Design and Implementation of a Robotized Laser Module for Weed

Control

Kai Blanco

1,2 a

, Luis Emmi

2 b

and Roemi Fern

´

andez

2 c

1

Universidad Polit

´

ecnica de Madrid, Spain

2

Centro de Autom

´

atica y Rob

´

otica UPM-CSIC, Arganda del Rey, Spain

Keywords:

Weed, Laser, Agriculture 4.0, Modular, Autonomous.

Abstract:

This paper presents the design of a low-cost, modular system mounted on a mobile platform for weed control

using laser technology. This proposal seeks to find an effective and sustainable solution for selective weed

management in agricultural settings, avoiding harmful methods such as herbicides. The methodology for

this work was based on the application of divergent-convergent thinking stages. Additionally, studies were

conducted on potential movement systems, and in line with the system’s needs, a Core XY movement was

selected. Standard elements and custom designs were adapted to the previous structure. Similarly, an analysis

of potential casing designs was carried out, and through a convergent process, a design suitable for its function

was selected. The results obtained in this work, such as the estimated movement system accuracy of less

than 0.2mm and the simulated treatment time of 3.62 seconds, in an estimated area of 0,25 m

2

, demonstrate

the feasibility of creating an effective, small-sized, and low-cost weed control system for users, providing the

necessary precision to avoid damage to surrounding crops.

1 INTRODUCTION

Despite the long history of humanity and its coex-

istence in society, it is in recent centuries that the

world has experienced significant population growth,

due to various factors, among them globalization (Bo-

nanno, 1994; Byerlee et al., 2009). This exponen-

tial increase in the number of people clashes with the

capacity of traditional agricultural methods to sus-

tain the growing demand for food, leading to short-

ages and rising prices; in addition to other effects re-

sulting from unregulated agricultural activities, such

as desertification (Danfeng et al., 2006; Portnov and

Safriel, 2004). This is why new production methods

are needed, as well as a review of existing ones to

improve their efficiency. Among these alternative ap-

proaches, agroecology stands out for promoting agri-

cultural systems that are both productive and ecolog-

ically balanced, by integrating local knowledge with

ecological principles. It emphasizes biodiversity, soil

health, and community involvement, promoting food

systems that work in harmony with nature.

a

https://orcid.org/0009-0008-0007-3599

b

https://orcid.org/0000-0003-4030-1038

c

https://orcid.org/0000-0003-0552-5407

In the quest to meet this growing demand, preci-

sion agriculture has emerged as a more efficient alter-

native. This is an agricultural practice that combines

different technologies to optimize the management of

crops and agricultural resources (Zhang and Kovacs,

2012). It is based on the collection and analysis of

detailed data about the area of operation, such as soil

condition or weather conditions. With this data, the

aim is to achieve more targeted and efficient man-

agement of agricultural practices, maximizing crop

yields while reducing the resources required and the

resulting environmental impact.

In recent decades, this has led to the integration

of robotics with traditional agricultural processes in

order to improve efficiency and increase production

volume (Emmi et al., 2023). Numerous developments

have focused on different stages of production, many

of them on the final stages of harvesting and sorting

the end product. An example of this type of robot

is presented by the company FarmWise (FarmWise

Labs, 2024), capable of mechanically and selectively

remove detected weeds while simultaneously collect-

ing information about them and the terrain. Other key

developments within this field are Carbon Robotics

(Carbon Robotics, 2025), Pixel Farming (Pixelfarm-

ing Robotics, 2025) and Weedbot (WeedBot, 2025),

Blanco, K., Emmi, L. and Fernández, R.

Design and Implementation of a Robotized Laser Module for Weed Control.

DOI: 10.5220/0013780300003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 363-370

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

363

among others.

This article focuses on the search for solutions for

the selective treatment of weeds in the early stages of

cultivation, when crops are most vulnerable. Damage

caused during initial growth, as well as nutrient de-

ficiencies, can lead to lower yields and reduced final

production. This deficiency, as previously mentioned,

is often due to the parallel growth of weeds alongside

the target crop. In the search for alternative methods

of weed control, the creation of a laser module is pro-

posed. This module, integrated into an autonomous

platform, would enable selective and safe weed re-

moval without risks to humans or the environment.

The article begins by detailing the materials and

methods employed throughout the project. It then

presents the design of key components, including the

laser treatment system and the motion control mech-

anism. Furthermore, it provides an in-depth analysis

of the power requirements, positioning accuracy, and

treatment time associated with the system. Finally,

the article concludes with the proposal of a protec-

tive housing and the final assembly approach, ensur-

ing both functionality and user safety.

