Data-Driven Control of a PEM Electrolyzer

Yeyson A. Becerra-Mora

1,2 a

, Juan Manuel Esca

˜

no

1 b

and Jos

´

e

´

Angel Acosta

1 c

1

University of Seville, Seville, Spain

2

Corporaci

´

on Unificada Nacional (CUN), Bogot

´

a, Colombia

Keywords:

PEM Electrolyzer, Gaussian Process Regression, Nonlinear Model Predictive Control.

Abstract:

Green hydrogen production has gained significant relevance in recent years to substitute fossil fuels in the

coming years. One of the most promising technologies for attaining such a milestone is the PEM electrolyzer;

nevertheless, some considerations related to controlling its temperature must be addressed, such as avoiding

high temperatures to extend its useful life and improve its efficiency. Therefore, this study proposes a data-

driven control strategy based on Gaussian Process Regression (GPR) and Nonlinear Model Predictive Control

(NMPC). GPR is used to identify the system, while NMPC is used to regulate the output temperature of the

PEM electrolyzer with the identified model. Simulations show a clear resemblance between the Gaussian

Process model and the phenomenological model, as well as the effectiveness of the controller. Furthermore,

error metrics and computational time are presented.

1 INTRODUCTION

The energy transition is a crucial step in the fight

against climate change for a sustainable future. It in-

volves substituting fossil fuels for renewable energy

sources such as solar, wind, and green hydrogen. The

significance of the energy transition has been recog-

nized by international agreements to tackle environ-

mental issues. For instance, the Paris Agreement ex-

poses the need to limit global warming to 1.5

◦

C by

the end of this century (United Nations Framework

Convention on Climate Change (UNFCCC), 2015).

In addition, countries in the European Union have

launched specific strategies such as the one from

Spain, ”Hydrogen Roadmap: A commitment to re-

newable hydrogen” (Ministerio para la Transici

´

on

Ecol

´

ogica y el Reto Demogr

´

afico (MITERD), 2020),

to achieve net-zero greenhouse gas emissions by 2050

at the latest.

Electrolyzers play a pivotal role in green hydro-

gen production as they are able to use electricity from

renewable sources to produce clean hydrogen (i.e. no

presence of greenhouse gases), which is considered

”green” (Carmo et al., 2013). There are four main

types of electrolyzers (Proton Exchange Membrane,

Alkaline, Solid Oxide Electrolysis Cell and Anion

a

https://orcid.org/0000-0002-6718-4962

b

https://orcid.org/0000-0003-1274-566X

c

https://orcid.org/0000-0003-0040-338X

Exchange Membrane), but only the Proton Exchange

Membrane (PEM) electrolyzer stands out for its effi-

ciency and ability to operate at high current densities.

Additionally, it is particularly suitable for integration

with intermittent renewable energy sources; neverthe-

less, its high cost because of the noble metals for be-

ing produced as well as its water management, could

become downsides of operating it.

Green hydrogen production through PEM elec-

trolyzers not only contributes to greenhouse gas emis-

sions reduction, but also offers a feasible solution

to store renewable energy and provides stability for

the electricity transmission grid. A significant chal-

lenge in a PEM is overheating, which can cause mate-

rial degradation and underperformance. The intermit-

tency in renewable sources can induce rapid fluctua-

tions in the supply energy to the electrolyzer, so that

additional heat is generated because of its load/unload

cycles. Moreover, operation in high current densities

to maximize hydrogen production contributes to the

increase in the internal temperature. The efficiency,

economic feasibility, and useful life of the PEM elec-

trolyzer can be compromised by overheating. There-

fore, an implementation of a temperature control sys-

tem is needed to mitigate such a problem. One of

the most effective methods is to integrate a cooling

system to prevent overheating by conserving its in-

ternal temperature in an optimal range. A refrigerant

fluid through the electrolyzer absorbs heat during op-

Becerra-Mora, Y. A., Escaño, J. M. and Acosta, J. Á.

Data-Driven Control of a PEM Electrolyzer.

DOI: 10.5220/0013738800003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 267-273

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

267

eration to dissipate it to the environment afterwards.

Thus, efficient functionality is guaranteed, as well as

the durability of the device is extended.

