Simulation-Driven Design and Optimization of a Parametric

Flat-Foot with Elastic Pads for a Planar Biped Robot

Koray Kadir Şafak

a

and Oğuzhan Aykut Ekşioğlu

b

Department of Mechanical Engineering, Yeditepe University, Istanbul, Turkey

Keywords: Bipedal Robot, Foot Optimization, Elastic Pads, Walking Simulation, Genetic Algorithm, Impact Mitigation.

Abstract: This paper presents the simulation-driven design and optimization of a compliant foot for a planar biped robot.

To enhance walking stability and reduce joint torques, 3D-printed elastic pads were fabricated and

experimentally characterized through compression testing. These prototypes provided baseline stiffness and

damping ranges that served as inputs to the simulation model. Using these data as a starting point, a genetic

algorithm optimized pad parameters to minimize joint torque overloads while maintaining gait stability.

Walking simulations were performed in MATLAB Simulink on flat terrain, comparing a rigid flat-foot with

the optimized compliant foot with pads. Results demonstrated up to 46% reduction in peak hip torques and

35% reduction in knee torques, along with smoother contact forces and stable zero moment point (ZMP)

trajectories. The study confirms that introducing passive compliance at the foot level improves bipedal

locomotion efficiency without additional actuation.

1 INTRODUCTION

Foot-ground interaction significantly influences the

stability, energy efficiency, and adaptability of

bipedal walking robots. Unlike rigid mechanical feet,

the human foot incorporates soft tissue structures and

arches that naturally absorb impact, assist in balance,

and conform to uneven terrain. Emulating these

biomechanical features in robotic platforms remains

a major research focus.

Various robotic foot designs have been explored

in the literature to address impact mitigation and

adaptability. Rigid flat feet are widely used due to

their simplicity, but they transmit high contact forces

to the structure. To reduce these forces, researchers

have incorporated elastic elements, such as

rubber pads (Li et al., 2008), pneumatic stiffness

adjustment mechanisms (Zang et al., 2017), and

multi-segment toe joints (ElDirdiry et al., 2017).

Sandwich structures with compliant layers (El

Asswad et al., 2017) and biomimetic feet with

embedded passive joints (ElDirdiry et al., 2017;

Venkadesan et al., 2020) have also been proposed to

approximate human foot dynamics. However, most of

a

https://orcid.org/0000-0002-4096-3712

b

https://orcid.org/0009-0007-3431-5851

these solutions require complex control or

mechanical modifications.

Recent work has also focused on optimization-

based design. For example, El Asswad et al. (2017)

used genetic algorithms to tune sandwich-type foot

parameters for impact resistance, while Venkadesan

et al. (2020) characterized stiffness properties of the

human arch to guide robotic foot design. Despite

these advances, few studies apply simulation-based

optimization specifically aimed at minimizing joint

torque within motor constraints during walking.

In this study, we propose a parametric flat-foot

design with elastic pads that balances mechanical

simplicity with improved impact buffering. Prototype

pads were fabricated via 3D printing and

experimentally characterized to determine their

stiffness and damping properties. These data provided

baseline ranges that served as inputs to the

optimization framework, rather than being treated as

fixed constants. The pads were then virtually

optimized in simulation to minimize peak joint

torques while maintaining gait stability.

