derived (Bradski

and Kaehler, 2000). An ArUco marker of UID 7 of

the 5×5 ArUco Dictionary was used as a load marker.

The frame rate was set at 60 fps along with an image

resolution of 1280 × 720p. The distance between the

camera and the marker is set to 80 cm. The marker is

positioned at various points, and the angles resulting

from the algorithm developed are retrieved. The step-

Experimental Validation of Load Attitude Estimation Using Computer Vision and IMU-Based Approaches for Slung-Load Aerial Robots

373

by-step method articulating the CV-based load atti-

tude estimation is shown in the form of Algorithm 1.

The CV-based method uses a monocular camera

to capture images of the ArUco marker attached to

the load. The marker’s corners are detected, and their

2D image coordinates are mapped to 3D world coor-

dinates using the camera’s intrinsic and extrinsic pa-

rameters, obtained through calibration. The pose es-

timation is performed, which computes the marker’s

rotation and translation vectors relative to the camera.

These vectors are then used to calculate the pitch, roll

and yaw angles of the load, as well as the distance of

the ArUco marker from the camera. The algorithm

is computationally efficient and suitable for real-time

applications, provided the marker remains in the cam-

era’s field of view and under adequate lighting condi-

tions.

Data: Camera frame, ArUco dictionary,

Camera calibration parameters

Result: Pitch, Roll, Yaw, Load Distance

Initialization: Load ArUco dictionary and

camera parameters;

while camera is active do

Capture frame;

Detect ArUco markers in frame;

if marker detected then

Decode marker ID;

Estimate marker corners;

Compute pose;

Extract rotation and translation

vectors;

Calculate pitch, roll, yaw, and load

distance;

Output attitude parameters;

else

Output no detection;

end

end

Algorithm 1: CV-based Load Attitude Estimation.

3.2 IMU-Based Load Attitude

Estimation and Setup

The experimental setup of this approach consists pri-

marily of an IMU MPU6050 fitted at the load position

and an ESP32-WROOM-DA microcontroller to inter-

pret IMU data and calculate the load attitude angles.

The IMU and ESP32 are connected through the I

2

C

communication protocol. The MPU6050 transmits a

14-byte raw integer string containing accelerometer

(a

x

,a

y

, and a

z

) and gyroscope (w

x

,w

y

, and w

z

) values

to the ESP32. The code developed in C++ is then de-

ployed on ESP32 which then processes the raw data

provided by MPU6050 and converts it into physical

units. These physical units are then converted to roll

and pitch angles using trigonometric functions by the

library MPU6050-light. The final outputs are then

timestamped and sent forward to the flight controller

over I

2

C or laptop (Arduino IDE Serial Monitor) over

serial communication.

For the experimental validation of the pro-

posed system, an off-the-shelf available 6-axis IMU

MPU6050 is used to determine the load attitude, α,

and β. An ESP32 is used to read and interpret the

raw data incoming from the IMU to produce the re-

quired attitude parameters for quadrotor control. The

step-by-step method articulating the IMU-based load

attitude estimation is shown in the form of Algorithm

2.

Data: IMU sensor data (accelerometer:

a

x

,a

y

,a

z

; gyroscope: w

x

,w

y

,w

z

)

Result: Pitch, Roll, Yaw

Initialization: Initialize IMU sensor and

calibrate accelerometer and gyroscope;

while IMU is active do

Read raw accelerometer data (a

x

,a

y

,a

z

);

Read raw gyroscope data (w

x

,w

y

,w

z

);

Convert raw data to physical units (m/s

2

for accelerometer, rad/s for gyroscope);

Calculate pitch, roll and yaw angles;

Output attitude parameters (pitch, roll,

yaw);

end

Algorithm 2: IMU-based Load Attitude Estimation.

4 EXPERIMENTAL AND

SIMULATION RESULTS

This section presents the results of experimental se-

tups as proposed in previous sections and provides a

comparative analysis of the salient features of both

ArUco marker-based and IMU-based methods with

the simulation of the pendulum-based suspended-load

setup.

