Smart Optimized Scheduling Under Constraints in Industry 5.0

Through Intelligent Computational Methods

Cherifa Nakkach

1

, Wiem Abbes

1

and Yvan Picaud

2

1

Orange Innovation Tunisia, Sofrecom Tunisia, Tunis, Tunisia

2

Orange Innovation, Lannion, France

Keywords: Industry 5.0, Metaheuristic, Smart Scheduling, Raw Material Optimization, Production Planning, Additive

Manufacturing.

Abstract: Production scheduling has become an integral component of next-generation industrial systems during the era

of Industry 5.0, which emphasizes collaboration between humans and machines, sustainability, and hyper-

personalization. To address complex scheduling challenges, this paper presents a smart scheduling framework

based on metaheuristic optimization tailored for manufacturing environments incorporating 3D printing

technologies. The proposed framework addresses several key objectives, including the optimization of energy

consumption, efficient utilization of raw materials, and minimization of total production time. By

incorporating metaheuristic algorithms such as Genetic Algorithms, Particle Swarm Optimization, and Ant

Colony Optimization, the system demonstrates adaptability to multiple constraints and competing priorities.

Experimental evaluations confirm the framework’s effectiveness in enhancing operational efficiency,

flexibility, and sustainability, in alignment with the core principles of Industry 5.0.

1 INTRODUCTION

With Industry 5.0, manufacturing has entered a new

era, where humans-centric design, sustainability, and

resilience are now equally important. Instead of

focusing solely on smart automation, cyber-physical

systems, and IoT integration, Industry 5.0 promotes a

symbiotic collaboration between humans and

machines. A flexible, adaptive, and intelligent

production system is essential in this dynamic

environment to meet demand for personalization,

real-time responsiveness, environmental

responsibility, and flexibility (Ghoujdam,2024).

An important enabling technology of Industry 5.0

is 3D printing, also known as additive manufacturing

(AM) (Dehghan,2025). In addition to its ability to

allow complex geometries, material efficiency, and

minimal tooling, it also supports decentralized, on-

demand, and sustainable manufacturing. Integration

of 3D printing into broader industrial production

workflows, however, presents complex scheduling

challenges. There are numerous factors to consider,

including variable job geometry, multiple material

requirements, fluctuating energy availability, and the

need to coordinate dynamically with other production

units, including robotic arms, inspection systems, and

finishing processes. The traditional deterministic

scheduling algorithms are often inadequate in this

context since they are poorly suited to cope with

multi-objective, combinatorial, and dynamic

production in Industry 5.0 (Chen,2024).

Consequently, meta-heuristic optimization

algorithms such as Genetic Algorithms (GA), Particle

Swarm Optimization (PSO), and Ant Colony

Optimization (ACO) are often considered effective

alternatives. In NP-hard problems, these algorithms

offer near-optimal solutions within a reasonable

amount of time even if the data is incomplete or

changing. We propose an intelligent production

scheduling framework that uses metaheuristics and

artificial intelligence algorithms to intelligently

schedule 3D printer jobs in a cyber-physical

production environment. It supports the following

features:

• Optimization with multiple objectives,

including energy efficiency, material use,

and production delays.

• Interaction with operators, which allows

them to intervene or guide scheduling

decisions.

Nakkach, C., Abbes, W. and Picaud, Y.

Smart Optimized Scheduling Under Constraints in Industry 5.0 Through Intelligent Computational Methods.

DOI: 10.5220/0013748500003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 511-517

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

511

2 RELATED WORKS

In manufacturing research, particularly in Industry

4.0, the issue of production scheduling has received

considerable attention. For scheduling in static

environments, linear programming, constraint-based

optimization, and heuristic rules have long been used.

The growing complexity of modern factories,

especially those that use additive manufacturing

(AM) often makes these methods unsuitable for real-

time, multi-objective optimization. As a powerful

tool for solving complex scheduling problems,

metaheuristic algorithms have gained a lot of

attention in recent years. In industrial scheduling

problems, Genetic Algorithms (GA), Particle Swarm

Optimization (PSO), Simulated Annealing (SA), and

Ant Colony Optimization (ACO) have been used

because they are capable of escaping local optima.

