An Educational Platform for Real-Time Control and Reinforcement

Learning Experiments Using Rotary Inverted Pendulum and LW-RCP

Doyoon Ju

a

, Jongbeom Lee

b

and Young Sam Lee

c

Department of Electrical and Computer Engineering, Inha University, Incheon, Korea

Keywords:

Control Engineering Education, LW-RCP, Stepper Motor Vector Control, Real-Time Control.

Abstract:

This paper presents an integrated experimental platform for hands-on education in control engineering, built

around a compact rotary inverted pendulum system based on a stepper motor and a Simulink-based Light

Weight Rapid Control Prototyping (LW-RCP) environment. The proposed platform supports real-time imple-

mentation of a wide range of control experiments, including current-based vector control, nonlinear swing-up

control, linear stabilization, and reinforcement learning-based control. The hardware consists of a rotary

inverted pendulum made with 3D-printed components and a hollow-shaft stepper motor, incorporating a com-

pact inverter realized through an L6234 motor driver. Its compact and lightweight design allows for tabletop

experimentation, enabling one-device-per-student operation and enhancing scalability in education. On the

software side, users can design controllers and collect real-time data through Simulink’s block-based modeling

interface without coding. Moreover, Python integration enables sim-to-real experiments with reinforcement

learning controllers. This platform complements traditional theory-centric control engineering education by

offering rich hands-on experiences, thereby increasing student motivation and fostering a deeper conceptual

understanding through the full process of controller design and system response analysis.

1 INTRODUCTION

Control engineering has long been a fundamental dis-

cipline in engineering education, traditionally focus-

ing on theory-oriented curricula such as mathemat-

ical modeling of systems, frequency response anal-

ysis, and controller design using state-space meth-

ods. These conventional approaches often rely on

simulation environments to help students understand

controller behavior indirectly. However, in mod-

ern industrial applications, engineers are expected to

possess practical capabilities to control complex and

nonlinear systems in real-time (Iqbal et al., 2017;

Faulwasser et al., 2017; Han and Qiao, 2014). Fields

such as drones, autonomous vehicles, and indus-

trial robotics demand not only theoretical knowledge

but also the ability to implement controllers that ac-

count for real-world constraints. Consequently, the

direction of engineering education has been shift-

ing from passive theoretical instruction to hands-

on, experiment-driven learning, where students ac-

a

https://orcid.org/0000-0001-7011-6779

b

https://orcid.org/0009-0004-8289-8092

c

https://orcid.org/0000-0003-0665-1464

tively design controllers and validate their perfor-

mance through experiments (Lei et al., 2022; Framing

et al., 2020; Precup et al., 2011).

However, to effectively implement hands-on edu-

cation in real-world control engineering classrooms,

it is essential to provide students with a hardware-

based experimental environment that enables direct

physical interaction with control targets. Despite

its importance, the widespread adoption of such en-

vironments is hindered by the high cost of exper-

imental equipment and limited infrastructure. For

instance, some universities utilize advanced instruc-

tional systems such as the Rotary Inverted Pendulum

from Quanser (Quanser Consulting Inc., 1990) or the

MicroAutoBox from dSPACE (dSPACE Inc., 1991),

but these systems entail high financial costs—often

ranging from thousands to tens of thousands of dol-

lars—as well as operational complexity and spatial

constraints, limiting their scalability and accessibil-

ity in educational contexts. Rapid Control Proto-

typing (RCP) has already been actively employed in

fields such as mechatronics (Deppe et al., 2004; Is-

ermann, 2008), automotive dynamics control (Lee

et al., 2004), and precision motion control (Hercog

and Jezernik, 2005; Bodo et al., 2024), where it has

274

Ju, D., Lee, J. and Lee, Y. S.

An Educational Platform for Real-Time Control and Reinforcement Learning Experiments Using Rotary Inverted Pendulum and LW-RCP.

DOI: 10.5220/0013740000003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 274-281

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

demonstrated high effectiveness in rapid controller

design and iterative testing using real hardware sys-

tems. Although this methodology has clear poten-

tial for educational applications, the high entry bar-

riers associated with conventional educational plat-

forms have prevented its widespread adoption in aca-

demic settings. As a result, many students are limited

to simulation-based learning or passive observation

of instructor-led demonstrations, thereby missing the

opportunity to experience real-time controller imple-

mentation and feedback-driven design processes first-

hand.

To address these limitations, this paper proposes

an integrated educational platform consisting of a

compact rotary inverted pendulum system driven

by a stepper motor and a Simulink-based Light

Weight Rapid Control Prototyping (LW-RCP) envi-

ronment (Lee et al., 2017). The hardware configura-

tion includes a hollow-shaft stepper motor, an L6234

three-phase inverter circuit, a pendulum sensor, and

an analog current sensor, all assembled using cost-

effective 3D printing techniques. The stepper motor

exhibits synchronous motor characteristics, making

it suitable for experimental learning in various con-

trol techniques such as current regulation, vector con-

trol, and PWM-based speed control. The pendulum’s

sensor data is transmitted through a slip ring passing

through the central axis of the motor. Owing to its

compact and lightweight design, the system can be

operated independently on a tabletop, enabling a one-

device-per-student setup. This facilitates an accessi-

ble and scalable experimental environment, thereby

offering a practical alternative to cost-intensive edu-

cational solutions.

