Real-Time Automated Visual Inspection of Decorative Wood Panels for

Zero Defects Manufacturing

Beatriz Coutinho

1 a

, Tom

´

as Martins

2 b

, Eliseu Pereira

1 c

and Gil Gonc¸alves

1 d

1

SYSTEC ARISE, Faculdade de Engenharia, Universidade do Porto, Rua Dr. Roberto Frias, 4200-465 Porto, Portugal

2

Faculdade de Engenharia, Universidade do Porto, Rua Dr. Roberto Frias, 4200-465 Porto, Portugal

Keywords:

Computer Vision, Defect Detection, Quality Monitoring, Non-Destructive Inspection, Zero Defects

Manufacturing.

Abstract:

In the wood panel manufacturing industry, maintaining high product quality is critical to ensure customer sat-

isfaction and minimize resource waste. Manual quality inspection methods are often inconsistent, increasing

the risk of defective panels reaching the market. This paper introduces an automated visual inspection system

for decorative wood panels, aligned with the Detection strategy of the Zero Defects Manufacturing (ZDM)

framework. Designed for real-time deployment on an NVIDIA Jetson Nano, the system inspects panels inde-

pendently without disrupting the production line and visually highlights detected defects for operator review.

Two implementation approaches were explored and compared: a traditional computer vision pipeline and a

deep learning-based solution. Due to the limited availability of real-world defect images, a synthetic dataset

was created using patch blending, tiling, and diverse augmentations to improve the model’s generalization

across spatial variations. Experimental evaluation with static images and live video showed that while tradi-

tional methods achieve moderate detection accuracy, they fail under varying lighting and camera angles. In

contrast, the YOLO-based approach delivered robust segmentation and superior defect detection, even under

challenging conditions. These results highlight the system’s potential to assist operators during manual in-

spections and contribute to practical advances to achieve ZDM.

1 INTRODUCTION

In today’s highly competitive industrial environment,

quality assurance plays a crucial role in manufactur-

ing, ensuring that products meet rigorous specifica-

tions and customer expectations (Hoffmann and Re-

ich, 2023). If defective products reach customers, it

can lead not only to economic losses and a decline

in customer trust, but also to a significant waste of

resources (Psarommatis et al., 2023). Consequently,

adopting rigorous quality inspection procedures is

one of the most effective ways for companies to min-

imize losses and operate in a more environmentally

conscious way.

This is particularly relevant in the wood panel

industry, where surface defects such as cracks, dis-

colorations, and scratches can compromise both the

a

https://orcid.org/0009-0000-9769-6726

b

https://orcid.org/0009-0008-9771-0688

c

https://orcid.org/0000-0003-3893-3845

d

https://orcid.org/0000-0001-7757-7308

aesthetic and functional quality of the final product.

While manual quality inspection remains common,

these methods often suffer from limitations includ-

ing low efficiency, subjectivity, and inconsistent re-

sults (Li et al., 2024).

To address these challenges, manufacturers are in-

creasingly adopting the Zero Defects Manufacturing

(ZDM) concept, which enables companies to proac-

tively reduce the occurrence of defects and the de-

livery of poor-quality products by implementing four

main strategies: Detection, Repair, Prediction, and

Prevention (Caiazzo et al., 2022). Detection and Re-

pair are reactive strategies aimed at identifying and

correcting defects after they occur. In contrast, Pre-

diction and Prevention focus on anticipating qual-

ity issues and implementing process improvements

to completely avoid defects. Although each strat-

egy independently contributes to better manufactur-

ing performance (Fragapane et al., 2023), their com-

bined application can significantly enhance produc-

tion throughput and reduce resource waste.

This paper presents the development of an auto-

446

Coutinho, B., Martins, T., Pereira, E. and Gonçalves, G.

Real-Time Automated Visual Inspection of Decorative Wood Panels for Zero Defects Manufacturing.

DOI: 10.5220/0013782200003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 446-456

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

mated visual quality inspection system aligned with

the Detection strategy of the ZDM framework. The

system has been designed for deployment at the final

stage of decorative surfaced wood panel production,

in collaboration with Sonae Arauco, a Portuguese

manufacturer. Prediction and Prevention strategies

for this production process have been previously de-

veloped and detailed in (Coutinho et al., 2024). The

proposed detection system is not intended to replace

human inspection, but rather to enhance it using com-

puter vision (CV) technology to provide real-time, ac-

curate defect identification and thereby support more

informed decision-making. Two implementation ap-

proaches were explored and benchmarked: one based

on traditional CV techniques and other using deep

learning (DL) methods.

The remainder of this paper is organized as fol-

lows: Section 2 presents the literature review. Sec-

tion 3 describes the methodology. Section 4 outlines

the system implementation. Section 5 presents and

discusses the experimental results, and Section 6 pro-

vides the conclusions and future work.

2 BACKGROUND AND RELATED

WORK

Combining automated detection-based systems

with manual inspection processes enhances hu-

man–machine collaboration and improves the overall

process (Lario et al., 2025). This combined approach

not only enables more efficient and accurate quality

control but also acts as a two-step verification,

reducing human error and minimizing the risk of

defective products passing undetected. Industry

trends increasingly favor AI-based solutions for

quality assurance, with CV playing a major role due

to its ability to deliver fast and consistent results (Li

et al., 2024).