Different control algorithms have been proposed

to regulate the internal temperature in PEM elec-

trolyzers. (Keller et al., 2022) proposed a feedfor-

ward control strategy and a PID adaptive parameter

to control the temperature of the PEM stack of a 100

kW water electrolyzer. An explicit Model Predictive

Control (eMPC) was embedded in a microcontroller

and implemented in a lab-scale PEM electrolyzer to

preserve the water temperature across it (Ogumerem

and Pistikopoulos, 2020). A heat management system

composed of a water pumping circuit, an air-cooler

and a PID controller has been developed in (Molina

et al., 2024) to control the water temperature in PEM

electrolyzers. (Barros-Queiroz et al., 2024) used a lin-

earized model of a PEM to propose a closed control

strategy based on MPC and a disturbance model to

regulate the electrolyser output temperature. An in-

telligent controller based on Gaussian Mixture Model

(GMM) and Gaussian Mixture Regression (GMR),

was used to control the electrolyser output tempera-

ture (Becerra-Mora et al., 2024).

Renewable energy sources (solar, wind, or hydro-

electric) can be used to power PEM electrolyzers and

thus to produce green hydrogen; however, these types

of sources are inherently nonlinear (behavior is not

proportional to the input). Hence, the dynamics of

the PEM electrolyzer can be considered nonlinear as

well. Usually, a nonlinear mathematical model of the

system is difficult to obtain. Even so, there are ba-

sically three options to know an approximate model:

A simpler linearized model can be deduced; a learn-

ing method can be used to construct estimates from

complex systems (Becerra-Mora and Acosta, 2024);

or first-principles models can be employed. Although

there already exists a phenomenological model for the

PEM electrolyzer (Mora and Bordons, 2022), this pa-

per presents an alternative way to build a machine

learning-based model. Moreover, such a model is em-

ployed in a nonlinear controller. Therefore, a super-

vised learning method, such as Gaussian Process Re-

gression (GPR) is employed to identify the complex

dynamics of a PEM electrolyzer. Once the system

model is identified, this is used in a Nonlinear Model

Predictive Control (NMPC) strategy to regulate the

output temperature of the system.

The paper is structured as follows. In Section 2,

the dynamics of a PEM electrolyzer is presented. In

Section 3, Gaussian Process Regression is explained

to carry out the system identification. In Section 4,

a Nonlinear Model Predictive Control strategy is ad-

dressed to perform set-point tracking. In Section 5,

experiments are described as well as their analysis of

results. Finally, in Section 6, conclusions and future

research are summarized.

2 PEM ELECTROLYZER

DYNAMICS

An electrolyzer contains an electrolytic cell with two

electrodes, an anode and a cathode, which are in

charge of providing an electric current across the wa-

ter to perform the splitting process of the molecule

(H

2

and O). Once the splitting process is performed,

an amount of water still remains in the process, which

is reused into the system to reduce wastewater and

improve its efficiency. In addition, residual water and

gases (Hydrogen and Oxygen) must pass through gas-

liquid separators to guarantee high purity in them.

Some issues such as low purity in gases, electri-

cal conductivity, and overheating are due to materials

degradation by high temperature. Therefore, efficient

operation and useful life in a PEM electrolyzer are

highly dependent on the internal temperature; there-

fore, the cooling system is essential to preserve it

within an optimal range.

Figure 1: Front view of the PEM Electrolyzer.

The electrolyzer dynamics is described in (Mora

and Bordons, 2022). A first-order differential equa-

tion (1) represents the thermal model that arises from

the simplified energy balance of the system:

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

268

C

t

dT

el

dt

=

˙

Q

gen

−

˙

Q

loss

−

˙

Q

cool

(1a)

˙

Q

gen

= I

el

(V

el

− n

c

V

tn

) (1b)

˙

Q

loss

=

1

R

t

(T

el

− T

amb

) (1c)

where C

t

is the stack thermal capacity (J/K), T

el

is the

electrolyzer temperature (K),

˙

Q

gen

is the heat gener-

ated in the system as a consequence of overvoltages

or irreversibilities (W),

˙

Q

loss

is the heat loss by envi-

ronmental interaction (convection and radiation) (W),

˙

Q

cool

is the heat dissipated by the cooling system (W),

I

el

is the current applied to the system, V

el

is the volt-

age applied to the system coming from the electro-

chemical system, n

c

is the number of cells, V

tn

is

the thermoneutral voltage, R

t

is the thermal resistance

(K/W) and T

amb

is the ambient temperature (K).