2 MATERIALS AND METHODS

The development presented in this article is, so far, a

theoretical model aimed at demonstrating the feasibil-

ity of a modular laser-based system for selective weed

removal during the early stages of crop growth. The

design focuses on creating a cost-effective and easily

adaptable structure that can be integrated into an au-

tonomous robotic platform.

For this purpose, the RB-VOGUI platform by

Robotnik has been used as the base for development;

an example of which can be seen in Fig. 1 (S.L.L.,

2025). This platform was selected due to its versa-

tility, robustness, and proven capabilities in agricul-

tural environments. The proposed module has been

conceptually integrated into the platform’s mechani-

Figure 1: RB-VOGUI platform.

cal and control architecture, considering its payload

capacity, dimensions, and energy requirements.

Furthermore, for the design and mechanical calcu-

lations of the proposed modular structure, Autodesk

Inventor 2015 was used (Autodesk, Inc., 2025). This

software enabled the creation of detailed 3D models

of the components and assemblies, as well as the per-

formance of preliminary simulations to evaluate as-

pects such as structural integrity, weight distribution,

and mounting feasibility on the proposed platform.

3 DESIGN APPROACH

The main objective of this paper is the design of a

modular, low-cost structure that can be attached to an

autonomous robotic platform and is capable of mo-

bilizing a laser system to eliminate emerging weeds

during the early stages of crop growth.

This section presents the final development of the

proposal, addressing each of the key elements re-

quired in the project to achieve the main objective

previously outlined. It details the specific steps for the

selection and optimization of the laser, including the

source and power necessary for effective weed treat-

ment.

In addition, the design of the movement system

and support structure is presented, with a focus on the

calculation and implementation of the laser orienta-

tion mechanism.

Finally, the integration of the system into the cho-

sen robotic platform is described, ensuring an efficient

connection and operation that enables the precise and

effective removal of emerging weeds during the early

stages of crop growth.

3.1 Laser System

The first element to be dimensioned, and upon which

all other developments of the project depend, is the

laser module. One of the key aspects in the devel-

opment of this project is the possibility for the re-

sulting model to be low-cost compared to current de-

velopments. For this reason, combined with energy

and space limitations, diode laser generation has been

chosen as the source.

Due to cost constraints and the availability of com-

mercial modules, the decision was made to seek an

existing module on the market for implementation in

the model. There are several factors that determine

the laser’s effectiveness for weed control. This rela-

tionship between these factors can be seen in Eq. 1

Dose(

J

mm

2

) =

P(W ) ∗ T(s)

A(mm

2

)

(1)

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

364

where:

• P is the optical power: The output power of the

module. That is, the final power applied by the

module to the weed for its eradication. This is the

parameter to be considered when dimensioning.

• T is the exposure time: This refers to the time the

laser pulse acts on the target weed. The longer

the action time, the greater the amount of energy

deposited on the plant matter.

• A is the area: This is the cross-section correspond-

ing to the portion of the laser beam impacting the

weed at a given height.

The main objective of using a laser is not the

complete destruction of the weed, but rather halt its

growth by damaging it. Some studies have already

explored the amount of energy needed to achieve this

and, in this way, determine the laser systems to be

used. For this project, the result obtained by An-

dreasen et al. (2024) of 12.7 J/mm² will be used as

a reference. This value refers to weeds that are at the

two leaf stage.

With this value as a reference, the dimensioning

and selection of the module depend solely on its op-

tical power, since the beam diameter can later be ad-

justed as needed using lenses.

Given the range of power outputs, prices, and

the reliability of each brand, the 40W module from

XTool was chosen for the development of this project.

The laser’s minimum specified area is 0.1×0.15 mm².

Since this area is too small to accurately focus on the

weeds, it is estimated that it will be adjusted to 1 mm².

Therefore, based on the previous data, the required

exposure time, per weed, is:

Time(s) =

12.7

J

mm

2

∗ 1mm

2

40W

= 0.31s (2)

Given the previous treatment time per weed, it has

been theorized that the positioning time for the laser

could not exceed the 50% of the total treatment time.

This is so that the robot can achieve a dynamic treat-

ment, that is, while moving.

3.2 Detection System

Alongside the laser module, another element of im-

portance for the proper functioning of the project is

the weed detection system. This system allows mon-

itoring the work environment, detecting the weeds,

and classifying them for the subsequent action of the

movement system and the laser responsible for the

treatment.

There are different alternatives when it comes to

capturing the necessary information from the environ-

ment for later processing. The main characteristic that

this type of system must fulfill is to allow 3D posi-

tioning of the weeds for more efficient processing and

more accurate detection of their morphology (Kateris

et al., 2021). For this project, due to the popularity of

this system in similar applications, as well as its key

features and ease of use, the ZED 2 camera is pro-

posed as the spatial capture system. It can be seen in

Fig. 2.

