Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a

Multitask Neural Network

Marios Gkionis

1 a

, Ole Morten Aamo

1 b

and Ulf Jakob Flø Aarsnes

2 c

1

Department of Engineering Cybernetics, Norwegian University of Science and Technology, Trondheim, Norway

2

Energy Modelling and Automation, NORCE Energy, Oslo, Norway

Keywords:

Fault Detection, Fault Diagnosis, Deep Neural Networks, Multitask Learning, Oil Well Drilling.

Abstract:

Drilling operations can be unexpectedly laden with mechanical faults, mud loss, and insufficient cuttings

transport that incur substantial costs. This can be avoided via accurate and early fault detection and diagnosis.

We present a novel Drilling Fault Detection and Diagnosis (FDD) system that leverages Multitask Neural

Networks (MTL-NNs). It accounts for the practical limitation that down-hole measurements are normally not

available in real-time and can perform FDD relying only on flow and pressure measurements at the drilling rig.

Data for training and testing are produced by a simulator based on the distributed flow and pressure dynamics

in the entire well governed by four coupled hyperbolic partial differential equations. Faults are incorporated

into the simulations so that the data contain information about how diagnostics of faults affect the dynamics.

Our numerical experiments, admittedly under quite ideal conditions, show that the proposed method exhibits

high generalization performance on diagnosis for fixed well depths, while incorporating varying well depths

into a single network requires increased size in both network and training data to maintain performance.

1 INTRODUCTION

Detection of the presence of a system fault, localiza-

tion and quantification constitute the field of engineer-

ing known as Fault Detection and Diagnosis (FDD).

Numerous techniques have been developed in this

field (Isermann, 2006), and they can be categorized as

data-based or model-based. The former (Venkatasub-

ramanian et al., 2003) utilize historic process knowl-

edge such as datasets from already occurred faults that

can help with detection and prognosis of future faults.

Rich historic datasets for faulty cases in drilling are

absent, since each new well corresponds to a new

(unseen) process. In addition, collecting faulty data

(on purpose) would be an unrealistically expensive

and lengthy process, probably making model-based

methods the more feasible option for FDD in drilling.

A common instance in the list of model-based FDD

methods is the design of a bank of observers (Zhang,

2000), which can be based on Kalman filters, such as

in (Jiang et al., 2020). Separate models are deployed

for incorporation of the individual faults. Each ob-

a

https://orcid.org/0009-0009-2626-9378

b

https://orcid.org/0000-0001-6899-1451

c

https://orcid.org/0000-0001-6272-7203

server corresponds to a model and is designed such

that the process states and outputs are estimated and

predicted respectively. The output prediction errors

(residuals) are stored for statistical change analysis,

thereby providing fault detection and identification.

Methodical design of the statistical change detection

algorithm and the observers is required and a notable

example of this method applied to drilling can be

found in (Willersrud et al., 2015) using down-hole

measurements. However, down-hole measurements

are normally not available in real-time in practice, so

in the present work we rely only on top-side measure-

ments.

Deep Learning (DL) has received rapidly increas-

ing attention from researchers and engineers since

massive amounts of data from processes are collected

and create the opportunity of insight from their sys-

tematic analysis and computational tools have been

improving. The enhancement of the capabilities of

DL has brought about the increase in prediction ac-

curacy, realization of explainability, and savings in

training time and utilization of memory (Alzubaidi

et al., 2021). In addition, two methods that help en-

hance generalization performance and data efficiency

are MTL and Physics-Informed NNs (PINNs) (Raissi

et al., 2019). The latter do so by employing math-

350

Gkionis, M., Aamo, O. M. and Aarsnes, U. J. F.

Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a Multitask Neural Network.

DOI: 10.5220/0013783800003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 350-361

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

ematical models that encode constitutive (physical)

laws (physics priors) that describe the available data,

which are normally either combined with the physics

priors, or the priors can fully replace the data. The

latter option may be desirable in applications such as

drilling, given the absence of historic field data.

MTL-NNs (Caruana, 1997) are NN variants

which are simultaneously trained for multiple sep-

arate prediction tasks, parameterized by shared and

task-specialized parameters. Since it is a Deep Neu-

ral Network (DNN), its utilization does not come

with the requirement of convergence analysis and in-

vestigation of appropriateness as a parameter estima-

tion scheme. This requirement relaxation renders the

implementation quicker and less application-specific.

Up to our knowledge, MTL is at an early stage of in-

corporation on FDD problems. The majority of pub-

lished work focuses on bearings (such as (Guo et al.,

2020), (Liu et al., 2021), and (Wang et al., 2022)) and

wind turbine fault diagnosis.

FDD for Drilling is fundamentally different than

FDD for the aforementioned applications. In Drilling,

faulty data for a new well being drilled are not avail-

able and historical data are not expected to be suf-

ficient for DNN training and Transfer-Learning to a

new well. In rolling bearing FDD, rich operation data

can be utilized to extract accurate fault signatures.

What is more, numerous sensors can be placed in dif-

ferent locations in rotary machinery applications to

extract data, whereas in our case we aim to achieve

FDD only using three time-series signal inputs, one

of which is a manipulated signal. The current work

serves as a starting point for investigating the applica-

tion of MTL for FDD in drilling.

In many applications, data is available from

sources that are described by inter-related latent

mechanisms. Such mechanisms can be encoded

through the shared part of a MTL-NN. To indepen-

dently train individual NNs for each task would lead

to redundant calculations of forward passes of the

shared features and failure to encode the common fea-

tures, thus leading to poorer generalization and pa-

rameter efficiency. The work in (Wang et al., 2021a)

exemplifies this, wherein the rolling bearing vibration

signals are considered in the training of the common

NN, leading to the enrichment of the encoded infor-

mation in the shared features. In general, learning

performance can be improved when auxiliary tasks

are incorporated into the NN, such as with the case

of (Amyar et al., 2020) that uses the COVID classi-

fication task to enhance the learning performance of

the other (main) tasks. MTL can also be valuable

when sensor data are not sufficient for effective Single

Task Learning (STL), as highlighted in (Wang et al.,

2021a). Among the different MTL architectures, we

employ the Multi-Head architecture (MH-NN), which

belong to the Hard-Parameter Sharing class of MTL

architectures (Yu et al., 2024).

It has been stressed in the literature that MH-

NNs are suitable for meta-learning (Hospedales

et al., 2020). For example, the work of (Wang

et al., 2021b) analyzes the connection between meta-

learning and MTL through MH-NNs. In (Zou and

Karniadakis, 2023), successful few-shot learning is

achieved through deployment of MH-NNs, providing

the first empirical observation of synergistic learning.

(Lin et al., 2021) showed that MH-NNs can perform

task-specific adaptation as well. This is a key motiva-

tion for opting to utilize MH-NNs in our pipeline.

