Quantitative Analysis of Ambient Temperature Effects on Steptime

Variations in Industrial Pneumatic Actuators

Jon Zubieta

a

, Unai Izagirre

b

and Luka Eciolaza

c

Mondragon Unibertsitatea, Electronics and Computer Science Department, Goiru Kalea, 2,

Arrasate - Mondragon 20500, Gipuzkoa, Spain

Keywords:

Ambient Temperature, Pneumatic Actuators, Sub-Cycle Time Analysis, Condition Monitoring, Predictive

Maintenance, Context-Aware Anomaly Detection, Industrial Control Systems, Industrial Automation.

Abstract:

This paper presents a quantitative analysis of the influence of ambient temperature on the cycle time of pneu-

matic actuators in industrial production environments. Sub-cycle time periods, known as Steptimes, are used

to characterize the duration of individual machine stages without requiring additional sensors. Building on the

concept of Mini-terms and following the IEC 60848 GRAFCET standard, Steptimes are defined as the elapsed

time between the activation and deactivation of PLC-controlled steps. Although the potential impact of ambi-

ent temperature on actuator performance is often acknowledged qualitatively, few studies have addressed this

effect through precise, quantitatively measured data. In this work, a detailed experimental study is conducted

using a PLC-controlled system composed of four automated modules. Steptimes and ambient temperature

have been continuously monitored and their effects modeled statistically. The results show a consistent in-

verse correlation between temperature and Steptimes, as expected. The contribution of this research work

is twofold: first, the feasibility and potential of using Steptime measurements to detect subtle environmental

effects in industrial assembly lines is demonstrated. Second, the impact of ambient temperature in highly

automated industrial assembly lines is quantitatively measured. By modeling subtle environmental effects,

deviations in Steptime can be more accurately interpreted, reducing the risk of false alarms and improving

system reliability.

1 INTRODUCTION

Monitoring sub-cycle time periods in industrial pro-

duction machinery, such as the time taken for indi-

vidual components to complete their tasks, provides

valuable insights into their operational health. These

measurements enable data-driven condition moni-

toring without requiring additional sensors, making

them an efficient tool for industrial environments.

An early concept in this field is that of Mini-terms

(Garcia and Montes, 2019a), (Garcia and Montes,

2019b), (Garc

´

ıa and Mont

´

es, 2019), defined as a sub-

division of the cycle time. Mini-terms enable granu-

lar analysis of component behavior by isolating time

intervals that reflect the performance of individual ac-

tuators or subsystems.

Building on this concept, (Zubieta et al., 2025)

proposed a scalable and standardized methodology

a

https://orcid.org/0000-0003-1831-3665

b

https://orcid.org/0000-0002-9811-5775

c

https://orcid.org/0000-0003-3966-7104

to define sub-cycle time periods of machines pro-

grammed in a PLC in compliance with the IEC 60848

standard, which defines the GRAFCET methodology.

In this approach, sub-cycle time periods, referred to as

Steptimes, are defined as the time elapsed between the

activation and deactivation of a specific step within

the machine’s operating sequence.

Unlike Mini-terms, which typically focus on ac-

tuator movements alone, Steptimes can be applied to

any functional step controlled by the PLC, including

compound actions involving multiple elements. They

are also task-based measurements rather than purely

action-based, meaning they can distinguish between

the same physical action performed in different con-

texts. For example, a pneumatic cylinder moving

from point A to point B may exhibit different Step-

times depending on whether it is operating under load

or unloaded. Variations in Steptimes can reveal early

signs of degradation or anomalies in actuators, valves,

or mechanical subsystems.

However, interpreting these time-based metrics

Zubieta, J., Izagirre, U. and Eciolaza, L.

Quantitative Analysis of Ambient Temperature Effects on Steptime Variations in Industrial Pneumatic Actuators.

DOI: 10.5220/0013733600003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 259-266

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

259

without considering environmental factors such as

ambient temperature can result in systematic devia-

tions in timing being mistakenly classified as anoma-

lies. This limitation motivates the present work,

which aims to quantify the effect of ambient temper-

ature on multiple pneumatic systems under real oper-

ating conditions.

Context-aware anomaly detection has become es-

sential in industrial diagnostics, enabling differentia-

tion between deviations induced by external factors,

such as ambient temperature or workload, and gen-

uine faults arising from internal component degrada-

tion. Contextual anomaly detection methods strive to

capture anomalies between elements with some type

of relationship, which is often unknown beforehand

(Su

´

arez-Varela and Lutu, 2025).

Among these extrinsic variables, ambient tem-

perature is a critical but frequently overlooked fac-

tor. Temperature changes can alter air viscosity, pres-

sure stability, and mechanical tolerances—especially

in pneumatic components, which are highly sensi-

tive to such physical conditions. While prior research

and standards (International Organization for Stan-

dardization, 2010) acknowledge the general impact of

temperature on compressed air systems, existing stud-

ies tend to be qualitative or based on simulations.

