Automated Process Control for the Beam Gas Curtain Vacuum

System at CERN

L. Cantu, R. Ferreira, J. Francisco Rebelo, A. Rocha, C. Vazquez Pelaez and L. Zygaropoulos

CERN, European Organisation for Nuclear Research, 1211 Meyrin, Switzerland

Keywords: Vacuum Control Systems, Process Automation, Machine Safety, SCADA Interface, Staged Commissioning,

Validation.

Abstract: The Beam Gas Curtain (BGC) system is a key diagnostic instrument for non-invasive proton beam profiling

in the Large Hadron Collider (LHC), relying on precise and safe gas injection into the beam pipe. Initially

operated via manual procedures through a supervisory control and data acquisition (SCADA) interface, BGC

injections required expert users, were time consuming and vulnerable to human error. This paper presents the

design and implementation of an automated gas injection control system, fully integrated within the LHC

Vacuum Control System SCADA and using Vacuum Framework. The solution includes a finite state machine

(FSM) deployed on a programmable logic controller (PLC), a new state-aware SCADA interface, and a

comprehensive interlock strategy combining device-level and process-level safety. The system was

extensively tested using simulations and staged commissioning, culminating in a successful deployment

during the LHC Year-End Technical Stop (YETS) 2024/25. Automation has drastically simplified operations,

increased reliability, and enhanced machine safety, requiring only two user actions to initiate an injection.

1 INTRODUCTION

The Beam Gas Curtain (BGC) is a promising

diagnostic tool for the High-Luminosity upgrade of

the LHC, providing non-invasive, high-resolution

profiling of the proton beam. Installed at Point 4 of

the LHC, it relies on the interaction between a

supersonic gas jet and the particle beam to create

fluorescence, enabling accurate 2D beam profile

imaging (Salehilashkajani et al., 2022).

The BGC operates by expanding high-pressure

gas through a specially designed nozzle (Tzoganis &

Welsch, 2013) into what is known as the injection

chamber, where the gas jet is shaped by a series of

three skimmers. The gas curtain, which is tilted 45

degrees relative to the horizontal plane, then

intersects the particle beam.

Finally, the curtain continues toward a dump

chamber where the gas is evacuated and a last

skimmer is used to not permit gas to reenter the

interaction chamber (Sequeiro et al., 2024).

The BGC was initially installed in the LHC during

YETS 2022/23 with dedicated vacuum equipment

and a manually operated control system. This paper

will describe the vacuum control system currently

used for BGC operation, which has enabled automatic

gas injection with only two user actions.