In this work, the training data is generated using a

transient drilling hydraulics model described by a sys-

tem of four first order semilinear partial differential

equations (PDEs). Despite the fact that this clearly

encodes the physics of the process into the NN, it

is not strictly a PINN, given that the latter utilizes

the operator terms of the underlying physical laws

in the NN’s loss function (Raissi et al., 2019). It

represents a step further from our work in (Gkionis

et al., 2025), wherein a steady-state model was uti-

lized instead. The MTL-NN approach is similar to

the model-based approach, since each fault requires

a separate model for data generation. Given that the

NN encodes the shared feature representations, fault-

independent observer design is redundant. Moreover,

the NN inherently incorporates and learns the statis-

tical assessment of residuals in the case of the design

bank of observers. We examined three different flow-

related faults, which are detailed at the beginning of

Section 3.

There are a few publications on Drilling FDD that

utilize MTL and PINNs, albeit not referenced in an-

alytical overviews of NN variants and FDD applica-

tions such as (Qiu et al., 2023). For instance, Convo-

lutional NNs are applied in (Jeong et al., 2020) and

(Jan et al., 2022), since the faults are provided as in-

puts in the form of multi-channel time series. How-

ever, these works solely examine Washout Fault De-

tection and up to our knowledge constitute the only

ones that apply PINNs and MTL in Drilling. In (Jan

et al., 2022), the different tasks include a classifica-

tion task and the enforcement of physical constraints.

However, the physics prior used in the estimation is

tied to a specific parametric model, which restricts the

generality of the NN.

We have outlined the rest of this publication as fol-

lows: Section 2 describes the pipeline of the FDD

scheme; the data collection, the formulation of the

data-source, and the structure and loss functions of

Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a Multitask Neural Network

351

the NN. Section 3 describes the relevant physics of

the application under study and declares which exact

signals are to represent the generic signals defined in

Section 2. We discuss the results in Section 4 and con-

clude with ideas for extending the scope of this work

in Section 5.

2 PROBLEM STATEMENT AND

METHODOLOGY

We consider a construction task that is scheduled to

be set into operation some time in the future. It is

assumed to be unique, so that there is no experi-

enced data available to learn from prior to the op-

eration. However, we assume that the operation can

be described by a dynamic system, taking inputs, de-

noted u : [0, T ] → R

p

, and giving outputs, denoted

y : [0,T ] → R

q

, that we assume will be available as

measurements in real time during the operation. At

any given time, one of m distinct faults may arise, in-

fluencing the relationship between inputs and outputs.

The operation is precisely defined so that a numeri-

cal simulator incorporating the potential faults can be

built and used for planning prior to performing the

operation in practice. Given a sequence of inputs,

{u}

n

i=1

(for some arbitrary n), the type of fault (if

any), an r-dimensional column-vector characterizing

the fault, d ∈ [−1,1]

r

, and an s-dimensional vector of

(physical) system parameters θ ∈ [−1, 1]

s

, the simula-

tor computes the corresponding sequence of outputs,

{y}

n

i=1

. We will denote this simulation as S

i

, where

the index i ∈ {0,1,...,m} identifies the type of fault,

with i = 0 corresponding to the fault-free operation.

In other words, we have

{y}

n

j=1

= S

i

({u}

n

j=1

,d, θ), i ∈ {0,1,...,m}. (1)

θ can represent system parameters that are ex-

pected to change during operation, or whose inclu-

sion in training can elevate the generalization perfor-

mance of the DNN through the mechanism of MTL.

Using data produced by the simulator, we aim to train

a DNN so that it can be used in real time during the

actual operation to detect a fault happening and yield

an alarm with the type of fault and its characteriz-

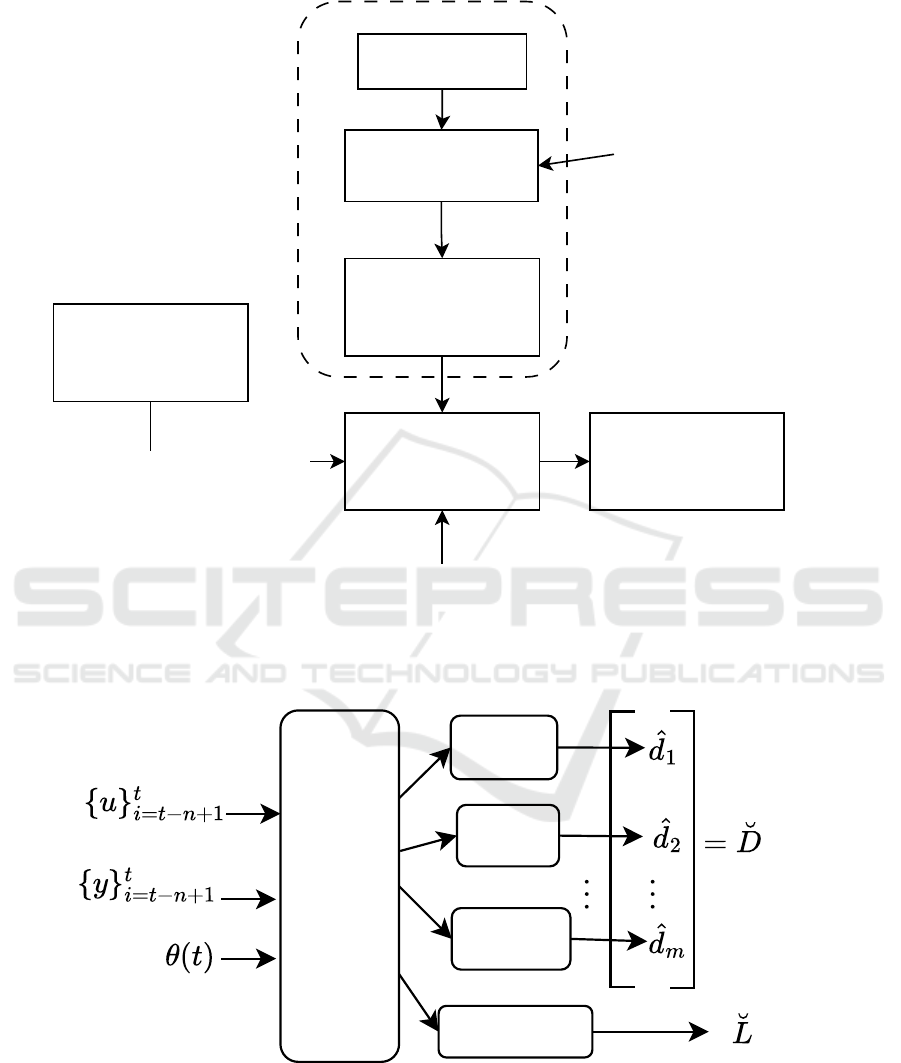

ing vector d. (see Figure 1 for the proposed work

flow). Denoting the neural network as f , we suggest

the input-output structure

(

˘

L,

˘

D) = f ({u}

n

i=1

,{y}

n

i=1

,θ) (2)

where

˘

L ∈ R

m+1

and

˘

D ∈ R

r×(m+1)

. For fault de-

tection, define the one-hot labeling vectors L

i

=

[l

0

,...,l

m

] where l

j

= 1 for j = i and l

j

= 0 for j ̸= i,

and let

ˆ

L equal the L

i

, i ∈ {0,...,m} that is most sim-

ilar to

˘

L. The corresponding estimate of the diagnos-

tics is then given by

ˆ

d =

˘

D

ˆ

L. We suggest Algorithm

1 for generating data for training and testing.