The nonlinear behavior of the PEM electrolyzer

is due to the current I

el

coming from a photovoltaic

source and the ambient temperature T

amb

. Therefore,

(1) can be rewritten as a nonlinear first-order differen-

tial equation as follows:

dT

el

dt

=

1

C

t

[I

el

(V

el

− n

c

V

tn

) −

1

R

t

(T

el

− T

amb

) −

˙

Q

cool

]

(2)

The data used in this study come from a phe-

nomenological model of the Hamilton-STD SPE-HG

1 kW PEM electrolyzer (see Fig. 1). Some technical

features of this system are operation voltage/current

(V/A) = 9 − 11/5 − 80, nominal temperature (ºC)

= 60, number of cells = 6, partial pressure H

2

/O (bar)

= 6.9/1.3, thermal capacity (J/K) = 9540 and thermal

resistance (K/W) = 0.11.

3 MODELING OF PEM

ELECTROLYZER WITH

GAUSSIAN PROCESS

Initially, the Gaussian Process (GP) can be consid-

ered as a generalization of the normal probability dis-

tribution, and according to (Rasmussen and Williams,

2006), GP is a collection of random variables, any

finite number of which have a joint Gaussian distribu-

tion. Therefore, it can be described by its mean and

covariance functions.

According to Section 2, a phenomenological

model of a PEM electrolyzer is defined; neverthe-

less, one of the goals of this study is to discover the

electrolyzer dynamics through a complete dataset of

inputs/outputs {x

I

,x

O

} coming from the phenomeno-

logical model and a regression problem defined by

Figure 2: Inputs and Output of the System.

x

O

= f (x

I

) + η, where f is an unknown function and

η an environmental noise. Hence, an output estimate

x

O∗

can be calculated given unseen inputs x

I ∗

. From

this point on, x

I

and x

O

stand for input and output sig-

nals of the system (see Fig. 2), respectively, in our

study. These can be written as follows:

x

I

= [I

el

,T

amb

,

˙

Q

cool

]

T

,

x

O

= [T

el

]

T

Note that x

O∗

is the estimate of the electrolyzer

temperature

ˆ

T

el

. Thus, Gaussian Process Regression

(GPR) is employed to estimate

ˆ

T

el

given unknown

data coming from x

I ∗

. The dynamics of the system,

as mentioned above, can be modeled as a multivariate

Gaussian distribution x

O

≈ N (µ(x

I

),K(x

I

,x

I

)), where

K, the covariance matrix, plays a fundamental role in

GPs.

K(x

I

,x

I

) =

k(x

I

1

,x

I

1

) k(x

I

1

,x

I

2

) ... k(x

I

1

,x

I

N

)

k(x

I

2

,x

I

1

) k(x

I

2

,x

I

2

) ... k(x

I

2

,x

I

N

)

.

.

.

.

.

.

.

.

.

.

.

.

k(x

I

N

,x

I

1

) k(x

I

N

,x

I

2

) . . . k(x

I

N

,x

I

N

)

(3)

This matrix K is formed by a kernel function

k(x

I

i

,x

I

j

) that provides the covariance between two el-

ements x

I

i

and x

I

j

. Similarity is a required property in a

kernel function as two similar inputs (x

I

i

,x

I

j

) and their

corresponding outputs (x

O

i

,x

O

j

) will have a higher cor-

relation than for dissimilar inputs/outputs. One of the

most used kernel functions is the Radial Basis Func-

tion (RBF), which is defined as follows:

k(x

I

i

,x

I

j

) = σ

2

1

exp

−

1

ℓ

(x

I

i

− x

I

j

)

T

(x

I

i

− x

I

j

)

+ σ

2

3

δ

i j

(4)

where σ

2

1

is the signal variance, ℓ is the length-

scale and σ

2

3

is the noise variance. In general, they

are called hyperparameters. The posterior distribution

stands for the estimate x

O∗

given some unknown data-

points x

I ∗

, so that the joint distribution can be defined

as

x

O

x

O∗

≈ N

x

I

x

I ∗

,

K(x

I

,x

I

) K(x

I

,x

I ∗

)

K(x

I ∗

,x

I

) K(x

I ∗

,x

I ∗

)

!

(5)

Data-Driven Control of a PEM Electrolyzer

269

The posterior distribution over x

O∗

is calculated

with the conditional probability property of Gaussian

distributions.Hence, mean and covariance become

µ

∗

= µ(x

I ∗

) + K(x

I ∗

,x

I

)K(x

I

,x

I

)

−1

(x

O

− µ(x

I

)),

Σ

∗

= K(x

I ∗

,x

I ∗

) − K(x

I ∗

,x

I

)K(x

I

,x

I

)

−1

K(x

I

,x

I ∗

)

(6)

A common assumption in practice is

[µ(x

I

),µ(x

I ∗

)]

T

= 0. GPs can thus be expressed

by their second-order statistics, the covariance matrix

K, which is a positive semidefinite matrix.