Accordingly, [Zhao et al., 2021] applied PSO for

optimizing job-shop scheduling under energy

constraints, whereas [Li and Wang, 2020] used GA in

cloud-based smart factories for dynamic scheduling.

3 PROBLEM DEFINITION AND

OBJECTIVES

3.1 Problem Definition

Since 3D printers are becoming increasingly

integrated into production workflows, task

scheduling has become increasingly difficult.

Because 3D printing involves layer-by-layer

geometry, extended production times, and high

resource sensitivity - particularly filament availability

- it presents unique challenges. In addition to static

job allocation, scheduling must take into account

fluctuating material stocks, tight delivery deadlines,

and energy limitations, as well as the continuous

influx of customer orders in real-time. The majority

of existing research has focused on optimizing

makespan and minimizing resource usage in

controlled environments, often overlooking the

dynamic nature of additive manufacturing. In most

models, energy and material consumption are

assumed to be constant, disregarding geometry

complexity and machine state for their variability. It

is also rare for conventional scheduling approaches to

accommodate the need to reprioritize tasks in

response to incoming orders or real-time disruptions.

A novel scheduling framework for 3D printing

environments is presented in this paper that takes into

account raw material availability, energy constraints,

delivery deadlines, and handling of orders in real-

time. Using intelligent computational methods, we

aim to ensure both operational efficiency and

responsiveness in resilient, human-centric

manufacturing systems.

3.2 Objectives

Scheduling tasks for 3D printing is aimed at

optimizing efficiency, reliability, and quality in the

production process. In order to minimize production

times (makespan), print jobs must be ordered and

allocated effectively across available printers. To

accomplish this, machines, materials, and energy

must be utilized most efficiently, while idle time and

waste must be minimized. Moreover, meeting

deadlines and prioritizing urgent tasks are essential to

timely delivery. As well as reducing energy

consumption and optimizing material usage,

sustainability is also dependent on minimizing carbon

emissions. A scheduling system must also guarantee

a balanced workload among printers, adapt

dynamically to unexpected changes such as machine

failures or urgent jobs, and minimize setup and

transition times. Furthermore, smart scheduling

strategies contribute to a robust and efficient

workflow for 3D printing by maintaining high

product quality (Kantaros,2025).

3.3 Proposed Smart Scheduling

Solution

3.3.1 Smart Scheduling Framework

Specifically, the Smart Scheduling Framework aims

to optimize task allocation in Industry 5.0

environments through intelligent, modular systems.

Dynamically generated task schedules are generated

utilizing computational intelligence approaches such

as Ant Colony Optimization, Artificial Bee Colony,

or Discrete Particle Optimization.

Essentially, the framework consists of four

components:

Input Layer: This layer collects information about

printing jobs, materials, deadlines, machine

availability, and filament types.

Optimisation Engine: Explores scheduling solution

space using metaheuristic algorithms. In each

algorithm, delays are minimized and filament

changes are minimized.

Evaluation Module: This module provides a multi-

criteria evaluation system for assessing the quality of

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

512

the generated schedules (e.g., number of delays, total

delay, filament changes, execution time). As a result,

operational efficiency and real-time manufacturing

goals are aligned.

Decision & Execution Interface: It provides a

schedule for 3D printing, which can be re-evaluated

or re-optimized in response to unexpected events.