2 BGC LAYOUT AND CONTROLS

2.1 Vacuum Equipment

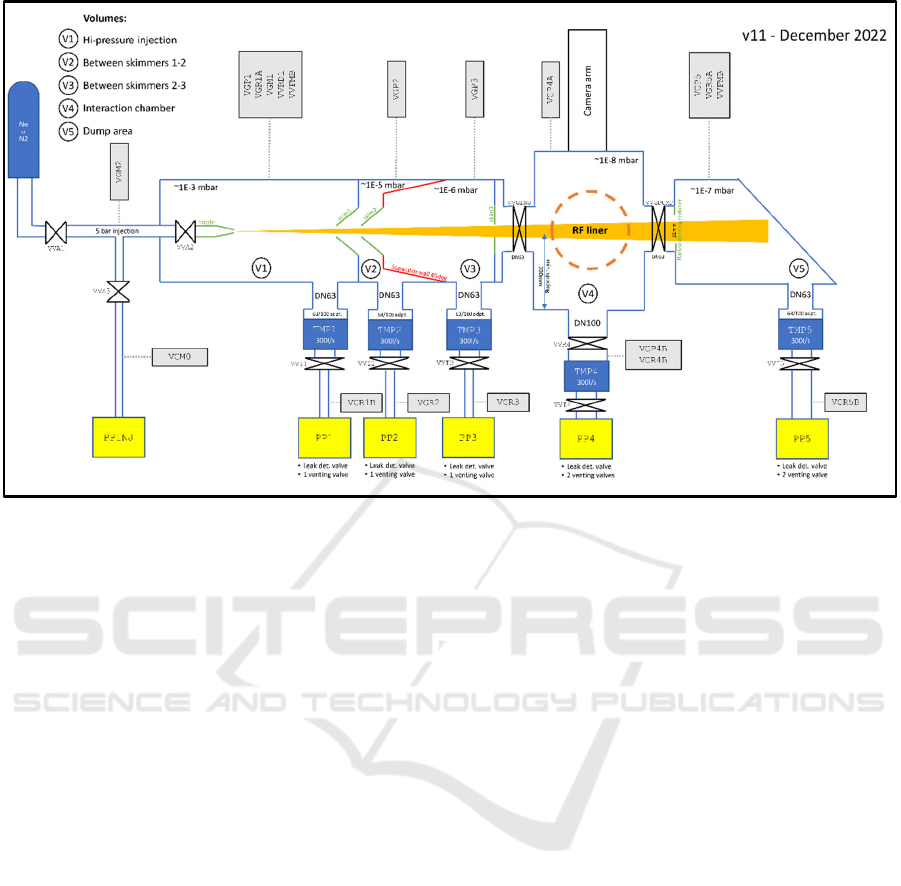

In Figure 1 we can see the layout of the BGC vacuum

system. A core element is the set of five fixed

pumping groups, each composed of a primary (PP1 to

PP5) and a turbomolecular pump (TMP1 to TMP5).

Three gate valves (VVGINJ, VVGDUMP and

VVR4) have the important functionality of isolating

the interaction chamber from the other chambers of

the BGC instrument and from the dedicated pumping

group. The injection line that supplies the BGC with

gas houses three injection valves (VVA1, VVA2 and

VVA3) used to start the gas injection. A primary

pump (PPINJ) is used to pump the gas remaining in

the nozzle after injections using the injection line.

Pressure throughout the volumes and the pumping

groups is monitored using piezoelectric (VGM0,

VGM1, VGM2), Pirani (VGR1A, VGR1B, VGR2,

VGR3, VGR4B, VGR5A and VGR5B) and Penning

282

Cantu, L., Ferreira, R., Rebelo, J. F., Rocha, A., Pelaez, C. V. and Zygaropoulos, L.

Automated Process Control for the Beam Gas Curtain Vacuum System at CERN.

DOI: 10.5220/0013744900003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 282-289

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

Figure 1: Layout of the BGC Vacuum System (Ady & Sequeiro, 2022).

(VGP1, VGP2, VGP3, VGP4A, VGP4B, VGP5)

gauges. In addition, the injection line is equipped with

two pressure transmitters (VGA1 and VGA2) to

monitor the pressure of the gas to be injected.

2.2 Vacuum Framework

The control of the BGC equipment is implemented

using the CERN Vacuum Framework, which consists

of a library of baseline PLC functions implemented

using structured text, common SCADA panels,

control scripts and files, ORACLE databases to store

device data, and vacCC, an application which allows

users to modify vacuum devices via a web browser

and which automatically generates SCADA and PLC

configuration files (Rocha et al., 2019). The

framework is essential to enable the configuration,

maintenance and operation of the very large

distributed vacuum control systems at CERN

(Antoniotti et al., 2014). Each vacuum device in the

framework is instantiated from what is known as a

control type, within which everything needed to

manage the equipment is defined.

Vacuum framework devices can be operated

either in automatic or manual mode. When the

equipment is in manual mode it can only receive

manual commands from users operating the SCADA,

whilst when in automatic mode the device is under

the control of an automatic process in the PLC. Only

operators with high enough permissions can swap

devices between automatic and manual modes.

Normal users can generally not manually operate a

device which is being controlled by a process.

2.3 Control System

The control system developed for the BGC consists

of six PLCs. Each of the five pumping groups is

controlled by a dedicated PLC (Simatic S7-1200), as

they are implemented using the standard solution for

fixed vacuum pumping groups on the LHC developed

at CERN (Ferreira et al., 2016). Finally, a sixth

controller is used to handle the rest of the equipment

as the main PLC of the BGC control system.

All Pirani and Penning gauges are managed by

dedicated controllers (Pfeiffer TPG300), which

interface with the PLCs through Profibus. The

piezoelectric gauges are connected to a standard

controller for LHC piezoelectric gauges developed at

CERN (Chatzigeorgiou & Kuhn, 2024), from which

the main PLC acquires pressure values through 0-10V

signals.

Finally, the pressure transmitters, gate valves and

injection valves are all controlled through the main

PLC I/O (Zygaropoulos, 2022).

2.4 Machine Safety

Given that the BGC injects gas directly into the LHC

beam pipe close to crucial and sensitive equipment

Automated Process Control for the Beam Gas Curtain Vacuum System at CERN

283

such as the radio frequency cavities that accelerate the

particle beam, machine safety must be a critical part

of the control system design, both at the hardware and

software levels.