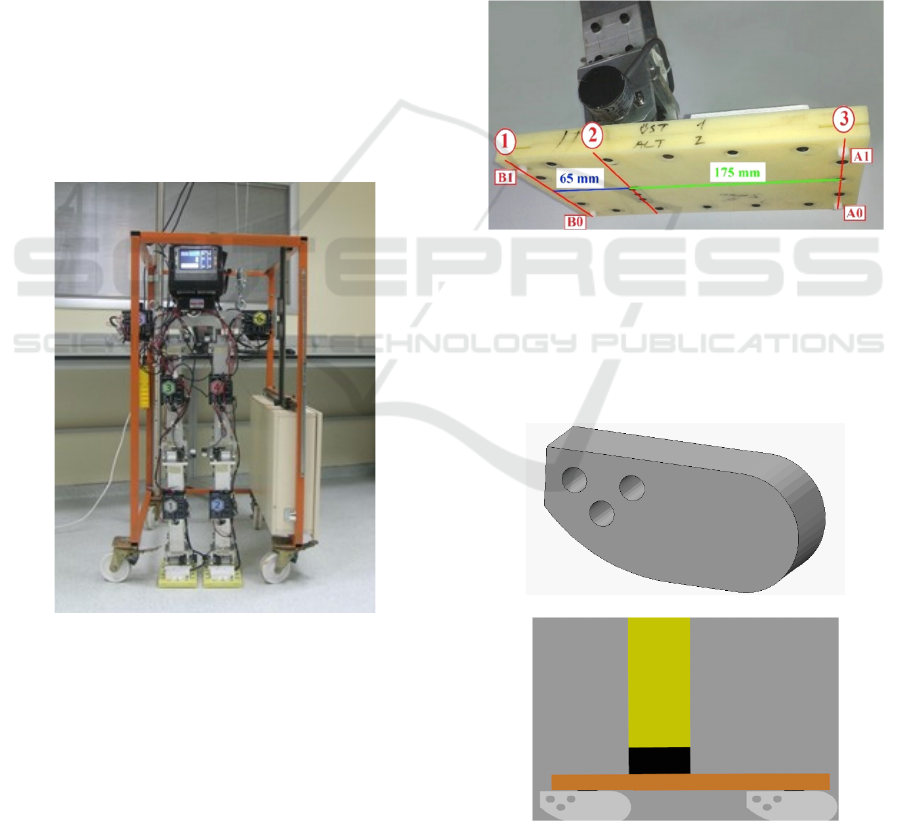

The research builds on an existing planar biped

robot platform YU-Bibot (see Figure 1), with six

actuated joints (Şafak & Baturalp, 2023). A detailed

¸Safak, K. K. and Ek¸sio

ˇ

glu, O. A.

Simulation-Driven Design and Optimization of a Parametric Flat-Foot with Elastic Pads for a Planar Biped Robot.

DOI: 10.5220/0013780000003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 357-362

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

357

simulation model is constructed using MATLAB

Simulink, incorporating contact dynamics and joint

actuation profiles derived from human-inspired gaits.

Elastic pads are modelled based on

experimentally determined stiffness and damping

values. A genetic algorithm is used to optimize the

pad parameters, targeting the minimization of peak

joint torques while respecting actuator limits.

Simulation results demonstrate that the optimized

foot configuration leads to reduced impact forces and

joint loading compared to the baseline rigid flat-foot

design.

Two configurations were investigated: a baseline

rigid flat foot and a flat foot with optimized elastic

pads. Comparative analysis highlighted the

improvements in joint torque reduction, contact force

smoothing, and zero moment point (ZMP) stability.

The rest of this paper is structured as follows:

Section 2 describes the foot design and elastic pad

fabrication; Section 3 outlines the simulation

framework; Section 4 details the optimization

methodology; Section 5 presents results and

discussion; and Section 6 concludes the paper.

Figure 1: YU-Bibot planar robot platform.

2 FOOT DESIGN AND ELASTIC

PAD IMPLEMENTATION

To improve ground compliance and reduce joint

torques during walking, we extend the flat-foot

design of the planar biped robot by integrating elastic

pads under each foot. The approach is motivated by

the human foot’s ability to adapt to ground

irregularities and absorb impact through soft tissue

structures.

2.1 Flat-Foot with Pads Concept

The base configuration of YU-Bibot uses rigid flat

feet without passive or active foot degrees of freedom

(see Figure 2). To enhance compliance while

retaining structural simplicity, three modular elastic

pads are mounted beneath each foot — two forefoot

pads and one heel pad — mimicking the key contact

regions of the human foot: the big toe mound, base of

the little toe, and centre of the heel. Each pad acts as

a passive elastic element with adjustable stiffness and

damping.

Figure 2: Existing foot structure and sensors.

The geometry of the pad layout is illustrated in

Figure 3. Each pad acts as a passive elastic element and

can be independently varied in stiffness and damping.

This parametric configuration enables targeted tuning

of impact absorption and dynamic stability.

(a)

(b)

Figure 3: (a) CAD drawing of elastic pads, (b)

Implementation of pads underneath rigid foot.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

358

2.2 Pad Fabrication and Material

Selection

Pads are fabricated using thermoplastic polyurethane

(TPU) via 3D printing. Two variants were tested:

orange (Shore-A 90, lower grid density) and white

(Shore-A 80, higher grid density).

Both designs use a sandwich-like internal

structure for lightweight compliance. The orange pad

weighed 36.5 g and measured 88 × 26 × 40 mm. The

grid pattern and material thickness were varied to

modify mechanical properties. These prototypes were

not the final optimized configuration but served as

experimental references for material properties.

