Manipulability Maximization of a Liquid-Handling Manipulator for

Sloshing Suppression via Container Tilting

Ryuji Nakagawa

a

and Ryosuke Tasaki

b

Department of Mechanical Engineering, Aoyama Gakuin University, Sagamihara, Kanagawa, Japan

Keywords: Manipulability, Sloshing Suppression, Optimization Problem, Trajectory Constraint.

Abstract: The manipulability index measures a robot’s motion capability. To avoid singularity problems and to achieve

unexpected changes in tasks, a method that explicitly considers this metric is needed. However, the index is

a nonlinear function that depends on the state of the manipulator, making optimization difficult in a short

period of time. In addition, real-time control of the robot, which requires computational efficiency, is

necessary to ensure safety in a dynamic environment. Previous studies have generated trajectories that

increase this metric, but different tasks require different constraints to be considered. Controlling not only the

trajectory but also the posture and velocity of the end-effector expands the area of practical use. In this paper,

we formulate a manipulability optimization problem for real-time control in liquid transfer and solve it

efficiently using inequality constraints. In liquid transfer experiments, the method successfully generates safe

and kinematic trajectories with high performance by optimizing both manipulability and controlling velocity

and attitude to suppress liquid surface vibration.

1 INTRODUCTION

Recent advances in collaborative robots have

responded to the shift from high-volume to high-mix

production, with increasing demand driven by their

flexibility in adapting to complex tasks (Kavraki et

al., 1996). Unlike industrial robots, collaborative

robots operate safely alongside humans without

traditional safety barriers. In Human-Robot

Collaboration (HRC) spaces, safety remains a

primary concern. Various motion planning

approaches, including RRT and CHOMP, address

collision avoidance and task constraints (LaValle &

Kuffner, 2001; Wang et al., 2019). However,

dynamic environments demand that robots rapidly

adapt to unpredictable situations, requiring

trajectories that maintain high kinematic

performance. The manipulator’s posture critically

affects adaptability (Haowen et al., 2024); poor

configurations limit responsive movements.

The manipulability ellipsoid (Yoshikawa, 1985)

describes the robot’s directional motion capability, and

the manipulability index—proportional to ellipsoid

volume—assesses proximity to singularities.

a

https://orcid.org/0009-0001-0525-5729

b

https://orcid.org/0000-0002-3619-4498

Maximizing this index enhances adaptability in

dynamic environments. Dufour et al. integrated a

linearized manipulability index into inverse kinematics

using Quadratic Programming (2020). Other methods,

such as Gaussian process regression for trajectory

optimization (Maric et al., 2019) and neural networks

(Jin et al., 2017), have also been proposed. More

recently, manipulability optimization has been applied

to multi-arm coordination (Kennel-Maushart et al.,

2021) and human–robot collaboration tasks (Zhang,

2022). However, most studies address manipulability

improvement or task-specific constraints separately,

and few have integrated them into a unified

framework.

In parallel, liquid transfer with open containers is

another challenging problem, where sloshing

suppression has been studied through trajectory

shaping and container tilting strategies (Yano &

Terashima, 2001; Moriello et al., 2018; Muchacho et

al., 2022). These methods effectively reduce liquid

oscillations but generally ignore the kinematic

performance of the manipulator, limiting their

applicability in tasks that require both stability and

adaptability.

350

Nakagawa, R. and Tasaki, R.

Manipulability Maximization of a Liquid-Handling Manipulator for Sloshing Suppression via Container Tilting.

DOI: 10.5220/0013759200003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 350-356