In addition, on the software side, the Simulink-

based LW-RCP environment allows users to de-

sign and execute control algorithms in real time

using a block diagram approach without requiring

complex programming. The system supports high-

frequency control loops operating at approximately

2 kHz and integrates essential real-time functionali-

ties such as PWM generation, current feedback, and

velocity response measurement into modular blocks.

This enables users to intuitively construct control

loops, perform parameter tuning, and visualize sys-

tem responses in real time. Furthermore, integration

with Python allows the deployment of reinforcement

learning-based controllers in sim-to-real experiments.

As a result, the platform extends its instructional

scope beyond traditional control theory to include

cutting-edge AI-based control strategies. Ultimately,

this integrated framework enables students to engage

in the complete cycle of control system design, imple-

mentation, and evaluation, fostering deeper concep-

tual understanding and enhancing motivation through

hands-on learning in control engineering.

This paper systematically describes the design

principles and overall system architecture of the pro-

posed control education platform and evaluates its

educational effectiveness and practical learning out-

comes through a set of representative experiments.

Section 2 discusses the hardware structure of the ro-

tary inverted pendulum system based on a stepper mo-

tor, including mechanical design elements and essen-

tial techniques for implementing current and vector

control. Section 3 elaborates on the software aspects

of the Simulink-based LW-RCP environment, such

as control loop design, real-time data acquisition,

and Python integration. Section 4 presents two ma-

jor experimental applications conducted on the pro-

posed platform:(1) energy-based swing-up followed

by LQR stabilization using vector control, and (2)

swing-up control of the rotary inverted pendulum us-

ing a reinforcement learning controller trained via a

sim-to-real approach. These experiments demonstrate

the platform’s practicality and expandability in sup-

porting both classical and modern control strategies.

Finally, Section 5 summarizes the educational signifi-

cance and current limitations of the platform, and dis-

cusses its potential applications and future directions

in control engineering education.