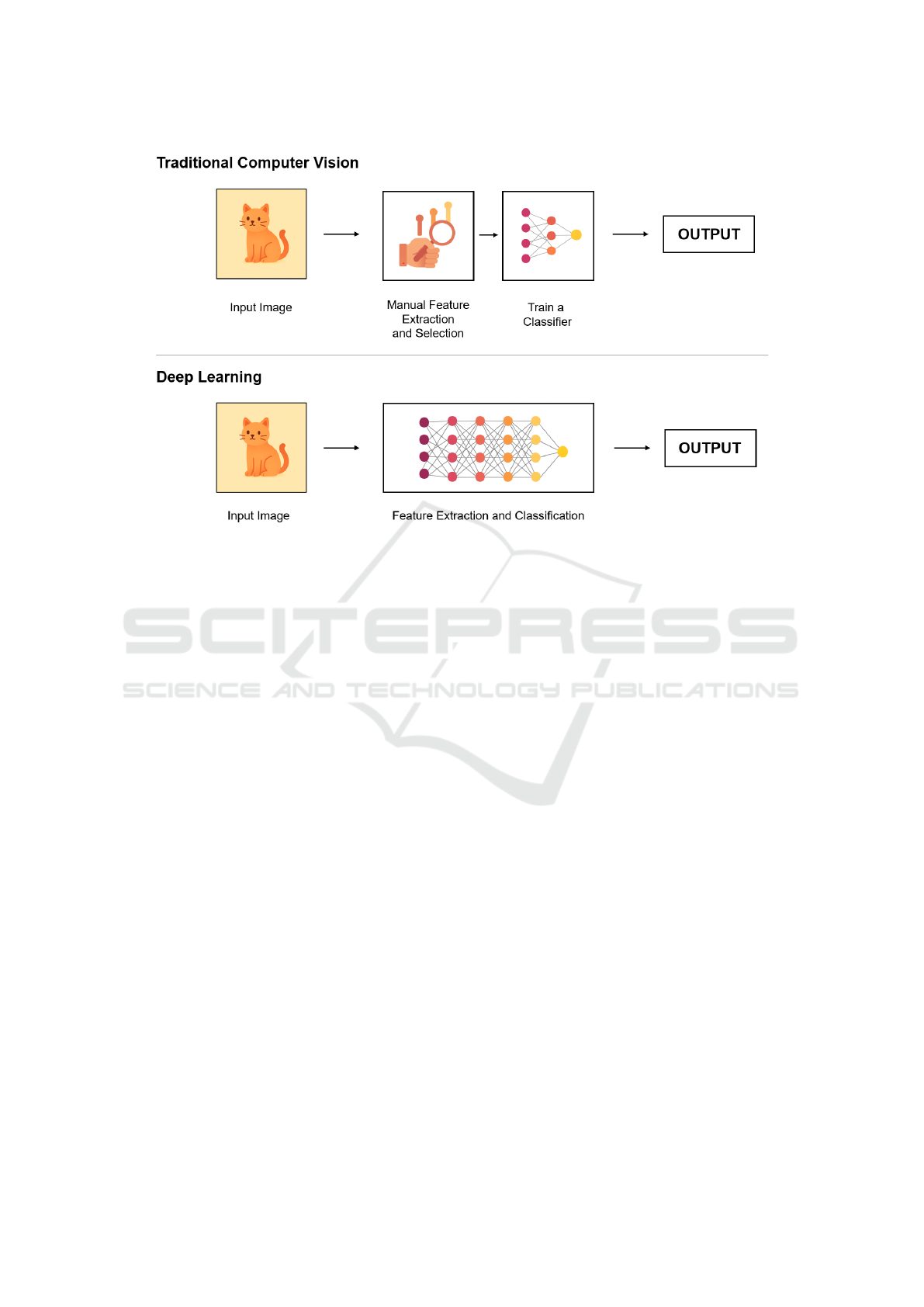

CV methods can be categorized into traditional

and DL techniques (O’Mahony et al., 2020). Tradi-

tional methods rely on techniques like filtering and

edge detection to extract features. While these tech-

niques perform well on well-defined and simple tasks,

they often struggle with variability in product appear-

ance or complex defect patterns (Li et al., 2024).

These methods are also highly domain-specific, re-

quiring manual tuning and expert knowledge for each

application. DL methods, in contrast, are more adapt-

able and capable of handling a wider range of in-

spection challenges, as they can learn directly from

raw image data. This ability to learn and gen-

eralize from data makes DL approaches typically

more scalable and effective across diverse use cases

(O’Mahony et al., 2020). In particular, architectures

such as Convolutional Neural Networks (CNNs), Au-

toencoder Neural Networks (AeNNs), Deep Resid-

ual Neural Networks (DRNNs), Fully Convolutional

Neural Networks (FCNNs), and Recurrent Neural

Networks (RNNs) have become especially prominent

in defect detection within smart manufacturing (Jia

et al., 2024). Figure 1 illustrates the main differ-

ences in workflow between traditional CV and DL ap-

proaches.

In the wood industry, particularly in the produc-

tion of melamine-faced panels, several studies have

explored the use of CV methods for defect detection

on finished products. Some of these contributions are

analyzed below.

Li et al. (2024) (Li et al., 2024) proposed a CV

framework based on an improved YOLOv8 model

to detect three types of defects in melamine-faced

panels: edge breakage, scratches, and surface dam-

age. To address the severe class imbalance in the

collected dataset, data augmentation and equalization

techniques were applied. These included the use of

a Generative Adversarial Network (GAN) to gener-

ate synthetic defect images, as well as oversampling

methods.