4 NONLINEAR MODEL

PREDICTIVE CONTROL

STRATEGY

Although the PEM electrolyzer model can be lin-

earized as in (Mora and Bordons, 2022), to conse-

quently propose a linear controller (Barros-Queiroz

et al., 2024), our approach is to deal with nonlinear

dynamics, looking for improved performance. In fact,

identifying a linear model is relatively easy; more-

over, when the plant is in operation around the op-

erating point, good performance can be achieved.

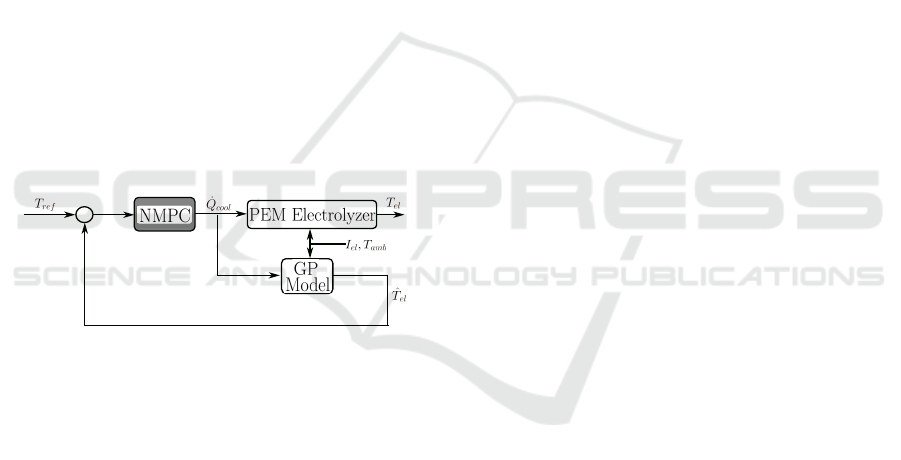

Figure 3: Block diagram of data-driven control system.

Nonlinear models may be very difficult in devel-

oping; nevertheless, learning methods such as the one

presented in the previous Section, can help in this

task. The electrolyzer model is identified off-line;

hence, the control loop is less complex than in the

case where the model shifts over time. A discrete rep-

resentation of the nonlinear model can be expressed

as:

x

k+1

= f (x

k

,u

k

,v

k

) (7)

where x

k

is the state/output (T

el

), u

k

is the ma-

nipulated variable (

˙

Q

cool

) and v

k

is the disturbance

(I

el

,T

amb

) at the instant k.

One of the better control strategies, both within

the industry and within the research community, has

been Model Predictive Control (MPC). This formula-

tion integrates different control algorithms (e.g. ro-

bust, optimal, stochastic, adaptive, and so on). How-

ever, stability and robustness proofs have been diffi-

cult to obtain because of the finite horizon used (Ca-

macho and Bordons, 1999). Despite having a non-

linear model, MPC concepts can be readily used.

However, there are some issues with regard to non-

convexity in optimization problems and processing

time.

Another goal of this study is to regulate the elec-

trolyzer temperature T

el

to maximize its hydrogen

production without reducing its useful life. Hence,

a Nonlinear Model Predictive Control (NMPC) strat-

egy is proposed in this study. According to equation

(7) and defining a reference temperature T

re f

, the op-

timization problem to be solved at each instant k can

be formulated as

min

˙

Q

cool

J(

ˆ

T

el

,

˙

Q

cool

) := δ

N

p

∑

i=1

(T

re f

(k + i) −

ˆ

T

el

(k + i|k))

2

+ λ

N

u

∑

i=1

(

˙

Q

cool

(k + i))

2

s.t.

˙

Q

min

≤

˙

Q

cool

≤

˙

Q

max

where N

p

and N

u

are the prediction and control

horizons, respectively, δ and λ are weight factors to

adjust the controller and

˙

Q are the boundaries for

the manipulated variable. Since the cooling system

can operate only between a maximum and a minimal

value, the input variable

˙

Q

cool

must be constrained.

Hence, the optimization problem attempts to reduce

the error between the reference and the estimated tem-

perature (

ˆ

T

el

) coming from the GPR model. The data-

driven control system is depicted in Fig. 3.