2 DESIGN AND EDUCATIONAL

FEATURES OF A ROTARY

INVERTED PENDULUM

SYSTEM USING A STEPPER

MOTOR

To simultaneously achieve hardware simplicity and

scalability for educational use, the proposed platform

is built around a stepper motor-based rotary inverted

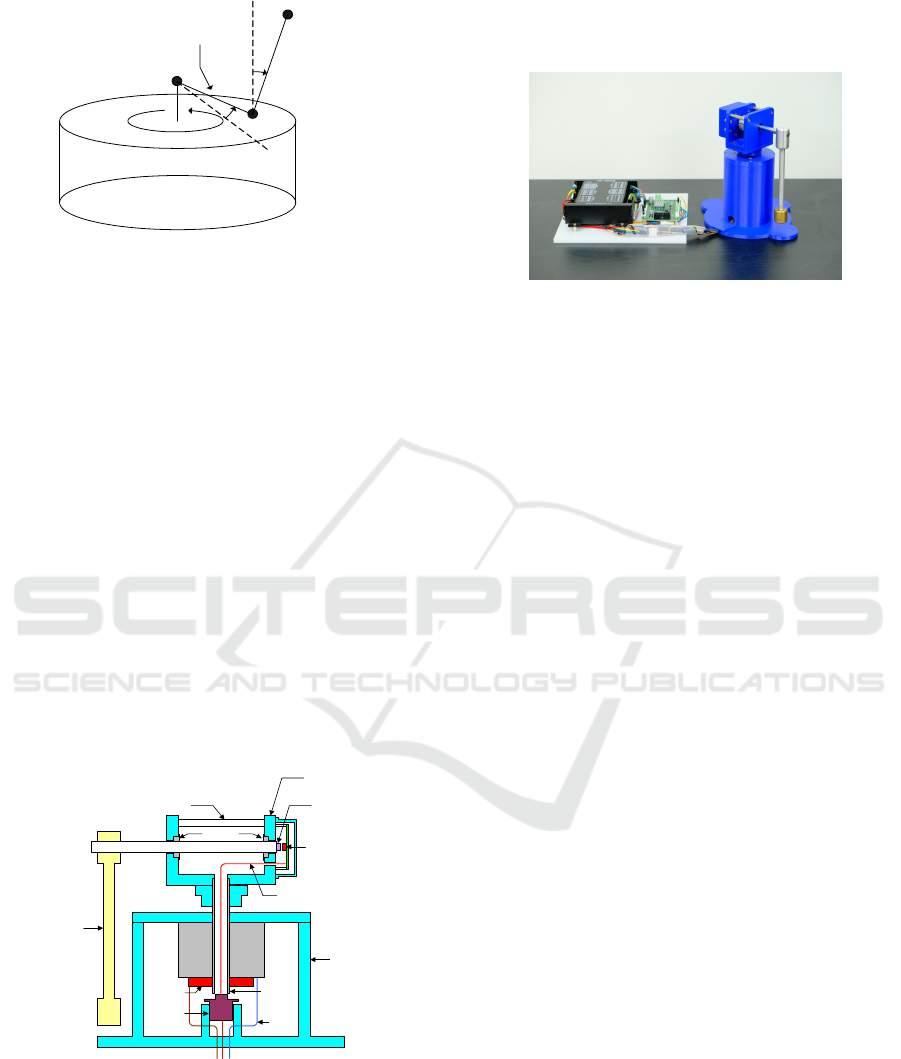

pendulum system. Figure 1 illustrates a conceptual

diagram of the system, designed to provide an intu-

itive understanding of its operating principle. The

complete hardware setup consists of a 3D-printed

frame, a hollow-shaft stepper motor, a three-phase in-

verter based on the L6234 driver, and a single-board

microcontroller serving as the control interface. The

platform is compact and lightweight enough for table-

top use, and all components can be easily sourced

from standard electronics markets. Furthermore, the

total cost remains within an affordable range of sev-

eral tens of thousands of Korean won, making it fea-

sible to implement one-device-per-student configura-

tions for hands-on control education.

The rotary inverted pendulum typically requires

An Educational Platform for Real-Time Control and Reinforcement Learning Experiments Using Rotary Inverted Pendulum and LW-RCP

275

Arm

pendulum

α

θ

r

0θ =

0α =

Figure 1: Conceptual diagram of the rotary inverted pendu-

lum system.

one motor for arm rotation and two encoders to mea-

sure the angular positions of both the arm and the pen-

dulum rod. Additionally, a slip ring is commonly re-

quired to enable unlimited rotation. However, apply-

ing such a configuration to a compact platform often

leads to increased mechanical complexity and higher

component costs. To address this issue, this study pro-

poses a hardware structure centered around a hollow-

shaft stepper motor. This type of motor offers high de-

sign flexibility for rotary experimental setups such as

inverted pendulums, allowing the pendulum rod to be

directly mounted through the motor’s central shaft. A

slip ring can be integrated within the shaft to securely

transmit sensor signals that capture the pendulum’s

angular motion. This design effectively minimizes

potential hardware failures during experiments, such

as cable twisting, signal loss due to poor contact, and

sensor noise. Furthermore, it simplifies maintenance.

Figure 2 illustrates the structural concept of the rotary

inverted pendulum reflecting this design approach.

bearing

pendulum

slip ring

step

motor

encoder cable

magnet

magnetic

encoder IC

3D-printed

mechanical part

hollow

shaft

motor

cable

PCB support

arm

capacitive

encoder

Figure 2: Conceptual structural diagram of the proposed

rotary inverted pendulum.