2.3 Compression Testing and

Characterization

Quasi-static compression tests were performed using

a universal testing machine at velocities ranging from

0.5 to 3 mm/s (orange) and up to 5 mm/s (white). The

load-displacement curves were analyzed to extract

spring constants and damping coefficients.

Results confirmed light damping behavior in all

cases (i.e., ζ

eq

<1). The white pads exhibited higher

stiffness and lower damping compared to the orange

pads, making them more suitable for forefoot

implementation. Average values used in simulation

were:

• k≈65,000 N/m, c≈4 Ns/m for white pads

• k≈4,800 N/m, c≈4.2 Ns/m for orange pads

These parameters were input into the robot

simulation model to represent contact dynamics

accurately.

3 SIMULATION AND

OPTIMIZATION

FRAMEWORK

3.1 Bipedal Robot Simulation

Environment

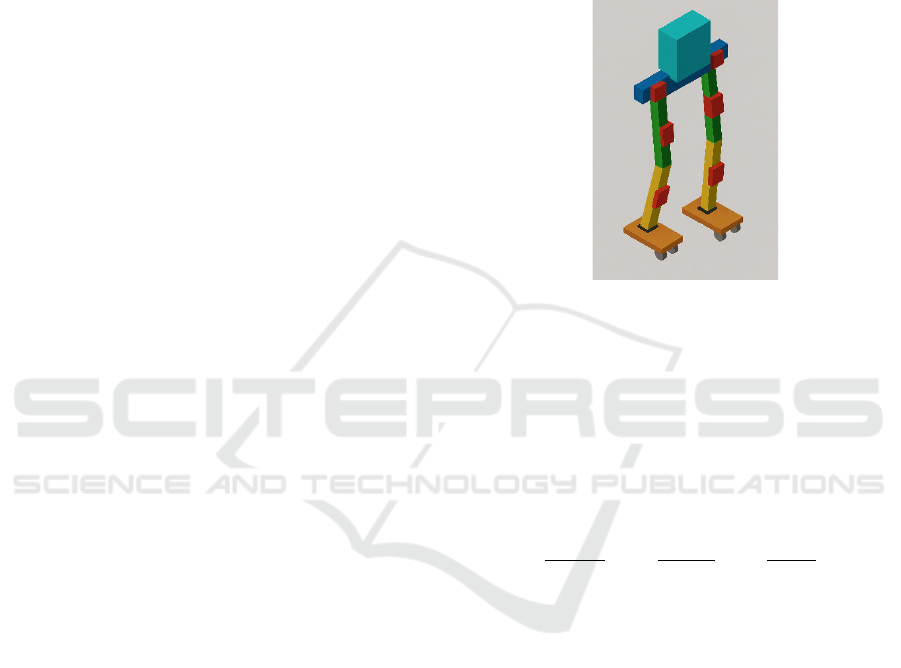

To evaluate the effect of compliant foot design on

joint loading, a detailed simulation model of the

planar bipedal robot was constructed using MATLAB

Simulink (Simscape Multibody). The model

incorporates six actuated joints and simulates single

and double support phases using realistic contact

dynamics (see Figure 4).

Elastic pads are modelled as compliant elements

beneath each foot, with separate stiffness and

damping coefficients for forefoot and heel pads.

Contact interactions are defined using spatial contact

force blocks, and walking motions are driven by

predefined joint angle trajectories based on previous

gait studies.

Each simulation run evaluates whether the robot

maintains balance and measures maximum joint

torques at ankle, knee, and hip. A fall condition is

detected if the hip height drops below a threshold.

Figure 4: Visualization of robot simulation model.

3.2 Optimization Objective and

Constraints

The main goal is to minimize joint torque spikes

during walking by tuning pad stiffness and damping.

The objective function is defined as the squared sum

of joint torque peak values divided by each joint

actuator’s maximum continuous torque limits:

J=

ankle

max,ankle

+

knee

max,knee

+

hip

max,hip

(1)

where τ

max

values are motor torque limits (5A rated).

The squared terms place stronger emphasis on torque

values approaching or exceeding actuator limits. The

optimization criterion is based on maximum

normalized torques at ankle, knee, and hip joints over

the gait cycle, rather than mean values.