3.3.2 3d Printing Task Scheduler Functional

Diagram

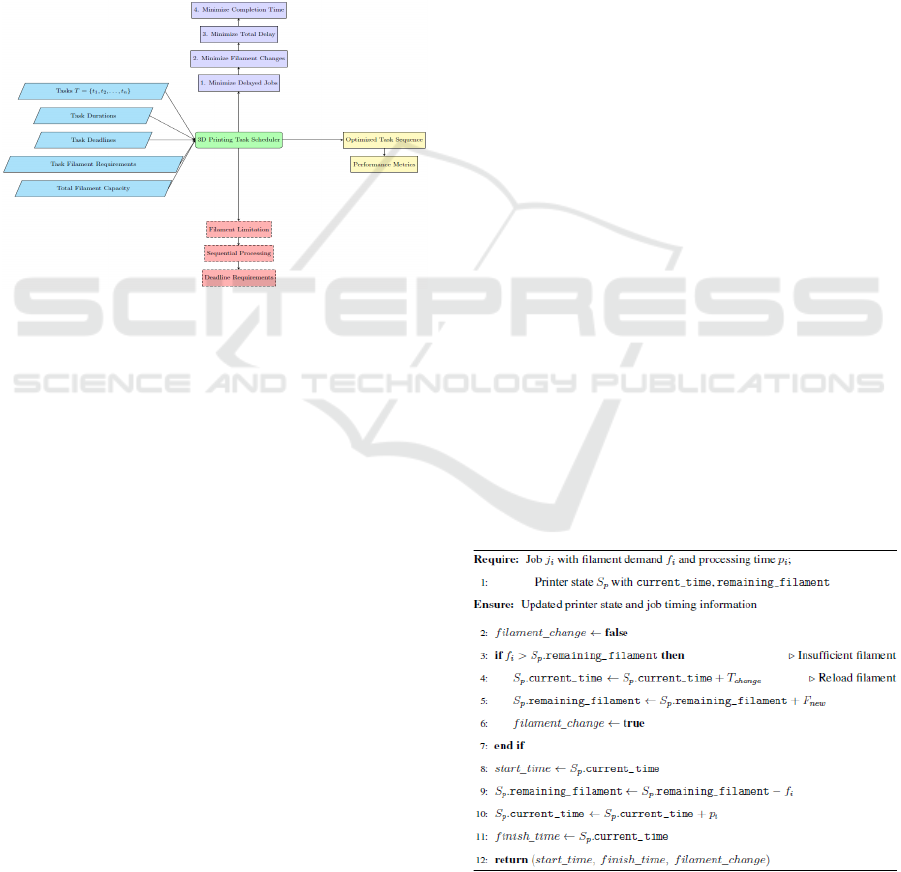

The description of 3D Printing Task Scheduler

Functional Diagram is provided in figure.1.

Figure 1: 3D Printing Task Scheduler Functional Diagram.

The diagram illustrates a multi-objective

optimization system that balances competing

priorities (speed, material efficiency, and deadline

compliance) while staying within physical and

resource constraints. In additive manufacturing, the

arrows illustrate the flow of information from inputs

through processing to final outputs.

Inputs:

Tasks T = {t₁, t₂, ..., tₙ}: Set of printing tasks to be

scheduled Task Durations: Estimated time required

for each printing task.

Task Deadlines: Delivery deadlines for each task

Task Filament Requirements: Amount of filament

material needed per task

Total Filament Capacity: Total available filament

stock/capacity

Central Processing Unit: The 3D Printing Task

Scheduler serves as the core optimization engine that

processes all input data to generate an optimal

printing schedule.

Optimization Objectives: The proposed system is

designed to simultaneously optimize four key

performance criteria that reflect both efficiency and

sustainability in modern manufacturing. First, it seeks

to minimize the overall completion time (makespan)

in order to accelerate project delivery and improve

throughput. Second, it aims to minimize the total

delay, thereby reducing cumulative lateness across all

scheduled tasks and ensuring smoother operations.

Third, the system focuses on minimizing the number

of filament changes, which not only shortens material

changeover time but also decreases material waste

and energy consumption. Finally, it strives to

minimize the number of delayed jobs, ensuring that

tasks are completed within their respective deadlines

to enhance reliability and customer satisfaction.

System Constraints:

The scheduler operates under strict limitations:

Filament Limitations:

Material availability constraints

Sequential Processing: Tasks must be processed one

at a time per printer

Deadline Requirements: Hard deadlines that must be

respected

Outputs The system generates:

Optimized Task Sequence: The optimal order for

executing printing tasks

Performance Metrics: Key performance indicators

measuring schedule effectiveness

To ensure consistency and enable fair comparisons,

all developed algorithms use a unified

implementation framework. As a result of this

standardization, all algorithms operate under the same

conditions and can be evaluated equally (Figure 2).

__________________________________________

Algorithm 1: Unified Job Processing Method.

Figure 2: Algorithm to process a job on a printer, updating

its timing and filament state.