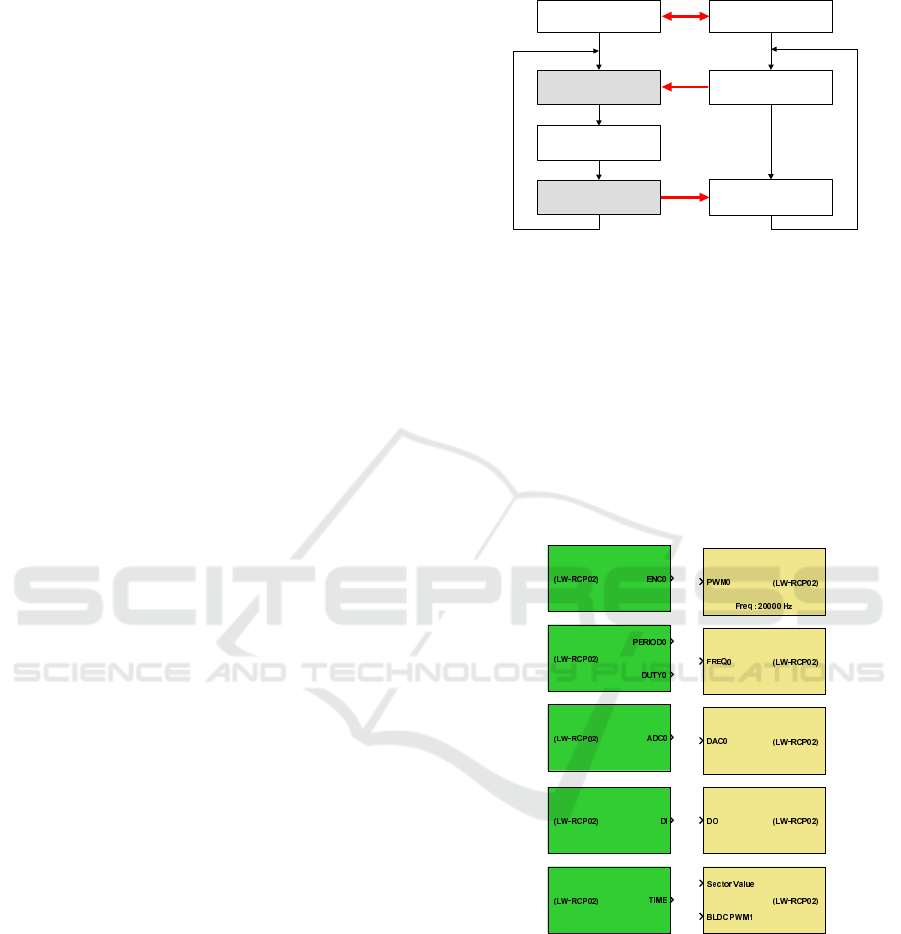

The actual appearance of the fabricated rotary in-

verted pendulum is presented in Fig.3, where the

overall structure and design features for miniaturiza-

tion of the proposed system can be intuitively ob-

served. The pendulum unit is approximately 17cm

in height and 7 cm in width, and the base has been

designed with a wider footprint to ensure stability

against reaction torques.

Figure 3: A rotary inverted pendulum constructed in the

laboratory.

The stepper motor is typically operated in an

open-loop configuration; however, in this system, pre-

cise control of the phase currents enables the experi-

mental implementation of various closed-loop strate-

gies such as vector control, current control, and

PWM-based speed control. This is based on the the-

oretical interpretation of the stepper motor as a syn-

chronous motor, thereby providing a pedagogical en-

vironment in which students can experiment with and

compare different control techniques on a physical

system.

One of the most valuable educational features of

the stepper motor is its ability to visualize the relation-

ship between control inputs and physical responses in

an intuitive manner. The one-to-one correspondence

between pulse count and angular displacement, as

well as the linear relationship between current com-

mands and torque generation, enables a foundational

understanding of system response. Through position

and speed control experiments, students can directly

observe the effects of control algorithms in real-time,

facilitating a shift from theoretical modeling to prac-

tical system understanding. This structural and func-

tional simplicity lowers the entry barrier for beginners

while offering a scalable experimental platform for

advanced learners to explore complex control strate-

gies.

Furthermore, the system is also well-suited for

experiments in system modeling and parameter es-

timation. Electrical parameters of the motor (e.g.,

resistance and inductance) and mechanical param-

eters (e.g., inertia and friction coefficients) can be

empirically identified from experimental data. This

supports white-box modeling approaches that foster

deeper physical understanding of control systems and

meet the goals of practice-oriented education. Un-

like black-box approaches, this integration of exper-

iment and modeling reinforces students’ insight into

the physical structure of the system.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

276

In summary, the proposed platform provides a

compact, simplified, and cost-effective hardware ar-

chitecture that fulfills key practical requirements in

control engineering education without reliance on ex-

pensive laboratory equipment. It enables learners to

engage directly with core concepts such as actuator

control, system identification, and feedback design,

thus creating a unified educational framework that

bridges theory, practice, design, and application.

3 REAL-TIME CONTROLLER

IMPLEMENTATION USING

LW-RCP

Traditional methods of real-time controller develop-

ment require implementing control algorithms in C

on a microcontroller and manually configuring hard-

ware components such as PWM, ADC, timers, and in-

terrupts. This workflow demands advanced program-

ming skills and often distracts learners from the core

principles of control design, redirecting their focus

toward low-level debugging and peripheral handling.

In educational settings where the objective is to link

theoretical knowledge to practical systems, such com-

plexity can become a barrier to effective learning. To

address these issues, this study introduces a Simulink-

based Light Weight Rapid Control Prototyping (LW-

RCP) environment, integrated with a rotary inverted

pendulum system. The environment enables intuitive

and iterative hands-on real-time control experiments

without requiring low-level coding. LW-RCP, devel-

oped in-house, allows users to construct control sys-

tems graphically using block diagrams while seam-

lessly interfacing with the hardware.

This environment has been successfully applied in

various experimental control tasks, including the con-

trol of a rotary double inverted pendulum using direct

collocation, and sim-to-real reinforcement learning

experiments on a linear double pendulum system (Lee

et al., 2025; Ju et al., 2025).