Figure 2: Capture system, ZED 2.

In summary, the combination of stereo-vision,

high-resolution image capture, and real-time process-

ing makes the ZED 2 an ideal candidate for the de-

velopment of this project in weed treatment, being a

powerful and effective tool.

3.3 Position and Targeting System

This subsection addresses the design and develop-

ment of the support structure for the laser module,

as well as the movement and orientation system of

the laser necessary for weed treatment. Additionally,

structural analyses will be conducted, taking into ac-

count considerations such as weight and strength, as

well as the integration of the module assembly into

the main structure of the tractor vehicle.

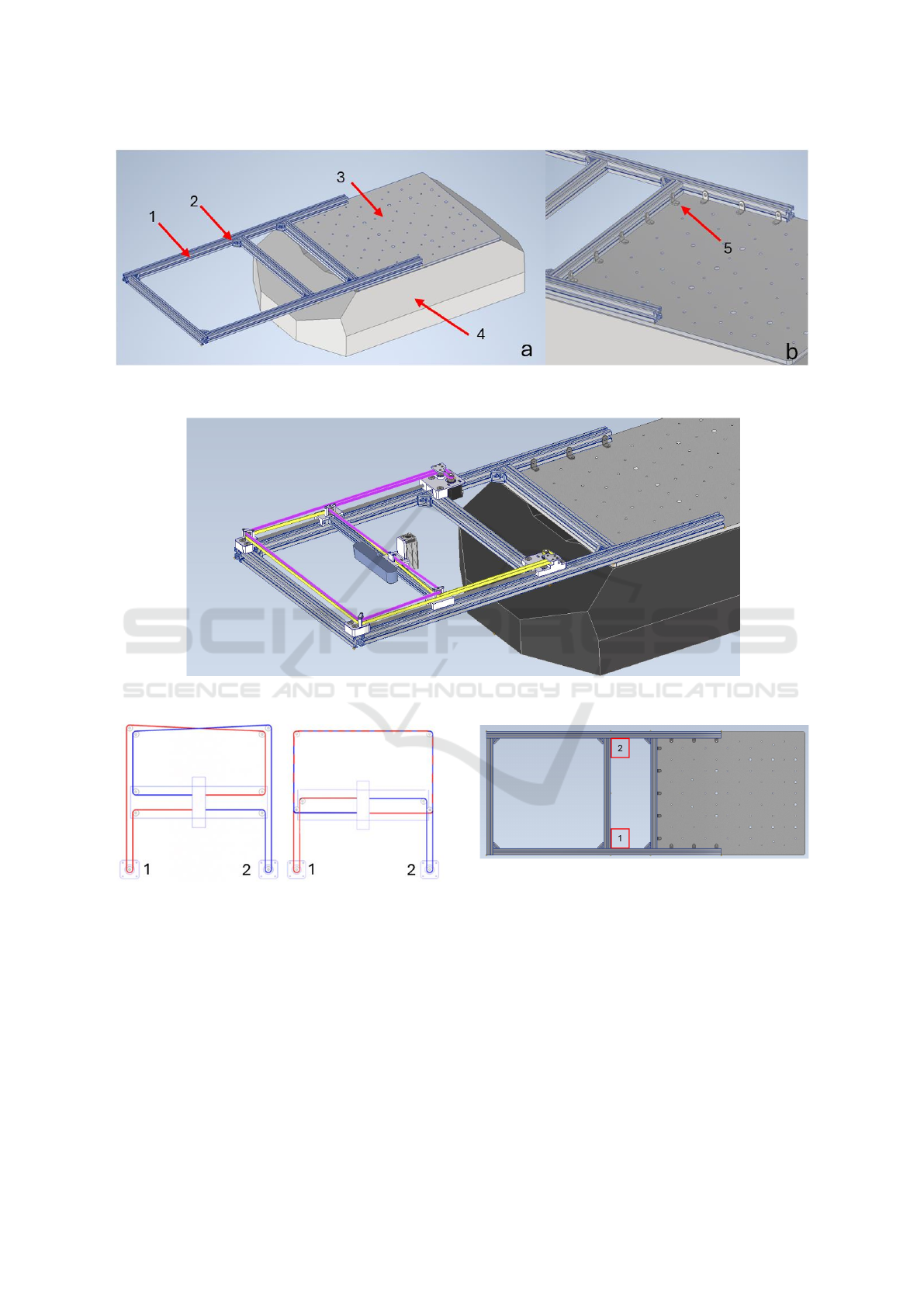

Firstly, for the correct integration of the main

structure onto the module, an intermediate element

was developed. This element consists of a 10 mm

thick aluminum plate that covers the entire upper part

of the RB-VOGUI. In addition, this aluminum plate

is perforated with various patterns of threaded holes

of different diameters. The creation of these patterns

was carried out with other projects in mind, as well as

to allow the integration of any additional components

that may be required during the development of this

project. This intermediate element can be seen in Fig.