Smart Optimized Scheduling Under Constraints in Industry 5.0 Through Intelligent Computational Methods

513

4 METAHEURISTIC

ALGORITHMS USED

4.1 Ant Colony Optimization (ACO)

An Ant Colony Optimization (ACO) algorithm is a

powerful metaheuristic algorithm that can be used to

assign print jobs to available printers with the best or

near-optimal sequence while satisfying a variety of

constraints such as time, material availability, and

energy consumption in the context of 3D printing task

scheduling. The ACO model is based on the foraging

behaviour of ants, where each node represents a

specific task or decision point (e.g., assigning a job to

a printer at a certain time). Pheromone trails (which

encode past schedule quality) and heuristic

information (such as estimate printing time) are used

to allow artificial "ants" to explore different

scheduling combinations. Pheromone levels are

updated after solutions are constructed to reinforce

the paths that lead to better performance - like

reduced total production time, balanced printer loads,

or lower energy consumption - while allowing less

effective paths to fade over time (Sarder,2023).

4.2 Particle Swarm Optimizer (PSO)

For solving optimization problems, PSO uses a

nature-inspired, population-based metaheuristic

algorithm. Using this method, animal groups such as

bird flocks or fish schools can be simulated

(Gad,2022). In PSO, each possible solution is

modeled as a moving "particle" guided by both its

own best position and the best known position found

by the swarm. Through these interactions, particles

are able to converge towards optimal or near-optimal

solutions over time. Each particle's position and

velocity are determined by equations that take into

account inertia, cognitive properties, and social

factors.

4.3 Greedy Algorithm

In Greedy Algorithm, we select the locally optimal

choice at each decision point as we build a solution

step by step (Zhao, 2021). 3D printing task

scheduling algorithms that prioritize immediate

gains, such as minimizing machine idle time or start

time, utilize greedy algorithms to assign tasks to the

earliest available slot and printer. Despite being

computationally efficient and able to produce

acceptable schedules in very short periods of time,

this method ignores the global structure of the

problem, resulting in suboptimal long-term results. It

may, for example, result in many delays or excessive

filament changes due to short-sighted decisions.

4.4 Migratory Bird Optimisation

(MBO)

Using the Migratory Bird Optimization algorithm, we

can simulate the migration behavior of migratory

birds in V-formations using a population-based

metaheuristic. This algorithm represents each

solution as a "bird" in a formation, with the best

performing solution taking the lead. To avoid

stagnation, birds periodically change positions based

on local and global neighborhood evaluations

(Wei,2023). Using MBO, scheduling problems can be

balanced between exploration and exploitation, with

the aim of finding globally efficient task sequences.

Although it avoids extremes, MBO rarely achieves

optimal performance in any single metric: in practice,

it tends to yield average results across all metrics.

4.5 Discrete Particle Optimisation

(DPO)

Particle Swarm Optimization (PSO) is adapted for

discrete and combinatorial problems, such as task

scheduling, by Discrete Particle Optimization (DPO)

(Franzoi,2022). Each particle represents a possible

sequence or configuration of scheduled tasks, with

the particle's movement determined by discrete

operators (e.g., swap, insertion) instead of continuous

velocity updates. Using both personal (personal best)

and collective (global best) experiences, DPO guides

the search for optimal outcomes. While DPO has an

intelligent search mechanism, it may suffer from

premature convergence or reduced diversity in

discrete spaces, reducing its effectiveness when

scheduling scenarios are highly constrained. We

found that DPO generated a relatively high number of

delayed tasks and a high total delay in our

experiments, showing that it had difficulty optimizing

task sequences under practical constraints.

5 RESULTS AND DISCUSSION

As part of this study, we utilized the Raise3D Pro2

(figure 3), a high-performance Fused Deposition

Modeling (FDM) 3D printer that was well-suited for

industrial-grade applications. Dual extrusions allow

the printer to print multi-materials or colors, which

introduces an additional level of complexity in

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

514

scheduling tasks. A 305 mm x 305 mm x 300 mm

build volume allows for the printing of medium to

large-sized parts that often require lengthy print

times. In addition to standard 0.4 mm nozzles, a range

of diameters can be selected based on the throughput

required. A wide range of filament types can be used

with Raise3D Pro2, including PLA, ABS, PETG,

TPU, and Nylon, each of which has its own thermal

and handling parameters. It also features a filament

run-out detection system and power loss recovery,

which enhance the reliability and resilience of the

production workflow. A heated bed and enclosed

build chamber ensure better print stability, but they

also add energy consumption constraints. The

printer's integrated touchscreen interface, remote

monitoring capabilities, and network and cloud

connectivity enable it to communicate with centrally

managed or artificially intelligent scheduling

systems.