The YOLOv8, a single-stage object detection

model built on CNNs, was enhanced by incor-

porating depth-separable convolutions (DSC), De-

formable Convolutional Networks (DCN), an Ef-

ficient Multiscale Attention (EMA) mechanism, a

Bi-directional Feature Pyramid Network (BiFPN),

and customized loss functions. These modifications

led to performance improvements over the baseline

model, achieving an overall mean average precision

(mAP@50) of 78%, precision of 84%, and recall of

78%. The resulting system demonstrated robustness

and efficiency in detecting subtle and irregular surface

defects.

Aguilera et al. (Aguilera et al., 2018) investigated

defect classification in melamine-faced panels using

multispectral images from the visible, near-infrared

(NIR), and long-wavelength infrared spectrums. A

feature descriptor learning approach combined with

a Support Vector Machine (SVM) classifier was ap-

plied, evaluating two descriptors: Extended Local Bi-

nary Patterns (E-LBP) and SURF, both using a Bag

of Words representation. The dataset included five

defect types: paper scraps, stains, white spots, paper

displacement, and bubbles. Data augmentation tech-

niques such as rotation, scaling, noise addition, and

translation were used to expand the training data.

Three experiments were conducted: using each

spectral band separately, combining bands through

early fusion (averaging images), and late fusion (com-

Real-Time Automated Visual Inspection of Decorative Wood Panels for Zero Defects Manufacturing

447

Figure 1: Traditional computer vision versus deep learning workflow.

bining descriptors). Results showed that combining

spectral bands, especially incorporating information

beyond the visible spectrum, significantly improved

classification performance compared to using visible

images alone.

Similarly, S

´

a et al. (de S

´

a et al., 2022) proposed

a technique for quality control, focusing on six de-

fect types: stains, paper displacement or detachment,

attached material, wrinkled paper, and folded paper.

The method followed a traditional CV approach, us-

ing feature extraction techniques, specifically Local

Binary Pattern (LBP) histograms, combined with an

SVM classifier. NIR imaging was used due to its ef-

fectiveness in highlighting surface irregularities.

To address the class imbalance in the dataset,

an undersampling strategy was applied, limiting the

training set based on the size of the minority class.

The system achieved strong performance, with preci-

sion, recall, and F1-score values above 74% across all

defect classes.

Finally, Mehta et al. (Mehta and Klarmann, 2024)

introduce a hybrid unsupervised approach for detect-

ing surface defects on melamine-faced panels using

high-resolution images captured with a fixed field-

of-view (FOV) RGB camera. To prepare the train-

ing data, the described method slices the images into

smaller crops, extracts features using a pre-trained

VGG16 model, and applies K-Means clustering to

group similar regions. Artificial defects were added

by overlaying texture segments, and data augmenta-

tion techniques, such as rotation, flipping, scaling,

and cropping, were applied.

For defect detection, an autoencoder network with

skip connections was trained to reconstruct image

patches. Defects are identified based on reconstruc-

tion errors, as the model learns to reproduce only nor-

mal patterns. This approach enabled precise and accu-

rate detection of surface defects, including irregulari-

ties on edges, corners, holes, and flat surfaces, without

relying on pre-defined regions of interest.

3 METHODOLOGY

This Section details the specific application scenario

of the system, along with its architecture, including

the hardware and software setup.

3.1 Use Case Description

Decorative surfaced panels are wood-based panels

coated on both surfaces with paper impregnated with

melamine resin, as illustrated in Figure 2, to enhance

resistance and durability. The manufacturing process

of these panels is complex, primarily involving the

precise cutting of panels and a pressing stage, where

heat and pressure are applied to bond the impregnated

paper to the surface.