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

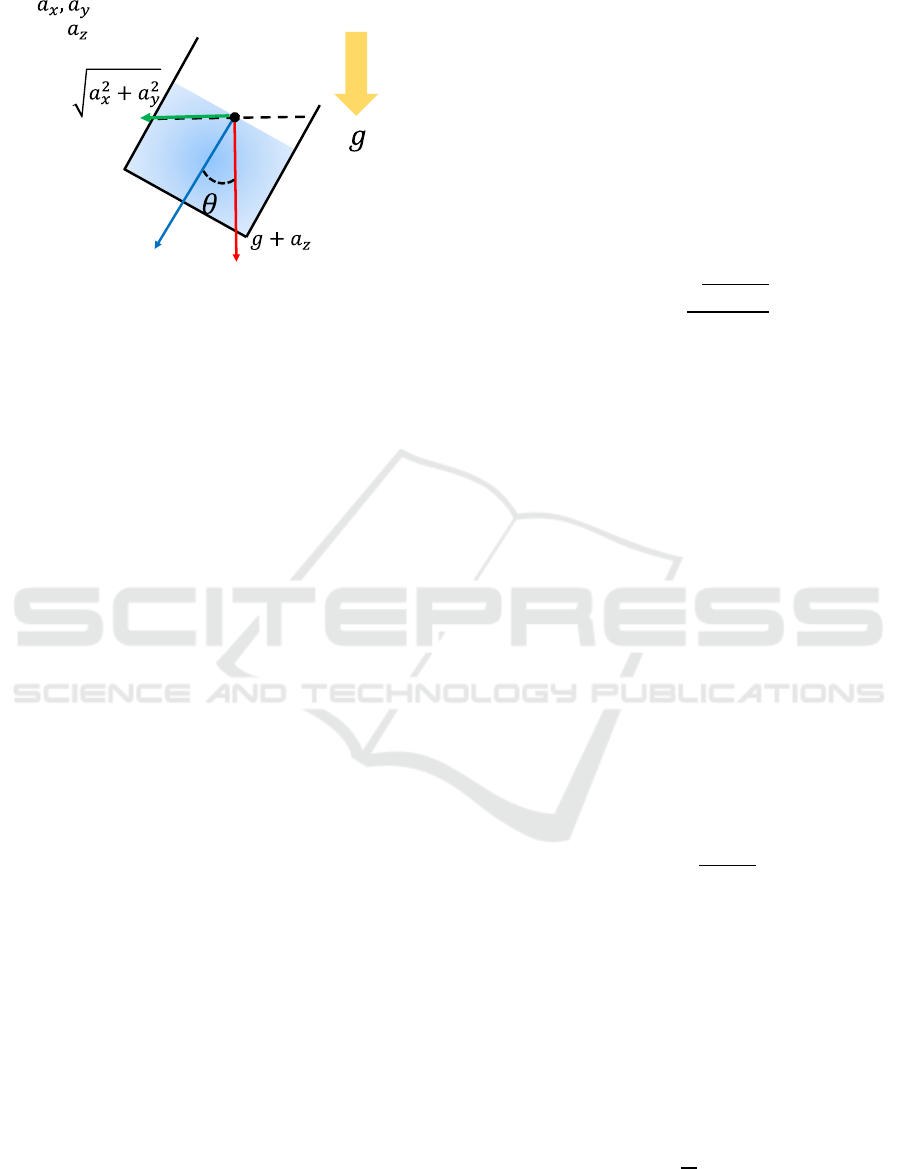

Figure 1: Schematic of sloshing suppression control.

This study proposes a trajectory optimization

framework that maximizes the manipulability index

while simultaneously suppressing liquid vibrations. A

key feature of the formulation is that sloshing

suppression is expressed as an inequality constraint

rather than as part of the objective function. This

keeps the objective lightweight and computationally

efficient, while the introduction of flexible constraints

allows the feasible range to be adaptively adjusted,

reducing computational load without sacrificing task

feasibility. These characteristics make the approach

suitable for real-time implementation in dynamic

environments. Effectiveness is validated through

experiments with a 7-DOF manipulator performing

liquid transfer tasks, confirming that the proposed

method achieves safe and kinematically efficient

trajectories that enhance manipulability while

suppressing sloshing.

2 PRINCIPLE OF SLOSHING

SUPPRESSION

Sloshing suppression during liquid transfer has been

extensively studied, with approaches including CFD-

based modeling (Muller et al., 2003; Diavareshkian &

Khalili, 2006) and filtered trajectory generation

targeting vibration frequencies (Yano et al., 2001;

Yano & Terashima, 2001). These typically assume

horizontal container orientation in linear systems. In

contrast, manipulator-based studies explore container

tilting to counteract acceleration-induced liquid

motion (Moriello et al., 2018; Muchacho et al., 2022).

This study proposes a trajectory optimization

method that dynamically adjusts container orientation

based on acceleration while enhancing the

manipulability index. The vibration control strategy

is detailed in this chapter.

2.1 Statement of Tilting Method

Figure 1 illustrates the schematic of the proposed

sloshing suppression control method. Vibration is

mitigated by minimizing horizontal acceleration

within the container, achieved by aligning the

container’s orientation with the direction of the

applied acceleration. The container’s tilt angle 𝜃

[rad] is calculated based on the horizontal

accelerations 𝛼

and 𝛼

[m/s²], the vertical

acceleration 𝛼

[m/s²], and gravitational acceleration

𝑔 [m/s²].

𝜃=tan

𝛼

+𝛼

(

𝑔+𝛼

)

(

1

)

In essence, sloshing is suppressed when the net

acceleration vector acting on the liquid aligns with the

normal vector of the liquid surface.