The control loop constructed in Simulink com-

municates in real-time with the LW-RCP hardware

via USB, supporting a high-frequency control rate

of up to 2 kHz. Since the stepper motor used in

the rotary inverted pendulum can be interpreted as

a synchronous motor, each phase current can be

precisely regulated to implement advanced control

strategies such as vector control, current control,

and PWM-based speed control. This enables stu-

dents to go beyond simple position control and intu-

itively learn current-based vector control architectures

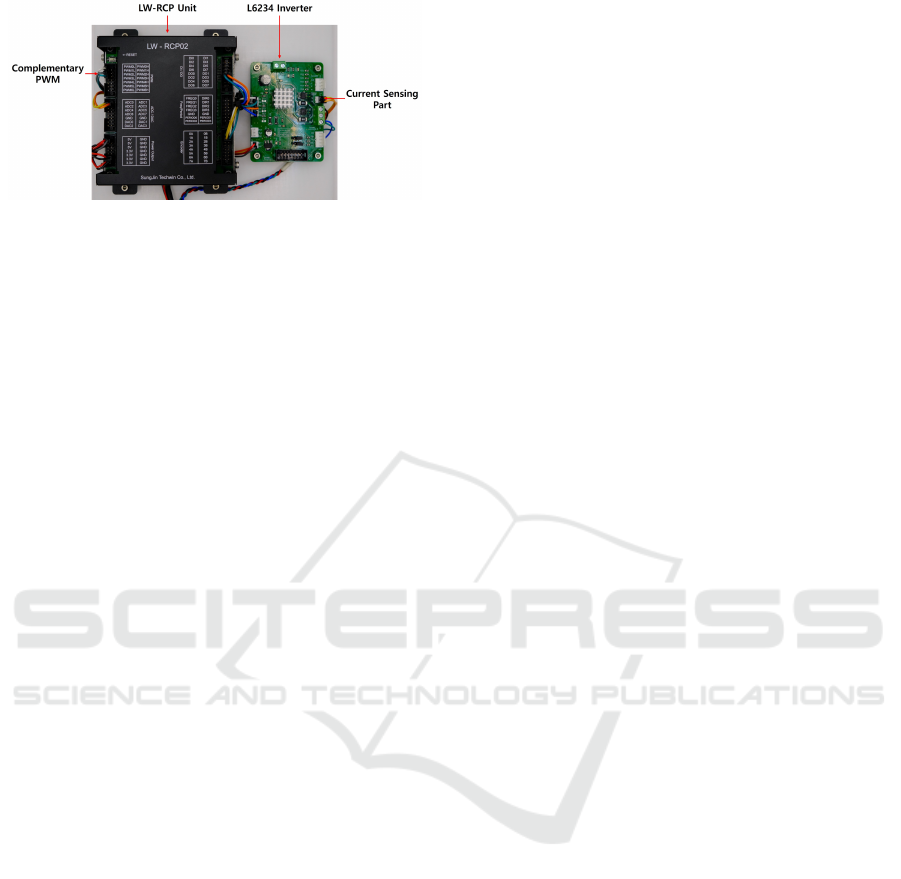

widely adopted in industrial systems. Figure 5 illus-

Initialization Initialization

Receive sensor data from

the LW-RCP unit

Compute control data

based on received

sensor data

Measure sensor data and

transmit it to Simulink (PC)

Loop

PC (Simulink)

LW RCP Unit

(ATSAM3X8E)

USB

USB

USB

Loop

Send computed control data

to the LW-RCP unit

Apply received control data

to output peripherals

Figure 4: Real-time execution and hardware interaction pro-

cess in LW-RCP.

trates an example configuration of core blocks pro-

vided in the LW-RCP environment. Students can eas-

ily construct position and velocity feedback loops us-

ing blocks such as ENC, PWM, and FREQ, and con-

duct experiments by assigning reference inputs via

analog channels while observing system responses in

real time. Additionally, Figure 6 presents the inte-

grated hardware setup, where the LW-RCP control

board and motor driver circuit are mounted together

on a single platform.

Figure 5: Simulink blocks for I/O and real-time control in

LW-RCP.

The real-time control experiments enabled by LW-

RCP significantly broaden the scope of control the-

ory application and offer structured opportunities for

comparative learning of diverse control strategies.

First, through vector control experiments with stepper

motors, students can learn how torque is generated

from current references to drive the pendulum arm

precisely. TThis fosters an intuitive understanding

of how current, speed, and position are linked within

the feedback loop. Second, swing-up and stabiliza-

An Educational Platform for Real-Time Control and Reinforcement Learning Experiments Using Rotary Inverted Pendulum and LW-RCP

277

Figure 6: Control board integrating LW-RCP and motor

driver.

tion control experiments allow learners to implement

and compare nonlinear energy-based controllers and

linear LQR-based stabilizers, as well as reinforce-

ment learning (RL) control policies. Simulink’s S-

Function and Stateflow tools enable students to con-

struct condition-based switching logics with block-

based modeling. Third, the platform supports model-

based control design. Electrical parameters (e.g.,

resistance, inductance) and mechanical parameters

(e.g., inertia, friction) of the motor can be estimated

from real experimental data and incorporated into dy-

namic models for designing state-space controllers.

This approach goes beyond black-box modeling to

cultivate white-box modeling and control synthesis

skills. Finally, Python integration allows sim-to-real

experimentation, where RL policies trained in simula-

tion can be transferred to physical systems. This pro-

vides hands-on exposure to both classical and mod-

ern AI-based control strategies and allows students

to evaluate the feasibility and limitations of neural-

network-based control in real-time environments.