Algorithm 1: Data Generation.

Result: Datasets X and Y filled with

input-output samples

Initialize datasets X and Y as empty;

while number of samples not reached do

Select i randomly from {0,...,m};

Select {u}

n

i=1

randomly from a class of

admissible input signals;

Select d randomly from [−1,1]

r

;

Select θ randomly from [−1,1]

s

;

Compute {y}

n

i=1

= S

i

({u}

n

i=1

,d, θ);

Add {u}

n

i=1

,{y}

n

i=1

,θ to dataset X , and

L

i

,dL

i

to dataset Y ;

end

Let the data sets X,Y produced by Algorithm 1

contain N samples ({u}

n

i=1

,{y}

n

i=1

,θ)

j

, (L

j

,D

j

), j ∈

{1,...,N}. Invoking the NN (2) for each sample in X

produces the predictions

˘

L

j

,

˘

D

j

, j ∈ {1,...,N}. The

loss used for training is

L = L

f d

|{z}

fault detection

+ L

d

|{z}

diagnosis

(3)

where

L

f d

= −

1

N

N

∑

j=1

L

j

· log

˘

L

j

(4)

and

L

d

=

1

N

N

∑

j=1

L

j

W ||(D

j

−

˘

D

j

)L

j

||

2

. (5)

W = [w

0

,w

1

,...,w

m

]

T

is a vector of weights.

In the above, we have for notational simplicity ig-

nored the fact that the diagnostics, d, may have di-

mension less than r for some faults (and dimension 0

for the fault-free case). This is handled in the imple-

mentation by masking out irrelevant components of d

during training and testing.

At every timestep, t, the sequences of inputs,

outputs, and parameters, {u}

t

i=t−n+1

,{y}

t

i=t−n+1

, and

θ(t), from the operation can be fed to the pre-trained

neural net to provide fault detection and diagnostics

in real time, that is

(

˘

L(t),

˘

D(t)) = f ({u}

t

i=t−n+1

,{y}

t

i=t−n+1

,θ(t)) (6)

ˆ

L(t) = argmax

L

i

,i∈{0,...,m}

L

i

· log

˘

L(t) (7)

ˆ

d(t) =

˘

D(t)

ˆ

L(t) (8)

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

352

Process Planning

Simulator setup

(multiple simulations)

NN Training for FDD

(FDD-NN)

FDD-NN

ALARMS AND

DIAGNOSTICS

Real-Time Data-feed

Real-Time operation

Planning and preparation phase

No available data prior to

plant being built

Meta-learning NN

adaptation in presence of

real-data

Figure 1: Data and process-planning pipeline.

COMMON

TRUNK

head 1

head 2

head m

head m+1

Figure 2: Depiction of a Multi-head Neural Network. Each one of the ”heads” corresponds to a separate Fault with the last

one corresponding to the detection task. Nomenclature of this figure corresponds to equations (6) - (8). The input θ represents

process parameters for which the dataseries are produced. This is an input that is relevant when the training data are produced

by different system parameters.

Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a Multitask Neural Network

353

This FDD scheme is depicted in Figure 2. The

MTL architectures tested for this work belong to

the Hard Parameter Sharing architecture (Yu et al.,

2024), meaning that the tasks share a subset of pa-

rameters and utilize a subset of specialized parame-

ters which are not shared with the other tasks. Fig-

ure 2 offers a general depiction of such an archi-

tecture. Specifically, we compared the generaliza-

tion performance between two similar architectures:

Fully Connected Multi-task NN (FCN-MTL-NN) and

Multi-head NN (MH-NN). The latter terminology is

not consistent in the literature (Yu et al., 2024). In

this work, we use this terminology when referring to

a NN that uses separate DNNs for each head, whereas

a Fully Connected Multi-task NN the heads are simply

the last activation function of the final linear operation

of the output layer. The consideration of certain pro-

cess parameters θ is important for cases during which

the system parameters change during operation. In-

stead of training multiple separate DNNs, we leverage

the context-sensitive MTL architecture (Silver et al.,

2008) for the system parameters and rely on a larger,

more generalized DNN. In this architecture, a task-

indicator (in this case, the system parameter vector θ)

is propagated in the DNN from the input. In addition,

more context-sensitive parameters may help achieve

a higher generalization performance, which we opt to

leverage in future work.

3 APPLICATION TO DRILLING

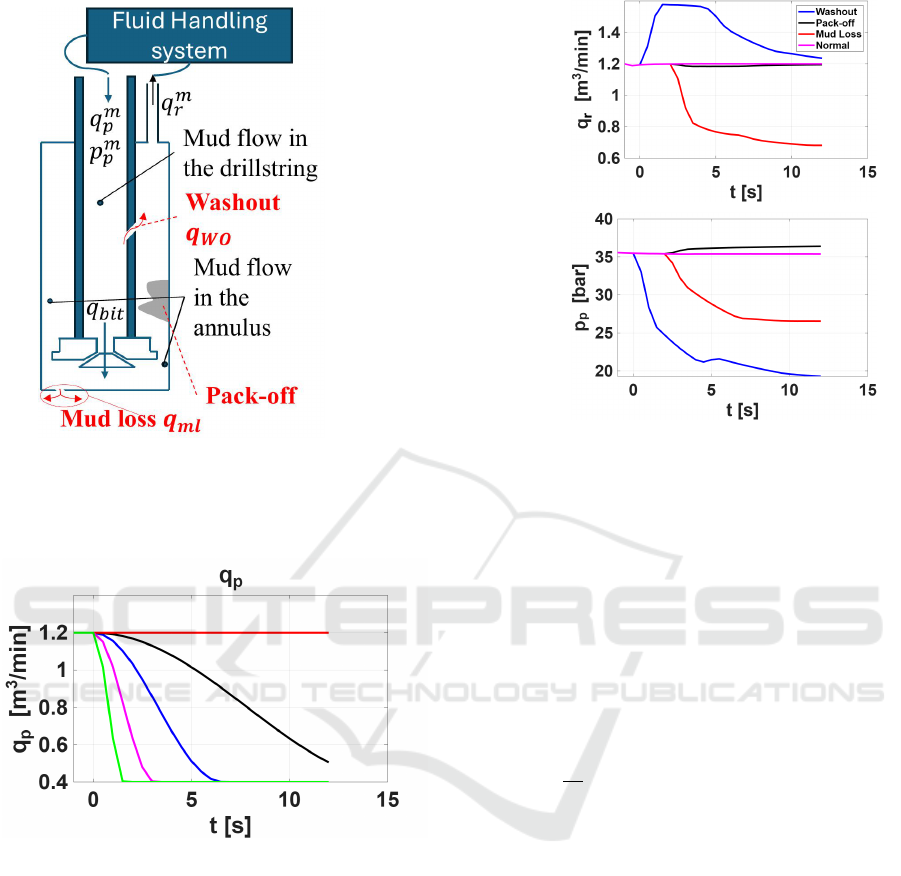

Figure 3a illustrates the drilling process. Measured

quantities are indicated with the superscript m, while

faults are highlighted in red. Drilling fluid, or ”mud,”