2.2 Acceleration Smoothing

As shown in (1), the manipulator adjusts the

container’s tilt in response to acceleration. However,

abrupt changes in acceleration, such as step inputs,

can result in infeasible motion due to excessive speed

requirements. To ensure feasibility, the acceleration

profile must be smooth. By regulating the rate of

change of acceleration, the manipulator generates

motion within its operational limits.

The rate of change of acceleration is referred to as

jerk. A low-jerk trajectory ensures smooth

acceleration, enabling the desired tilt of the container.

Accordingly, the optimal trajectory is obtained by

minimizing jerk, as defined by the evaluation

function below, where 𝑥(𝑡) denotes position.

𝐽(𝑥

(

𝑡

)

)=

𝑑

𝑥

(

𝑡

)

𝑑𝑡

𝑑𝑡

(

2

)

The functional reaches its extremum when 𝑥(𝑡)

satisfies the Euler–Poisson equation, allowing the

trajectory to be expressed as a fifth-order polynomial.

𝑥

(

𝑇

)

=𝑥

+𝑥

−𝑥

(

6𝑇

−15𝑇

+10𝑇

)

−𝑣

(

3𝑇

−8𝑇

+6𝑇

−𝑇

)

−𝑣

(

3𝑇

−7𝑇

+4𝑇

)

(3)

−0.5𝑎

(

𝑇

−3𝑇

+3𝑇

−𝑇

)

+0.5𝑎

(

𝑇

−2𝑇

+𝑇

)

𝑇=

𝑡

𝑡

(4)

:

Horizontal acceleration

: Vertical acceleration

Gravity

Liquid surface

Manipulability Maximization of a Liquid-Handling Manipulator for Sloshing Suppression via Container Tilting

351

where 𝑥, 𝑣, and 𝑎 represent the position, velocity,

and acceleration, respectively, while the subscripts 0

and 𝑓 denote the starting and ending points. Equation

(4) is scaled by the final time 𝑡

. This is known as the

minimum jerk model (Flash & Hogan, 1985), which

generates a trajectory with minimal jerk based on the

current state and the endpoint state. In this study, the

trajectory generated using this model is referred to as

the minimum jerk trajectory. When the container is

transported along a smooth acceleration, the lateral

acceleration of the liquid is cancelled by tilting the

container.

3 MANIPULATOR KINEMATICS

AND MANIPULABILITY

Manipulator kinematics consists of forward

kinematics, which computes the end-effector pose

from joint angles, and inverse kinematics, which

determines joint configurations for a desired task-

space pose. The manipulability index, derived from

the Jacobian, reflects the manipulator’s motion

capability.

3.1 Kinematics and Manipulability

The forward kinematics of a manipulator with 𝑛

degrees of freedom at joint configuration 𝑞∈ℝ

is

expressed as

𝑥=𝑓

(

𝑞

)(

5

)

where 𝑥∈ℝ

is the end-effector pose (position and

orientation in task space) and 𝑓

(

∙

)

is a nonlinear

mapping. Since solving this relation directly is often

computationally demanding, it is commonly

linearized through differential kinematics:

𝑥 =𝐽

(

𝑞

)

𝑞

(

6

)

where 𝑥 =

𝑣

𝜔

∈ℝ

represents the linear

velocity 𝑣 and angular velocity 𝜔 of the end-effector,

and 𝑞 is the joint velocity vector. The Jacobian matrix

𝐽

(

𝑞

)

∈ℝ

×

maps joint velocities to task-space

velocities. In this context, 𝐽

(

𝑞

)

represents the

manipulator Jacobian, distinct from the cost

functional 𝐽(𝑥

(

𝑡

)

) defined in (2).

Manipulability is an important index in motion

planning, and increasing it allows for greater

flexibility in motion and avoidance of singularities.

This index is defined as follows

𝑚(𝑞)=

𝑑𝑒𝑡

(

𝐽(𝑞)𝐽(𝑞)

)

=𝜎

(

7

)

where 𝜎

are the singular values of 𝐽(𝑞). Since 𝜎

>

0, 𝑚(𝑞)>0. If 𝑚(𝑞) is close to 0, the manipulator is

close to a singular configuration. Conversely, larger

values correspond to configurations that allow greater

dexterity and adaptability.