3.

To ensure the modularity of the structure, as well

as to keep the weight and cost low, standardized

30x30 Bosch support profiles have been chosen. The

use of this type of profile guarantees the possibility of

integrating any component in a quick, simple, and ro-

bust manner. In turn, the availability of standard ele-

ments for assembly ensures that the resulting structure

is simple yet strong, capable of withstanding harsh

working conditions and meeting the requirements of

Design and Implementation of a Robotized Laser Module for Weed Control

365

Figure 3: Integration Element. a) Mobile platform. b) Inte-

gration plate.

the laser module’s movement system.

To ensure proper integration with the mobile plat-

form, as well as to simplify the design and guarantee

a sturdy structure, the design shown in Fig. 4 is pro-

posed.

Concerning the selection of the targeting system,

it plays a decisive role in determining the project’s

performance. An evaluation was carried out of differ-

ent mechanisms commonly used in the literature for

orienting the laser beam onto the weeds: cartesian,

angular and mixed, among others. Firstly, a mixed

configuration was ruled out, as it would complicate

both the current design and its subsequent control.

Among the remaining options, the Cartesian system

was selected for this purpose due to its simplicity,

both in terms of design and control.

Within the Cartesian movement typology, there

are some variants that enable smoother and faster mo-

tion compared to traditional versions. One of these

variants is known as Core XY. This system uses two

stepper motors to achieve the movement of the head

through a specific arrangement of belts and pulleys,

so that motion along the X and Y axes results from

the combined rotation of both motors. The belts in

this system are crossed, allowing for fast and stable

movements, as can be seen in Fig. 6.

In addition, this architecture reduces the vibra-

tions and torsions typically found in other Cartesian

variants, providing high precision and stability. This

configuration is widely used in other applications,

such as 3D printers (Goszal et al., 2021; Soon et al.,

2020; Vasquez et al., 2020).