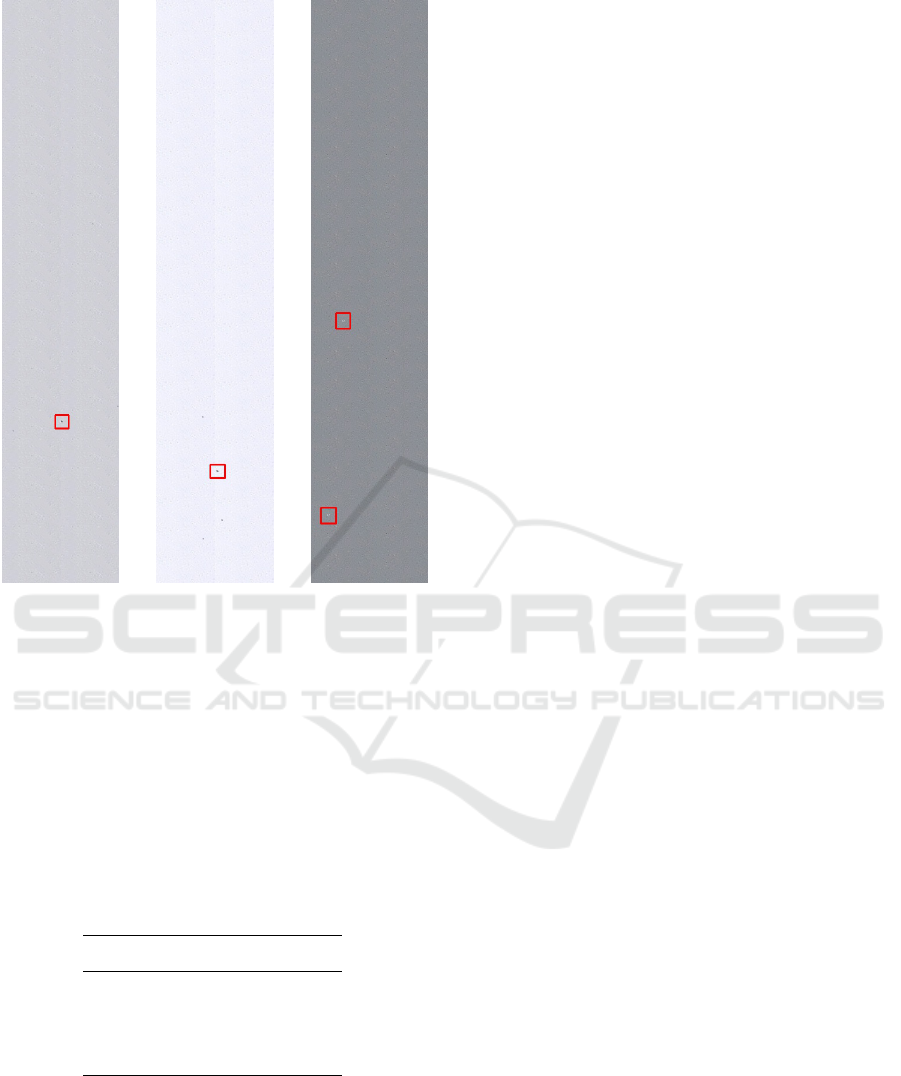

After impregnation, the panels undergo manual

inspection by factory operators to detect any surface

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

448

Figure 2: Decorative surfaced panel (Akij Board, 2023).

or visible defects. Common issues include torn paper,

uneven glue distribution within the paper that causes

creases after pressing, and small stains caused by dust

or other particles present during production. Exam-

ples of these defect types are illustrated in Figure 3.

Some of these defects, such as stains, can be ex-

tremely small, sometimes as little as 1mm

2

, while the

panels produced by Sonae Arauco can reach sizes up

to 6 meters by 3 meters. This disproportion between

panel size and defect scale makes the quality inspec-

tion process challenging for operators who are not po-

sitioned directly next to the entire surface of the panel,

as exemplified in Figure 4, increasing the risk of de-

fects going undetected.

3.2 System Architecture

After analyzing the requirements for the system, an

initial hardware setup was selected for experimen-

tal testing before deployment. The main require-

ment was that the solution should function as a non-

destructive inspection (NDI) system and operate en-

tirely independently from the company’s network and

production line infrastructure. To meet this constraint,

an NVIDIA Jetson Nano was chosen to enable local

image processing and CV model deployment, with an

RGB camera attached to capture real-time footage of

the panels (Figure 5). The camera features a high-

resolution 4056 x 3040 pixel sensor and captures only

visible light. The entire system, including the Jetson

Nano and the camera, is enclosed in a metal case to

protect it from dust, sparks, and other environmental

factors.