3.2 Manipulability Optimization

Optimization-based motion planning enables robots

to generate efficient and safe trajectories under task-

specific constraints. In manipulability optimization,

the objective is to maximize 𝑚(𝑞) , thereby

enhancing motion flexibility and avoiding

singularities. The problem is formulated as:

min

𝑚

(

𝑞

)(

8

)

Subject to

𝑥 =𝐽

(

𝑞

)

𝑞

𝑞

≤𝑞≤𝑞

𝑞

≤𝑞 ≤𝑞

where 𝑞

and 𝑞

are the upper and lower limits of the

joint angle, and 𝑞

and 𝑞

are the joint velocity

limits. Maximizing 𝑚(𝑞) is crucial for generating

trajectories that exhibit high motion performance,

enhancing the overall agility and efficiency of the

manipulator.

The gradient of the manipulability index is

required for iterative optimization. In this study, the

gradient is computed numerically using finite

differences:

∇𝑚

=

𝜕𝑚

(

𝑞

)

𝜕𝑞

=

𝑚

(

𝑞+𝑑𝑒

)

−𝑚

(

𝑞

)

𝑑

(

9

)

where ∇𝑚

is the 𝑖-th element of vector ∇𝑚, and 𝑑 is

a small positive constant. 𝑒

is the unit vector in the

direction of the 𝑖-th joint.

4 MANIPULABILITY

OPTIMIZATION FOR LIQUID

TRANSFERRING TASK

This section proposes a method to optimize

manipulability during liquid transfer by formulating

motion planning as an optimization problem,

incorporating the minimum jerk trajectory as a

constraint.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

352

4.1 Minimum Jerk Trajectory

Constraint

To suppress sloshing during liquid transfer, it is

essential to generate smooth accelerations that do not

excite liquid oscillations. For this purpose, the

minimum jerk trajectory model is adopted as a

constraint in the manipulability optimization

problem. The minimum jerk model provides an

analytic trajectory with minimized jerk, defined by

the third derivative of position, and can be expressed

in polynomial form using the start and end conditions

of the motion.

The general expression of a minimum jerk

trajectory between initial state (𝑥

,𝑣

,𝑎

) and final

state 𝑥

,𝑣

,𝑎

is given by

𝑥(𝑡) = 𝑓(𝑥

,𝑥

,𝑣

,𝑣

,𝑎

,𝑎

,𝑡,𝑡

)

(

10

)

where 𝑡

is the final time. This trajectory guarantees

smooth position, velocity, and acceleration profiles.

In practical liquid transfer tasks, the final velocity and

acceleration are often set to zero (𝑣

= 0, 𝑎

= 0),

which simplifies the formulation.

For real-time implementation, it is convenient to

express the trajectory in recursive form. The position

at the next step is computed from the current state

(𝑥(𝑡),𝑣(𝑡),𝑎(𝑡)) and the target endpoint 𝑥

as

𝑥(𝑡+∆𝑡)= 𝑓(𝑥

,𝑥(𝑡),𝑣(𝑡),𝑎(𝑡),𝑇′)

(

11

)

where ∆𝑡 is the control interval and 𝑇

=∆𝑡𝑡

−𝑡

⁄

represents the normalized time increment. This

recursive formulation allows the trajectory to be

updated at each control step, making it suitable for

online optimization.

In the proposed framework, the minimum jerk

trajectory is not treated as an additional objective, but

rather as an inequality constraint on feasible motions:

𝑥

≤𝑥 ≤𝑥

(

12

)

where the bounds 𝑥

,𝑥

are derived from the

minimum jerk trajectory. To account for the trade-off

between manipulability and trajectory tracking, a

deviation parameter 𝜁 and a scaling function 𝛼(𝑡) are

introduced:

𝑣

±

=𝑓

𝑥

±𝜁𝛼,𝑥

(

𝑡

)

,𝑣

(

𝑡

)

,𝑎

(

𝑡

)

,𝑇

(

13

)