2.4.1 Control Hardware Safety

Considerations

At the hardware level, all PLCs and equipment

controllers are connected to a UPS, meaning that if a

power loss is experienced during gas injection, the

injection and gate valves can still be operated and the

pressure in the chambers can still be monitored.

Pumping group devices, though, are powered

locally in the LHC tunnel to adhere to the standard

LHC fixed pumping group control architecture

(Ferreira et al., 2016) (as normally pumping groups

are placed very distant from the control rack location

and would experience too large a voltage drop),

meaning that in the case of power loss, they are not

connected to backup power (as UPS connections are

not available in the LHC tunnel).

The standard hardware that controls vacuum

pumping groups at CERN is designed to vent both the

turbo-molecular and primary pump of a pumping

group after a power loss using a charged capacitor

(Zygaropoulos & Wickham, 2024).

The BGC is the only case in the LHC where the

following two types of pumping group configurations

are found: pumping groups without isolating valves,

and a pumping group with a turbo-molecular pump

equipped with a venting valve. These configurations

have fewer intermediate valves directly controlled by

the pumping group between the beam pipe and

venting points.

It was decided, therefore, to remove the automatic

venting functionality, as it is of the utmost importance

to minimize any possible risk of venting the beam

pipe.

The compressed air lines that supply the pumping

group, injection and gate valves are provided with

reservoirs. If there is a loss of both the compressed air

and the reservoir, the gate valves will not close

automatically as they are bistable, but the injection

valves will close automatically, avoiding the risk of

continued injection.

2.4.2 Device Interlocks

Software interlocks, called device interlocks in this

context, are also used in this system to ensure the

machine safety of the LHC. Device interlocks are

separated in two categories:

Start interlocks, which permit or not, a valve to

open or a pumping group to start but will not

close or stop them if open or running.

Full interlocks, which do not allow a valve to

open or a pumping group to start and will close

or stop them if open or running.

Given the critical nature of the BGC, when

operating the instrument manually, devices which

have been interlocked must be manually reset through

the SCADA after the underlying interlock condition

has been cleared. This is required in order to re-

acquire control of the equipment and resume normal

operation.

Table 1: Start interlock conditions for each device.

Device Start Interlock conditions

VVGINJ and

VVGDUMP

• All pumping groups must be

in nominal state

• All Penning gauges must be

on and not in error

• Pressure thresholds on all

Penning gauges

Pumping

Group VVIs

• The pumping group Pirani

gauge must be on and not in

error

• Pressure threshold on the

pumping group Pirani gauge

• VGR1A must be on and not

in error

• VGR1A pressure must be

50x greater than the pumping

group Pirani gauge’s

Pumping

Group

Processes

• Adjacent Gate and/or

Injection valve/s closed, not

in error and not in warnin

g

The start interlocks listed in Table 1 serve several

protective functions for the BGC. On VVGINJ and

VVGDUMP, they ensure that these valves can only

open when the injection and dump vacuum chambers

are under nominal vacuum conditions. For the VVIs

of the pumping groups, the interlocks prevent

potential backflow of oil from the primary pumps into

the BGC chambers or the LHC beam pipe by ensuring

that the valves can only be opened when the pressure

differential between the injection chamber and the

primary pump volume is high enough. Finally, the

interlocks associated with the pumping group

processes ensure that these groups can only start

pumping when the chamber they are connected to is

properly isolated.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

284

Table 2: Full interlock conditions for each device.

Device Full Interlock conditions

VVGINJ and

VVGDUMP

• All pumping groups must

be in nominal state and not

in error

• All Penning gauges must be

on and not in error (except

VPG1, not on during

injection)

• Pressure thresholds on all

Penning gauges (except

VPG1)

Dump

Pumping

Group Turbo

Ventin

g

Valve

• VVGDUMP closed, not in

error and not in warning

VVA1

• VVA3 closed, not in error

and not in warnin

g

VVA3

• VVA1 closed, not in error

and not in warning

PPINJ

• All injection valves not in

error and not in warning

The full interlocks listed in Table 2 provide

additional protection for the BGC system. On

VVGINJ and VVGDUMP, they act on valve

operation if pressures in the injection or dump

chambers are too high, or if a pumping group fails,

thereby safeguarding the beam vacuum. The full

interlock on the turbo venting valve of the dump

chamber pumping group ensures the beam pipe

cannot be accidentally vented by venting the pumping

group with VVGDUMP open. The full interlocks on

VVA1 and VVA3 protect the neon gas bottle from

being accidentally emptied through PPINJ. Finally,

the protection on PPINJ itself blocks pumping from

the injection line when faults are detected in one or

more injection valves.