5 EXPERIMENTS

In this Section, we present the results of performing

two types of experiments to control the electrolyzer

temperature T

el

. First, we identify the nonlinear dy-

namics of the system using GPR; second, we propose

a NMPC strategy to regulate the output temperature

with the model initially identified. Indeed, the phe-

nomenological model of the system is not used to de-

velop the control strategy, but rather for testing the

controller in it. The simulations are run in Matlab

®

on a laptop with an Intel

®

Core i9-13900H 2.6 GHz

CPU and 32 Gb RAM.

5.1 Data Used in the Study

On the one hand, data related to ambient temperature

T

amb

were collected throughout the four seasons of the

year in Seville, Spain. Actually, five different scenar-

ios were used (i.e. autumn, winter, spring, summer

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

270

and extreme summer). On the other hand, data related

to photovoltaic cells to generate electrical current in

the system I

el

were collected on sunny/cloudy days.

Therefore, ten different combinations were generated

between T

amb

and I

el

. Additionally, data were sam-

pled every second, which means 86400 samples per

day.

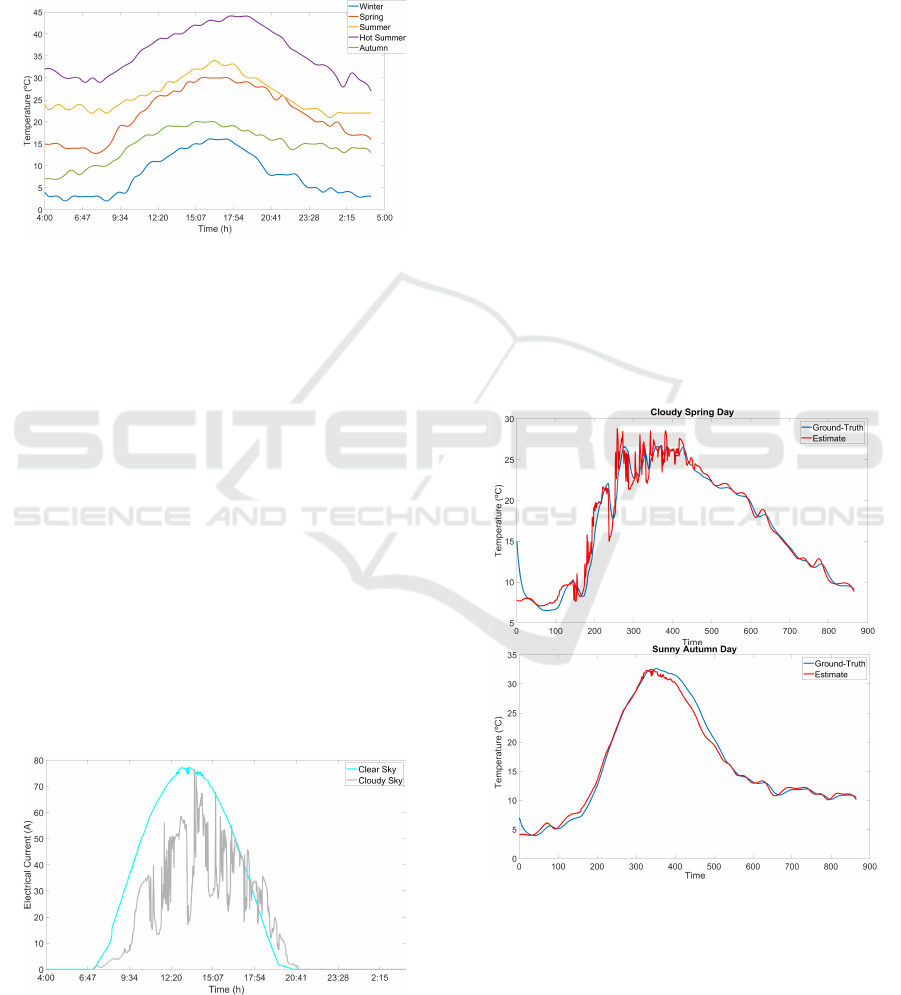

Figure 4: Ambient temperature.