The main objective of this work is to quantita-

tively analyze the impact of ambient temperature on

the cycle time of pneumatic actuators used in in-

dustrial production lines, focusing on Steptime vari-

ations observed in a PLC-controlled experimental

setup. The ultimate aim is to enhance context-aware

anomaly detection by distinguishing timing devia-

tions induced by environmental conditions from those

caused by actual component degradation. This dis-

tinction will contribute to more accurate and reliable

predictive maintenance in industrial environments.

The results show that while some pneumatic cylin-

ders exhibit a strong correlation between ambient

temperature and Steptime duration, others remain

largely unaffected. This actuator-specific variability

highlights the need for localized context-aware mon-

itoring rather than universal assumptions about tem-

perature sensitivity.

This work makes two main contributions, by pro-

viding regression analyses, calculating R

2

values, and

per-cylinder behavior across a large set of samples.

On one hand, the results demonstrate that Steptime

measurements can effectively capture subtle environ-

mental influences in industrial assembly lines. On

the other hand, the impact of ambient temperature in

highly automated industrial assembly lines has been

quantitatively measured, a factor often acknowledged

but rarely quantified in existing literature.

The findings are especially relevant for re-

searchers aiming to design robust, temperature-aware

anomaly detection strategies in real industrial au-

tomation environments, as well as for those seeking

to develop holistic and precise monitoring systems.

2 RELATED WORK

Understanding how component behavior evolves un-

der different conditions is essential for developing ro-

bust condition monitoring and fault detection strate-

gies in industrial systems. In recent years, there has

been increasing interest in using time-based metrics,

such as cycle durations or sub-cycle time intervals,

to assess machine health without additional sensors.

However, the interpretation of these metrics is often

done in isolation, without considering external influ-

ences or contextual information.

This section reviews existing research in two rele-

vant areas. First, the studies addressing the influence

of ambient temperature on the performance of pneu-

matic actuators have been examined. This study fo-

cuses primarily on these components. Subsequently,

an overview is presented of context-aware anomaly

detection approaches that integrate environmental and

operational context into fault-detection frameworks.

2.1 Environmental Influence on

Pneumatic Actuator Dynamics

The influence of temperature on pneumatic systems

has been recognized across various industrial studies,

although it is often addressed only indirectly or quali-

tatively. In their review of artificial neural network ap-

plications for HVAC and thermal systems, (Mohanraj

et al., 2012) mention that ambient temperature affects

system dynamics and energy efficiency, yet no quanti-

tative relationship is established between temperature

and actuator behavior or timing.

(Sorli et al., 1999) present a dynamic model of

pneumatic actuators based on thermodynamic princi-

ples, which includes temperature as part of the gas be-

havior within the actuator chambers. However, their

study is simulation-based and does not provide exper-

imental validation of how ambient temperature affects

the cycle time of real actuators.

(Fang et al., 2018) experimentally analyze the

effect of internal heating on the performance of a

pneumatic engine. Although the study includes tem-

perature variations and quantifies their influence on

output power and torque, it focuses on energy en-

gines rather than standard pneumatic actuators, and

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

260

the heating is applied internally rather than through

ambient changes.

(Park and Joung, 2022) examine how heat load

influences the thermal control performance of pneu-

matic loop heat pipes. While this work includes pre-

cise temperature control analysis, it is focused on

thermal management devices rather than actuator dy-

namics, and does not investigate timing or speed re-

sponses.

Finally, (Pham et al., 2020) explore the effect

of humidity on friction in pneumatic cylinders. Al-

though related, their focus is on surface interaction

and tribology rather than dynamic response, and tem-

perature is not examined.

Across these studies, the consensus is that envi-

ronmental conditions (temperature, humidity) can af-

fect pneumatic behavior, yet none of them offer a

quantitative correlation between ambient temperature

and pneumatic actuator cycle time. This gap is par-

ticularly relevant for condition monitoring and pre-

dictive maintenance, where timing deviations may

be misinterpreted if temperature effects are not ac-

counted for. The present work addresses this gap by

providing a regression-based experimental analysis of

ambient temperature influence on pneumatic actua-

tor timing, validated through a PLC-controlled exper-

imental setup representative of industrial systems, in-

corporating both pneumatic and electric actuators.

2.2 Contextual Anomaly Detection

Context-aware anomaly detection is increasingly rele-

vant in industrial diagnostics, as it distinguishes devi-

ations from extrinsic factors (e.g., temperature, work-

load) from true faults due to component degrada-

tion. In contrast, traditional methods often rely on

fixed thresholds and neglect context, leading to false

alarms.

(Chandola et al., 2009) classify anomalies into

point, contextual, and collective types. A point

anomaly occurs when a single instance deviates

strongly from the dataset, such as an unusually high-

value credit card transaction for a user.

A contextual anomaly is anomalous only in a

given context. Detection requires distinguishing con-

textual attributes (e.g., time, location) from behavioral

attributes (observed values). For instance, 5

◦

C may

be normal in winter but unusual in summer, or a high-

value purchase typical at holidays but suspicious oth-

erwise.

Collective anomalies arise when a group of re-

lated data points is anomalous as a whole, though

each may appear normal individually. They often

occur in time-series, sequences, or graphs—for ex-

ample, a normal-looking sequence of computer op-

erations that together indicate a cyberattack. Unlike

point anomalies, they depend on inter-point relation-

ships, and unlike contextual anomalies, they result

from internal patterns rather than environmental at-

tributes.