The statuses used in the interlock logic that need

to be exchanged between the main and pumping

group controllers (pump nominal and error status, the

start interlock on the intermediate valve and the start

interlock on the pumping process) are transmitted via

hard-wired signals.

2.5 Operation and Limitations

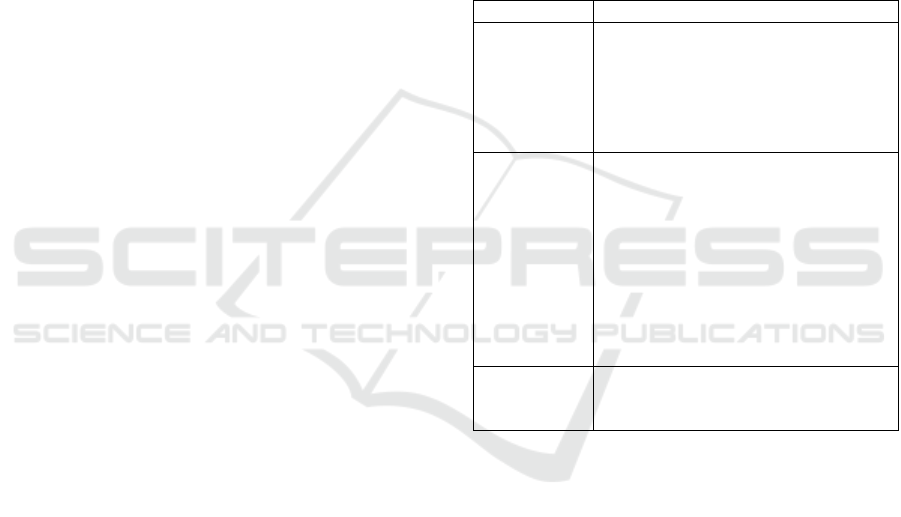

Initially, when a gas injection was required, the BGC

vacuum system was operated manually by sending

separate commands to each device following a

written procedure with great care, whilst also

monitoring pressures and the status of the system as a

whole. A schematic representation of the actions that

users would have to follow to start an injection can be

seen in Figure 2.

Figure 2: Manual actions needed for injection.

As a result, only expert users with a high level of

familiarity with the system were allowed to start an

injection.

The complicated nature of the procedure meant

that the system was prone to human errors and that

starting the injection took a lot of attention and work.

To make the whole process more reliable,

efficient and accessible for new users, it was proposed

to develop a system that could automatically handle

the gas injection.

3 AUTOMATION OF THE GAS

INJECTION

The objective of the automated control system is to

execute the gas injection sequence described in

Section 2.5, as well as returning the instrument to its

initial stand-by state following an injection. In

addition, the process must be able to recover from

equipment failures and react to detected risks to the

LHC beam pipe (such as detected high pressures),

returning the instrument to the safest possible

conditions. Furthermore, the control system must

prioritise machine safety, ensure reliability and

reduce operational time and user effort.