Ultimately, LW-RCP functions not merely as an

experimental tool but as a practical medium for con-

trol engineering education. When combined with

the proposed rotary inverted pendulum system, it en-

ables repetitive, individual experimentation and fos-

ters autonomous learning of the entire feedback pro-

cess: controller design, implementation, verifica-

tion, tuning, and response analysis. This hands-on

setup bridges the gap between theory and practice

by addressing real-time system behavior and hard-

ware responsiveness—key elements often overlooked

in simulation-centric curricula.

4 VECTOR-CONTROL-BASED

EXPERIMENTS WITH A

ROTARY INVERTED

PENDULUM

This section presents three representative control ex-

periments conducted using the proposed experimental

platform to validate the connection between control

theory and real-world implementation and to demon-

strate its effectiveness in practice-based education.

All experiments were implemented in real-time us-

ing the Simulink-based LW-RCP environment. The

hardware platform consisted of a stepper motor-based

rotary inverted pendulum system, an L6234 inverter,

current sensors, and an analog input interface. The ex-

periments focused on the following two strategies:(1)

energy-based swing-up using vector control for speed

regulation, and (2) sim-to-real application of a rein-

forcement learning-based controller.

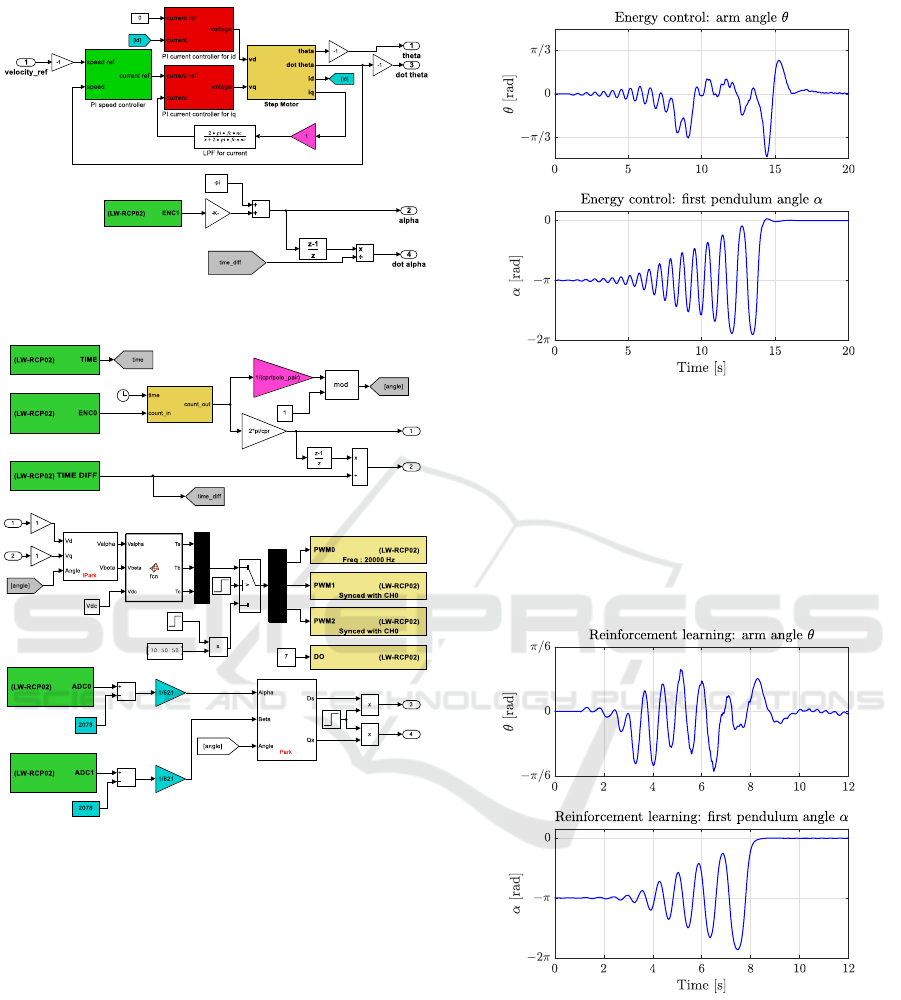

In the first experiment, a vector-control-based

speed controller was implemented for the stepper mo-

tor driving the arm of the rotary inverted pendulum,

and this controller was used to realize an energy-

based swing-up control strategy. The stepper motor

was modeled as a synchronous motor, and the current

references generated in the d-q coordinate frame were

transformed via a Park transformation and modulated

using space vector pulse width modulation (SVPWM)

before being transmitted to the L6234 motor driver.

Closed-loop control was achieved through real-time

current feedback (Yang et al., 2003). The entire con-

trol algorithm was implemented in Simulink using

block diagrams, with a control cycle set to 2 kHz.