(Hayes and Capretz, 2014) proposed a two-stage

framework for Big Sensor Data, combining univari-

ate Gaussian detection with a context-aware post-

processing layer built on MapReduce k-means clus-

tering. By leveraging spatial, temporal, and opera-

tional metadata, the system remains scalable and re-

duces false positives. Tests on a commercial dataset

showed that context filtering improves anomaly de-

tection in large sensor networks.

Koio et al. (Juba and Koio, 2025) proposed a

wearable IoT framework that monitors occupational

hazards and falls by combining real-time analytics

with context (ambient conditions, posture, motion).

This approach reduces false positives and demon-

strates the value of context-aware models for worker

safety in high-risk environments.

3 EXPERIMENTAL SETUP

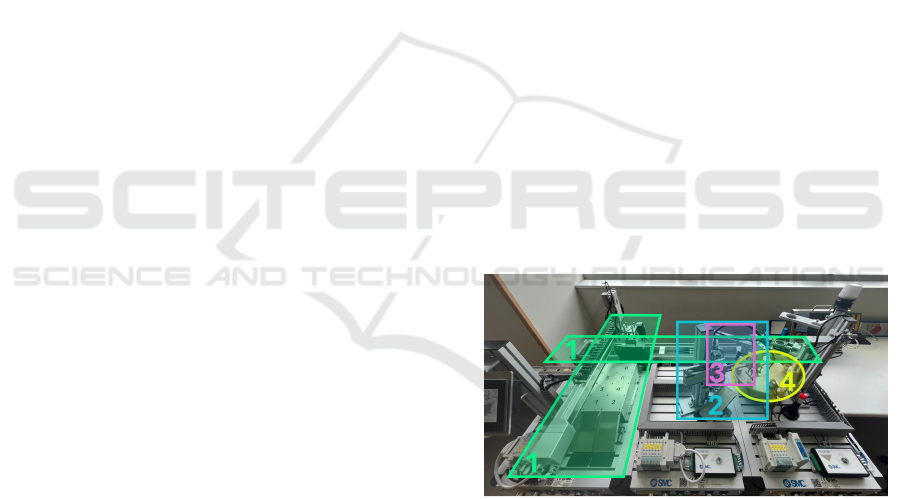

The experimental setup (Figure 1) includes four mod-

ules representing machines in a sequential line, pro-

grammed with GRAFCET methodology.

Figure 1: Experimental use-case.

Figure 2 illustrates the interaction between the

four modules. Module 1 operates independently,

while Modules 2, 3, and 4 are interdependent. Mod-

ules 2 and 3 function in parallel, although Module

2 exhibits a longer cycle time. Once both modules

complete their respective tasks, Module 4 initiates its

operation. Upon completion, the cycle restarts with

Modules 2 and 3. As Module 2 consistently deter-

mines the overall cycle duration, it constitutes a bot-

tleneck in the system, following widely accepted def-

initions in the literature (Azid et al., 2020), (Su et al.,

2022), (Yang et al., 2022).

Quantitative Analysis of Ambient Temperature Effects on Steptime Variations in Industrial Pneumatic Actuators

261

Figure 2: GRAFCET diagram from Modules 1, 2, 3 and 4.

The experiments were carried out using a Siemens

1516-F PLC, which acted as the central controller

throughout the study. System data were collected us-

ing the OPC-UA client-server communication proto-

col. The four modules comprising the experimental

setup are described below.

• Module 1: As can be seen in figure 3, it has two

main components: (a) a crane with a vacuum grip-

per actuated vertically by a pneumatic cylinder to

lift parts from a platform , and (b) a conveyor belt

that transports the part and returns it to its initial

position. The crane then replaces the part on the

platform, repeating the cycle continuously.

(a) (b)

Figure 3: Module 1 setup.

• Module 2: This module has a horizontal pneu-

matic arm with a vacuum gripper mounted on a

vertical pneumatic cylinder. The gripper picks a

part from a rotary platform, transfers it to a sec-

ond location, then returns it. The table advances

one position and the cycle repeats (Figure 4).

• Module 3: This module has an arm that rotates

around a vertical axis to reach two positions. At

the first, it picks a part from a rotary platform

with a pneumatic gripper on a cylinder; at the sec-

ond, it delivers the part. The arm then returns it

Figure 4: Module 2 setup.

to the platform, and once Module 2 completes its

task, the table advances and the cycle repeats (Fig-

ure 5).

Figure 5: Module 3 setup.

• Module 4: This module is composed of a rotary

table that receives two parts per cycle, one from

Module 2 and one from Module 3. Once both

parts are placed, the table rotates by one posi-

tion. Modules 2 and 3 then pick up the parts from

the new positions, perform their respective opera-

tions, and return the parts to the table. The plat-

form rotates again, completing the cycle and initi-

ating a new one (Figure 6).