Figure 3: Raise3D Pro2 printer.

5.1 Evaluation of Metaheuristics for 3D

Printing Task Scheduling

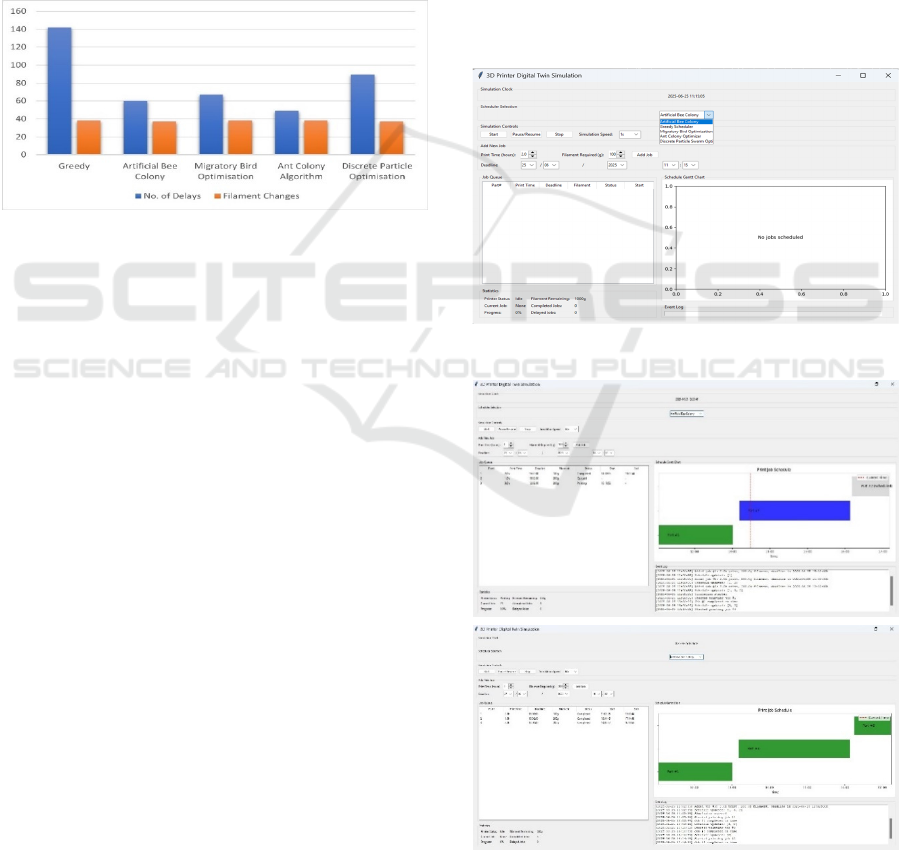

As part of the evaluation of metaheuristic algorithms

for 3D printing task scheduling, a number of key

performance metrics were considered to assess both

the quality and applicability of the solutions. The key

metrics for our framework are filament changes, total

delay, and execution time. Delays indicate the

system's ability to respect timing constraints, an

essential factor in high-speed production.

Furthermore, the total delay provides a deeper

understanding of the extent of disruptions, even when

the number of delays remains low. Material

efficiency and machine downtime are also affected by

the number of filament changes, which lead to higher

operational costs and reduced printer availability. As

a final consideration, the algorithm's execution time

determines its suitability for real-time or near-real-

time scheduling, particularly in Industry 5.0

environments. We gain a comprehensive view of each

algorithm’s performance by analyzing these metrics

together: some methods reduce total delay but

produce excessive filament changes or compute too

slowly, while others balance speed, precision, and

resource efficiency better. Through table 1 and table

2, we ensure that both technical constraints and

industrial objectives are aligned with the scheduling

strategy chosen.

Table 1: Evaluation of metaheuristics for 3d printing task

scheduling.

Algorithm No. of

Delays

Number

of

Filament

Changes

Total Delay

(s)

Execution

Time (s)

Greedy 142 38 184,579.709 13,846.793

Artificial

Bee Colony

60 37 307,032.071 13,816.793

Migratory

Bird

Optimisation

67 38 434,737.523 13,846.793

Ant Colony

Algorithm

49 38 249,998.075 13,846.793

Discrete

Particle

Optimisation

89 37 467,556.575 13,816.793

Table 2: Summary Analysis.