Figure 7 illustrates the Simulink implementation of

the speed controller, and Figure 8 shows the SVPWM

modulation and signal output structure. The swing-

up control strategy was based on the energy-shaping

method proposed by

˚

Astr

¨

om and Furuta (

˚

Astr

¨

om and

Furuta, 2000), which gradually increases the pendu-

lum’s kinetic energy until it reaches a critical thresh-

old. The controller estimates the current energy of the

pendulum using its position and velocity, then adjusts

the control input to compensate for the energy gap

relative to the reference value. Figure 9 presents the

structure of this energy-based control algorithm and

visualizes the measured pendulum angle and veloc-

ity response. The experiment showed that the pendu-

lum, starting from a downward-hanging position, ac-

cumulated energy through successive motor actions,

reached the required energy level, and successfully

transitioned to the upright position. Afterward, the

control was switched to a Linear Quadratic Regula-

tor (LQR) based on a linearized state-space model,

and the pendulum maintained its upright equilibrium

reliably. This experiment allows students to experi-

ence the integrated process of applying both nonlin-

ear energy-based and linear state-space-based control

strategies to a real-time system, thereby bridging the

gap between theoretical understanding and practical

implementation.

The second experiment involves a sim-to-real

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

278

Figure 7: Simulink model of vector-control-based speed

controller for swing-up energy control.

Figure 8: SVPWM generation block diagram converting

dq-axis current commands.

transfer of a reinforcement learning (RL) policy

trained in a Python environment to a real-world con-

trol platform. An agent trained using the Truncated

Quantile Critics (TQC) algorithm (Kuznetsov et al.,

2020) in a Python-based simulation was exported and

deployed on the physical system. Real-time control

commands were transmitted to the LW-RCP hardware

via MATLAB Simulink, enabling the learned policy

to operate the platform. The system receives torque

and pendulum angle measurements as input and ap-

plies the RL model’s output as PWM signals to the

hardware. To minimize the sim-to-real transfer gap,

physical factors such as friction and sensor noise were

incorporated into the simulation model. Experimental

results confirmed that the trained policy successfully

executed both swing-up and balance control on the

Figure 9: Experimental results of energy-based swing-up

control.

real system. Specifically, the controller gradually in-

creased the pendulum’s energy and then stabilized it

at the upright position by damping oscillations near

the equilibrium. The control behavior is visualized

in Figure 10, offering learners a direct and quantita-

tive understanding of the gap between theoretical RL-

based control and its real-world deployment.

Figure 10: Execution of swing-up and stabilization tasks

using a TQC-trained reinforcement learning.

Through the above experiments, it was verified

that the proposed platform provides an environment

capable of implementing and comparing a wide range

of control strategies in real time—from classical vec-

tor control-based speed control and mathematically

designed optimal control to data-driven reinforcement

learning approaches. This integration of control the-

ory with physical systems allows learners to validate

An Educational Platform for Real-Time Control and Reinforcement Learning Experiments Using Rotary Inverted Pendulum and LW-RCP

279

the effectiveness of each strategy through experimen-

tation and develop practical intuition for controller

design. In particular, by experiencing the perfor-

mance differences and implementation constraints of

each control method firsthand, the platform demon-

strates its potential to realize an experiment-centered

educational environment that goes beyond traditional

simulation-based learning.

5 CONCLUSION

This paper proposed a hands-on educational plat-

form for control engineering that integrates a stepper-

motor-based rotary inverted pendulum system with a

Simulink-based Light Weight Rapid Control Proto-

typing (LW-RCP) environment. The proposed plat-

form was validated through experiments that demon-

strated both its design principles and educational ef-

fectiveness. By incorporating a hollow-shaft step-

per motor, a low-cost L6234 motor driver, and a 3D-

printed frame, the platform offers an affordable, com-

pact, and scalable hardware solution. All compo-

nents are easily obtainable from commercial markets,

and the system is designed to support one-device-per-

student deployment for large-scale classroom use.

On the hardware side, interpreting the stepper mo-

tor as a synchronous motor allows students to engage

in advanced control practices such as current and vec-

tor control, extending their learning beyond basic po-

sition control toward current-based strategies used in

industrial systems. Coupled with the Simulink-based

LW-RCP environment, students can visually imple-

ment real-time controllers without writing code, per-

form parameter tuning, and analyze system responses

in a fully autonomous manner. Moreover, Python

integration enables sim-to-real transfer of reinforce-

ment learning (RL) policies, offering intuitive and

hands-on experiences with modern AI-based control

techniques.

Experimental demonstrations included vector-

control-based swing-up, LQR-based stabilization,

and RL-based policy control, highlighting the plat-

form’s versatility in supporting diverse control strate-

gies. These experiments allowed learners to compare

different approaches under realistic constraints and to

gain a deeper understanding of real-time control im-

plementation. The integration of both classical and

modern methods creates a meaningful bridge between

theoretical concepts and practical execution.