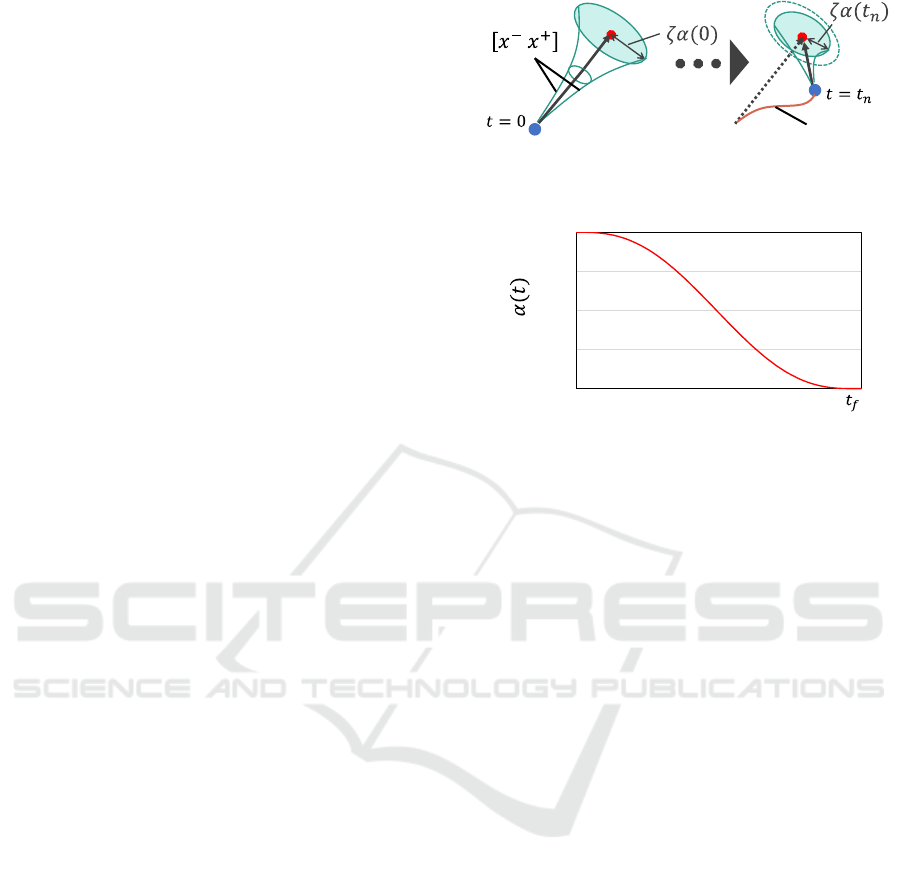

(a) Feasible search region defined by deviation parameter

𝜁 and scaling coefficient 𝛼(𝑡).

(b) Time profile of scaling coefficient 𝛼(𝑡).

Figure 2: Concept of minimum jerk trajectory constraint.

Here, 𝜁≥0 represents the maximum allowable

deviation from the nominal trajectory, while 𝛼(𝑡) is a

time-varying coefficient that gradually decreases

from 1 at the start of the motion to 0 at the end. This

flexible constraint design enlarges the search space at

the beginning of the motion and tightens it near the

goal, thereby reducing computational load while

ensuring convergence to the target. In this

formulation, 𝑣 represents the linear velocity subject

to inequality constraints, while the angular velocity 𝜔

is determined to satisfy the tilting condition in (1) at

every step. Thus, the container orientation is

continuously adjusted to align with the resultant

acceleration vector, ensuring sloshing suppression

during the transfer. Moreover, any sudden change in

deviation must be gradual, as it may lead to abrupt

shifts in the search range. Based on these conditions,

𝛼 was also derived using the minimum jerk model,

along with the trajectory. Figure 2 illustrates this

concept: (a) the feasible region defined by the flexible

constraint shrinks as the task approaches completion;

(b) the scaling coefficient 𝛼(𝑡) decreases smoothly

from 1 to 0 according to the minimum jerk model.

Combining these elements, the constraints of the

optimization problem for liquid transfer can be

expressed as:

𝑥 =𝐽

(

𝑞

)

𝑞

𝑞

≤𝑞≤𝑞

𝑞

≤𝑞 ≤𝑞

𝑥

≤𝑥 ≤𝑥

Start

Goal

Generated path

Range

0

0.25

0.5

0.75

1

Time

0

Manipulability Maximization of a Liquid-Handling Manipulator for Sloshing Suppression via Container Tilting

353

Figure 3: Experimental setup.

with

𝑥

±

=

𝑣

±

𝜔

±

𝑣

±

=𝑓

𝑥

±𝜁𝛼,𝑥

(

𝑡

)

,𝑣

(

𝑡

)

,𝑎

(

𝑡

)

,𝑇

By embedding the minimum jerk model as a

constraint rather than as part of the cost function, the

optimization remains computationally lightweight.

This design is essential for real-time liquid transfer,

where both manipulability enhancement and sloshing

suppression must be achieved simultaneously.

4.2 Experimental Results

To validate the proposed method, liquid transfer

experiments use a KUKA LBR iiwa 7 R800 (7 DOF).

The setup is shown in Figure 3. A wine glass was

transported from the origin (0, 0, 0) to a position

0.5 m along the y-axis within 2.0 s. Trajectory and

manipulability were evaluated for various values of

𝜁, representing the maximum deviation. The case

with 𝜁 = 0, where manipulability is not considered, is

defined as the reference trajectory.

In this study, proposed method is evaluated under

two conditions: Scenario A, a reference trajectory

with high manipulability, and Scenario B, a reference

trajectory with low manipulability that passes near a

singularity.

