Anomaly Detection in Directed Energy Deposition: A Comparative Study

of Supervised and Unsupervised Machine Learning Algorithms

Berke Ayyıldızlı, Beyza Balota, Kerem Tatari, Shawqi Mohammed Farea and Mustafa Unel

Faculty of Engineering and Natural Sciences, Sabancı University, Istanbul, Turkey

Keywords:

Directed Energy Deposition (DED), Thermal Imaging, Anomaly Detection, Supervised Learning,

Unsupervised Learning, Machine Learning.

Abstract:

Directed Energy Deposition (DED) is a promising additive manufacturing technology increasingly utilized in

critical industries such as aerospace and biomedical engineering for fabricating complex metal components.

However, ensuring the structural integrity of DED-fabricated parts remains a significant challenge due to the

emergence of in-process defects. To address this, we propose a comprehensive anomaly detection framework

that leverages in-situ thermal imaging of the melt pool for defect identification. Our approach encompasses

both supervised and unsupervised machine learning techniques to capture diverse defect patterns and accom-

modate varying levels of labeled data availability. Supervised methods—including ensemble classifiers and

deep neural networks—are employed to learn from annotated thermal data, while unsupervised methods, such

as autoencoders and clustering algorithms, are used to detect anomalies in unlabeled scenarios and uncover

previously unknown defect patterns. The pipeline incorporates essential preprocessing techniques—such as

feature extraction, normalization, and class rebalancing—to enhance model robustness. Experimental eval-

uations offer a detailed comparison between the supervised classifiers and unsupervised models utilized in

this work, emphasizing the predictive performance and practical applicability of each learning paradigm. No-

tably, the supervised classification-based framework achieved high performance in detecting porosity-related

anomalies, with an F1 score of up to 0.88 and accuracy reaching 99%.

1 INTRODUCTION

Directed Energy Deposition (DED) is a key addi-

tive manufacturing process that enables the fabrica-

tion and repair of complex metal components layer

by layer using a focused energy source. Its flexibility

makes it particularly well-suited for high-stakes in-

dustries such as aerospace, healthcare, and automo-

tive manufacturing, where mechanical integrity is es-

sential for ensuring safe and reliable operation (Dass

and Moridi, 2019; Li et al., 2023). Compared to tradi-

tional manufacturing techniques, DED facilitates the

creation of intricate geometries and enables localized

repairs, offering significant advantages in both design

flexibility and material efficiency.

Despite these benefits, DED processes are prone

to critical in-process defects—most notably poros-

ity, lack of fusion, and cracking—that can degrade

the performance and service life of the fabricated

parts (Tang et al., 2022). Early identification of

such defects is essential, especially in applications

where structural failure could have catastrophic con-

sequences. Conventional inspection techniques, in-

cluding manual review and post-process nondestruc-

tive evaluation methods such as X-ray Computed To-

mography (XCT), are limited by their inability to pro-

vide real-time feedback and often require significant

time and resources (Tang et al., 2022; Herzog et al.,

2024). Additionally, fixed-threshold and rule-based

monitoring methods fall short in capturing the com-

plex and transient thermal patterns present in DED

processes (Herzog et al., 2024).

In contrast, machine learning (ML) has emerged

as a promising approach for real-time, non-invasive

defect detection, offering the ability to learn complex

and nonlinear relationships from high-dimensional

data sources such as thermal imagery (Gaja and Liou,

2018). These data-driven methods can generalize

across subtle patterns that are difficult to capture using

deterministic thresholds or handcrafted rules, making

them ideal for DED monitoring. In the existing lit-

erature, a variety of supervised ML classifiers have

been employed for defect detection, including dis-

criminant analysis, support vector machines, and en-

Ayyıldızlı, B., Balota, B., Tatari, K., Farea, S. M. and Unel, M.

Anomaly Detection in Directed Energy Deposition: A Comparative Study of Supervised and Unsupervised Machine Learning Algorithms.

DOI: 10.5220/0013729800003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 503-510

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

503

semble methods (Khanzadeh et al., 2018), as well as

deep neural network architectures (Patil et al., 2023).

In addition, unsupervised learning techniques—such

as self-organizing maps (SOM), K-means clustering,

and Density-Based Spatial Clustering of Applications

with Noise (DBSCAN) —have also been explored for

identifying anomalies in thermal data during the DED

process (Taheri et al., 2019; Garc

´

ıa-Moreno, 2019;

Farea et al., 2024).

However, several research gaps remain unad-

dressed. First, there is a lack of comparative stud-

ies that rigorously evaluate supervised and unsuper-

vised ML methods side-by-side for DED defect de-

tection, especially in terms of robustness under real-

world conditions. Most prior works tend to focus

exclusively on one paradigm without assessing the

strengths and limitations of both. Second, threshold

selection in anomaly detection—particularly for un-

supervised methods like autoencoders—often lacks

standardized or domain-specific criteria, making it

difficult to generalize results across datasets and ap-

plications. Lastly, practical concerns such as extreme

class imbalance, data quality issues, and interpretabil-

ity are frequently underexplored, despite their signifi-

cant impact on real-world deployment.