Figure 6: Module 4 setup.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

262

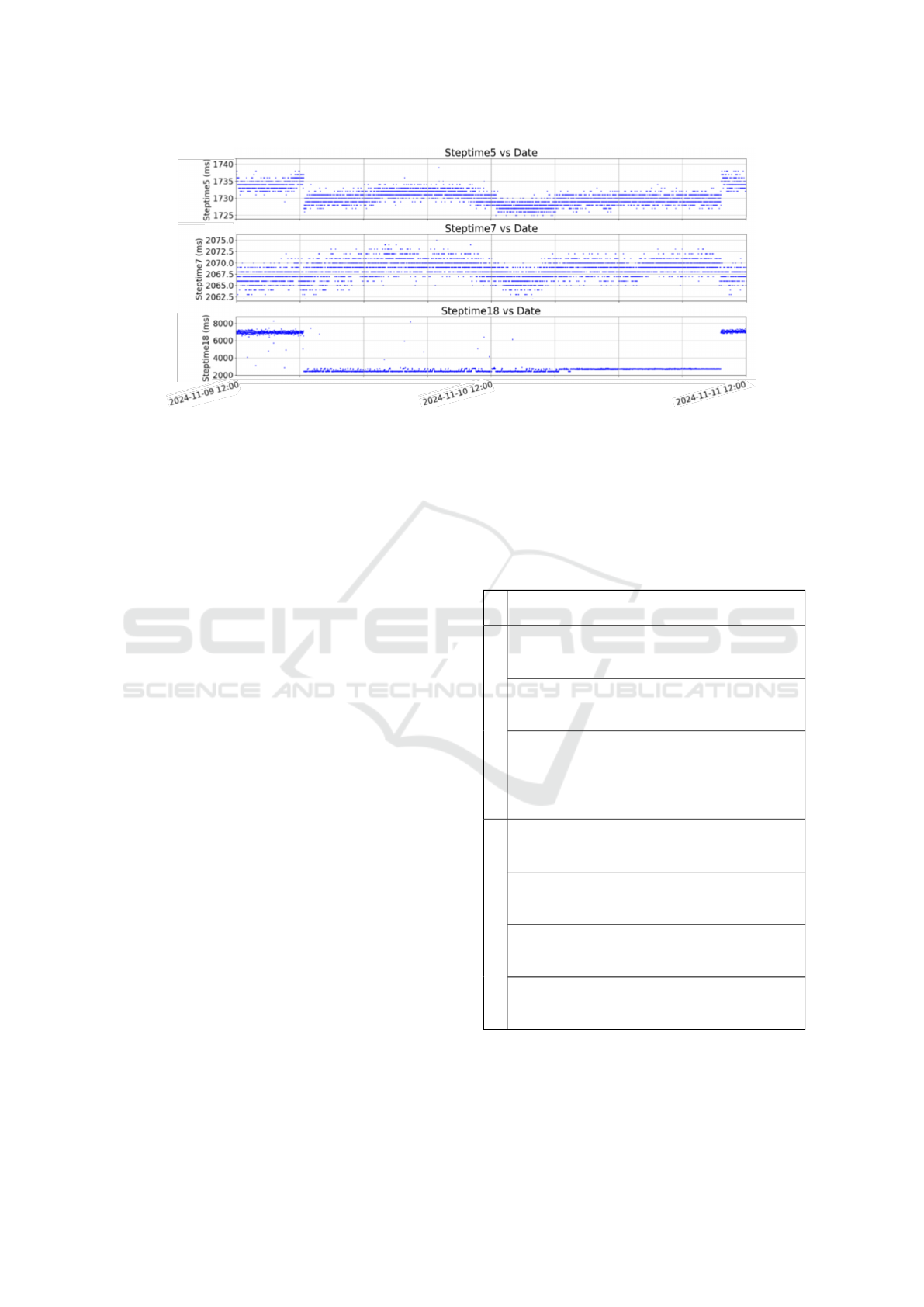

Figure 7: Time series data of Steptime5, Steptime7 and Steptime18 from the experimental use-case shown in section 3.

4 EXPERIMENTAL PROCEDURE

Environmental factors such as ambient temperature

can affect the behavior of components like pneumatic

cylinders and valves, thereby influencing the dura-

tion of operations within a production cycle. Previous

work (Zubieta et al., 2025) has shown that anomalies

in the production line are reflected in Steptime vari-

ations; accordingly, fluctuations in ambient tempera-

ture are also expected to impact Steptime values.

Experiments were carried out in a laboratory in-

sulated from outdoor conditions and equipped with an

air conditioning system that operated on working days

but was inactive during weekends. During weekdays,

additional heat sources included the automated se-

tups, robots, and researchers, resulting in temperature

oscillations between 22 and 25 °C. In contrast, week-

ends without air conditioning showed nearly constant

temperatures close to 22 °C.

Steptimes represent the interval between the acti-

vation and deactivation of a specific step in the pro-

duction line. Each time a step is deactivated, its Step-

time is recorded. Figure 7 illustrates the high resolu-

tion and precision of Steptime measurements, show-

ing the time series of Steptimes 5, 7, and 18 over two

days of uninterrupted machine operation.

The literature indicates that the effect of ambient

temperature in industrial assembly lines has been dis-

cussed only qualitatively, with few quantitative stud-

ies. To address this gap, Steptime measurements were

collected across a range of temperatures and statisti-

cally modeled against ambient temperature, with the

aim of assessing their thermal sensitivity and identi-

fying the most affected stages.