3.3 Genetic Algorithm Optimization

A genetic algorithm (GA) is used to find optimal pad

parameters:

• k

fore

,k

heel

∈

20000, 300000

N/m

• c

fore

,c

heel

∈

10000, 150000

Ns/m

These ranges were established from the

experimentally measured stiffness and damping of

3D-printed pad prototypes, which served as a basis

and starting point for the optimization rather than

fixed values. GA uses population size 50, crossover

Simulation-Driven Design and Optimization of a Parametric Flat-Foot with Elastic Pads for a Planar Biped Robot

359

probability 0.8, with convergence based on stall for

100 generations. Each evaluation runs a full walking

simulation.

3.4 Gait Generation

To simulate realistic walking dynamics, the robot’s

joint trajectories were defined based on a previously

generated walking gait for YU-Bibot. The gait was

developed through offline trajectory planning using

human-inspired profiles and validated in an earlier

work (Şafak & Baturalp, 2023).

The walking cycle consists of distinct stance and

swing phases for each leg, with ankle, knee, and hip

joints actuated via time-based reference profiles. The

gait assumes walking on flat terrain at constant

velocity and does not use feedback control during this

study. The same gait is used across all foot

configurations to ensure fair comparison between the

baseline and optimized feet.

Although the gait was initially tuned for the

baseline flat foot, the simulation revealed that the

compliant foot with pads improved torque

distribution without compromising the overall

kinematics or balance.

4 RESULTS AND DISCUSSION

4.1 Simulation Setup

The walking simulation was run using predefined

joint trajectories based on flat-ground walking gait.

Each simulation covered one full step cycle, with

joint torques monitored throughout. Two foot

configurations were compared: baseline flat-foot

(rigid sole, no compliance) and flat-foot with

optimized elastic pads (using GA-tuned stiffness and

damping).

Motor torque limits were taken as

τ

max,ankle

=24.2 Nm, τ

max,knee

=17.7 Nm, and

τ

max,hip

=11.8 Nm, based on hardware specs.

4.2 Torque Reduction Results

The simulation showed that the optimized pad

configuration substantially reduced joint torque

peaks, especially at the ankle and knee. The

comparative results are summarized in Table 1.

Table 1: Max and RMS Joint Torques – Baseline vs.

Optimized Pad Design.

Joint Metric

Baseline

(flat foot)

Optimized

(with pads)

Ankle

Max (Nm) 13.8 11.6

RMS (Nm) 4.6 4.7

Knee

Max (Nm) 31.3 20.4

RMS (Nm) 12.1 8.6

Hip

Max (Nm) 57.2 30.8

RMS (Nm) 22.1 14.2

The optimized foot with elastic pads significantly

reduced maximum joint torques across all joints, most

notably at the hip (46%) and knee (35%). These

reductions indicate improved impact buffering and

smoother load transfer during the stance phase.

RMS torques also decreased substantially at the

knee (30%) and hip (36%), which suggests a

reduction in sustained joint loading over the gait

cycle. Interestingly, the ankle RMS torque slightly

increased, likely due to the redistribution of force

during heel-strike and push-off with the compliant

pads. This trade-off appears acceptable given the

larger reductions elsewhere and the peak torque at the

ankle still remaining well below motor limits.

These results confirm that pad-based compliance

can mitigate peak loads while also reducing overall

energy demand on major joints, particularly at the

knee and hip — both of which are commonly critical

in robotic actuation systems.