is pumped through the drill string to the drill bit and

then returns through the annulus to the Fluid Handling

System (FHS), where it is cleaned and recirculated

into the well. The pump rate q

p

serves as the process

input (u(t) = q

p

(t)), while the pump pressure p

p

and

return flow q

r

are the outputs (y(t) = [p

p

(t),q

r

(t)]).

The relationship between input and output varies de-

pending on whether a fault is present. The FHS is

assumed to be open to the atmosphere on the annu-

lus side, meaning that the pressure at that boundary is

fixed at 1 bar. Managed Pressure Drilling (MPD) can

be easily integrated as long as the pressure at the inlet

of the MPD choke and the flow rate of the backpres-

sure pump are measured. Washout occurs when fluid

bypasses the normal flow path due to a crack or hole in

the drill string, causing a shortcut from the drill string

to the annulus. Its diagnostics include the crack loca-

tion and size, represented as z

wo

and C

wo

. Mud loss

happens when drilling fluid leaks from the well into

Table 1: Training parameters.

Parameter Value

Batch type Mini batch (size=400)

Number of sam-

pled trajectories

{Washout: 8000, Packoff:

8000, Mud loss: 8000}

Layer structure

for head

NN

head

=

[80,80,80, 80, 80, 80,2]

MH-NN struc-

ture

[75, 1699, 1699, 1699,

NN

head

, NN

head

, NN

head

,

[80, 80, 80, 80, 80, 80, 4]]

FC-NN struc-

ture

[75, 1272, 1272, 1272,

1272, 1272, 12]

Number of

trainable pa-

rameters

MH-NN: 6580134, FC-NN:

6588972

Activation func-

tions

GELU (and SoftMax for the

categorization output)

Loss function Diagnosis: MSE, Detection:

Cross Entropy

Regularization L2 (0.01)

Optimizer AdamW (0.9,0.9)

(Loshchilov and Hutter,

2017)

Hardware NVIDIA RTX A2000 Lap-

top GPU (cuda) with Py-

Torch

the reservoir. The key diagnostics for mud loss are

the reservoir pressure and the mud-loss coefficient,

denoted as p

r

and k

I

respectively. Pack-off refers to

the partial or complete blockage of recirculation flow,

often caused by inadequate hole cleaning, which al-

lows cuttings to accumulate in the well. The key di-

agnostic for pack-off is the size coefficient linked to

the pressure-drop across the blockage denoted by C

po

.

See equations (10) - (12) in the Appendix for details

of the fault modeling.

The task of constructing an oil well constitutes a

unique operation of the sort introduced in Section 2.

The well is planned in detail before the operation, fa-

cilitating the setup of a simulator of the operation.

In this work, we base the simulator on a mathemat-

ical description of the pressure and flow in the drill

string and annulus in the form of a hyperbolic par-

tial differential equation. The details of the model

are given in the Appendix. For a constant pump rate

of q

p

(t) = 1200 [l/min], Figure 3b shows the return

flow and pump pressure computed by the simulator

for carefully selected examples of the three faults of

interest. Notice that the pump pressure and return rate

stay constant in the fault-free case (magenta lines).

In the case of washout (blue lines), the return rate

suddenly increases due to the short-cut suddenly cre-

ated by the crack in the pipe. It quickly returns to

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

354

(a) Well schematic, depicting the Faults consid-

ered for this work. Figure from (Gkionis et al.,

2025).

(b) Simulated trajectories from the Partial Differ-

ential Equations describing the system (see Ap-

pendix), showcasing the different behavior in-

duced by the occurrence of different Faults.

Figure 3: Well schematic (left) and signatures of the different Faults (right).

Figure 4: Different q

p

trajectories. Each different color cor-

responds to a different set of A and γ of Equation (9). Blue:

[0.8, 0.47], black: [0.8, 0.2], red: [0.8, 0], purple: [0.8, 1],

green: [0.8, 02].

the original value of the pump flow, though, as mass

balance is enforced. Due to the short-cut, the flow

experiences less frictional pressure loss, and the re-

quired pump pressure to circulate therefore decreases.

In the case of mud loss (red lines), the return flow

decreases and stays low because mud is permanently

lost to the reservoir. Less fluid therefore circulates,

requiring a lower pump pressure. In the pack-off case

(black lines), the flow stays relatively constant (since

no mud is lost), while the frictional pressure loss in-

creases due to the restriction pack-off causes, requir-

ing a higher pump pressure to circulate. The pressure

and flow signatures of the faults show quite distinct

features that can easily be identified by visual inspec-

tion. The purpose of the neural network, however, is

to detect as early as possible less obvious faults that

may evolve into serious problems for the operation if

not counteracted.

Data for training and testing is produced accord-

ing to Algorithm 1. In the algorithm, a set to draw

admissible input signals from is defined by

q

p

(t) =

A

j

2

cos

max

0,min{γ

j

t,π}

+ 1

(9)

where the parameters A

j

,γ

j

are uniformly sampled

from [0.2,1.0] and [0,2π/T

lim

] respectively. This cor-

responds to ramping the pump down from a rate gov-

erned by A

j

at a slope governed by γ

j

, which are likely

operations of the pump in practice. Examples of this

are shown in Figure 4.

As it has been already mentioned, this work

focuses on performing accurate Diagnosis in the

Drilling application. It is assumed that the faults do

not occur simultaneously and that the system is oper-

ating in steady-state up until a fault occurrence.

As a first step to assessing the robustness of the

FDD scheme, we generate data using simulations for

uniformly sampled values of the depth of the well L

in the range [2000m,4000m]. The architecture used

for this addition is the one shown in Figure 2 with

θ(t) equal to L(t) normalized to the interval [−1,1].

L clearly varies slowly compared to the dynamics of

pressure and flow.

Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a Multitask Neural Network

355

Table 2: Detection accuracy for the different faults.

- Washout Mud Loss Pack-off

Fixed depth (3000m) 99.5% 100% 100%

Variable depth 99.7% 100% 100%

The motivation for using the specific time window

of T = 12s and sampling time of ∆t = 0.5s is linked

to the dynamics of the system. The nature of the pres-

sure waves in this system is such that there will be a

delay until the effects of a fault become apparent at

the topside boundary. This can be verified via visual

inspection of the delays for the first signal changes to

occur Figure 3b).