5 RESULTS AND DISCUSSION

Table 1 summarizes the definitions of the Steptimes

analyzed in this section.

Table 1: Definitions of Steptimes analyzed in Section 5.

Step-

time

Definition

Module 1

8, 3,

14, 17

Extension time of vertically

mounted pneumatic cylinders (rod

down).

5, 9,

11

Retraction time of a vertically

mounted pneumatic cylinder (rod

down).

15 Two parallel actions: retraction of

a vertical cylinder (rod down) and a

conveyor belt driven by an electric

motor; duration set by the longer

action.

Module 2

2 Extension time of a horizontally

mounted pneumatic cylinder (un-

loaded).

9 Extension time of a horizontally

mounted pneumatic cylinder (under

load).

3 Extension time of a vertical pneu-

matic cylinder (rod down, un-

loaded).

7 Extension time of a vertical pneu-

matic cylinder (rod down, under

load).

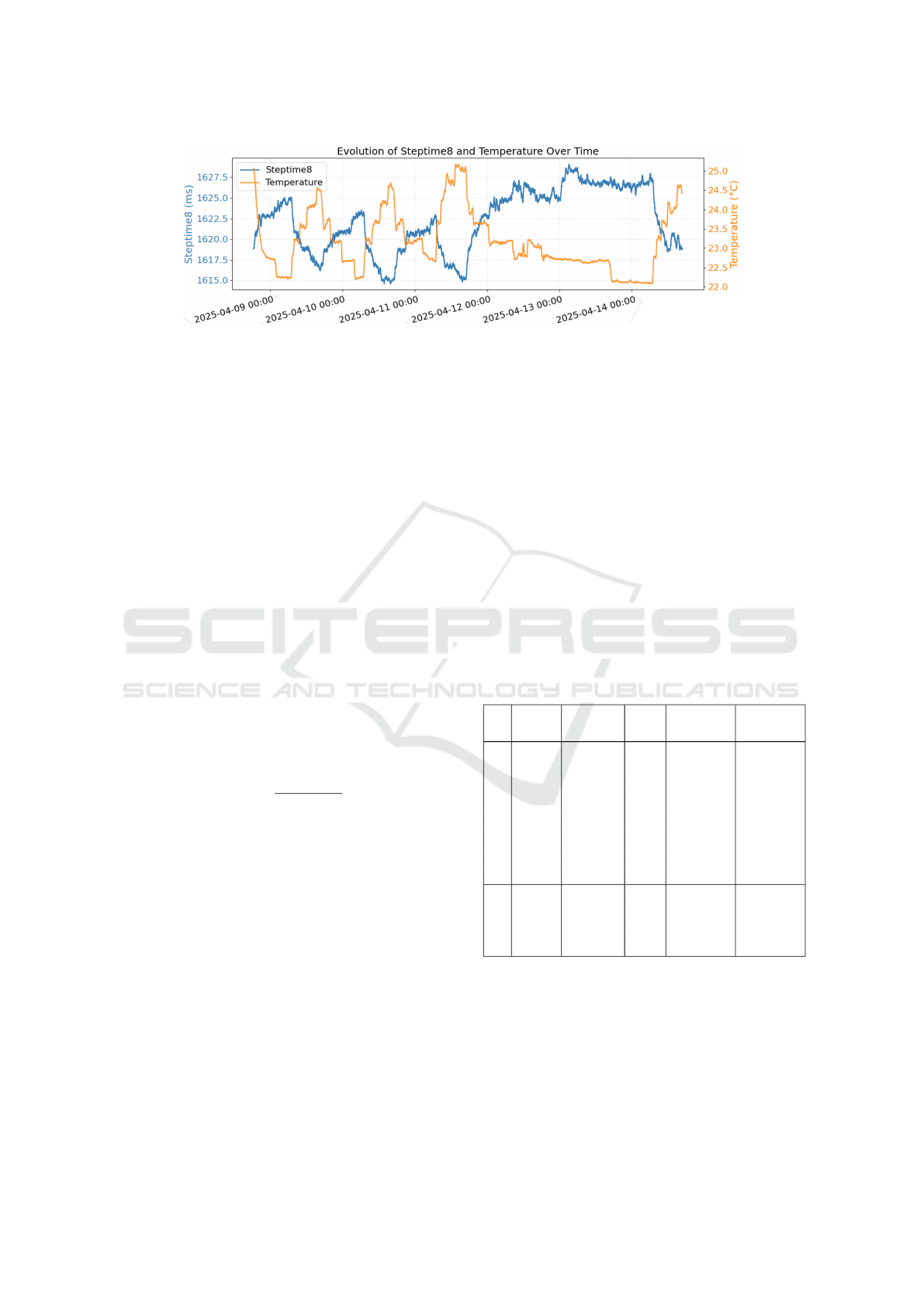

Results in Figure 8 show a clear visual relation-

ship between ambient temperature and Steptime 8.