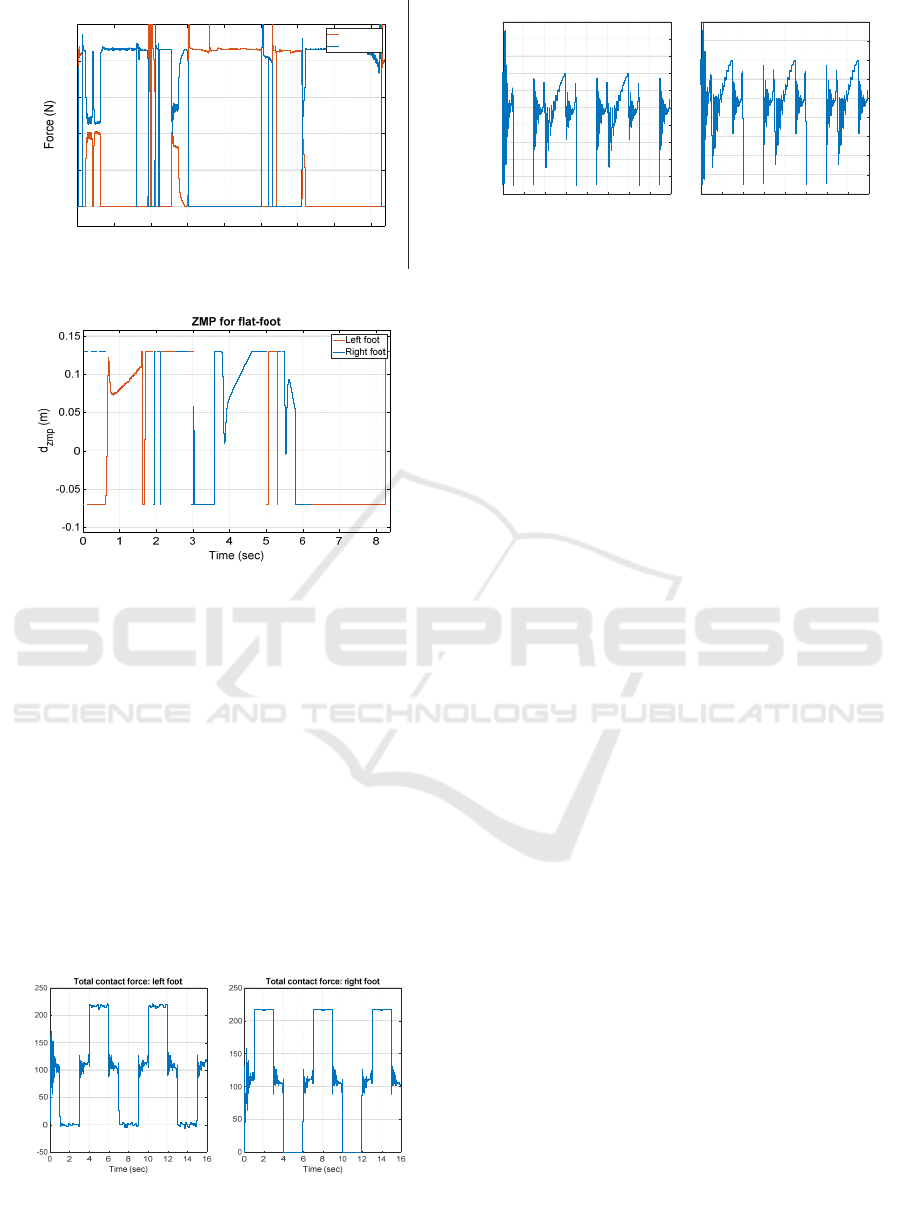

4.3 Contact Force and Stability

The total vertical ground reaction force (GRF) and

zero moment point (ZMP) were analyzed for both the

baseline flat-foot and the optimized foot with elastic

pads. ZMP stability analysis follows established

approaches in (Kajita et al., 2003; Erbatur et al.,

2002). As shown in Figure 5, the rigid flat foot

produced sharp GRF peaks at heel-strike and toe-off,

with abrupt changes in load transfer. The

corresponding ZMP trajectory (Figure 6) exhibited

rapid shifts, occasionally approaching the edge of the

support polygon. These behaviors reflect the limited

compliance of the rigid sole, leading to higher impact

forces and reduced stability margins.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

360

Figure 5: Total contact forces for flat foot (baseline).

Figure 6: ZMP for flat foot (baseline).

The addition of elastic pads resulted in smoother

contact force profiles with fewer sharp transients

compared to the baseline. The total ground reaction

forces (Figure 7) remained within expected limits. To

assess dynamic stability during walking, the Zero

Moment Point (ZMP) was tracked throughout the gait

cycle (Figure 8). The ZMP represents the point on the

ground where the net moment due to gravity and

inertia forces is zero, and it must remain within the

foot’s support area to ensure stable motion (Kajita et

al., 2003; Erbatur et al., 2002). For both the baseline

and optimized foot designs, the ZMP remained inside

the support polygon during the stance phase,

confirming that the robot maintained balance

throughout the simulated steps.

Figure 7: Total contact forces for flat foot with pads.

Figure 8: ZMP for flat foot with pads.

Notably, the forefoot pads converged to much

higher stiffness values than the heel pads in the

optimization, echoing the biomechanical distribution

in the human foot. This natural-like stiffness gradient

appears to enhance impact buffering at heel-strike

while maintaining push-off stability.

4.4 Discussion and Implications

The results support the effectiveness of simulation-

driven foot design using parametric compliance. Even

in a planar biped without active foot control, passive

elasticity can significantly reduce actuator demand,

improve gait stability, and protect mechanical

components.