4 RESULTS AND DISCUSSION

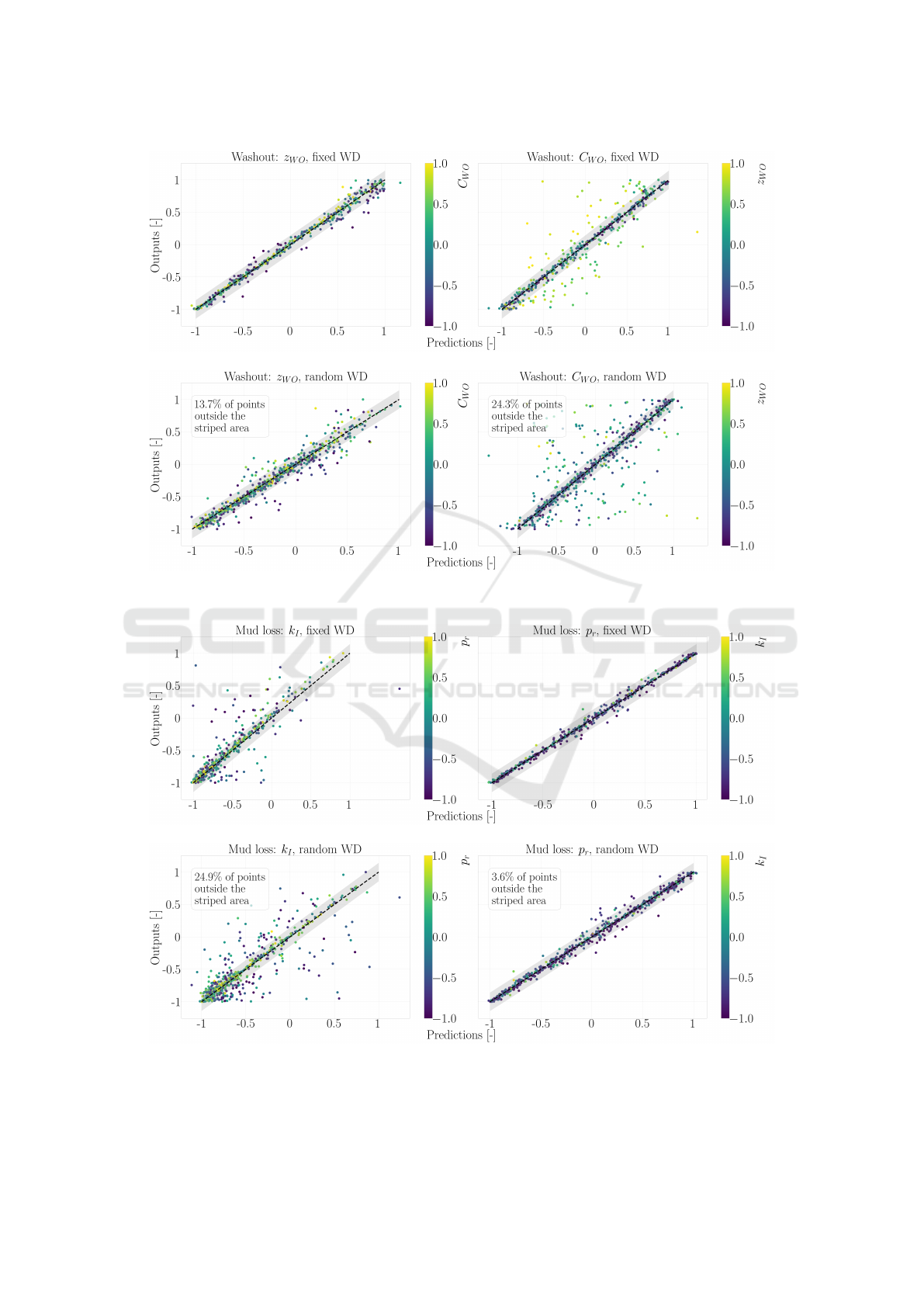

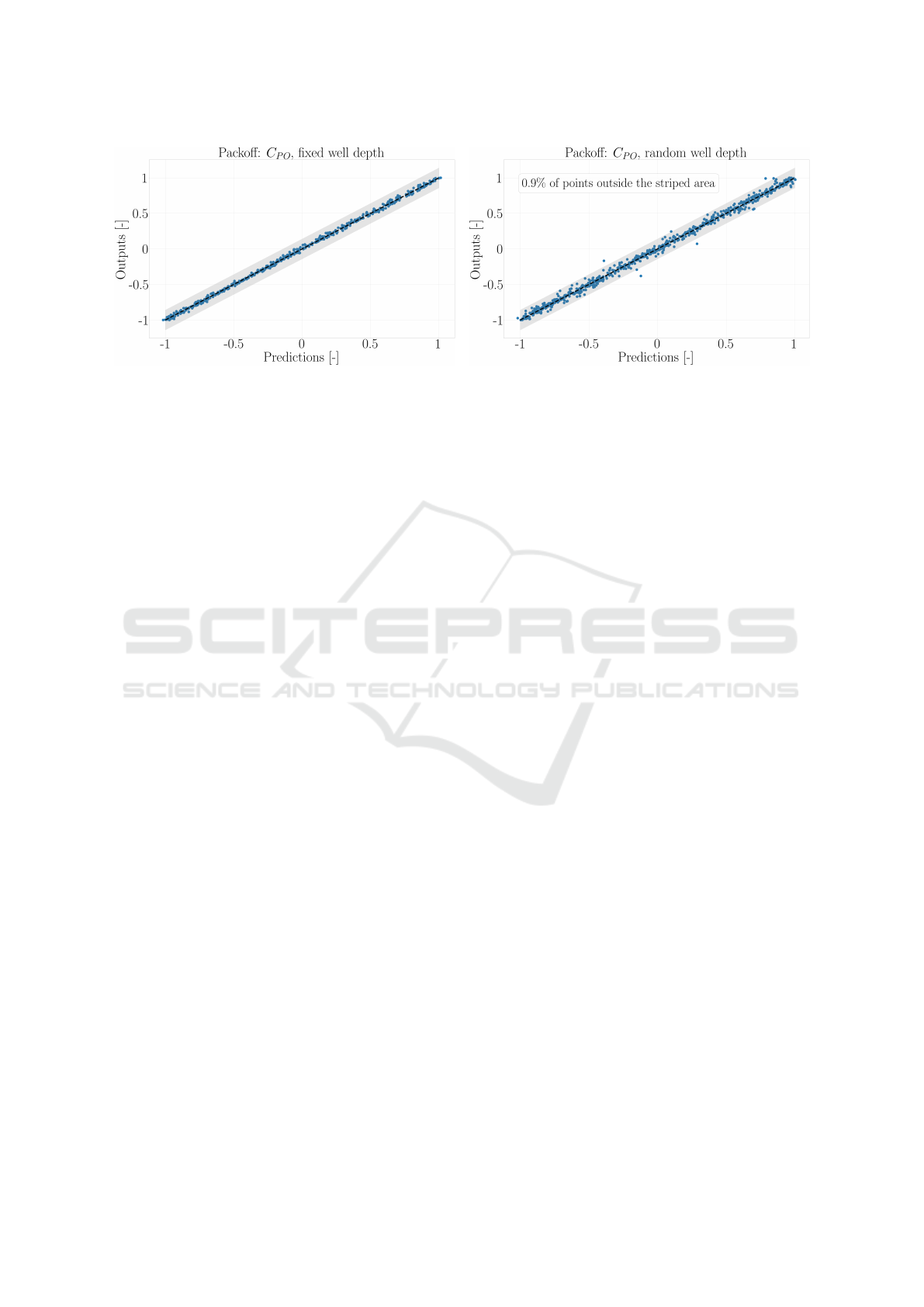

The hyperparameters of the training algorithm are

provided in Table 1. Figures 5a and 5b show the scat-

terplots for the predictions on the diagnostic variables

for fixed (first row) and randomized well depth (sec-

ond row) for Washout and Mud Loss respectively and

Figure 6 shows the same information for Pack-off. In

this section, we present the results of applying the test

data to the trained network. The performance of clas-

sification of the type of fault (i.e. fault detection) is

summarized in Table 2 for the cases of fixed and vari-

able well depth. It can be observed that Diagnosis

is accurate when the well depth is fixed and exhibits

moderate robustness with respect to the well depth

parameter. The MH-NN trained on data a fixed well

depth of 3000 m exhibits quite higher accuracy using

the same number of training datapoints (8000).

1. The MH-NN (Figure 2) generalizes equally well

with a FCN that has multiple outputs. The depth

of the NN was crucial to the results; a shallow NN

(with the same number of trainable parameters)

resulted in gradient vanishing , as well as with

depth quite larger than the one used for this work.

2. The NN trained for trajectories with randomly

sampled well depths exhibited unsurprisingly

lower accuracy for Fault Diagnosis. Enlarging

the training dataset and/or the NN would improve

the prediction accuracy. In addition, utilization of

useful biases linked to the effect of the well depth

in the dynamics, and application of meta-learning

in already trained NNs can result in improvement

of the NN’s generalization performance.

3. The outliers in Figure 5a and Figure 5b are not

surprising. C

wo

becomes difficult to correctly di-

agnose when the washout occurs close to the bit,

since then the flow through the crack and the

flow through the bit are indistinguishable from

the top-side, several kilometers away. Diagnosing

z

wo

for small washouts is also quite difficult be-

cause accurate localization is sensitive to the dif-

ference between the pump rate and the rate of flow

through the bit. It is this difference that causes

a change in the pump pressure which can be de-

tected top-side. When it comes to mud loss (Fig-

ure 5b, the reservoir pressure p

r

is generally well

predicted, while the index k

I

is occasionally quite

wrong. We do not have a clear explanation for

this behavior, but in practice, it is more impor-

tant to obtain an accurate estimate of the reservoir

pressure because then the down-hole pressure one

needs to aim for in order to stop the loss is known.

The down-hole pressure can be lowered to some

extent by ramping down the pump, and to a larger

extent by changing the mud weight.

4. The high prediction quality (for fixed well depth),

achieved without weight scheduling or special

regularization (Mao et al., 2024), suggests that

task domination (Senushkin et al., 2023) may be

absent in the studied datasets.

5. In spite of the established theory (Zhang et al.,

2016) that overparameterization generates im-

plicit regularization, the multi-head architecture

still required weight decay in order to generalize

in an acceptable level.

5 CONCLUSIONS AND FUTURE

WORK

In this work, a MTL-NN was successfully trained

to perform accurate Fault Diagnosis through deploy-

ment of a single multi-head NN trained on simulated

time-series trajectories. It constitutes a preliminary

step towards using generalized NNs that predict ac-