3.1 Implementation of the Automatic

Injection Process

Process Control with Vacuum Framework is achieved

by creating a new, instantiable, control type, which will

take control of all required equipment instances

according to the desired logic. The automated control

Automated Process Control for the Beam Gas Curtain Vacuum System at CERN

285

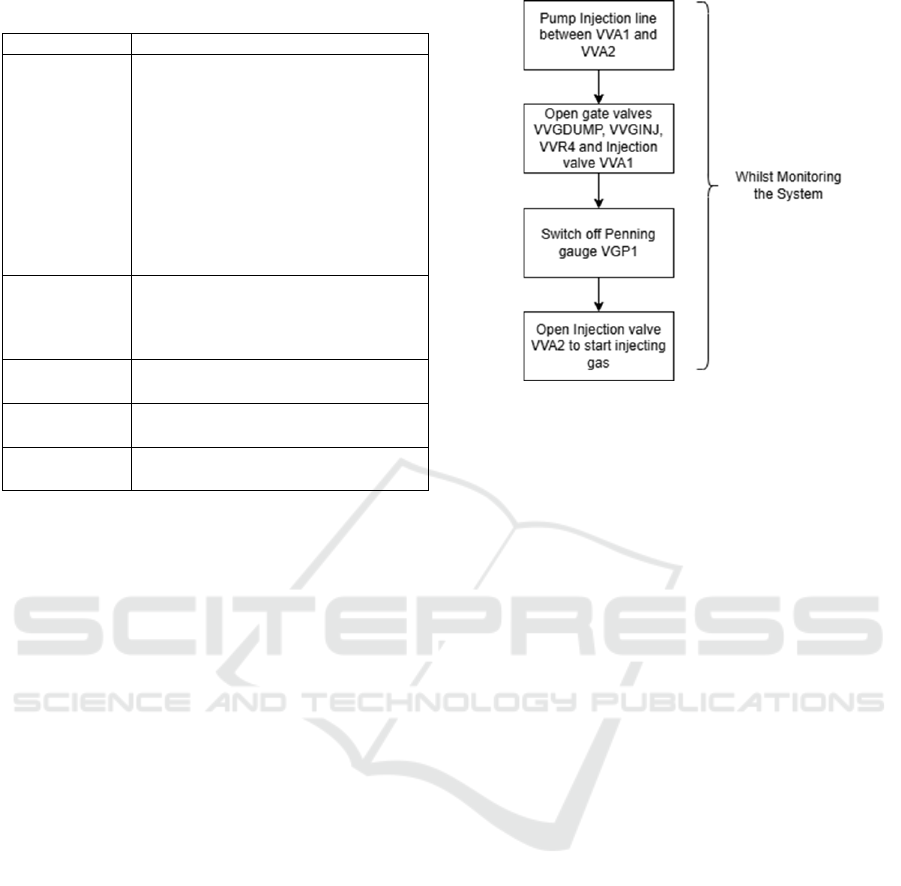

logic is implemented as a finite state machine (FSM)

in the main PLC. All BGC devices that are part of the

automatic injection scope are forced to automatic mode

and are sent automatic commands by the process.

The status of the instrument during the automatic

injection is monitored by process interlocks (which

will be described in a later section).

The FSM states correspond to the stages of the

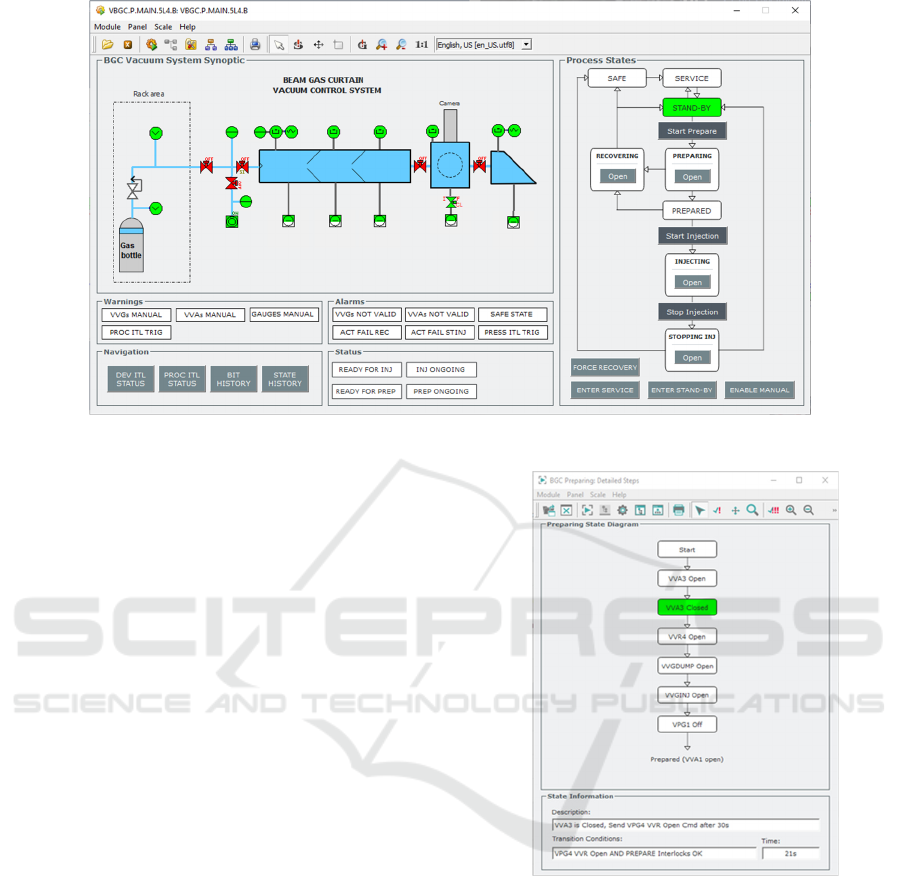

injection cycle and can be seen in Figure 3. The

functions of these states are described below:

Figure 3: Automated injection FSM.