The time-series and ambient temperature (yellow)

over six consecutive days of machine operation re-

Quantitative Analysis of Ambient Temperature Effects on Steptime Variations in Industrial Pneumatic Actuators

263

Figure 8: Temporal variation of Steptime 8 and ambient temperature.

veals a marked inverse correlation. During April

12–13, the temperature remained relatively stable,

corresponding to the weekend when the laboratory air

conditioning was turned off. Consistently, Steptime 8

also exhibited reduced variability in this period.

5.1 Statistical Analysis

To quantify the relationship between Steptimes and

ambient temperature, a simple linear regression

model was employed as shown in (1):

Y = β

0

+ β

1

X + ε (1)

where Y denotes the Steptime (ms), X the ambient

temperature (°C), β

0

the intercept, β

1

the slope, and

ε the random error term accounting for variability not

explained by the model. β

1

shows how much Step-

time (ms) is expected to change when the temperature

increases by 1 ºC.

On the other hand, model performance for each

Steptime was assessed using the coefficient of deter-

mination (R

2

), defined as in equation (2).

R

2

= 1 −

∑

(y

i

− ˆy

i

)

2

∑

(y

i

− ¯y)

2

(2)

where y

i

are the observed values of a given Step-

time, ˆy

i

the corresponding regression predictions ob-

tained with the equation (1, and ¯y the mean of the

Steptime. R

2

therefore expresses, for each operation,

the proportion of variability in its duration that is ex-

plained by ambient temperature. For example, R

2

=

0.59 for Steptime 8 indicates that 59% of its variation

is attributable to temperature changes, whereas values

close to zero imply that temperature has very little in-

fluence on those operations.

To determine whether the observed tempera-

ture–Steptime associations could be attributed to ran-

dom variability, we tested the null hypothesis that

the regression slope is zero (H

0

: β

1

= 0) for each

Steptime. A two-sided t-test was used to obtain p-

values, and statistical significance was interpreted at

α = 0.05. The p-value quantifies the probability of

observing a slope at least as extreme as the estimated

one if, in truth, temperature had no effect. We report

exact p-values (values < 0.001 shown as “< 0.001”

) as indicators of statistical evidence; practical rele-

vance is summarized by the slope (ms/

◦

C) and R

2

.

As in any linear regression, validity relies on the

assumptions of linearity, independence, homoscedas-

ticity, and approximate normality of residuals. These

assumptions were not formally tested in this study, but

the consistency of the results across different Stepti-

mes and modules supports the adequacy of a linear

model within the observed temperature range.

5.2 Statistical Analysis Results

Table 2 summarizes the regression results for the most

relevant Steptimes from Modules 1 and 2.

Table 2: Selected Steptimes from Module 1 and Module 2.

Step-

time

Slope

(ms/°C)

R

2

p-value n (sam-

ples)

Module 1

3 -4.02 0.57 < 0.001 13851

5 -5.64 0.53 < 0.001 13820

8 -3.97 0.59 < 0.001 13809

9 -5.56 0.45 < 0.001 13794

11 -5.64 0.53 < 0.001 13797

14 -3.98 0.57 < 0.001 13806

15 -3.14 0.05 < 0.001 13693

17 -3.49 0.50 < 0.001 13813

Module 2

2 -3.19 0.21 < 0.001 21697

3 -1.17 0.02 < 0.001 21704

7 -0.20 0.00 0.01 21681

9 -3.40 0.03 < 0.001 21700

For Module 1, all Steptimes exhibit negative slopes,

indicating that higher ambient temperature systemat-

ically reduces their duration. The effect sizes vary

between –3.14 and –5.64 ms/

◦

C, with Steptimes 5, 9,

and 11 showing the strongest sensitivities. The corre-

sponding R

2

values (0.45–0.59) suggest that between

45% and 59% of the variability in these Steptimes can

be explained by temperature. All associated p-values

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

264

are below 0.001, confirming that these trends are sta-

tistically significant.

By contrast, Module 2 Steptimes display weaker

and more inconsistent relationships with temperature.

Although the slopes remain negative, their magni-

tudes are generally smaller (–0.20 to –3.40 ms/

◦

C)

and the R

2

values are close to zero (0.00–0.21). This

indicates that ambient temperature explains little of

the timing variability in Module 2. Only Steptime 7

shows a marginally significant effect (p = 0.01) but

with negligible explanatory power (R

2

= 0.00).