The disturbances of the system correspond to the

ambient temperature (Fig. 4) and the current ap-

plied to the electrolyzer (Fig. 5). The temperature of

Seville T

amb

varies from 3ºC to 44ºC throughout the

year. The hottest months are July and August, as well

as the coldest, January and February. The behavior of

I

el

comes from the photovoltaic system that shows the

influence of irradiance on this variable. As expected

in this kind of system, the electrical current on cloudy

days is reduced compared to sunny days. Moreover,

note that both disturbances have nonlinear behavior,

which is the reason to use a nonlinear regressor (GPR)

and a nonlinear control strategy (NMPC) to identify

the system and regulate the output temperature, re-

spectively.

In addition, the optimal operating range for this

electrolyzer should be between 5 A - 80 A, therefore,

I

el

is saturated at 80 A approximately as the tempera-

ture of Seville can provoke higher levels of electrical

current into the electrolyzer.

Figure 5: Electrical current from a photovoltaic cell.

5.2 Identification of the System

As stated above, the variables [I

el

,T

amb

,

˙

Q

cool

] define

the dynamics of the system. In Section 3 some fun-

damentals of GP are described as a method to con-

struct an estimate of this dynamics. We have defined

three inputs denoted as x

I

and one output denoted as

x

O

to construct a dataset that describes such dynam-

ics. The variables I

el

and T

amb

have been measured

from the photovoltaic system and the climatological

station, respectively. The PEM electrolyzer has been

excited with step signals in the variable

˙

Q

cool

to pro-

duce different levels of temperature at the output of

the electrolyzer T

el

.

One of the purposes of this study is to get as much

data as possible to create a digital twin (Machado

et al., 2023) of the system. Therefore, the step sig-

nals must be enough to reproduce the system dy-

namics; otherwise, the reproductions are poor, or the

method is not capable of generalizing new inputs.

Thus, we set 7 different levels of cooling capacity

(0,25,50,75,100,125,150) W. Note that GPR does

not make distinction between disturbances I

el

,T

amb

and the manipulated variable

˙

Q

cool

, they are all inputs

for this method.

Figure 6: GP model of PEM electrolyzer.

The dataset comprises 6,048,070 samples, by

grouping different scenarios (e.g. summer-cloudy-75

W, spring-sunny-25 W, winter-cloudy-150 W and so

on) and collecting samples every second; neverthe-

less, it has been resampled to 100 seconds to reduce

computational complexity without compromising the

Data-Driven Control of a PEM Electrolyzer

271

quality of reproductions. In this experiment, the re-

duced dataset (60,480 samples) is used as a train-

ing set to learn the complete behavior of the system

throughout the year. The training time has been ap-

proximately 0.63 seconds. To validate a proper learn-

ing, new inputs x

I ∗

associated with the variable

˙

Q

cool

(heat dissipated) are used. In this case, we estimate

the output x

O∗

(i.e.

ˆ

T

el

) with 2 different excitations (30

W, 70 W) in

˙

Q

cool

. During the training and validation

process, the hyperparameters (σ

2

1

, ℓ, σ

2

3

) must be tuned

to achieve better performance.

Two different scenarios (Cloudy spring day, Au-

tumn sunny day) are used to compare ground-truth

(phenomenological model) with estimates (GPR).

The simulations have been conducted over a 24 hour

period, starting at 4:00 a.m. Qualitatively, estimates

(red line) are very similar to ground-truth (blue line)

as can be seen in Fig. 6. Quantitatively, we have used

the root mean squared error (RMSE) to measure the

error between the ground-truth and the estimate. The

scenario of a cloudy spring day shows an RMSE of

1.31ºC and the scenario of a sunny autumn day shows

an RMSE of 0.93ºC, which means that an average low

distance between the 2 curves is presented.