The trade-off is a slight increase in ankle RMS

torque, possibly due to dynamic coupling effects

introduced by the pads. This could be addressed in

future work via adaptive gait tuning or a hybrid

passive-active compliance approach.

5 CONCLUSION

This study presented a simulation-driven approach to

improving the foot-ground interaction of the YU-

Bibot planar biped robot. A modified flat-foot design

with elastic pads was introduced, inspired by human

foot contact regions. Prototype pads were fabricated

and experimentally characterized to provide baseline

stiffness and damping ranges, which served as inputs

to a genetic algorithm–based optimization

framework.

Walking simulations were conducted in

MATLAB Simulink on flat terrain for two

configurations: a baseline rigid flat foot and a flat foot

with optimized elastic pads. Comparative analysis

showed that the optimized design reduced peak

torques by up to 46% at the hip and 35% at the knee,

with RMS torques also significantly reduced at these

joints. While ankle RMS torque slightly increased,

the overall load distribution across joints improved.

012345678

Time (sec)

0

50

100

150

200

Total vertical contact force

Right foot

Left foot

Force (N)

Force (N)

0246810121416

time (sec)

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

0.12

d_zmp (m)

ZMP left

0246810121416

time (sec)

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

d_zmp (m)

ZMP right

Simulation-Driven Design and Optimization of a Parametric Flat-Foot with Elastic Pads for a Planar Biped Robot

361

Ground reaction force analysis indicated that the

elastic pads smoothed impact transients compared to

the rigid baseline, while Zero Moment Point (ZMP)

trajectories remained well within the support

polygon, confirming stable walking. These results

demonstrate that introducing passive compliance at

the foot level can mitigate joint loads and enhance

stability without requiring additional actuation or

complex control.

The findings also suggest a natural-like

distribution of compliance—stiffer forefoot and

softer heel—as an effective configuration for impact

absorption and propulsion, similar to human foot

mechanics. Future work will include hardware

implementation of the optimized pad design on the

physical robot.

The proposed approach demonstrates the value of

coupling simulation, experimental characterization,

and optimization in advancing bio-inspired robotic

design.

REFERENCES

El Asswad, M., AlFayad, S., & Khalil, K. (2017).

Optimization of HYDROÏD robot foot. International

Journal of Mechanical & Mechatronics Engineering,

17(3), 63–70.

ElDirdiry, O., Zaier, R., & Al-Yahmedi, A. (2017). Design

of biomechanical legs with a passive toe joint for

enhanced human-like walking. The Journal of

Engineering Research, 14(2), 166–181.

Erbatur, K., Okazaki, A., Obiya, K., Takahashi, T., &

Kawamura, A. (2002). A study on the zero moment

point measurement for biped walking robots.

Proceedings of the 7th International Workshop on

Advanced Motion Control (AMC) (pp. 431–436).

https://doi.org/10.1109/AMC.2002.1026959.

Kajita, S., Kanehiro, F., Kaneko, K., Fujiwara, K., Harada,

K., Yokoi, K., & Hirukawa, H. (2003). Biped walking

pattern generation by using preview control of the zero-

moment point. In Proceedings of the IEEE

International Conference on Robotics and Automation

(Vol. 2, pp. 1620–1626). IEEE. https://doi.org/10.

1109/ROBOT.2003.1241826.

Li, J., Huang, Q., Zhang, Y., Yu, H., & Li, K. (2008,

September). Flexible foot design for a humanoid robot.

2008 IEEE International Conference on Automation

and Logistics (pp. 1414–1419). https://doi.org/10.

1109/ICAL.2008.4636375

Şafak, E., & Baturalp, K. (2023). Parametric design and

prototyping of a low-power planar biped robot.

Biomimetics, 8(4), 346. https://doi.org/10.3390/

biomimetics8040346

Venkadesan, M., Yawar, A., Eng, C. M., Lieberman, D. E.,

& Mandre, S. (2020). Stiffness of the human foot and

evolution of the transverse arch. Nature, 579, 97–100.

https://doi.org/10.1038/s41586-020-2053-y

Zang, X., Liu, H., Li, Z., Lin, Y., & Zhao, J. (2017). Design

and experimental development of a pneumatic stiffness

adjustable foot system for amphibious spherical robots.

Applied Sciences, 7(10), 1005. https://doi.org/10.

3390/app7101005

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

362