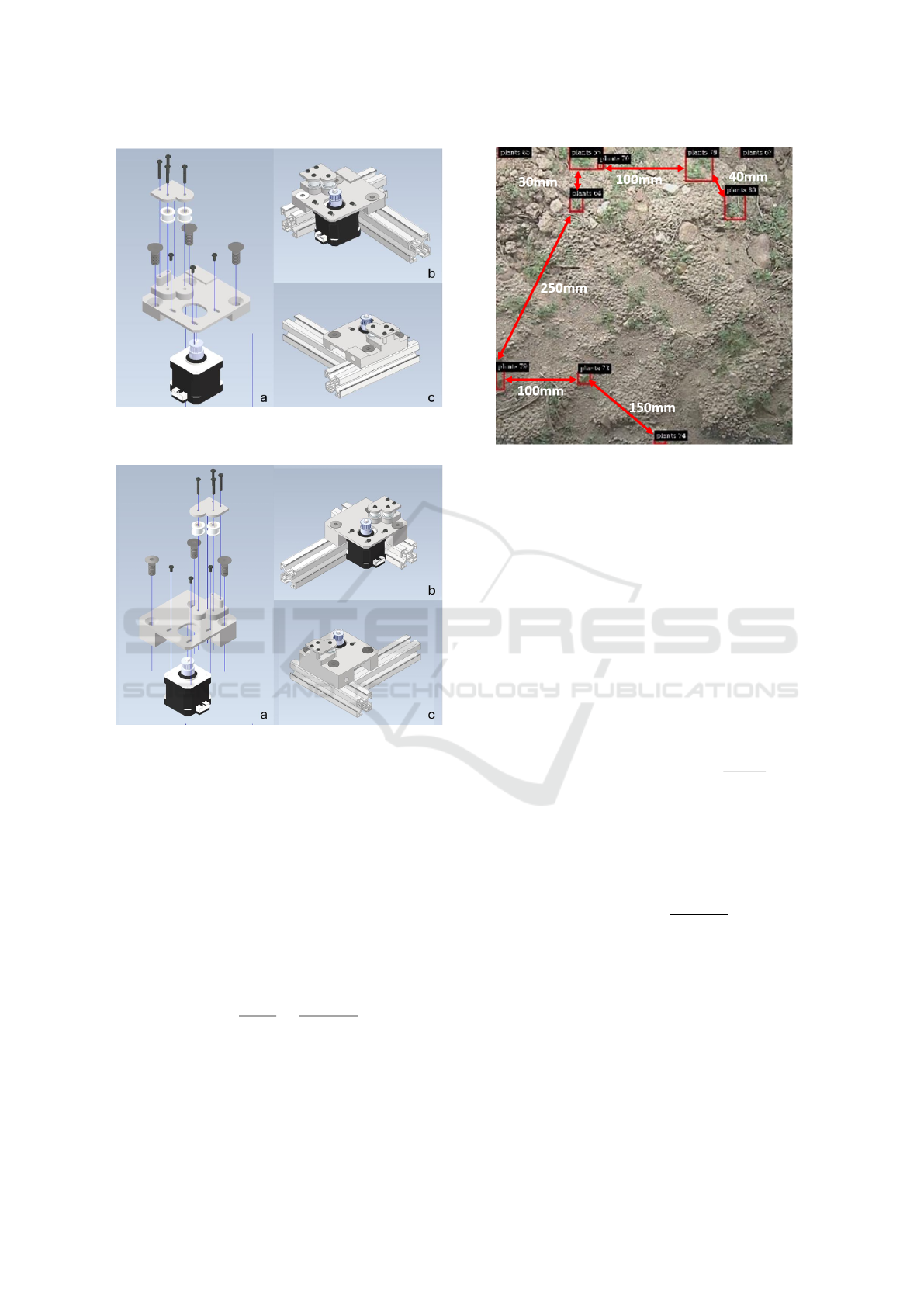

For the integration of this movement system into

the previously designed structure, the design of cus-

tom parts is proposed to incorporate the necessary

standard components. Firstly, each of the two mo-

tors responsible for the movement must be positioned

at different heights to avoid interference in the move-

ment of both belts. Additionally, the design must al-

low for the incorporation of pulleys that enable the

belts’ displacement. The motors selected to drive

the Core XY mechanism are two standard 42x42 mm

Nema 17 motors (Community, 2025).

At the same time, these motors must be mounted

onto the structure, maintaining a fixed position at

varying heights, as mentioned earlier. From this point

on, references to both motors and their mounting as-

semblies will follow the naming shown in Fig. 7.

The final design of both assemblies can be seen in

Fig. 8 and Fig. 9, representing the left and right motor

assemblies respectively.

Finally, the connection of all the components that

form the Core XY mechanism is proposed through

two separate belts. Each belt is positioned at a differ-

ent height to prevent interference between them. In

addition, the pulley system is designed to avoid un-

necessary friction and to keep the entire working area

of the module clear. The final result of the implemen-

tation can be seen in Fig. 5, where both belts and their

path along the structure can be observed.

4 RESULTS

This section presents a brief discussion of other key

elements to consider in the design for its future op-

eration. One of these elements is the speed at which

the laser is expected to operate, so that the working

time can be estimated, as well as its mode of opera-

tion, that is, whether the mobile platform can move

and carry out the treatment dynamically or, on the

contrary, must stop each time the treatment is to be

applied.

First, it is necessary to take into account the char-

acteristics of the selected Nema 17 motors. It is

shown that the nominal speed achievable with this

type of motor reaches up to 1000 rpm, enabling high

speeds. An estimate can be made of the maximum

linear speed, under no load, of the belt driven by the

motor. To do this, it is first necessary to convert this

rpm value into linear speed using the following equa-

tion:

v = ω ∗ r (3)

Where ω is the angular velocity in radians per sec-

ond (rad/s) and r is the radius of the pulley driven

by the motor. Converting rpm to radians per second

gives:

ω =

1000 ∗ 2π

60

=

1000 ∗ π

30

≈ 104.72rad/s (4)

Given the pulley’s diameter of 12.2 mm:

r =

12.2mm

2

= 0.0061m (5)

From which the lineal velocity is obtained:

v = 104.2

rad

s

∗ 0.0061m (6)

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

366

Figure 4: Structure integration. a) Main assembly (1. Bosch 30x30 profiles, 2. Corner joint, 3. Integration plate, 4. RB-

VOGUI). b) Detail of the integration with the perforated plate (5. Fasteners).

Figure 5: Complete assembly of the structure and movement system.

Figure 6: Core XY diagram. The image on the left shows

an expanded version of the figure on the right to facilitate

understanding of the paths of the different belts.

v ≈ 0.635m/s (7)

Therefore, the maximum linear speed of the belt in

no-load conditions is approximately 0.635 m/s. This

performance is similar to other assemblies with com-

parable characteristics and loads, as seen in 3D print-

ers like the Ultimaker S5 or the Kingroon KLP1,

achieving travel speeds of up to 400 mm/s. Based

on this, an example treatment is proposed. With it,

an estimate of the treatment time required to clear a

Figure 7: Placement and designation of both motors.

specific area can be made. Fig. 10 shows a real exam-

ple of weed detection from the WeLaser project sys-

tem (WeLaser Project, 2024) as an application case.