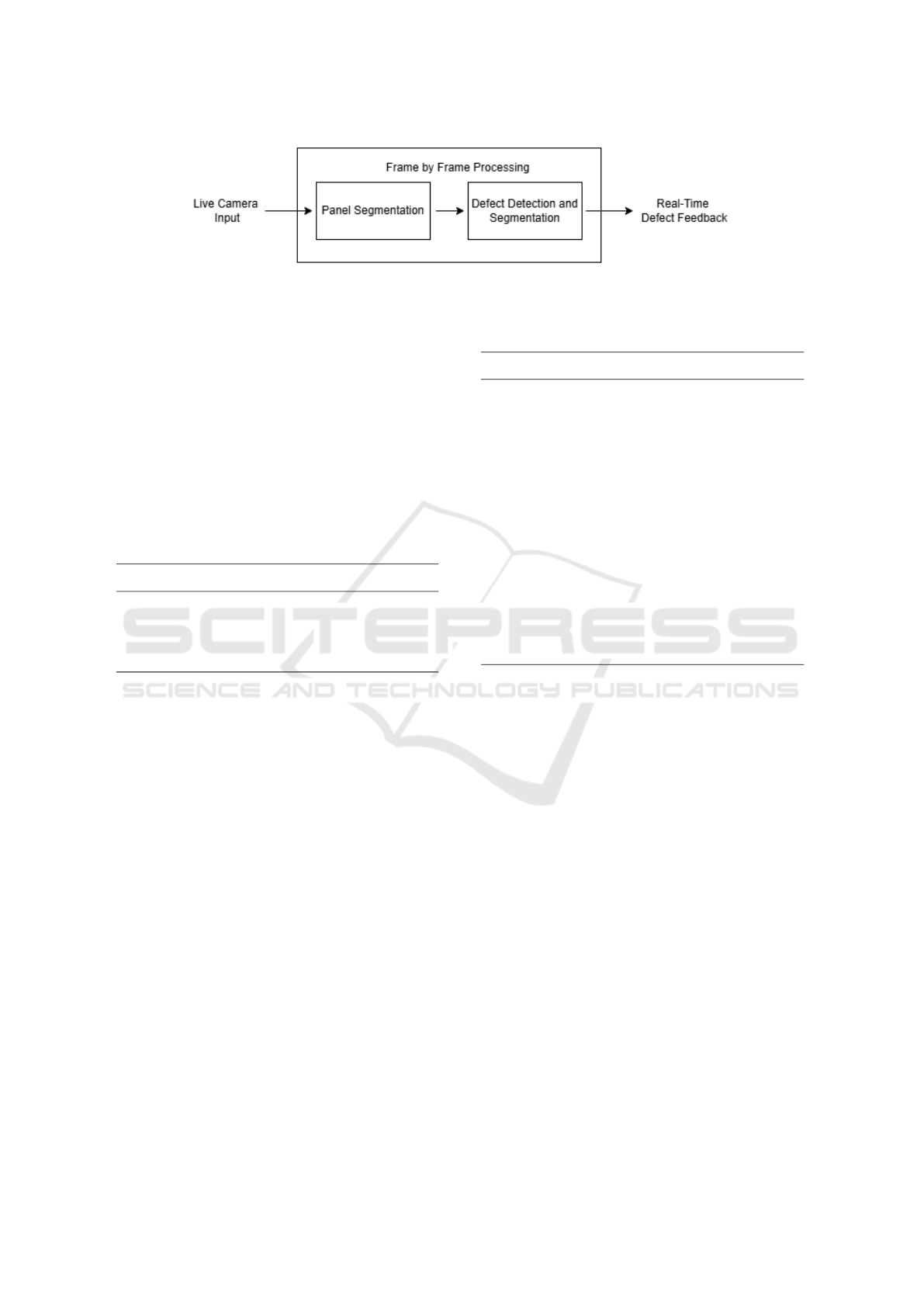

Supported by this hardware configuration, the

software pipeline processes the live images captured

by the camera frame-by-frame. Due to the size of the

panels and the constraints of the existing infrastruc-

ture, the camera cannot exclusively capture only the

panel in each frame. Therefore, each frame under-

goes segmentation to isolate the panel from the back-

ground. Once the panel area is identified, the system

detects and segments any surface defects present. The

final output is a live video stream where the detected

defects are highlighted with bounding boxes, provid-

ing real-time visual feedback. A simplified overview

of this pipeline is illustrated in Figure 6.

For this experimental phase and proof of concept,

the system focuses exclusively on white panels, the

most commonly produced type, to simplify initial de-

velopment and validation. The focus is on detecting

scratches and stains, as they are frequent and visu-

ally distinct defects. According to the factory quality

standards, any defect larger than 1mm

2

is considered

relevant, therefore this threshold was adopted during

development. Additionally, at this initial stage, the

system will also be limited to visible light inspection.

4 IMPLEMENTATION

As previously mentioned, two approaches were com-

pared: one based on traditional CV techniques and

the other on DP methods. Due to the limited avail-

ability of real images and defective panel samples,

a synthetic dataset was first created to support the

model’s development and evaluation. This Section

begins with a description of the dataset generation

process, followed by an explanation of the implemen-

tation of both panel segmentation and defect detection

processes.

4.1 Synthetic Dataset

Due to the limited number of real-world images, a

synthetic dataset was generated to supplement the

training and testing of the system’s models. As de-

scribed earlier, the real-time system involves two

stages: panel segmentation and defect detection on

the isolated panel. These stages require two distinct

datasets.

For the segmentation model, simple augmentation

techniques such as blurring and contrast adjustment

were applied to enhance the dataset. For defect detec-

tion, a synthetic dataset was created by exploring mul-

tiple image augmentation and blending techniques to

simulate realistic surface defects on panel images.

Two categories of images were required to train

the detection algorithm:

1. Defect-Free Panel Images: capturing variations

in angles, panel sizes, lighting conditions, and

other contextual factors.

2. Panel Images With Simulated Surface Defects:

incorporating different defect formats, sizes, and

locations.

For the first category, a combination of geomet-

ric transformations and blending techniques was ap-

Real-Time Automated Visual Inspection of Decorative Wood Panels for Zero Defects Manufacturing

449

(a) Stains caused by impurities on

the paper surface during pressing.

(b) Paper crease caused by uneven

glue distribution.

(c) Stains caused by the pressing

plate.

Figure 3: Examples of typical surface defects observed during the production process.

Figure 4: Manual quality inspection of decorative surfaced

panels at Sonae Arauco’s factory (Ricardo Castelo, 2024).

plied. Geometric transformations included rotation,

translation, scaling, and flipping, which helped simu-

late different perspectives and contexts. In addition,

a variety of blending and composition methods were

explored to create realistic lighting and texture varia-

tions. These included:

• Alpha Blending.

• Gradient and Radial Gradient Blending.

• Fourier Transform (FFT) Blending.

• Poisson Image Editing (Seamless Cloning).

• Perlin Noise and Gaussian Blur.

• Image Tiling and Patch-Based Composition.

For the second category, to simulate surface de-

fects on the panels, two main strategies were ex-

plored:

• Synthetic Dot-Based Defects: This method in-

volved overlaying randomly distributed black dots

of varying sizes and densities onto defect-free

Figure 5: Image acquisition system featuring an NVIDIA

Jetson Nano in an industrial enclosure, paired with an RGB

camera.

panel images. Although simple and efficient, it

often produced unrealistic defects that lacked the

texture and complexity of real defects.

• Patch-Based Defects: To improve realism, actual

defect regions were extracted from the limited set

of real-world images. These defect patches were

then augmented through random scaling, rotation,

and blending before being placed on clean panel

backgrounds, resulting in more natural and con-

vincing defect simulations.

4.2 Panel Segmentation

This Section outlines the implementation process of

the panel segmentation step for both the traditional

CV and DL approaches.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

450

Figure 6: Simplified pipeline of the computer vision system for real-time defect detection.

4.2.1 Traditional Computer Vision Approach

The traditional CV approach to panel segmentation

relies on color and contour analysis to isolate the

panel from the background in each frame. This pro-

cess begins by converting the input RGB image to the

HSV color space for more effective color-based fil-

tering. A binary mask is then generated by threshold-

ing the HSV image within predefined lower and upper

bounds corresponding to the white tones of the panel,

as specified in Table 1.

Table 1: HSV threshold values used for the white panel’s

segmentation.