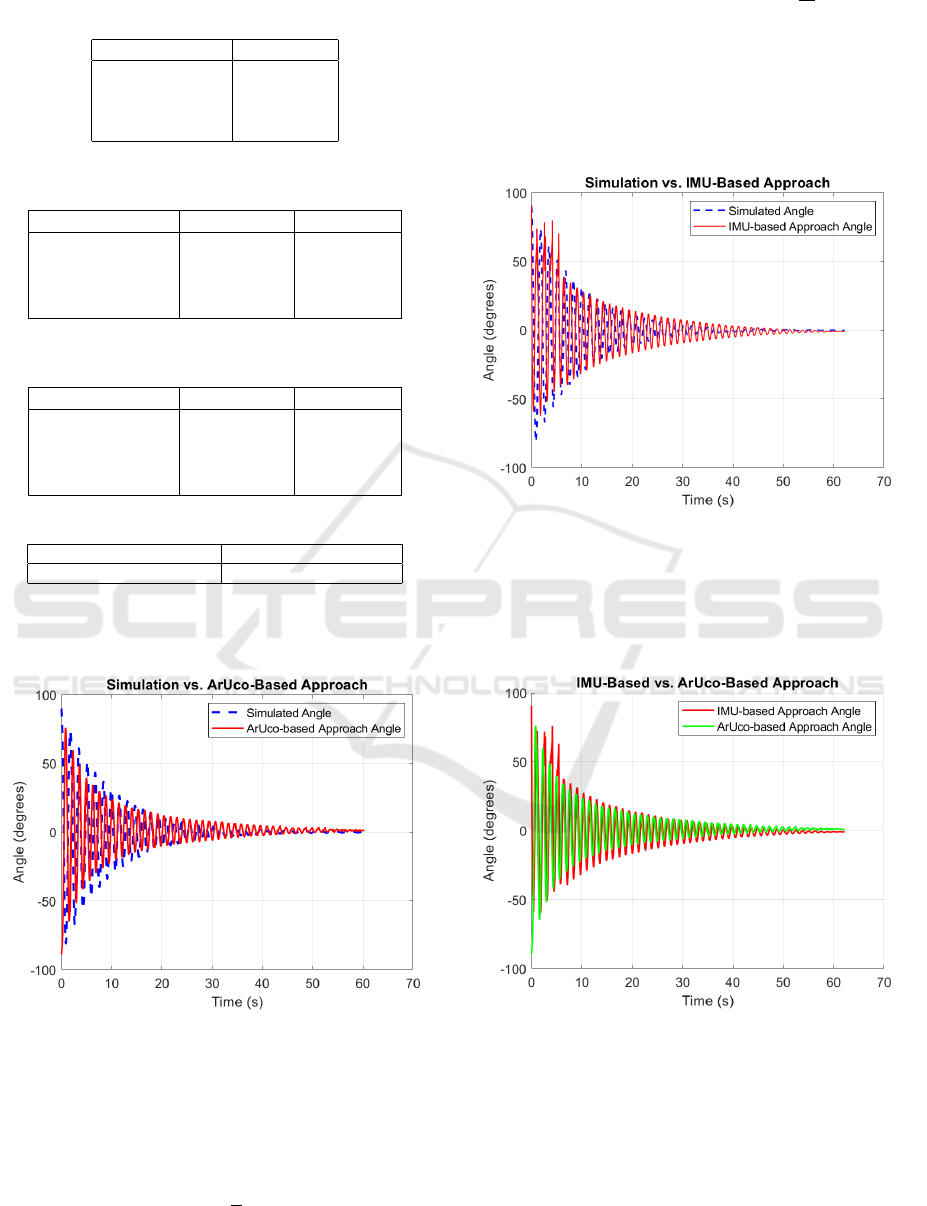

Table 1 presents the summary of variables taken

under consideration for the experiment.

The following Tables 2 and 3 summarize the data

collected during aggressive maneuvers using both

sensing methods. The measurements demonstrate

each method’s responsiveness and coverage across

relevant dynamic states.

The pendulum serves as a common platform for

comparison of feedback using an ArUco marker and

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

374

Table 1: Summary of variables obtained using both meth-

ods.

ArUco Based IMU-based

1. Pitch 1. Pitch

2. Roll 2. Roll

3. Yaw 3. Yaw

4. Load Distance

Table 2: Feedback from IMU-based method during an ag-

gressive maneuver.

Observation No. Pitch (Deg.) Roll (Deg.)

1 32.52 14.82

2 32.49 14.92

3 31.98 15.03

4 31.70 15.09

Table 3: Feedback from ArUco-based method during an ag-

gressive maneuver.

Observation No. Pitch (Deg.) Roll (Deg.)

1 -146.8 46.3

2 -138.5 53.0

3 -133.4 56.9

4 -124.5 59.6

Table 4: Summary of frequency of feedback attained.

ArUco Based Frequency IMU-based Frequency

31.21 Hz 370.48 Hz

IMU. The pendulum swing angle here is α represent-

ing the load attitude.

Figure 4: Pendulum load swing angle (α) vs Time plot for

CV-based method compared with pendulum simulation.

Figure 4 demonstrates the performance of the CV-

based feedback system. The plot shows the simulated

response of a pendulum governed by the non-linear

dynamic equation:

¨

α = −b

˙

α −

g

L

sin(α)

where damping coefficient b = 0.016

Ns

m

, length of

string L = 0.6m, α represents the angular displace-

ment of the pendulum load. These experimental data

points obtained from the physical pendulum are com-

pared with the simulated trajectory, with α corre-

sponding to the pitch angle measured using the CV-

based method.