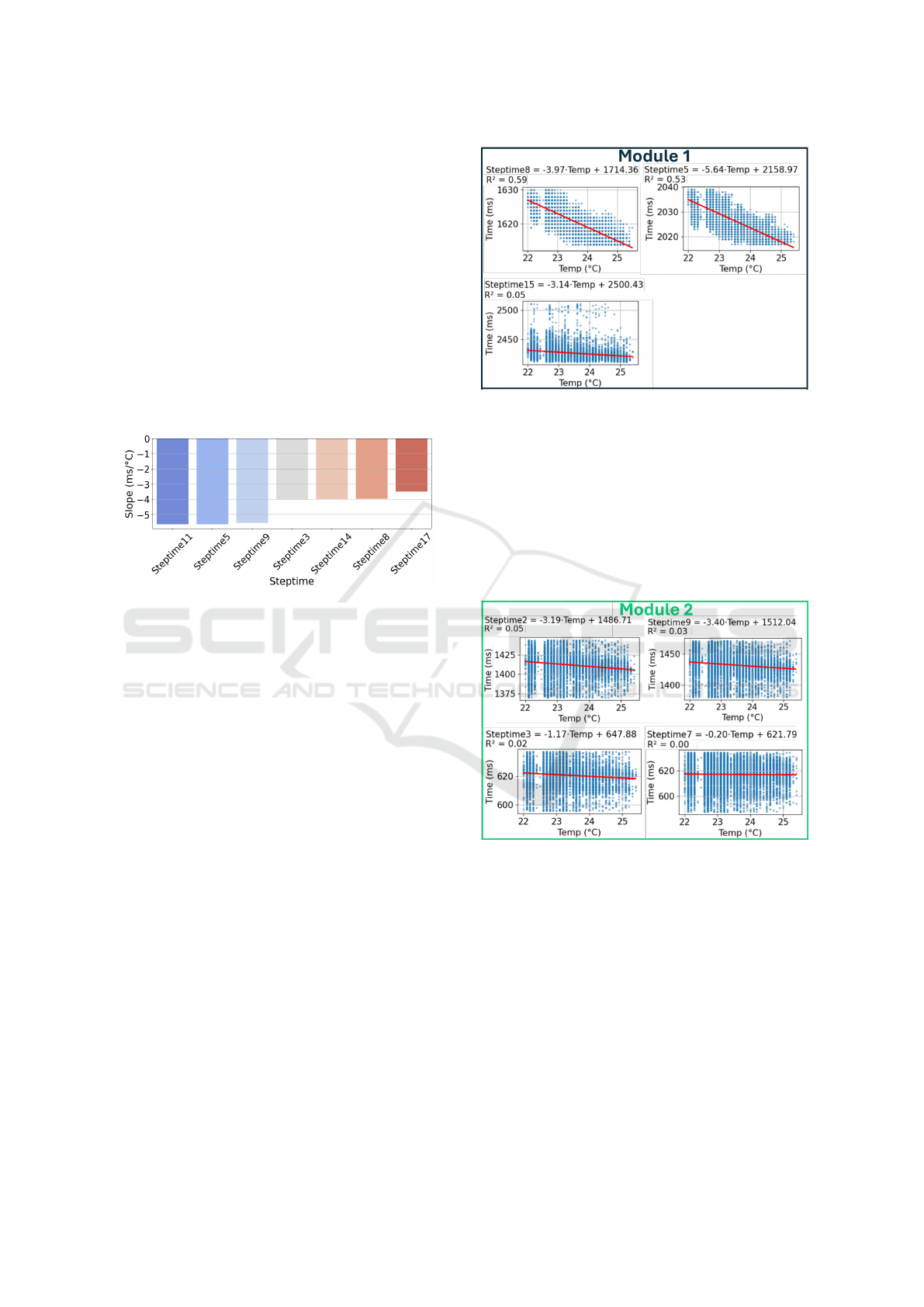

Figure 9 summarizes the most temperature-

sensitive Steptimes across the entire use case, pre-

senting the estimated slopes in ms/°C. Notably, all of

these steps belong to Module 1.

Figure 9: Estimated Temperature Sensitivity of the Most

Affected Steptimes in the use case (all from module 1).

Extension-related Steptimes (3, 8, 14, and 17)

exhibit more moderate slopes (between -3 and -

4 ms/

◦

C). This pattern suggests that the mechani-

cal and pneumatic dynamics during retraction phases

are more strongly influenced by temperature changes

than during extension phases, possibly due to dif-

ferences in internal chamber pressures and frictional

forces.

Figure 10 presents the linear regression results for

three representative Steptimes from Module 1. Step-

times 8 and 5 exhibit clear negative slopes, with esti-

mated coefficients of –3.97 ms/°C and –5.64 ms/°C,

respectively. Their corresponding R

2

values (0.59 and

0.53) indicate a moderate to strong linear correlation

between ambient temperature and Steptime duration.

These results confirm that both operations are sig-

nificantly influenced by temperature variations, with

Steptime 5 showing a particularly high thermal sen-

sitivity. In contrast, a conveyor belt and a pneumatic

cylinder operate in parallel within Steptime 15. Since

both actions start simultaneously and the belt is the

last to complete its task, the Steptime duration is de-

termined by the belt. Due to the mechanical nature of

the conveyor and its electric drive, it is barely influ-

enced by temperature changes, which explains its low

R

2

= 0.05.

Figure 11 shows regression results for four Step-

Figure 10: Linear Regression and R

2

between Stepti-

mes(ms) from Module 1 and Temperature(Cº).

times from Module 2. Although slopes remain nega-

tive, the very low R

2

values (0.00–0.05) indicate that

temperature explains little of their variability. Thus,

Module 2 timing is largely unaffected by ambient

temperature in the observed range. These differences

highlight the need for actuator-specific analysis, as

sensitivity may depend on movement type, load, or

control strategy.

Figure 11: Linear Regression and R

2

between Stepti-

mes(ms) from Module 2 and Temperature(Cº).