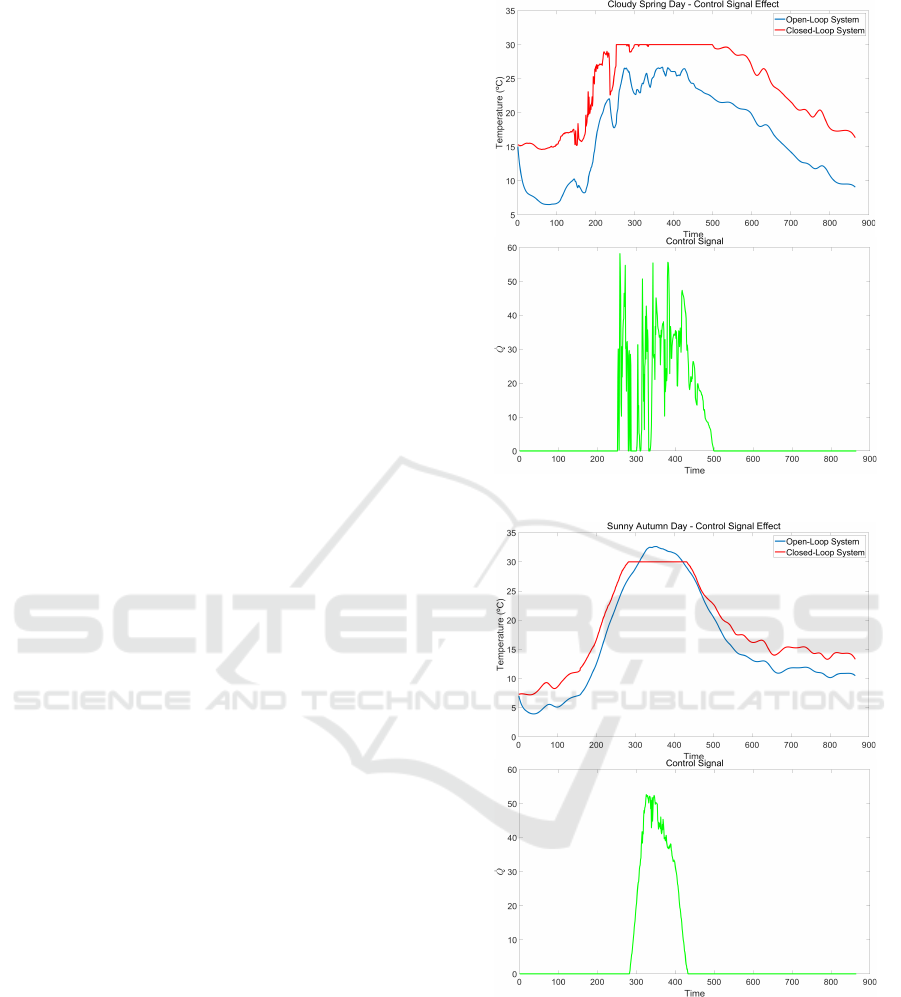

5.3 Nonlinear Control Strategy

The results in the previous Section show the behav-

ior of the system in open-loop. In this Section a

NMPC strategy (i.e. closed-loop) is implemented to

preserve the electrolyzer temperature T

el

below a ref-

erence temperature T

re f

because of the reasons ex-

plained above. In Section 4 the input variable

˙

Q

cool

(i.e. manipulated variable), the disturbances I

el

and

T

amb

and the output variable T

el

(i.e. controlled vari-

able) are defined.

The optimization problem searches for the opti-

mal value of

˙

Q

cool

that minimizes the quadratic error

between T

re f

, which has been set to 30 ºC, and

ˆ

T

el

,

which is the estimated temperature obtained from the

GP model. Moreover, the constraint must be satisfied

˙

Q ∈ {0,150}. The function fmincon from Matlab

®

along with the interior point algorithm are used to

solve the optimization problem. The prediction N

p

and control N

u

horizons are set to 10 samples. The

computational latency to solve the optimization prob-

lem has been approximately 415.81 seconds.

As in the experiment of the previous Section,

two different scenarios are proposed to evaluate the

NMPC strategy, the cloudy spring day and the sunny

autumn day. The phenomenological model is used to

test the performance of the control law; the blue line

and the red line represent the behavior of the open-

loop and closed-loop system, respectively (see Fig. 7

Figure 7: Control signal effect - Cloudy spring day.

Figure 8: Control signal effect - Sunny autumn day.

and Fig. 8). The two scenarios show a controlled

temperature in the electrolyzer less than or equal to

the reference temperature. Note that neither of them

overcomes T

re f

. The control signal effect (green line)

is more intense in the cloudy spring day than in the

sunny autumn day as the former reachs the set-point

faster than the latter; therefore a higher correction is

needed.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

272

6 CONCLUSIONS AND FUTURE

WORK

In this study, we presented a data-driven control ap-

proach for a PEM electrolyzer. A dataset was built

from a phenomenological model of the system. This

dataset was used to build a GPR-based machine learn-

ing model. Furthermore, a NMPC strategy is pro-

posed to control the output temperature of the elec-

trolyzer from the machine learning model. The ex-

periments corroborated a good system identification

by providing a low RMSE between the ground-truth

and estimate, as well as the use of such a machine

learning model to develop a control strategy that pre-

serves the temperature at the set-point.