The box in the image is approximately 500 mm wide,

allowing an estimation of the distances between the

various detected weeds.

The path needed to connect each point to the next

can be obtained by first computing the optimal se-

quence using algorithms such as the Traveling Sales-

man Problem (TSP). Then, path-planning algorithms

like D

∗

can be used to compute the shortest path be-

tween each pair of consecutive points, especially in

Design and Implementation of a Robotized Laser Module for Weed Control

367

Figure 8: Motor 1 assembly. a) Exploded view. b) Rear

view. c) Front view.

Figure 9: Motor 2 assembly. a) Exploded view. b) Rear

view. c) Front view.

dynamic environments where the terrain may change

the weed’s position and orientation.

Assuming the necessary laser exposure time (t

e

)

previously obtained as 0.31 seconds, the total time

required for the example treatment of the weeds de-

tected in the previous image, at 400 mm/s, is obtained

as follows:

Total distance(D) = ΣD

∗

= 580mm (8)

Which, using the obtained speed in Eq. 7 is:

Travel time(t) =

D

speed

=

580mm

635mm/s

= 0.91s (9)

Combining both, treatment and travel times:

Total time(T ) = t + t

e

= 0.91s + 7 ∗ 0.31s = 3.08s

(10)

Figure 10: Example of weed detection.

In this example, the travel time, 0.91s, represents

only a 30% of the total treatment time, complying

with the previous hypothesis.

This obtained time demonstrates the efficiency of

the design, allowing, although at low speeds, the dy-

namic treatment of the weeds. That is, as the mobile

platform is guided over the target crop, the proposed

module will be able to eliminate the weeds as they are

detected. It is important to keep in mind that oscilla-

tions caused by irregularities in the terrain may lead

to deviations in the system’s accuracy and should be

addressed in future studies. Additionally, thanks to

the precision of the 1.8° Nema 17 motors, a laser po-

sitioning accuracy of the following is expected:

Linear accuracy = Angular accuray

C

2π rad

(11)

Where C is the circumference of the pulley.

C = 2πr = 2π ∗ 6.1mm = 38.36mm (12)

From which it is obtained:

Linear accuracy = 0.0314rad

38.36mm

2π rad

= 0.192mm

(13)

Therefore, since no reduction is found during the

established travel of the belts, a theoretical position-

ing accuracy of less than 0.2 mm is expected for the

laser on the weed. It is important to keep in mind

that this value will most likely be altered in real-world

scenarios, although a millimeter precision is still ex-

pected.

Finally, it is important to take into account the

energy consumption of the system, since it is ex-

pected that, together with the mobile platform, they

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

368

Figure 11: Proposed housing design.

will carry out the treatment autonomously; for this,

it must be powered by the batteries that can be in-

cluded within the mobile platform. Below, in Table 1,

a breakdown of the main approximate energy expen-

ditures, as well as the total, considering only the main

components, is shown.

Table 1: Power usage.