curately for wider spectrum of faults and well param-

eters, as well as parameters of the fault-free process.

Our NN generalizes to different well depths with sig-

nificant room for improvement. In addition, the re-

quirement for an increased network depth is typically

suggestive of the presence of hierarchical complexity

in the dataset.

An immediate idea for extending this work would

be to improve the data-efficiency of MTL that per-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

356

(a) Scatterplots of Washout diagnostics on test data, using the MH-NN for fixed Well Depth and random Well

Depth

(b) Scatterplots of Mud Loss diagnostics on test data, using the MH-NN for fixed Well Depth and random Well

Depth

Figure 5: Scatterplots for the faults. The values are normalized in [-1, 1]. The x-axis represents the network’s prediction and

the y-axis represents the actual values for the diagnostics.

Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a Multitask Neural Network

357

(a) Scatterplot of Pack-off diagnostics on test data, using the

MH-NN.

(b) Scatterplot using MH-NN trained on randomized well

depth data.

Figure 6: Scatterplots for the faults. Values normalized in [−1, 1]. The x-axis represents the network’s prediction and the

y-axis represents the actual values for the diagnostics.

forms FDD with the same NN for different well

depths (as well as other well characteristics, such as

the well geometry, varying drill string cross-sections,

and drilling fluid), given the satisfactory accuracy that

we have achieved using the same NN that was trained

for data generated using a fixed well depth.

In addition to this, considering more well param-

eters would bring about higher generalization per-

formance and creating a more general NN that can

then be used to finely update a subset of the Network

parameters for unseen wells based on meta-learning

(Hospedales et al., 2020) and few-shot learning (Zou

and Karniadakis, 2023). What is more, it is specu-

lated that the consideration of multiple sources of pa-

rameter uncertainty will render detection of the faults

challenging, since it is expected that there will be very

similar curves corresponding to different faults and

different well parameters. This possibility gives rise

to the requirement for developing and training NNs

that incorporate uncertainty (He and Jiang, 2023).

Further work on rendering the scheme more robust

and realistic via incorporating uncertainty in the data

and the system parameters would be to include col-

ored noise in the input data.

The most important limitation of our work is, ad-

mittedly, the complete reliance on simulated data for

NN training. The motivations for this are as follows.

• Preliminary investigation of the feasibility of per-

forming FDD given the known dynamics of a

problem. Up to our knowledge, this is the first

work that tackles the inverse problem of identify-

ing fault parameters in drilling for multiple faults

and utilizing only topside measurements. There-

fore, a first step towards FDD is to investigate its

feasibilty with synthetic data.

• Insufficient number of real process data. As ex-

plained in Section 1, real drilling data during

faulty operations are not expected to be sufficient

for DNN training. This is true for other applica-

tions as well (for example, in (Tercan et al., 2018)

and (Weber et al., 2020)). Tackling this chal-

lenge requires utilization of methods that transfer

knowledge from simulations to real data.