Stand-by: Default operational state (when not

injecting) where all valves are forced closed.

Awaits a “Prepare” command to proceed.

Preparing: Injection line is evacuated with

PPINJ, gate valves are opened, Penning gauge

VPG1 is turned off, VVA1 is opened.

Prepared: System is ready for injection. If

“Start Injection” command is not issued within

10 minutes, returns to Stand-by automatically

through Recovery.

Injection: VVA2 opens to inject the gas curtain.

Stops on user command or automatically after

20 hours, transitioning to Stopping Injection. If

process conditions are breached or an actuator

failure is detected, also transitions to Stopping

Injection.

Stopping Injection: All valves close, injection

line is pumped, VPG1 is reactivated. Returns to

Stand-by if successful, or to Safe if the process

conditions were breached or an actuator failure

was detected.

Recovery: Triggered if process conditions are

breached or an actuator failure is detected

during Preparing or Prepared. Actuators are

driven to safe positions before moving to Safe.

Safe: All actuators are forced to their safest

state. Can only be exited by a vacuum expert.

Default state on PLC startup.

Service: Expert-only state for manual control

and maintenance. No automatic commands are

sent to the devices.

Whilst the injection is exclusively performed

using the automatic process described above, experts

also have the option to activate manual control

through a specific command. This will allow them to

individually set devices to manual mode and perform

manual operations. Manual control is mostly used

whilst the instrument is in the Service state for

operations such as leak detections.

3.2 Process Interlocks and State-Based

Safety

Failures or hazards during the automatic injection are

detected by using process interlocks. Process

interlocks are conditions applied to the states of the

process. If the conditions are not met, the process will

either not be able to start or will move from the

current state to the Safe state in a controlled manner.

As the vacuum levels and equipment states in the

BGC chambers will differ based on the operational

state of the instrument, different sets of process

interlocks exist:

Start Process Interlocks: act during the Stand-

by state of the process and, if not satisfied, do

not allow the process to move to the preparing

state.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

286

Figure 4: New BGC User Interface

Prepare Process Interlocks: act during the

Preparing and Prepared states and, if not

satisfied, move the process to the Recovery

state and then to the Safe state.

Injection Process Interlocks: act during the

Injecting state and if not satisfied, move the

process to the Stopping Injection state and then

to the Safe state.

The process interlocks are calculated based on a

set of pressure values and device statuses.

The device interlocks described in section 2.4.2

are still active even during the automatic injection,

protecting the integrity of the beam vacuum by acting

on individual devices, whilst process interlocks

protect the overall procedure.

3.3 New User Interface

For users to send the needed commands and to

monitor the system in the context of the automatic

injection, a new user interface was developed, which

can be seen in Figure 4.

On the right side of the main panel, the FSM for

the automatic injection can easily be monitored and

commands can be sent, with only two button presses

needed to start a gas injection. Some of the states

shown in the “Process States” box on the SCADA

main screen have internal steps that can be viewed in

the detailed steps panels such as the one shown in

Figure 5.

Figure 5: Preparing state detailed panel.

Various statuses, warnings and alarms are also

visible on the UI. Particularly important are the

alarms, which are configured to send an SMS

notification to predetermined vacuum experts when

triggered, so that action can be taken promptly.