Component Qty Power/unit Total Power

Laser Mod-

ule

1 144 W 144 W

ZED2 1 4.5 W 4.5 W

Nema 17 2 7.25 W 14.5 W

Mobile Plat-

form

1 4 × 400 W 1600 W

Total Power 1762.98 W

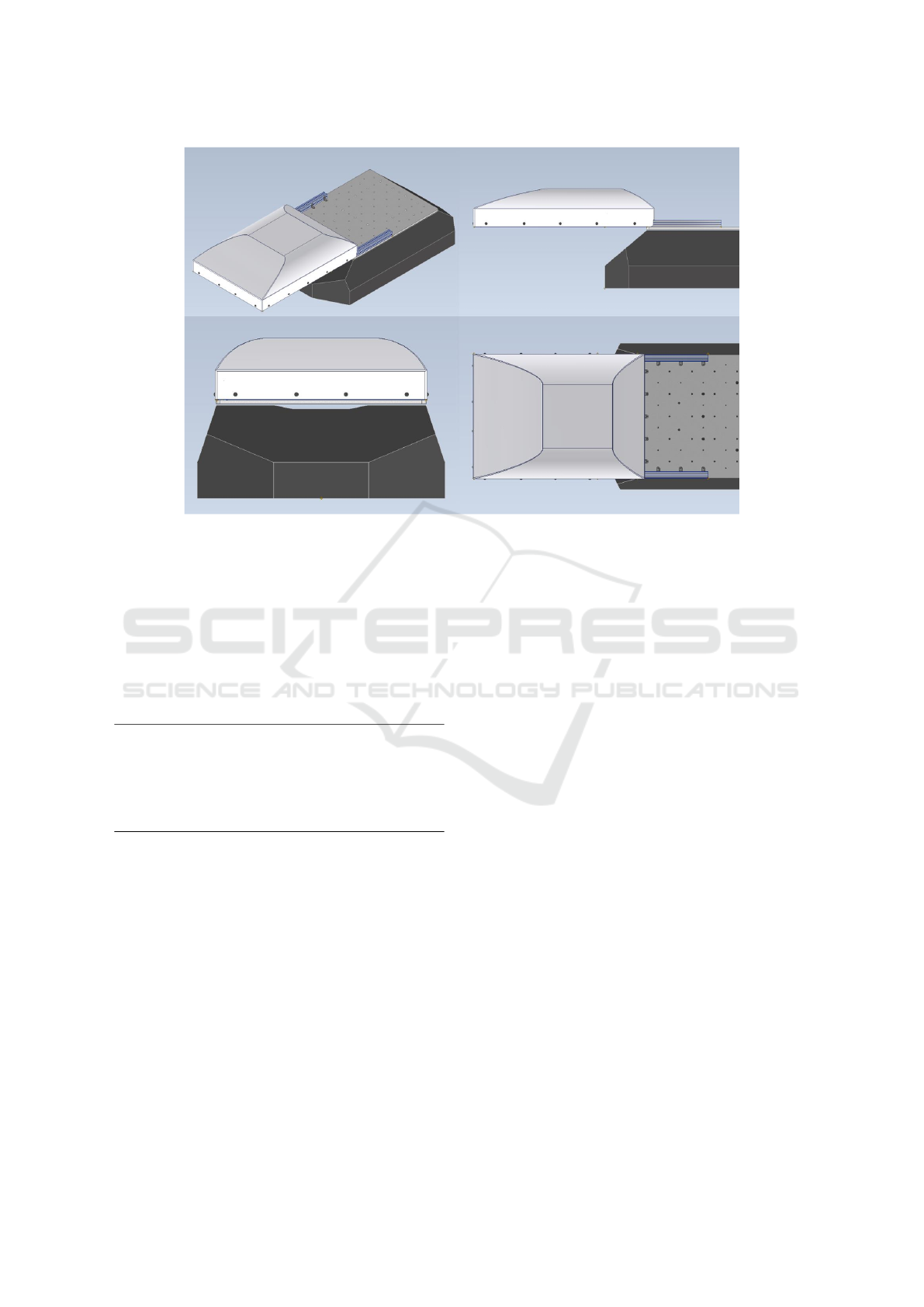

Finally, a housing design has been proposed to

enclose the system and ensure user safety. The fi-

nal housing consists of a single piece that fits over

the base structure and is attached to it using 14 M6

screws fastened to the Bosch profiles that make up

the frame. Additionally, it is designed with a 1mm

clearance over the structure to avoid any assembly is-

sues caused by tolerances in other components or by

temperature variations.

The rear part of the housing is semi-open, allow-

ing the structure to connect to the integration plate

while keeping the area where the laser operates cov-

ered. In this way, any direct reflections of the laser

from the inside are prevented. This proposed design

can be seen in Fig. 11.

In line with this safety approach, the entire bot-

tom area remains open. If necessary, and to prevent

harm to operators during system control, flaps or any

other protective elements can be installed around the

structure down to the ground, thereby avoiding any

unwanted reflections of the laser beam.

5 CONCLUSIONS

In this paper, the primary objective has been success-

fully achieved: to serve as a foundational exercise for

future research endeavors. The approach has proven

to be a highly suitable tool for acquiring the neces-

sary knowledge for such tasks, while also providing a

conceptual framework that can be applied in the field

of laser-based weed treatment. From the perspective

of agroecology, such innovations can promote more

sustainable agricultural practices by reducing reliance

on chemical herbicides. Integrating this technology

within ecological farming systems may help preserve

soil health, biodiversity, and long term productivity.

The results presented, along with the methodology

followed, are consistent with what is expected in a

research-oriented study, contributing to the advance-

ment of Agriculture 4.0 technologies.

Regarding the specific objectives of the proposal,

the design and development of a modular structure

have been accomplished, offering high flexibility and

scalability. This demonstrates the feasibility of cre-

Design and Implementation of a Robotized Laser Module for Weed Control

369

ating an efficient and cost-effective structure that is

also highly adaptable and capable of being updated as

needed. The modular approach and the use of stan-

dardized components not only reduce manufacturing

costs but also facilitate future maintenance and sys-

tem upgrades.