Since the synthetic data bear similarities with the

real drilling data, the knowledge encoded in DNNs

trained with simulation data may be exploited such

that the DNN adapts to sparse real process data. The

techniques that facilitate this adaptation are Trans-

fer Learning and Meta-Learning (Hospedales et al.,

2020), (Ranaweera and Mahmoud, 2021). Numer-

ous industrial applications which leverage Transfer

Learning exist in literature, many of which are de-

tailed in (Yan et al., 2023). For example, the au-

thors in (Tercan et al., 2018) tackle the problem of low

availability of real industrial data for training in injec-

tion mold methods by training a DNN with simulated

data and then introduce new NN parameters for train-

ing on real data while keeping the simulation-trained

ones frozen, or use the already trained values of the

weights as initial values for training with the limited

real training data. The authors in (Weber et al., 2020)

train base DNN models to detect room occupancy us-

ing synthetic data from room occupancy simulations

and physical simulations. These base models are sub-

sequently updated through a transfer step to adapt to

the limited (and more expensive to sample) real data.

Up to our knowledge, there is not any research work

that applies Transfer Learning and/or Meta-Learning

to bridge the gap between simulated and real data in

drilling applications.

Last but not least, to enhance the practicability of

the developed algorithm, extensive testing with state-

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

358

of-the-art drilling simulators can be conducted. Such

simulators (for example, OpenLAB from (Gravdal

et al., 2021)) can model faults which cannot are gov-

erned by much more complicated dynamics, such as

Gas-Kick (Sun et al., 2018).

REFERENCES

Alzubaidi, L., Zhang, J., Humaidi, A. J., Al-dujaili, A.,

Duan, Y., Al-Shamma, O., Santamar

´

ıa, J. I., Fadhel,

M. A., Al-Amidie, M., and Farhan, L. (2021). Review

of deep learning: concepts, cnn architectures, chal-

lenges, applications, future directions. Journal of Big

Data, 8.

Amyar, A., Modzelewski, R., and Ruan, S. (2020). Multi-

task deep learning based ct imaging analysis for

covid-19: Classification and segmentation. medRxiv.

Caruana, R. (1997). Multitask learning. Machine Learning,

28:41–75.

Gkionis, M., Wilhelmsen, N. C. A., and Aamo, O. M.

(2025). Fault diagnosis for drilling using a multitask

physics-informed neural network. In Proceedings of

the 14th IFAC Symposium on Dynamics and Control

of Process Systems, including Biosystems (DYCOPS).

To appear.

Gravdal, J. E., Sui, D., Nagy, A. P., Saadallah, N., and

Ewald, R. (2021). A hybrid test environment for veri-

fication of drilling automation systems.

Guo, S., Zhang, B., Yang, T., Lyu, D., and Gao, W. (2020).

Multitask convolutional neural network with informa-

tion fusion for bearing fault diagnosis and localiza-

tion. IEEE Trans. Ind. Electron., 67(9):8005–8015.

He, W. and Jiang, Z. (2023). A survey on uncertainty quan-

tification methods for deep learning.

Hospedales, T. M., Antoniou, A., Micaelli, P., and Storkey,

A. J. (2020). Meta-learning in neural networks: A

survey. IEEE Transactions on Pattern Analysis and

Machine Intelligence, 44:5149–5169.

Isermann, R. (2006). Fault-diagnosis systems : an introduc-

tion from fault detection to fault tolerance.

Jan, A., Mahfoudh, F., Dra

ˇ

skovic, G., Jeong, C., and Yu,

Y. (2022). Multitasking physics-informed neural net-

work for drillstring washout detection. 2022(1).

Jeong, C., Yu, Y., Mansour, D., Vesslinov, V., and Meehan,

R. (2020). A physics model embedded hybrid deep

neural network for drillstring washout detection.

Jiang, H., hui Liu, G., Li, J., Zhang, T., and Wang,

C. (2020). A realtime drilling risks monitoring

method integrating wellbore hydraulics model and

streaming-data-driven model parameter inversion al-

gorithm. Journal of Natural Gas Science and Engi-

neering, page 103702.

Lin, Z., Zhao, Z., Zhang, Z., Baoxing, H., and Yuan, J.

(2021). To learn effective features: Understanding the

task-specific adaptation of {maml}.

Liu, Z., Wang, H., Liu, J., Qin, Y., and Peng, D. (2021).

Multitask learning based on lightweight 1DCNN for

fault diagnosis of wheelset bearings. IEEE Trans. In-

strum. Meas., 70:1–11.

Loshchilov, I. and Hutter, F. (2017). Decoupled weight

decay regularization. In International Conference on

Learning Representations.

Mao, D., Chen, Y., Wu, Y., Gilles, M., and Wong, A. (2024).

Robust analysis of multi-task learning efficiency: New

benchmarks on light-weighed backbones and effective

measurement of multi-task learning challenges by fea-

ture disentanglement.

Qiu, S., Cui, X., Ping, Z., Shan, N., Li, Z., Bao, X., and Xu,

X. Y. (2023). Deep learning techniques in intelligent

fault diagnosis and prognosis for industrial systems:

A review. Sensors (Basel, Switzerland), 23.

Raissi, M., Perdikaris, P., and Karniadakis, G. E. (2019).

Physics-informed neural networks: A deep learning

framework for solving forward and inverse problems

involving nonlinear partial differential equations. J.

Comput. Phys., 378:686–707.

Ranaweera, M. and Mahmoud, Q. H. (2021). Virtual to real-

world transfer learning: A systematic review. Elec-

tronics.

Senushkin, D., Patakin, N., Kuznetsov, A., and Konushin,

A. (2023). Independent component alignment for

multi-task learning. 2023 IEEE/CVF Conference on

Computer Vision and Pattern Recognition (CVPR),

pages 20083–20093.

Silver, D. L., Poirier, R., and Currie, D. (2008). Inductive

transfer with context-sensitive neural networks. Ma-

chine Learning, 73:313–336.

Sun, X., Sun, B., Zhang, S., Wang, Z., Gao, Y., and Li, H.

(2018). A new pattern recognition model for gas kick

diagnosis in deepwater drilling. Journal of Petroleum

Science and Engineering.

Tercan, H., Guajardo, A., Heinisch, J., Thiele, T., Hop-

mann, C., and Meisen, T. (2018). Transfer-learning:

Bridging the gap between real and simulation data

for machine learning in injection molding. Procedia

CIRP, 72:185–190.

Venkatasubramanian, V., Rengaswamy, R., Kavuri, S. N.,

and Yin, K. K. (2003). A review of process fault de-

tection and diagnosis: Part iii: Process history based

methods. Comput. Chem. Eng., 27:327–346.

Wang, H., Liu, Z., Peng, D., Yang, M., and Qin, Y. (2021a).

Feature-level attention-guided multitask cnn for fault

diagnosis and working conditions identification of

rolling bearing. IEEE Trans. Neural Netw. Learn. Syst.