Figure 5: Pendulum load swing angle (α) vs Time plot for

IMU-based method compared with pendulum simulation.

Figure 5 displays the performance of the IMU-

based feedback system in contrast with the simulation

of the system.

Figure 6: Pendulum load swing angle (α) vs Time plot for

both proposed methods.

The Figure 6 demonstrates the comparison of the

IMU-based and CV-based feedback system for pitch

angle, α, of the pendulum.

Experimental Validation of Load Attitude Estimation Using Computer Vision and IMU-Based Approaches for Slung-Load Aerial Robots

375

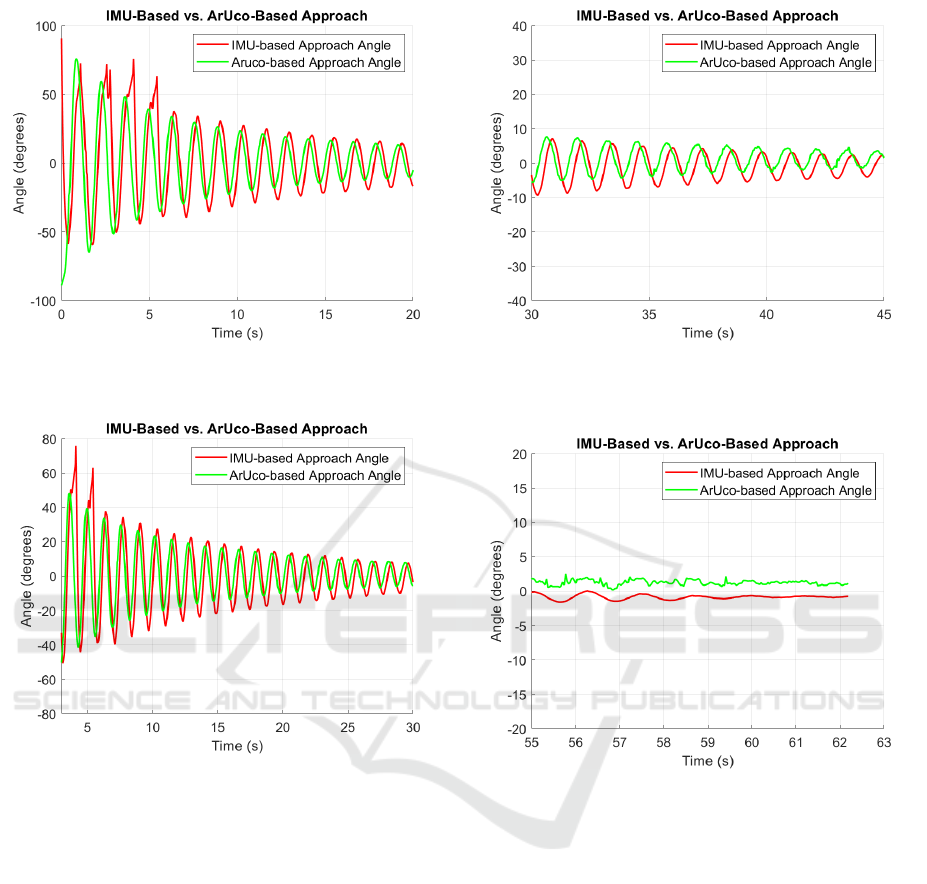

Figure 7: Anomaly in peaks of IMU-based load swing angle

during large swing angle variation (greater than ±25

◦

).

Figure 8: Another set of experimental values recorded for

IMU-based method vs. CV-based method for pendulum

swing angle.

In Figures 7 and 8, when there are greater vari-

ations in the pendulum swing angle, the IMU per-

forms poorly and is unable to accurately determine

the pendulum load swing angle. However, the CV-

based method outperforms the IMU-based method by

providing a consistent and accurate determination of

the pendulum load swing angle.

When an almost steady state condition is

achieved, the α angle obtained from the IMU-based

method exhibits better results compared to the CV-

based method, as projected in Figure 9.

As demonstrated in Figure 10, the pendulum sys-

tem tends towards the neighborhood of equilibrium

zero, i.e., near 0

◦

, the CV-based method displays very

distorted behavior, while the IMU-based method pro-

vides relatively better angle feedback α, which is very

useful in the case of quadrotor suspended load when

the swing angle of load is usually smaller in value.

Figure 9: Anomaly in peaks of swing angle (α) using CV-

based approach and IMU based approach during smaller an-

gle variations (< ±10

◦

).

Figure 10: Smaller variation of pendulum swing angle

(±5

◦

) experimental output values for both methods.