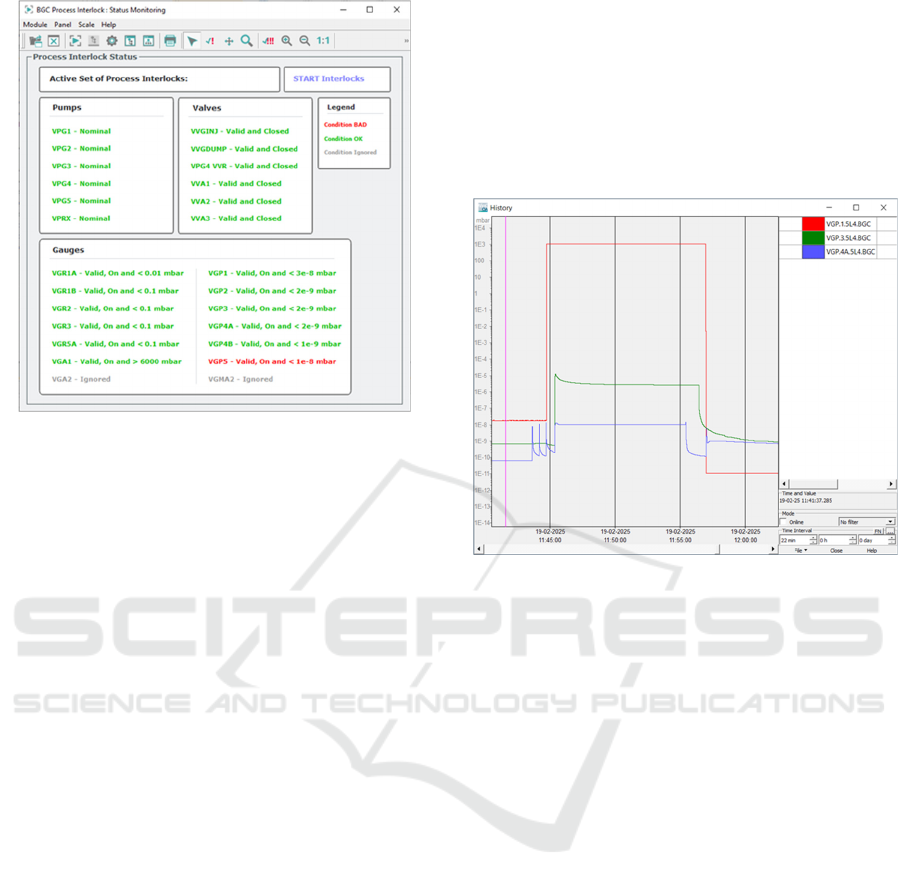

Panels to monitor the status of both process

(Figure 6) and device interlocks are also available and

can be very useful for the users to better understand

what may be blocking the gas injection.

Automated Process Control for the Beam Gas Curtain Vacuum System at CERN

287

Figure 6: Process interlocks details panel.

3.4 Testing and Installation

A testing checklist was produced after identifying all

potential failures and hazardous conditions the

process needed to handle, as well as the general

functionalities required for automatic injection.

The checklist was used to thoroughly test the full

control chain by running the code on a virtual PLC

using the Siemens PLCSim Advanced software

(Siemens, 2022) connected to a local SCADA

instance. All the controlled devices were simulated

within the PLC by writing custom code.

The installation and commissioning of the new

control process along with the newly developed

control crate for the main PLC took place during

YETS 2024/25 in three stages of commissioning:

1. Device consistency across the whole control

chain was ensured, from SCADA to

hardware, by individually actuating each

device and monitoring its actual status on the

field.

2. All device interlocks were validated by

manually triggering each condition using

simulators and jump wires, ensuring the

control system responded correctly. These

simulators mimicked the behaviour of real

components (e.g., specific resistance for

Penning gauges, relay actuation for valves)

and were used throughout the testing

process.

3. The full functionality of the automatic

injection was tested in three stages:

a. Process tests with simulators connected

to all valves.

b. Process tests with simulators connected

to gate valves only (injecting gas only in

the injection chamber).

c. Process tests injecting directly in the

LHC beam pipe with vacuum sector

valves closed (Penning gauge pressures

demonstrating a successful injection are

shown in Figure 7).

Figure 7: Penning gauge pressures during test injection in

the LHC beam pipe (1E3 mbar value indicates the Penning

gauge is off).

The different features introduced with the

automated injection were tested by manually

introducing failures and checking that the instrument

recovered as expected. This was achieved by using

simulators to trigger process interlocks such as high

pressures in some of the gauges and incorrect valve

positions or error statuses.

Commissioning reports documenting the results

of all performed tests were produced, uploaded to

CERN’s internal repository, and are readily available

for consultation (Cantu, 2025).

The new injection control system was

successfully handed over for operations to the Beam

Instrumentation group at CERN together with a user

manual containing all necessary information (Cantu,

2024).

4 CONCLUSIONS

The development and deployment of the automated

vacuum control system for the BGC marks a

significant advancement in its safe and reliable

operation. The initial manually operated system,

while functional, was labour-intensive, prone to

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

288

human error due to its complexity and difficult for

new users to become familiarised with. By applying

industrial automation principles, the injection process

has been transformed into a robust, streamlined

procedure requiring minimal user intervention.

The use of a PLC-based finite state machine,

tightly integrated with CERN’s Vacuum Framework

and supervised via a purpose-built user interface,

ensures consistent and reproducible operation.