Most importantly, the platform’s educational sig-

nificance lies in enabling students to experience the

full process of controller design, system implementa-

tion, real-time experimentation, and data-driven anal-

ysis. This end-to-end learning cycle not only rein-

forces motivation but also helps translate abstract the-

ory into real-world applications. It serves as an effec-

tive path toward fostering practical control engineer-

ing skills and can be regarded as a valuable example

of hands-on engineering education.

Future work may extend the platform into remote

laboratories and modular kits applicable to various

physical systems. Control engineering education is

expected to evolve into a more intuitive and person-

alized direction with such platforms, contributing sig-

nificantly to the realization of a learner-centered edu-

cational paradigm that integrates theory, practice, de-

sign, and implementation.

ACKNOWLEDGEMENTS

This work was supported by the National Research

Foundation of Korea(NRF) grant funded by the Korea

government(MSIT)(RS-2024-00347193).

REFERENCES

˚

Astr

¨

om, K. J. and Furuta, K. (2000). Swinging up a pendu-

lum by energy control. Automatica, 36(2):287–295.

Bodo, G., Tessari, F., Buccelli, S., and Laffranchi, M.

(2024). A rapid control prototyping and hardware-in-

the loop approach for upper limb robotic exoskeletons

control. Applied Sciences, 14(5).

Deppe, M., Zanella, M., Robrecht, M., and Hardt, W.

(2004). Rapid prototyping of real-time control laws

for complex mechatronic systems: A case study. Jour-

nal of Systems and Software, 70(3):263–274.

dSPACE Inc. (1991). dspace official home page.

www.dspace.com. Accessed: 7 June 2025.

Faulwasser, T., Weber, T., Zometa, P., and Findeisen, R.

(2017). Implementation of nonlinear model predic-

tive path-following control for an industrial robot.

IEEE Transactions on Control Systems Technology,

25(4):1505–1511.

Framing, C.-E., Hedinger, R., Iglesias, E. S., Heßeler, F.-

J., and Abel, D. (2020). Edubal: An open balancing

robot platform for teaching control and system theory.

IFAC-PapersOnLine, 53(2):17168–17173.

Han, H. and Qiao, J. (2014). Nonlinear model-predictive

control for industrial processes: An application to

wastewater treatment process. IEEE Transactions on

Industrial Electronics, 61(4):1970–1982.

Hercog, D. and Jezernik, K. (2005). Rapid control proto-

typing using matlab/simulink and a dsp-based motor

controller. International Journal of Engineering Edu-

cation, 21(3):1–9.

Iqbal, J., Ullah, M., Khan, S. G., Khelifa, B., and

´

Cukovi

´

c,

S. (2017). Nonlinear control systems - a brief

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

280

overview of historical and recent advances. Nonlin-

ear Engineering, 6(4):301–312.

Isermann, R. (2008). Innovative products with embedded

control. Control Engineering Practice, 16(1):14–29.

Ju, D., Lee, T., and Lee, Y. S. (2025). Transition control of

a rotary double inverted pendulum using direct collo-

cation. Mathematics, 13(4).

Kuznetsov, A., Shvechikov, P., Grishin, A., and Vetrov, D.

(2020). Controlling overestimation bias with trun-

cated mixture of continuous distributional quantile

critics. In Proceedings of the 37th International Con-

ference on Machine Learning, volume 119, pages

5556–5566.

Lee, T., Ju, D., and Lee, Y. S. (2025). Transition control

of a double-inverted pendulum system using sim2real

reinforcement learning. Machines, 13(3).

Lee, W., Shin, M., and Sunwoo, M. (2004). Target-identical

rapid control prototyping platform for model-based

engine control. Proceedings of the Institution of Me-

chanical Engineers, Part D: Journal of Automobile

Engineering, 218(7):755–765.

Lee, Y. S., Jo, B., and Han, S. (2017). A light-weight rapid

control prototyping system based on open source

hardware. IEEE Access, 5(1):11118–11130.

Lei, Z., Zhou, H., Hu, W., and Liu, G.-P. (2022). Unified

and flexible online experimental framework for con-

trol engineering education. IEEE Transactions on In-

dustrial Electronics, 69(1):835–844.

Precup, R.-E., Preitl, S., Radac, M.-B., Petriu, E. M.,

Dragos, C.-A., and Tar, J. K. (2011). Experiment-

based teaching in advanced control engineering. IEEE

Transactions on Education, 54(3):345–355.

Quanser Consulting Inc. (1990). Quanser official home

page. www.quanser.com. Accessed: 7 June 2025.

Yang, S.-M., Lin, F.-C., and Chen, M.-C. (2003). Control

of a two-phase linear stepping motor with three-phase

voltage source inverter. In IEEE International Electric

Machines and Drives Conference, 2003. IEMDC’03.,

volume 3, pages 1720–1725.

An Educational Platform for Real-Time Control and Reinforcement Learning Experiments Using Rotary Inverted Pendulum and LW-RCP

281