5 CONCLUSION AND FUTURE

PROSPECTS

This paper presents a comparative analysis of two

load attitude measurement methods for drones carry-

ing suspended loads- a CV based system using fidu-

cial markers and a sensor-based system employing an

IMU. Each method yields an easy to implement so-

lution offering unique advantages in different scenar-

ios. The IMU-based method performs well when the

load deviation is less (±10

◦

), and results in faster re-

sponse (approximately 370 Hz), making it easily in-

tegrable with flight controllers, making it suitable for

real-time precision maneuvering requirements when

faster control feedback is essential. Future work will

focus on integrating this system into actual flight con-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

376

trol loops in quadrotor with slung load. The CV based

method, although relatively more computationally in-

tensive but provides rather accurate load attitude mea-

surements. The CV based method performs even well

for extreme maneuvers when the load deviation is

greater than ±25

◦

. However, further improvements

would be required to effectively tackle the robustness

issues that accommodate illumination variations and

camera calibration errors. In our future works, along

with the addresal of these robustness issues, we intend

to test the proposed algorithms under real-world con-

ditions, including non-rigid cables to hang the load

under the environmental disturbances for the actual

drone having suspended cargo in 3D space.

REFERENCES

Bradski, G. and Kaehler, A. (2000). Opencv. Dr. Dobb’s

Journal of Software Tools, 3(2).

de Angelis, E. L. and Giulietti, F. (2023). An improved

method for swing state estimation in multirotor slung

load applications. Drones, 7(11):654.

Deng, X., Tsukada, T., Zhu, Y., and Nam, T. (2024). Angle

estimation using infrared camera in outdoor environ-

ment. IEEE Access.

Gao, Z., Xue, Z., and Lin, C. (2014). Design and imple-

mentation of a wireless mems ahrs for crane swing

monitoring. Sensors, 14(10):18670–18687.

Garg, V., Niranjan, S., Prybutok, V., Pohlen, T., and Gligor,

D. (2023). Drones in last-mile delivery: A systematic

review on efficiency, accessibility, and sustainability.

Transportation Research Part D: Transport and Envi-

ronment, 123:103831.

Garrido-Jurado, S., Mu

˜

noz-Salinas, R., Madrid-Cuevas, F.,

and Mar

´

ın-Jim

´

enez, M. (2014). Automatic generation

and detection of highly reliable fiducial markers under

occlusion. Pattern Recognition, 47(6):2280–2292.

Guerrero-S

´

anchez, M. E., Mercado-Ravell, D. A., Lozano,

R., and Garc

´

ıa-Beltr

´

an, C. D. (2017). Swing-

attenuation for a quadrotor transporting a cable-

suspended payload. ISA Transactions, 68:433–449.

Huang, J., Xu, W., Zhao, W., and Yuan, H. (2022). An

improved method for swing measurement based on

monocular vision to the payload of overhead crane.

Transactions of the Institute of Measurement and Con-

trol, 44(1):50–59.

Lee, S. J. and Kim, H. J. (2017). Autonomous swing-

angle estimation for stable slung-load flight of multi-

rotor uavs. In 2017 IEEE International Conference on

Robotics and Automation (ICRA), pages 4576–4581.

IEEE.

Mugala, S., Okello, D., and Seruganda, J. (2020). Un-

manned aerial vehicles: Opportunities for developing

countries and challenges. In 2020 IST-Africa Confer-

ence (IST-Africa), pages 1–10. IEEE.

Nguyen, S. and Caverly, R. (2021). Cable-driven robot

payload estimation with imu-aided ekf sensor fusion.

IEEE Transactions on Instrumentation and Measure-

ment, 70:1–9.

Palunko, I., Cruz, P., and Fierro, R. (2012). Agile load trans-

portation: Safe and efficient load manipulation with

aerial robots. IEEE Robotics & Automation Magazine,

19(3):69–79.

Prajapati, P., Parekh, S., and Vashista, V. (2022). On-board

cable attitude measurement and controller for outdoor

aerial transportation. Robotica, 40(5):1650–1664.

Tang, S., W

¨

uest, V., and Kumar, V. (2018). Aggres-

sive flight with suspended payloads using vision-

based control. IEEE Robotics and Automation Letters,

3(2):1152–1159.

Thakar, P. S., Bandyopadhyay, B., and Gandhi, P. S.

(2014). Sliding mode control for an underactuated

slosh-container system using non-linear model. Inter-

national Journal of Advanced Mechatronic Systems,

5(5):335–344.

Z

´

uniga, N. S., Munoz, F., M

´

arquez, M. A., Espinoza, E. S.,

and Carrillo, L. R. G. (2018). Load transportation us-

ing single and multiple quadrotor aerial vehicles with

swing load attenuation. In 2018 International Confer-

ence on Unmanned Aircraft Systems (ICUAS), pages

269–278. IEEE.

Experimental Validation of Load Attitude Estimation Using Computer Vision and IMU-Based Approaches for Slung-Load Aerial Robots

377