Lower Bound Upper Bound

Hue (H) 0 180

Saturation (S) 0 50

Value (V) 180 255

Following that, contours are extracted from this

mask using OpenCV’s cv.findContours method.

These contours are approximated to polygons, and

only those with four vertices are considered as pos-

sible panel shapes. The bounding rectangles of these

polygons are then evaluated based on their aspect ra-

tio, filtering out shapes that do not match the expected

panel proportions. Finally, from the remaining ones,

the contour with the largest area is selected as the

panel, which is then segmented.

4.2.2 Deep Learning Approach

The DL approach to panel segmentation employed a

YOLO-based instance segmentation model, eliminat-

ing the need for color-based and contour-driven tech-

niques. The model was trained using the configura-

tion parameters listed in Table 2. As this was the

initial phase of the project, only a single set of hy-

perparameters was used to assess the feasibility of the

method.

During training, both real and synthetic panel im-

ages were resized to 640×640 pixels and paired with

their instance masks before being fed into the model.

Table 2: YOLOv8 model training configuration for panel

segmentation.

Parameter Value

Architecture YOLOv8 instance segmen-

tation (yolov8n-seg.pt)

Weights COCO pre-trained segmen-

tation weights

Input Resolution 640×640

Confidence

Threshold

0.25

Training Epochs 100

Batch Size 16

IoU Threshold 0.7

Learning Rate Initial lr

0

= 0.01, final lr

f

=

0.01

Training ran for 100 epochs with batches of 16 im-

ages. The model was initialized with COCO pre-

trained weights, which come from training on a large

dataset of common objects. This helped the model

learn general visual features faster and improved ac-

curacy during fine-tuning on panel images. Training

optimization was carried out using Stochastic Gradi-

ent Descent (SGD). Finally, model performance was

monitored using metrics such as Intersection over

Union (IoU) and confidence scores, with a detection

being considered positive if its IoU exceeded 0.7.

At inference time, the model outputs multiple in-

stance masks with associated confidence scores. The

largest mask by pixel area is selected, assuming the

panel is the dominant object in the image. This seg-

mentation mask is then used as input for the subse-

quent defect detection stage.

4.3 Defect Detection

This Section outlines the implementation process of

the defect detection step for both the traditional CV

and DL approaches.

Real-Time Automated Visual Inspection of Decorative Wood Panels for Zero Defects Manufacturing

451

4.3.1 Traditional Computer Vision Approach

In the traditional CV approach, the defect detection

process starts by applying to the input segmented

panel an adaptive Gaussian threshold, producing a bi-

nary image that highlights potential defects by invert-

ing the pixel intensities. From this image, contours

are extracted using OpenCV’s cv.findContours

method. To reduce false positives caused by noise or

small irrelevant surface details, only contours exceed-

ing a certain size threshold corresponding to defects

larger than a minimum relevant size are considered as

defects. This filtering process takes advantage of the

company’s quality standards, which specify that only

defects above a specific physical size are meaningful

for quality assessment. Lastly, for each detected de-

fect, a bounding box is drawn to highlight the affected

area in the original frame.

4.3.2 Deep Learning Approach

The DL defect detection uses a YOLO-based object

detection model trained to identify and localize sur-

face stains in various lighting and distance settings.

The model was trained using the configuration param-

eters listed in Table 3.

Table 3: YOLOv8 model training configuration for defect

detection.

Parameter Value

Architecture YOLOv8 (yolov8n.pt)

Weights COCO pre-trained segmen-

tation weights

Input Resolution 640×640

Confidence

Threshold

0.25

Training Epochs 100

Batch Size 16

IoU Threshold 0.7

Learning Rate Initial lr

0

= 0.01, final lr

f

=

0.01

The training dataset consisted of panel images

pre-segmented to isolate the relevant region, with

each image annotated with bounding boxes around

the defects. As with the segmentation task, both real

and synthetic data were used to increase variability.

Similarly, the model was initialized with COCO pre-

trained weights to improve generalization, and opti-

mization was performed using SGD.

During inference, the defect detection model takes

the segmented panel image as input and returns a set

of bounding boxes with confidence scores. Predic-

tions below a confidence threshold of 0.50 were dis-

carded to reduce false positives. The final output is

an annotated image with all identified defects clearly

marked for visual inspection. If no defects are de-

tected, the input image is returned unchanged, indi-

cating a defect-free panel surface.

5 RESULTS

This Section presents the results of the synthetic

dataset generated and a comparison of the outcomes

of the two approaches under two different settings:

using the dataset and their real-time performance.

5.1 Synthetic Dataset

For the segmentation model, 83 real-world images

were collected at various distances, angles, and light-

ing conditions. These images were augmented using

techniques such as flips, brightness, and saturation ad-

justments, resulting in a final dataset of 199 images.

An example of augmentation applied to a real panel

image is shown in Figure 7.

(a) Original panel image. (b) Augmented image

(flipped and brightness-

adjusted).

Figure 7: Example of data augmentation applied to a real

panel image for the segmentation dataset.

For the defect detection dataset, among the meth-

ods described in Section 4.1, the most effective ap-

proach was tiling sections of clean panels combined

with augmented defect patches extracted from real-

world defective panel images. These synthetic de-

fective panels were further enhanced with geomet-

ric transformations, noise addition, and contrast ad-

justments to maximize defect diversity. Starting with

26 real-world defective images, the dataset was ex-

panded to 138 images. Two examples of syntheti-

cally generated defective panel images are illustrated

in Figure 8.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

452

(a) Generated

through patch

tiling.

(b) Generated

through patch

tiling and contrast

adjustment.

Figure 8: Example of synthetically generated defective

panel images.