6 CONCLUSIONS AND FUTURE

WORK

This study presented a quantitative analysis of how

ambient temperature influences the cycle time of

pneumatic actuators in industrial production lines. By

monitoring Steptimes, the experiments demonstrated

that temperature measurably affects operation dura-

tions. A simple linear regression model quantified this

relationship through temperature coefficients (β

1

) and

coefficients of determination (R

2

). The effect mag-

Quantitative Analysis of Ambient Temperature Effects on Steptime Variations in Industrial Pneumatic Actuators

265

nitude varied across steps, suggesting that mechani-

cal configuration, load conditions, and movement dy-

namics shape each actuator’s thermal sensitivity.

These findings demonstrate that Steptime mea-

surements provide a sensitive, non-invasive indicator

of environmental influences in assembly lines. Incor-

porating such context into monitoring can improve di-

agnostics, reduce false alarms, and enable earlier de-

tection of genuine degradation.

On the other hand, no abnormal operation, faults,

or failures of the pneumatic actuators were observed

within the tested ambient range (22–25 °C). The influ-

ence of temperature was reflected exclusively in vari-

ations of Steptime values, without leading to perfor-

mance degradation or malfunction.

Future work will develop a context-aware mon-

itoring system to automatically distinguish whether

Steptime deviations arise from external factors or gen-

uine faults. The approach relies on correlations be-

tween Steptimes during normal operation: external

influences will be reflected consistently in these cor-

relations, whereas intrinsic faults will disrupt them.

ACKNOWLEDGEMENTS

The authors would like to thank the Basque Gov-

ernment and their HAZITEK program for supporting

project “GIZAK-IA”.

REFERENCES

Azid, I. A., Ani, M. N. C., Hamid, S. A. A., and Kamarud-

din, S. (2020). Solving production bottleneck through

time study analysis and quality tools integration. In-

ternational Journal of Industrial Engineering, 27(1).

Chandola, V., Banerjee, A., and Kumar, V. (2009).

Anomaly detection: A survey. ACM computing sur-

veys (CSUR), 41(3):1–58.

Fang, Y., Lu, Y., Yu, X., and Roskilly, A. P. (2018). Exper-

imental study of a pneumatic engine with heat supply

to improve the overall performance. Applied Thermal

Engineering, 134:78–85.

Garc

´

ıa, E. and Mont

´

es, N. (2019). Mini-term 4.0. a real-

time maintenance support system to prognosticate

breakdowns in production lines. In ICINCO (1), pages

180–187.

Garcia, E. and Montes, N. (2019a). Mini-term, a novel

paradigm for fault detection. In IFAC MIM 2019, 9th

IFAC Conference on Manufacturing Modelling, Man-

agement and Control, pages 165–170. IFAC / Elsevier.

Garcia, E. and Montes, N. (2019b). Mini-term, a novel

paradigm for fault detection. IFAC-PapersOnLine,

52(13):165–170.

Hayes, M. A. and Capretz, M. A. (2014). Contextual

anomaly detection in big sensor data. In 2014 IEEE

International Congress on Big Data, pages 64–71.

IEEE.

International Organization for Standardization (2010). ISO

8573-1:2010: Compressed air – Part 1: Contaminants

and purity classes. Standard, International Organiza-

tion for Standardization, Geneva. ISO 8573-1:2010.

Juba, I. and Koio, M. (2025). Wearable iot for dual mon-

itoring: Real-time occupational hazard detection and

resident fall prevention. International Journal of Age-

ing, Safety, healthcare & Science Innovation, pages

69–86.

Mohanraj, M., Jayaraj, S., and Muraleedharan, C. (2012).

Applications of artificial neural networks for refrig-

eration, air-conditioning and heat pump systems—a

review. Renewable and sustainable energy reviews,

16(2):1340–1358.

Park, C. and Joung, W. (2022). Effect of heat load

on pneumatic temperature control characteristics of

a pressure-controlled loop heat pipe. International

Journal of Heat and Mass Transfer, 186:122472.

Pham, V.-H., Nguyen, T.-D., and Bui, T.-A. (2020). Be-

havior of friction in pneumatic cylinders with different

relative humidity. Tribology in Industry, 42(3):400.

Sorli, M., Gastaldi, L., Codina, E., and de las Heras, S.

(1999). Dynamic analysis of pneumatic actuators.

Simulation Practice and Theory, 7(5-6):589–602.

Su, X., Lu, J., Chen, C., Yu, J., and Ji, W. (2022). Dy-

namic bottleneck identification of manufacturing re-

sources in complex manufacturing system. Applied

Sciences, 12(9):4195.

Su

´

arez-Varela, J. and Lutu, A. (2025). Uncovering issues in

the radio access network by looking at the neighbors.

arXiv preprint arXiv:2504.14686.

Yang, Q., Liu, W., et al. (2022). Production line balance

optimization design of s company. Manufacturing and

Service Operations Management, 3(1):57–71.

Zubieta, J., Izagirre, U., Eciolaza, L., de Buruaga, A. S.,

and Galdos, L. (2025). Step-time measurement:

A scalable sub-cycle time defining methodology for

anomaly detection and predictive maintenance in se-

quential production lines. Journal of Manufacturing

Systems, 83:1–11.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

266