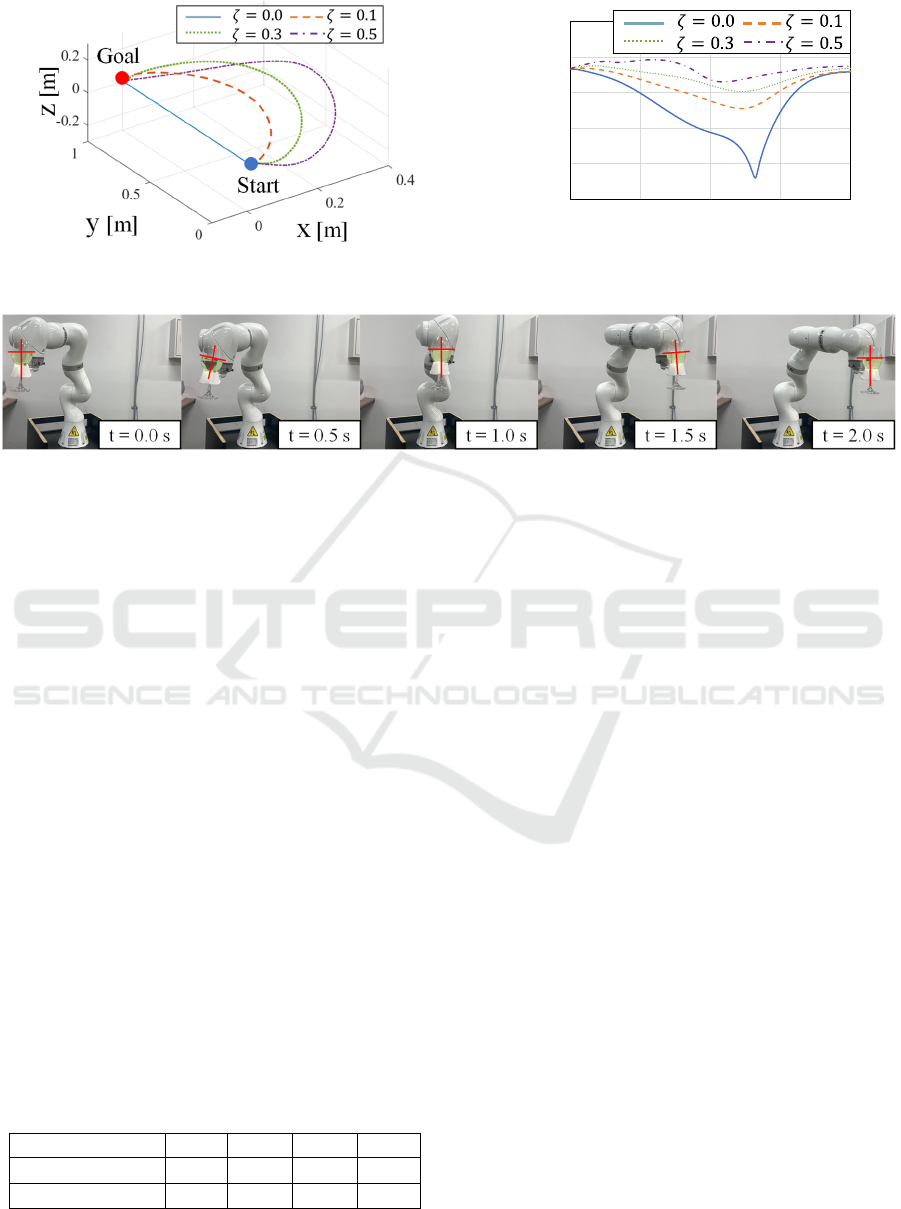

4.2.1 Scenario A: High Manipulability

Trajectory

Figure 4 shows the transport trajectories, while Figure

5 presents the corresponding manipulability,

normalized by the robot’s maximum value. As 𝜁

increases, trajectory deviation becomes more

pronounced. At 𝜁 = 0, the trajectory is a straight line,

reflecting the minimum jerk model without

manipulability optimization.

Figure 4: Liquid transferring trajectory (Scenario A).

Figure 5: Scaled manipulability (Scenario A).

Figure 5 indicates that the proposed method

maintains high manipulability across all conditions.

The reference trajectory ( 𝜁 = 0) results in lower

manipulability, suggesting limited kinematic

performance and potential instability near

singularities. In contrast, optimized trajectories avoid

such regions, confirming the method’s effectiveness.

Notably, 𝜁 = 0.3 achieves a favorable balance

between trajectory deviation and manipulability.