Al

g

orith

m

Summar

y

Anal

y

sis

Greedy Lowest total delay, but too many

individual delays

Artificial Bee

Colon

y

Good trade-off: fast, few delays

Migratory Bird

Optimisation

Average performance, not optimal in

any specific criterion

Ant Colony

Al

g

orith

m

Best overall compromise

Discrete Particle

Optimisation

Globally inefficient despite good

execution time

5.2 Discussion

Based on the comparability of the five algorithms,

distinct performance characteristics can be identified

in terms of scheduling efficiency, resource

optimization, and execution time. It is clear from the

Greedy algorithm's results (184,579.709) that it

successfully prioritizes task allocation in the short

run. Despite this, it exhibits a very high number of

individual delays (142), indicating poor robustness in

situations with tight deadlines. Compared to other

algorithms, the Artificial Bee Colony (ABC) has

relatively few delays (60) and the shortest execution

time (13,816.793), making it an ideal choice for real-

Smart Optimized Scheduling Under Constraints in Industry 5.0 Through Intelligent Computational Methods

515

time or near-real-time scheduling in Industry 5.0. The

slightly higher total delay (307,032.071) can be

attributed to the algorithm's efficiency. There is no

clear advantage in any of the metrics in the Migratory

Bird Optimization (MBO) algorithm. There is a

possibility that its lack of specialization could limit its

applicability in situations where specific performance

objectives are important (e.g., minimizing delays or

changing resource allocations). In terms of global

efficiency, the Ant Colony Algorithm (ACO) stands

out as the most balanced approach. Providing the best

overall balance between delay minimization and

stability, it has the least number of delays (49) and a

moderate total delay (249,998.075).

Figure 4: Results of metaheuristic Algorithms.

Thus, it is a good candidate for scheduling systems

that are adaptive and dynamic in smart

manufacturing. As a result, Discrete Particle

Optimization (DPSO), though slightly faster in

execution, exhibits a relatively high number of delays

(89) and a higher total delay (467,556.575). Despite

its speed, it cannot optimize task sequencing

effectively, making it less practical for industrial

applications requiring quality and timeliness. As a

result, the Ant Colony Algorithm is the most robust

and consistent approach, followed by the Artificial

Bee Colony algorithm, which offers good speed-to-

effectiveness tradeoffs. In general, the Greedy and

DPSO methods are unreliable. Figure 4 shows these

results.

5.3 Results

An overview of the 3D printing job schedule is

provided by a Gantt chart, which makes it easy to see

which jobs are running, waiting, or finished, and how

resources are allocated. The use of this type of

visualization helps production managers optimize

printer utilization, minimize idle time, and meet

deadlines by adjusting job sequences accordingly. A

gantt chart in 3D printing scheduling offers several

key features that enhance management and planning.

Their timelines provide a clear picture of when each

job begins and ends. Additionally, they help to

understand task relationships and potential conflicts

by displaying work dependencies and overlaps. In

addition to highlighting current progress and resource

usage, Gantt charts facilitate effective monitoring of

ongoing jobs. Using this visualization, planners can

identify bottlenecks or scheduling conflicts quickly

and make interactive adjustments, making it easier to

improve efficiency and meet deadlines. Each green

bar represents a print job in a horizontal Gantt chart

labeled "Print Job Schedule." Each bar corresponds to

the job's start and end times on the timeline below,

visually identifying when each job begins and ends

(Figure 5 and figure 6). Using the chart, you can see

how jobs overlap or are sequenced, providing a clear

view of the schedule. Users can also track progress in

real time by using a "Current Time" marker.

Figure 5: Scheduling interface for 3D printing tasks.

Figure 6: Gantt chart-based scheduling interface for 3D

printing tasks.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

516

6 CONCLUSIONS

This study evaluated and compared several

metaheuristic algorithms (greedy, artificial bee

colony, migratory bird optimization, ant colony

algorithm, and discrete particle optimization) for the

complex task of scheduling 3D printing operations.

Our evaluation relied on four critical performance

metrics: number of delays, filament changes, total

delay, and execution time. The results demonstrate

that no single algorithm excels in all aspects,

highlighting the trade-offs between speed, accuracy,

and operational efficiency.