Additionally, an appropriate laser module has

been successfully selected. As the core component

of the system responsible for delivering treatment to

the weeds its selection was critical. After analyzing

several available options, a laser was chosen that bal-

ances power and precision, ensuring effective weed

elimination while avoiding damage to surrounding

crops. Future research should focus on constructing

a real model, in order to analyze and compare the pre-

viously obtained accuracy and speed.

Overall, the project has met all its intended goals,

enabling the development of a modular, economi-

cal, and efficient system for laser-based weed control.

Furthermore, this work contributes to the ongoing re-

search in this area by providing a solid foundation for

future studies and technological developments.

ACKNOWLEDGEMENTS

This research was funded by the European Union’s

Horizon project “AGROSUS: AGROecological

strategies for SUStainable weed management in key

European crops” (Grant Number: 101084084).

REFERENCES

Andreasen, C., Vlassi, E., and Salehan, N. (2024). Laser

weeding of common weed species. Frontiers in Plant

Science, 15:1375164.

Autodesk, Inc. (2025). Autodesk inventor (version 2026).

3D CAD Software. Mechanical design, documenta-

tion, and simulation.

Bonanno, A. (1994). From Columbus to ConAgra: The

globalization of agriculture and food. University

Press of Kansas.

Byerlee, D., De Janvry, A., and Sadoulet, E. (2009). Agri-

culture for development: Toward a new paradigm.

Annu. Rev. Resour. Econ., 1(1):15–31.

Carbon Robotics (2025). Carbon robotics — ai-based

robotics for laser weeding. https://es.carbonrobotics.

com/. Accessed on July 3, 2025.

Community, R. (2025). Nema 17 stepper motor (1.7

′′

face-

plate) — stepper motor standard. RepRap Wiki Page.

Accessed in July 2025.

Danfeng, S., Dawson, R., and Baoguo, L. (2006). Agricul-

tural causes of desertification risk in minqin, china.

Journal of environmental management, 79(4):348–

356.

Emmi, L., Fern

´

andez, R., Gonzalez-de Santos, P., Francia,

M., Golfarelli, M., Vitali, G., Sandmann, H., Hustedt,

M., and Wollweber, M. (2023). Exploiting the internet

resources for autonomous robots in agriculture. Agri-

culture, 13(5):1005.

FarmWise Labs (2024). Feeding our world and our future.

https://farmwise.io/. Accedido el 7 de agosto de 2025.

Goszal, V. F., Nuha, H. H., and Abdurohman, M. (2021).

Manufacturing a plotter printer with computer nu-

merical control based pen ink using corexy mech-

anisms. JURNAL MEDIA INFORMATIKA BUDI-

DARMA, 5(2):370.

Kateris, D., Kalaitzidis, D., Moysiadis, V., Tagarakis, A. C.,

and Bochtis, D. (2021). Weed mapping in vineyards

using rgb-d perception. Engineering Proceedings,

9(1):30.

Pixelfarming Robotics (2025). Robot one — autonomous

agricultural robot for laser weed control. https://

pixelfarmingrobotics.com/robot-one/. Accessed on

July 3, 2025.

Portnov, B. A. and Safriel, U. N. (2004). Combating de-

sertification in the negev: dryland agriculture vs. dry-

land urbanization. Journal of Arid Environments,

56(4):659–680.

S.L.L., R. A. (2025). Rb-vogui: Autonomous mobile robot

for indoor and outdoor environments. Robotnik web-

site. Accessed in July 2025.

Soon, C. F., Ramilan, M. F., Hanafi, D., Zakaria, W. N. W.,

Khialdin, S. B. M., Isa, H., and Tee, K. S. (2020).

Development of a 3d bio-printer using corexy mech-

anism and syringe-based extrusion. Indonesian Jour-

nal of Electrical Engineering and Computer Science,

18(3):1180–1187.

Vasquez, J., Twigg-Smith, H., Tran O’Leary, J., and Peek,

N. (2020). Jubilee: An extensible machine for multi-

tool fabrication. In Proceedings of the 2020 CHI

Conference on Human Factors in Computing Systems,

pages 1–13.

WeedBot (2025). Weedbot — high-precision laser weeding

technology. https://weedbot.eu/. Accessed on July 3,

2025.

WeLaser Project (2024). Welaser - a disruptive precision

weeding technology using a high-power laser. Ac-

cessed: 2025-06-25.

Zhang, C. and Kovacs, J. M. (2012). The application of

small unmanned aerial systems for precision agricul-

ture: a review. Precision agriculture, 13:693–712.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

370