The observed increase in manipulability with

larger 𝜁 suggests that the most favorable postures lie

away from the reference path. Minor differences in

final manipulability are attributed to jerk

minimization delays. Since 𝜁 = 0.5 shows the largest

arrival error, adjusting the constraint coefficient α in

real time is recommended.

4.2.2 Scenario B: Low Manipulability

Trajectory

Figure 6 shows the transport trajectories, while Figure

7 presents the corresponding manipulability. Similar

to Scenario A, trajectory deviation increases with

larger 𝜁 values, and manipulability generally

improves as 𝜁 increases. The reference trajectory

0.6

0.7

0.8

0.9

1

00.511.52

Time [s]

Scaled manipulability

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

354

exhibits manipulability values near zero, whereas the

proposed method effectively maintains higher

manipulability, even for 𝜁 = 0.1, enabling singularity

avoidance.

These results indicate that manipulability

decreases near singularities, and the proposed method

effectively avoids such configurations. By

formulating sloshing suppression as a manipulability

optimization problem, the method simultaneously

enhances both manipulability and vibration

suppression. Under Scenario B, the method

demonstrates effectiveness for singularity avoidance.

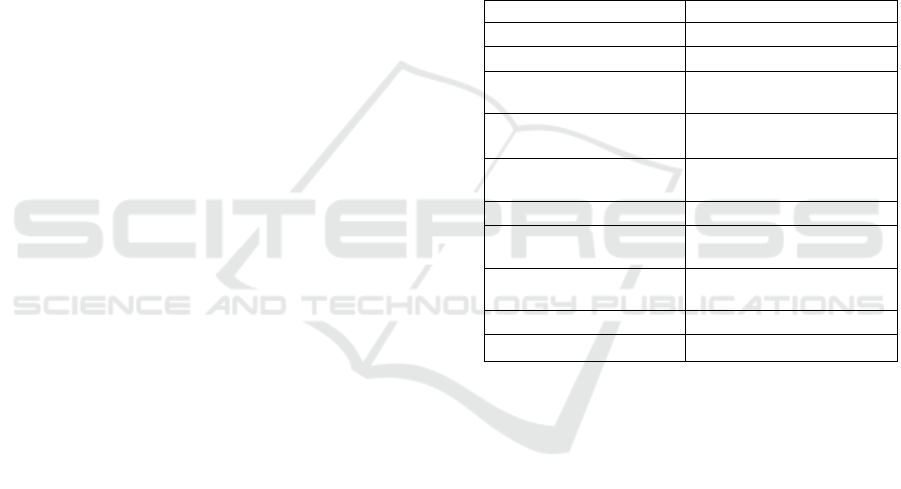

Finally, Figure 8 illustrates the motion generated

by the proposed method. The container tilt aligns with

the direction normal to the liquid surface, confirming

the effectiveness of the control. The average and

maximum computation times are summarized in

Table 1. By avoiding a complex objective, the

proposed method achieved computation times below

10 ms in all cases, sufficient for 100 Hz real-time

control. A wider flexible constraint slightly increased

computation time, reflecting the expansion of the

feasible search space.

Table 1: Computation time under different constraints.

Condition

𝜁

0.0

0.1 0.3 0.5

Avg. time [ms] 0.182 0.472 0.807 1.08

Max. time [ms] 0.612 1.02 1.69 3.06

5 CONCLUSIONS

This study proposed a manipulability optimization

method that accounts for task-specific constraints,

such as end-effector speed and orientation during

liquid transfer. Trajectories were generated using a

minimum jerk model to achieve both vibration

suppression and high manipulability. By

incorporating trajectory flexibility as a constraint and

gradually tightening it, the method ensured timely

and feasible motion execution.

Experimental results confirmed that high-

manipulability trajectories can be achieved without

extending execution time, demonstrating the

method’s feasibility under time constraints. Although

the end time was fixed, further improvements could

be made by adapting it to the manipulator’s condition.

Future work will extend the constraint formulation to

both state and joint spaces and explore redundancy

resolution in highly constrained tasks.

REFERENCES

Diavareshkian, M. H., & Khalili, M. (2006). Simulation of

sloshing with the volume of fluid method. Fluid

Dynamics & Materials Processing, 2(4), 299–308.

Dufour, K., & Suleiman, W. (2020). On maximizing

manipulability index while solving a kinematics task.

Journal of Intelligent Robotic Systems, 100(1), 3–13.

Figure 8: Liquid transfer using tilting motion control. The red lines show the glass’s central axis and liquid surface’s

orientation. The different lengths of the vertical axis represent the tilt in the depth direction (t = 0.5 s, 1.5 s).