5.2 Comparison of Traditional and

Deep Learning Approaches

Both approaches were evaluated and compared in two

settings: using static images from the dataset and

through real-time video capture and processing.

5.2.1 Evaluation Through Images

To evaluate the performance of the traditional ap-

proach, metrics such as precision, recall, and IoU

were calculated. The IoU metric measures the overlap

between predicted bounding boxes and actual boxes,

and the greater the overlap, the more accurate the pre-

diction.

For panel segmentation, the results were very

poor, with all metrics close to zero. This is mainly

due to fixed threshold values, such as the HSV ranges

and panel proportions, that make the approach highly

sensitive to lighting conditions and panel positioning.

Consequently, the method lacks the flexibility needed

to generalize effectively across the diverse synthetic

dataset.

In contrast, for defect detection, the results

showed a mean IoU of 0.584, an average precision

of 55.1%, an average recall of 62.1%, and an average

F1-Score of 60.2% (Table 4). These results suggest

that the approach performs reasonably well at detect-

ing defects, though there is room for improvement,

particularly in increasing precision to reduce the num-

ber of false positives. Figure 9 presents examples of

annotated detection results: in (a) only 1 of 3 defects

was detected; in (b) 1 of 4; and in (c) all defects were

successfully detected.

Table 4: Performance metrics of the traditional computer

vision defect detection approach.

Metric Value (%)

Mean Precision 55.1

Mean Recall 62.1

Mean IoU 58.4

Mean F1-Score 60.2

Despite the moderate detection performance, the

poor segmentation results compromise the overall ef-

fectiveness of the traditional CV approach, making it

not suitable for application across diverse conditions.

The DP approach was also evaluated by assessing

the panel segmentation and defect detection models

separately. For both models, approximately 20% of

the total data was reserved and used for testing.

Table 5 presents the performance metrics of the

YOLO-based panel segmentation model. The high

scores across the considered metrics indicate that the

model is highly effective. In particular, the results

suggest a strong alignment between the predicted

panel locations and the ground truth annotations. This

confirms that the model is precise, making it a reliable

predecessor to the defect detection model and suitable

for integration into the automated inspection system.

Table 5: Performance metrics of the YOLO-based panel

segmentation model.

Metric Value (%)

Mean Precision 99.3

Mean Recall 100.0

Mean F1-Score 99.6

Real-Time Automated Visual Inspection of Decorative Wood Panels for Zero Defects Manufacturing

453

(a) Panel with 3

defects.

(b) Panel with 4

defects.

(c) Panel with 2

defects.

Figure 9: Example results from traditional computer vision

defect detection approach.

Table 6 presents the performance metrics of the

YOLO-based defect detection model. The results

show a strong overall performance, with high values

for all metrics. In this context, both precision and re-

call are equally relevant, as minimizing false positives

and false negatives is essential to the reliability of the

inspection process.

Table 6: Performance metrics of the YOLO-based defect

detection model.

Metric Value (%)

Mean Precision 80.0

Mean Recall 86.9

Mean F1-Score 83.3

Figure 10 shows an example of the YOLO-based

pipeline applied to a panel image. Despite the promis-

ing results of this DL approach, the models were

trained and tested on a relatively small dataset, with

most of the data being synthetic. Therefore, it is im-

portant to note that further work is needed to validate

and refine these models using larger and more diverse

real-world datasets.

Nonetheless, in both panel segmentation and de-

fect detection tasks, the DL approach clearly outper-

forms the traditional CV method. The YOLO-based

models achieve higher precision, recall, and F1-score,

demonstrating greater robustness and generalization

across different conditions. As expected, the tradi-

tional approach struggles, especially in segmentation,

due to its dependence on hard-coded parameters and

its sensitivity to environmental variations.

5.2.2 Evaluation with Live-Video

To perform the real-time evaluation, a set of sample

panels was used under various conditions, including

different lighting setups and panel angles (tilted ver-

sus upright positioning). Under each scenario, the

maximum range, measured as the distance from the

camera to the panel at which the approach remained

functional, was recorded in meters (m). These results

are summarized in Table 7.

The results indicate that the traditional CV ap-

proach is highly sensitive to both the lighting and

the positioning of the panel, with the performance

degrading significantly under the suboptimal condi-

tions. This outcome was expected, as previously

noted, since the relies heavily on fixed thresholds,

which are difficult to maintain consistently in variable

environments. In contrast, the YOLO-based method

demonstrates more robustness, maintaining reliable

panel segmentation and defect detection even when

the lighting is lower or the panel is tilted. These

results are further supported by the previously dis-

cussed performance metrics obtained on the static

image dataset. In terms of processing time, there

were no significant differences between the two ap-

proaches.

6 CONCLUSIONS AND FUTURE

WORK

This paper presented an automated visual inspection

system for melamine-faced wood panel production,

designed to support operators and enhance inspection

efficiency and reliability. The system integrates the

Detection strategy into a broader ZDM framework,

alongside existing Prediction and Prevention compo-

nents.

The proposed solution emphasizes a non-

destructive, non-disruptive architecture that runs

entirely on-device, using an NVIDIA Jetson Nano

paired with an RGB camera to capture real-time

footage of the production line. The image processing

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

454

(a) Original image. (b) After panel segmentation. (c) After defect detection

and annotation, showing

the detection confidence

score.

Figure 10: Example of the YOLO-based approach pipeline applied to a panel image.

Table 7: Comparison of real-time performance between traditional CV and YOLO-based methods for panel segmentation and

defect detection.