Wang, H., Liu, Z., Peng, D., Yang, M., and Qin, Y.

(2022). Feature-level attention-guided multitask CNN

for fault diagnosis and working conditions identifi-

cation of rolling bearing. IEEE Trans. Neural Netw.

Learn. Syst., 33(9):4757–4769.

Wang, H., Zhao, H., and Li, B. (2021b). Bridging multi-task

learning and meta-learning: Towards efficient training

and effective adaptation. ArXiv, abs/2106.09017.

Weber, M., Doblander, C., and Mandl, P. (2020). Towards

the detection of building occupancy with synthetic en-

vironmental data. ArXiv, abs/2010.04209.

Willersrud, A., Blanke, M., Imsland, L. S., and Pavlov,

A. K. (2015). Fault diagnosis of downhole drilling in-

Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a Multitask Neural Network

359

cidents using adaptive observers and statistical change

detection. Journal of Process Control, 30:90–103.

Yan, P., Abdulkadir, A., Luley, P.-P., Rosenthal, M., Schatte,

G. A., Grewe, B. F., and Stadelmann, T. (2023). A

comprehensive survey of deep transfer learning for

anomaly detection in industrial time series: Methods,

applications, and directions. IEEE Access, 12:3768–

3789.

Yu, J., Dai, Y., Liu, X., Huang, J., Shen, Y., Zhang, K.,

Zhou, R., Adhikarla, E., Ye, W., Liu, Y., Kong, Z.,

Zhang, K., Yin, Y., Namboodiri, V., Davison, B. D.,

Moore, J. H., and Chen, Y. (2024). Unleashing the

power of multi-task learning: A comprehensive sur-

vey spanning traditional, deep, and pretrained founda-

tion model eras. ArXiv, abs/2404.18961.

Zhang, C., Bengio, S., Hardt, M., Recht, B., and Vinyals,

O. (2016). Understanding deep learning requires re-

thinking generalization. ArXiv, abs/1611.03530.

Zhang, Q. (2000). A new residual generation and evalu-

ation method for detection and isolation of faults in

non-linear systems. International Journal of Adaptive

Control and Signal Processing, 14:759–773.

Zou, Z. and Karniadakis, G. E. (2023). L-hydra: Multi-

head physics-informed neural networks. ArXiv,

abs/2301.02152.

APPENDIX

In this section, the partial differential equations de-

scribing the drilling dynamics, including the poten-

tial faults, are given. The state variables are pressure

in the drill string (p

d

(z,t)), pressure in the annulus

(p

a

(z,t)), volumetric flow in the drill string (q

d

(z,t)),

and volumetric flow in the annulus (q

a

(z,t)). q

p

(t)

is the applied pump rate (volumetric flow) into the

drill string, while p

0

is the atmospheric pressure at

the outlet of the annulus. The well length is L, so that

z ∈ [0,L] and z = 0 is at the top of the well. For sim-

plicity, a vertical well with spatially invariant cross

section is assumed.

The nomenclature with the respective values is

given in Table 3 used in the simulations of Section 3.

The three faults that we consider are modeled as

follows. The washout flow is given by

q

wo

(t) = C

wo

p

p

d

(z

wo

,t) − p

a

(z

wo

,t), (10)

the mud loss flow is given by

q

ml

(t) = k

I

(p

a

(L,t) − p

r

), (11)

and the pack-off pressure loss is given by

p

po

(t) =

A

a

C

2

po

q

2

a

(L,t). (12)

We have opted to diagnose Pack-off by considering

that it takes place at the bottom of the well.

Denoting ∂

x

y ≜

∂y

∂x

and the Dirac delta function by

δ(z), we have the dynamics

∂

t

p

d

(z,t) = −

β

A

d

(∂

z

q

d

(z,t) + δ(z − z

wo

)q

wo

) (13)

∂

t

q

d

(z,t) = −

A

d

ρ

∂

z

p

d

(z,t) − f

d

(q

d

(z,t)) + A

d

g

(14)

∂

t

p

a

(z,t) = −

β

A

a

(∂

z

q

a

(z,t) − δ(z − z

wo

)q

wo

) (15)

∂

t

q

a

(z,t) = −

A

a

ρ

∂

z

p

a

(z,t) − f

a

(q

a

(z,t)) + A

a

g

(16)

+ δ(z − L)p

po

with boundary conditions

q

d

(0,t) = q

p

(t) (17)

p

a

(0,t) = p

0

(18)

p

d

(L,t) = p

a

(L,t) +

1

C

2

bit

q

2

d

(L,t) (19)

q

a

(L,t) = −q

d

(L,t) + k

I

max{p

a

(L,t) − p

r

,0}.

(20)

In practice, only the pump rate q

p

(t), pump pressure

p

p

(t) = p

d

(0,t) and return flow q

r

(t) = −q

a

(0,t) are

commonly measured. The diagnostics are normal-

ized to the interval [−1, 1]. For example, let C

wo

∈

[C

wo,min

,C

wo,max

]. Then, the normalized diagnostic is

given by

d = 2

C

wo

−C

wo,min

C

wo,max

−C

wo,min

− 1. (21)

The simulator implements the dynamics using first or-

der finite differences on a staggered grid.

From Table 3, the friction coefficient quantifies

the pressure drop along a pipe (drillstring and an-

nulus in our case) per unit length for a fluid flow of

1 m

3

/min across the pipe. The formula is given be-

low.

f

d/a

≜ ∆p

d/a

A

d/a

ρ

(22)

∆p

d/a

was selected as 5 bar/km/(m

3

/min)

2

for the

drillstring and 3 bar/km/(m

3

/min)

2

for the annulus.

The bit valve coefficient expresses the pressure

drop over the bit at a given flow. We assumed a 10 bar

pressure drop at 1.5 m

3

/min flow. The valve coeffi-

cient formula is given below.

C

bit

≜

q

p

∆p

bit

/ρ

(23)

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

360

Table 3: List of symbols in the PDE equations with their respective values (if they correspond to a fixed parameter).

Symbol Description Value

β Bulk modulus of the drilling fluid 1.8 × 10

4

bar

ρ Density of the drilling fluid 1000 kg/m

3

g Acceleration of gravity 9.81 m/s

2

A

d/a

Cross-sectional area of drill

string/annulus

[127,366] cm

2

f

d/a

Drillstring and annulus friction

coefficients

[13.7,65.9] 1/m

3

C

bit

Bit valve coefficient 0.0053 m

3

/s/bar

0.5

C

wo

Washout size coefficient (diagnostic) –

z

wo

Washout location (diagnostic) –

C

po

Pack-off size coefficient (diagnostic) –

z

po

Pack-off location (diagnostic) –

k

I

Flow coefficient for mud-loss

(diagnostic)

–

p

r

Reservoir pressure (diagnostic) –

Real-Time Fault Detection and Diagnosis for Oil Well Drilling Using a Multitask Neural Network

361