The results suggest that a data-driven control strat-

egy is useful when a phenomenological model does

not exist or when it is too simple to represent non-

linear dynamics. Direct measures in the system are

enough to build a dataset and develop a machine

learning model.

Future work will implement the data-driven con-

trol strategy in the real system (PEM electrolyzer), be-

sides, it will include a covariance analysis to represent

confidence in the estimate, as well as a tuning of the

weight factors to find a smoother control signal. Fur-

thermore, a stochastic MPC approach (Hern

´

andez-

Rivera et al., 2024) would be interesting to deal with

measurement uncertainties. Finally, a stability analy-

sis is considered to extend these results.

ACKNOWLEDGEMENTS

The authors acknowledge support from the Na-

tional Program for Doctoral Formation (Minciencias-

Colombia, 885-2020), and the emerging research

group Multi-Robot and Control Systems (MACS) for

their assistance with the review of the manuscript.

REFERENCES

Barros-Queiroz, J., Torrico, B., Bordons, C., Nogueira,

F., and Ridao, M. (2024). Temperature control for

a PEM electrolyser powered by a renewable source,

volume 45, pages 1–6.

Becerra-Mora, Y., Chicaiza, W. D., juliana Sobral Barros-

Queiroz,

´

Angel Acosta, J., and Esca

˜

no, J. M. (2024).

Aprendizaje de la se

˜

nal de control para un elec-

trolizador tipo PEM, volume 45, pages 1–6.

Becerra-Mora, Y. A. and Acosta, J.

´

A. (2024). Data-driven

learning and control of nonlinear system dynamics.

Nonlinear Dynamics.

Camacho, E. F. and Bordons, C., editors (1999). Model pre-

dictive control. Springer-Verlag, Berlin Heidelberg.

Carmo, M., Fritz, D. L., Mergel, J., and Stolten, D. (2013).

A comprehensive review on pem water electrolysis.

International Journal of Hydrogen Energy, 38:4901–

4934.

Hern

´

andez-Rivera, A., Velarde, P., Zafra-Cabeza, A., and

Maestre, J. M. (2024). Optimal drug administration in

cancer therapy using stochastic non-linear model pre-

dictive control. In 2024 European Control Conference

(ECC), pages 862–867.

Keller, R., Rauls, E., Hehemann, M., M

¨

uller, M., and

Carmo, M. (2022). An adaptive model-based feed-

forward temperature control of a 100 kw pem elec-

trolyzer. Control Engineering Practice, 120:104992.

Machado, D. O., Chicaiza, W. D., Esca

˜

no, J. M., Gallego,

A. J., de Andrade, G. A., Normey-Rico, J. E., Bor-

dons, C., and Camacho, E. F. (2023). Digital twin of

a fresnel solar collector for solar cooling. Applied En-

ergy, 339:120944.

Ministerio para la Transici

´

on Ecol

´

ogica y el Reto

Demogr

´

afico (MITERD) (2020). Hoja de

ruta del hidr

´

ogeno: Una apuesta por el

hidr

´

ogeno renovable. Vicepresidencia Cuarta

del Gobierno de Espa

˜

na. Dispon

´

ıvel em:

https://www.miteco.gob.es/content/dam/miteco/

es/ministerio/planes-estrategias/hidrogeno/

hojarutahidrogenorenovable tcm30-525000.PDF.

Molina, P., Rios, C., de Leon, C. M., and Brey, J. (2024).

Heat management system design and implementation

in a pem water electrolyser. International Journal of

Hydrogen Energy.

Mora, M. and Bordons, C. (2022). Desarrollo y vali-

daci

´

on experimental del modelo din

´

amico de un elec-

trolizador pem de 1kw para su integraci

´

on con gen-

eraci

´

on renovable. XLIII Jornadas de Autom

´

atica: li-

bro de actas, pages 560–567.

Ogumerem, G. S. and Pistikopoulos, E. N. (2020). Para-

metric optimization and control for a smart proton ex-

change membrane water electrolysis (pemwe) system.

Journal of Process Control, 91:37–49.

Rasmussen, C. and Williams, C. (2006). Gaussian Pro-

cesses for Machine Learning. The MIT Press.

United Nations Framework Convention on Climate

Change (UNFCCC) (2015). Paris agreement.

https://unfccc.int/files/meetings/paris nov 2015/

application/pdf/paris agreement spanish .pdf. Ac-

cessed: 2024-05-30.

Data-Driven Control of a PEM Electrolyzer

273