Traditional CV YOLO

Panel Segmentation

Upright Panel under Enhanced Lighting Up to 1.9 m Up to 2.7 m

Upright Panel under Normal Room Lighting Up to 1.1 m Up to 2.7 m

Tilted Panel under Enhanced Lighting Not Functional Up to 2.1 m

Tilted Panel under Normal Room Lighting Not Functional Up to 2.1 m

Defect Detection

Detection of All Defect Types Up to 1.3 m Up to 1.7 m

Detection of Major Defects Only Up to 1.9 m Up to 2.7 m

Detection Failure Threshold Beyond 1.9 m Beyond 2.7 m

pipeline performs both panel segmentation and

surface defect detection, highlighting any identified

defects for operator review. Two implementation

strategies were compared: a traditional CV approach

based on thresholding and contour analysis, and a

DL approach based on YOLOv8 models. Due to the

limited availability of real defect data, a synthetic

dataset was generated using patch blending and data

augmentation techniques to support model training

and evaluation.

Experimental results from static and real-time

video inputs showed that the traditional approach is

highly sensitive to lighting and positioning variations,

resulting in inconsistent performance. In contrast, the

YOLO-based solution consistently delivered more ac-

curate and robust results, making it the more suitable

approach for practical deployment.

Future work will focus on:

• Extending the detection capabilities to a wider va-

riety of panel textures, colors, and defect types.

• Evaluating different camera types and lighting

setups (e.g., visible, infrared) under various ac-

quisition conditions to enhance defect visibility.

This includes exploring multi-camera systems for

broader spectral coverage.

• Expanding both real-world and synthetic datasets

to improve model generalization.

• Fine-tuning the DL models and optimizing hyper-

parameters for improved performance.

• Deploying and testing the system directly on the

production line.

Real-Time Automated Visual Inspection of Decorative Wood Panels for Zero Defects Manufacturing

455

ACKNOWLEDGEMENTS

This work was partially supported by the HORIZON-

CL4-2021-TWIN-TRANSITION-01 openZDM

project, under Grant Agreement No. 101058673.

REFERENCES

Aguilera, C. A., Aguilera, C., and Sappa, A. D. (2018).

Melamine faced panels defect classification beyond

the visible spectrum. Sensors, 18.

Akij Board (2023). Melamine Faced Board. https://akijboar

d.com/melamine-board/. Last Accessed: 2024-05-27.

Caiazzo, B., Nardo, M. D., Murino, T., Petrillo, A., Piccir-

illo, G., and Santini, S. (2022). Towards zero defect

manufacturing paradigm: A review of the state-of-the-

art methods and open challenges. Computers in Indus-

try, 134.

Coutinho, B., Pereira, E., and Gonc¸alves, G. (2024). 0-

dmf: A decision-support framework for zero defects

manufacturing. In Proceedings of the 21st Interna-

tional Conference on Informatics in Control, Automa-

tion and Robotics, pages 253–260. SCITEPRESS -

Science and Technology Publications.

de S

´

a, F. P., Aguilera, C., Aguilera, C. A., and Conci, A.

(2022). Melamine Faced Panel Inspection, Towards

an Efficient Use of Natural Resources, volume 224,

pages 165–183. Springer Science and Business Media

Deutschland GmbH.

Fragapane, G., Eleftheriadis, R., Powell, D., and Antony, J.

(2023). A global survey on the current state of prac-

tice in zero defect manufacturing and its impact on

production performance. Computers in Industry, 148.

Hoffmann, R. and Reich, C. (2023). A systematic literature

review on artificial intelligence and explainable artifi-

cial intelligence for visual quality assurance in manu-

facturing. Electronics, 12(22).

Jia, Z., Wang, M., and Zhao, S. (2024). A review of

deep learning-based approaches for defect detection

in smart manufacturing. Journal of Optics (India),

53:1345–1351.

Lario, J., Mateos, J., Psarommatis, F., and

´

Angel Ortiz

(2025). Towards zero defect and zero waste manu-

facturing by implementing non-destructive inspection

technologies. Journal of Manufacturing and Materi-

als Processing, 9.

Li, R., Xu, Z., Yang, F., and Yang, B. (2024). Defect detec-

tion for melamine-impregnated paper decorative par-

ticleboard surface based on deep learning. Wood Ma-

terial Science and Engineering.

Mehta, D. and Klarmann, N. (2024). Autoencoder-based

visual anomaly localization for manufacturing quality

control. Machine Learning and Knowledge Extrac-

tion, 6:1–17.

O’Mahony, N., Campbell, S., Carvalho, A., Harapanahalli,

S., Hernandez, G. V., Krpalkova, L., Riordan, D., and

Walsh, J. (2020). Deep learning vs. traditional com-

puter vision. In Advances in Intelligent Systems and

Computing, volume 943, pages 128–144. Springer

Verlag.

Psarommatis, F., May, G., and Azamfirei, V. (2023). The

role of human factors in zero defect manufacturing: A

study of training and workplace culture. In Alfnes,

E., Romsdal, A., Strandhagen, J. O., von Cieminski,

G., and Romero, D., editors, Advances in Production

Management Systems. Production Management Sys-

tems for Responsible Manufacturing, Service, and Lo-

gistics Futures, pages 587–601, Cham. Springer Na-

ture Switzerland.

Ricardo Castelo (2024). Sonae Arauco quer “domesticar as

f

´

abricas” para serem mais eficientes. https://eco.sapo

.pt/reportagem/sonae-arauco-quer-domesticar-as-f

abricas-para-serem-mais-eficientes/. Last Accessed:

2025-05-21.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

456