Figure 6: Liquid transferring trajectory (Scenario B).

Figure 7: Scaled manipulability (Scenario B).

0

0.2

0.4

0.6

0.8

1

0 0.5 1 1.5 2

Time [s]

Scaled manipulability

Manipulability Maximization of a Liquid-Handling Manipulator for Sloshing Suppression via Container Tilting

355

Flash, T., & Hogan, N. (1985). The coordination of arm

movements: An experimentally confirmed

mathematical model. The Journal of Neuroscience,

5(7), 1688–1703.

Haowen, Y., Laha, R., Figueredo, L., & Haddadin, S.

(2024). Enhanced Dexterity Maps (EDM): A new map

for manipulator capability analysis. IEEE Robotics and

Automation Letters, 9(2), 1628-1635.

Jin, L., Li, S., La, H. M., & Luo, X. (2017). Manipulability

optimization of redundant manipulators using dynamic

neural networks. IEEE Transactions on Industrial

Electronics, 64(6), 4710–4720.

Kavraki, L. E., Svestka, P., Latombe, J. C., & Overmars, M.

H. (1996). Probabilistic Roadmaps for Path Planning in

High-Dimensional Configuration Spaces, IEEE Trans.

on Robotics and Automation, 12(4), 556-580.

Kennel-Maushart, F., Poranne, R., & Coros, S. (2021).

Manipulability optimization for multi-arm

teleoperation. In Proceedings of the 2021 IEEE

International Conf. on Robotics and Automation

(ICRA) (pp. 3956–3962). IEEE.

LaValle, S. M., Kuffner, J. J. (2001). Rapidly-exploring

random trees: Progress and prospects, Algorithmic and

Computational Robotics, 303-307.

Maric, F., Limoyo, O., Petrovic, L., Ablett, T., Petrovic, I.,

& Kelly, J. (2019). Fast manipulability maximization

using continuous-time trajectory optimization. In

Proceedings of the 2019 IEEE/RSJ International

Conference on Intelligent Robots and Systems (IROS)

(pp. 8258–8264). IEEE.

Moriello, L., Biagiotti, L., Melchiorri, C., & Paoli, A.

(2018). Manipulating liquids with robots: A sloshing-

free solution. Control Engineering Practice, 78, 129–

141.

Muchacho, R. I. C., Laha, R., Figueredo, L. F. C., &

Haddadin, S. (2022). A solution to slosh-free robot

trajectory optimization. In Proceedings of the 2022

IEEE/RSJ International Conference on Intelligent

Robots and Systems (IROS) (pp. 223–230). IEEE.

Muller, M., Charypar, D., & Gross, M. (2003). Particle-

based fluid simulation for interactive applications. In

Proceedings of the 2003 ACM SIGGRAPH

/Eurographics Symposium on Computer Animation (pp.

154–159). ACM.

Wang, X., Li, X., Guan, Y., Song, J., & Wang, R. (2019).

Bidirectional potential guided RRT* for motion

planning. IEEE Access, 7, 95046–95057.

Yano, K., Higashikawa, S., & Terashima, K. (2001). Liquid

container transfer control on 3D transfer path by hybrid

shaped approach. In Proceedings of the 2001 IEEE

International Conference on Control Applications (pp.

1168–1173). IEEE.

Yano, K., & Terashima, K. (2001). Robust liquid container

transfer control for complete sloshing suppression.

IEEE Transactions on Control Systems Technology,

9(3), 483–493.

Yoshikawa, T. (1985). Manipulability of robotic

mechanisms. The International Journal of Robotics

Research, 4(2), 3–9.

Zhang, H., Sheng, Q., Hu, J., Sheng, X., Xiong, Z., & Zhu,

X. (2022). Cooperative transportation with mobile

manipulator: A capability map-based framework for

physical human-robot collaboration. IEEE/ASME

Transactions on Mechatronics, 27(6), 4396–4405.

APPENDIX

Only the main symbols frequently used throughout

the paper are listed here. Other symbols are defined

locally in the text.

Table A1: List of symbols.

Symbol Definition

𝑞

Joint angle vector

𝑞

Joint velocity vector

𝑥

End-effector pose

(position and orientation)

𝑥 =

𝑣

𝜔

End-effector velocity

(linear

𝑣, angular 𝜔)

𝐽

(

𝑞

)

Jacobian matrix of the

mani

p

ulato

r

𝑚(𝑞)

Manipulability index

𝜁

Deviation parameter for

flexible constraint

𝑎

(

𝑡

)

Time-varying scaling

coefficient

𝜃

Container tilt angle [rad]

𝑡,𝑡

Time, final time

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

356