Device and process-level interlocks provide a dual

layer of protection, safeguarding the accelerator

infrastructure and the injection process itself. The

thorough validation strategy, including simulated

fault scenarios and staged commissioning, has

demonstrated the system’s capacity to handle

operational anomalies gracefully and has been fully

documented with commissioning and testing reports.

Following deployment during YETS 2024/25, the

system was handed over to the Beam Instrumentation

group for routine use. Users have reported that the

system significantly reduces operational complexity,

improves reliability and saves time. Positive feedback

has highlighted the clarity of the user interface, the

robustness of the automation, and the reduction in

manual interventions required to perform an

injection.

REFERENCES

Ady, M., & Sequeiro, C. C. (2022, December). BGC

schematics for discussion. In EDMS.

https://edms.cern.ch/document/2489128/1

Antoniotti, F., Kopylov, L., Mikheev, M., Gomes, P.,

Boccioli, M., Merker, S., Blanchard, S., & Pereira, H.

(2014). Developments on the SCADA of CERN

Accelerators Vacuum. In 14th International

Conference on Accelerator & Large Experimental

Physics Control Systems. https://cds.cern.ch/

record/1977437

Cantu, L. (2024). BGC Automated Process User Manual. In

EDMS. https://edms.cern.ch/document/2757469/5

Cantu, L. (2025). BGC Automated process testing and

installation. In EDMS. https://edms.cern.ch/

document/3174228/1

Chatzigeorgiou, N., & Kuhn, J. (2024, April). EDA-04939-

V1-0 v.0: Piezo Gauge Controller Crate. In EDMS.

https://edms.cern.ch/item/EDA-04939-V1-0/0

Ferreira, R., Blanchard, S., Pigny, G., Vestergard, H., &

Gomes, P. (2016). Consolidation of the controls for

turbo-molecular pumping groups at CERN's particle

accelerator complex. In 24th Mediterranean

Conference on Control and Automation (MED),

Athens, Greece, 2016, 961-966, doi: 10.1109/

MED.2016.7535968.

Rocha, A., Amador, I., Blanchard, S., Fraga, J., Gomes, P.,

Pigny, G., Poulopoulou, P., & Lima, C. (2019).

Vacuum Controls Configurator: a web based

configuration tool for large scale vacuum control

systems. In 17th Int. Conf. on Acc. and Large Exp.

Physics Control Systems ICALEPCS2019.

https://doi.org/10.18429/JACoW-ICALEPCS2019-

MOPHA123

Salehilashkajani, A., Zhang, H. D., Ady, M., Chritin, N.,

Forck, P., Glutting, J., Jones, O. R., Kersevan, R.,

Kumar, N., Lefevre, T., Marriott-Dodington, T.,

Mazzoni, S., Papazoglou, I., Rossi, A., Schneider, G.,

Sedlacek, O., Udrea, S., Veness, R., & Welsch, C. P.

(2022). A gas curtain beam profile monitor using beam

induced fluorescence for high intensity charged particle

beams. Applied Physics Letters, 120(17).

https://doi.org/10.1063/5.0085491

Sequeiro, C. C., Ady, M., Bregliozzi, G., Chatzigeorgiou,

N., Churchman, A. R., Kersevan, R., Lefevre, T.,

Mazzoni, S., Pigny, G., Rossi, A., Sameed, M.,

Schneider, G., Sedlacek, O., Sidorowski, K., Pelaez, C.

V., Veness, R., Zygaropoulos, L., Stringer, O., Webber-

Date, A., . . . Udrea, S. (2024). Beam gas curtain

monitor: Vacuum studies for LHC integration and

operation. Physical Review Accelerators and Beams,

27(4). https://doi.org/10.1103/physrevaccelbeams.

27.043201

Siemens. (2022). PLCSim Advanced (V5.0) [Software].

Tzoganis, V., & Welsch, C. (2013). Alignment of a Nozzle-

Skimmer system for a non invasive gas jet based beam

profile monitor. IBIC 2013: Proceedings of the 2nd

International Beam Instrumentation Conference, 803–

806. https://epubs.stfc.ac.uk/work/10855638

Zygaropoulos, L. (2022). Beam Gas Curtain Vacuum

Control System Technical Specifications. In EDMS.

https://edms.cern.ch/document/2757469/4

Zygaropoulos, L., & Wickham, J. M. (2024, October).

EDA-04947-V1-0 v.0: R2E Local Crate. In EDMS.

https://edms.cern.ch/item/EDA-04947-V1-0/0.

Automated Process Control for the Beam Gas Curtain Vacuum System at CERN

289