Overall, these findings emphasize the importance

of multi-criteria evaluation when selecting a

scheduling strategy for industry 5.0 systems, where

real-time responsiveness, material efficiency, and

reliability are key. Future work may explore hybrid

metaheuristics, reinforcement learning, or adaptive

scheduling frameworks that can dynamically respond

to changing constraints and workload priorities in

cyber-physical environments. As a perspective for

this work, Artificial Intelligence (AI) will play a

strong role in enhancing our system. AI techniques

can be integrated to model and optimize energy

consumption (Nakkach, 2023), (Nakkach, 2024)

enabling more sustainable and efficient production

planning. Moreover, predictive maintenance based on

computer vision and deep learning (Nakkach, 2022)

can be employed to detect early signs of wear,

anomalies, or defects in machines and 3D-printed

parts. Such capabilities will help anticipate failures,

minimize downtime, and improve overall system

reliability. Together, these AI-driven approaches will

reinforce the adaptability, efficiency, and

sustainability of cyber-physical production

environments in line with the vision of Industry 5.0.

REFERENCES

Chen, Shu-Chuan, et al. "Multi-Objective Optimization in

Industry 5.0: Human-Centric AI Integration for

Sustainable and Intelligent Manufacturing." Processes

12.12 (2024): 2723.

Dehghan, Shayan, et al. "The Integration of Additive

Manufacturing into Industry 4.0 and Industry 5.0: A

Bibliometric Analysis (Trends, Opportunities, and

Challenges)." Machines, 13.1 (2025): 62.

Franzoi, Robert E., and Brenno C. Menezes. "Large-Scale

Discrete-Time Scheduling Optimization: Industrial-

Size Applications." IFAC-PapersOnLine, 55.10

(2022): 2581-2586.

Gad, Ahmed G. "Particle swarm optimization algorithm

and its applications: a systematic review." Archives of

computational methods in engineering 29.5 (2022):

2531-2561.

Ghoujdam, Mousaab El Khair, et al. "Exploring the

Technologies of Industry 5.0, Benefits and

Applications: A Systematic Review." Industry 5.0 and

Emerging Technologies: Transformation Through

Technology and Innovations (2024): 23-37.

Kantaros, Antreas, et al. "The Role of 3D Printing in

Advancing Automated Manufacturing Systems:

Opportunities and Challenges." Automation 6.2 (2025):

21.

Kim, Kyeongho, Soonjo Kwon, and Minjoo Choi.

"Optimization of Production Scheduling for the

Additive Manufacturing of Ship Models Using a

Hybrid Method." Journal of Marine Science and

Engineering 12.11 (2024): 1961.

Nakkach, Cherifa, Amira Zrelli, and Tahar Ezzdine. "An

efficient approach of vehicle detection based on deep

learning algorithms and wireless sensors networks."

International Journal of Software Innovation (IJSI) 10.1

(2022): 1-16.

Nakkach, Cherifa, Amira Zrelli, and Tahar Ezzedine.

"Long-Term Energy Forecasting System Based on

LSTM and Deep Extreme Machine Learning."

Intelligent Automation & Soft Computing 37.1 (2023).

Nakkach, Cherifa, and Yvan Picaud. "AI-Driven Smart Air

Conditioning System for a Sustainable and Energy-

Efficient Industrial Future." International Conference

on Innovative Intelligent Industrial Production and

Logistics. Cham: Springer Nature Switzerland, 2024.

Sardar, Abdullah, et al. "Optimization of daily operations in

the marine industry using ant colony optimization

(ACO)-An artificial intelligence (AI) approach."

TransNav, International Journal on Marine Navigation

and Safety of Sea Transportation, 17.2 (2023): 289-

295.

Wei, Lixin, et al. "A multi-objective migrating birds

optimization algorithm based on game theory for

dynamic flexible job shop scheduling problem." Expert

Systems with Applications, 227 (2023): 120268.

Zhao, ZiYan, MengChu Zhou, and ShiXin Liu. "Iterated

greedy algorithms for flow-shop scheduling problems:

A tutorial." IEEE Transactions on Automation Science

and Engineering 19.3 (2021): 1941-1959.

Smart Optimized Scheduling Under Constraints in Industry 5.0 Through Intelligent Computational Methods

517