In this study, we introduce a comprehensive

framework that leverages both supervised and unsu-

pervised ML techniques to detect porosity-related de-

fects in DED using thermal image data. The unsu-

pervised models include autoencoders and DBSCAN,

whilst the supervised models include Random For-

est, Extreme Gradient Boosting (XGBoost), and Con-

volutional Neural Networks (CNNs). These mod-

els are tested on a dataset comprising 1,564 thermal

images of the melt pool, where only 4.5% of im-

ages contain porosity-related defects (Zamiela et al.,

2023). This severe class imbalance introduces model-

ing challenges and necessitates preprocessing strate-

gies tailored to noisy, sparse, and imbalanced data.

A preprocessing pipeline was implemented to over-

come these limitations, including outlier removal,

data imputation, normalization, and class rebalancing.

Furthermore, feature extraction was used to support

interpretable models and reduce input dimensional-

ity. Extracted features include statistical descrip-

tors of the melt pool’s thermal distribution—such as

mean, standard deviation, skewness, and interquartile

range—which have been shown in prior research to

correlate with melt pool quality and porosity forma-

tion (Garc

´

ıa-Moreno, 2019).

This work offers a comparative study of ML meth-

ods for DED defect detection, with an emphasis on

practical issues such as data imbalance, preprocess-

ing complexity, thresholding strategies, and model

interpretability. By combining domain knowledge

with modern ML techniques, the proposed framework

aims to advance real-time defect detection in additive

manufacturing. Ultimately, the results contribute to

the goal of establishing DED as a robust and reliable

process for safety-critical industrial applications.

2 METHODOLOGY

2.1 Preprocessing Pipeline

Due to inconsistencies and noise present in the raw

thermal image data, a robust preprocessing pipeline

was implemented to prepare model-ready inputs and

enhance the performance of both supervised and un-

supervised learning models.

Some images in the dataset contain zero-valued

pixels and/or pixels with missing values. The values

of these pixels were imputed using the mean of their

respective columns within each image. Then, the ther-

mal data underwent min-max normalization, scaling

pixel values to the range of [0, 1]. This normalization

step was crucial for stabilizing gradient-based opti-

mizers in neural network training and ensuring con-

sistency and comparability across ML models.

For the shallow models, feature extraction was

employed to reduce dimensionality and enhance in-

terpretability. Each thermal image was transformed

into a structured feature vector comprising 11 statis-

tical descriptors: minimum (Min Temp), maximum

(Max Temp), mean (Mean Temp), standard devia-

tion (Std Temp), median (Median Temp), first quar-

tile (Q1), third quartile (Q3), interquartile range

(IQR), skewness, kurtosis, and peak temperature pixel

(High Temp Pixels). These features summarize the

spatial and statistical properties of the melt pool tem-

perature distribution, providing a compact and infor-

mative input format for training the supervised tree-

based classifiers—the Random Forest and XGBoost

classifiers.

Considering the inherent imbalance in the dataset,

the Synthetic Minority Oversampling Technique

(SMOTE) was employed during the training of the

supervised models. SMOTE generates synthetic mi-

nority class samples by interpolating between existing

anomalous instances, mitigating classification bias,

and improving the defect detection recall.

Collectively, these preprocessing strategies en-

sured the dataset’s compatibility and consistency

across diverse ML models, ultimately enhancing the

effectiveness and interpretability of the anomaly de-

tection framework.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

504

2.2 Supervised ML Models

2.2.1 Ensemble Tree-Based Models

The ensemble tree-based models include two effective

classifiers as follows:

Random Forest: It is an ensemble ML algorithm

that combines multiple decision trees to deliver robust

predictions through majority voting (Rigatti, 2017).

Random forests are particularly effective in handling

high-dimensional data, reducing overfitting, and pro-

viding feature importance insights, making them a

preferable choice for anomaly detection in DED pro-

cesses using thermal image-derived features.

XGBoost: It is an advanced gradient boosting

framework that builds upon traditional tree-based en-

semble methods by employing iterative training of

shallow decision trees (Chen and Guestrin, 2016).

XGBoost is especially renowned for its performance

on structured, tabular datasets and its inherent robust-

ness in managing class imbalance, sparse features,

and noisy data, making it particularly suitable for

anomaly detection in DED processes.

Both classifiers were configured and fine-tuned to

achieve optimal performance while ensuring general-

izability. Through preliminary experimentation and

cross-validation, the hyperparameters were selected

according to Table 1, ensuring the best compromise

between predictive accuracy and model simplicity.

The random state was set at 42 for reproducibility of

experimental results.

For both classifiers, a structured feature vector

comprising 11 statistical features extracted from the

thermal images was used as input. The dataset was

divided into training and test sets using a stratified

70%-30% split, preserving the original class distribu-

tion within each subset. The SMOTE algorithm was

then applied solely to the training set to avoid data

leakage and realistically simulate practical scenarios,

resulting in balanced class proportions that enhance

the classifier’s sensitivity to anomalies.

By leveraging carefully extracted statistical fea-

tures, robust oversampling techniques, and thorough

hyperparameter tuning, these supervised approaches

significantly enhances the defect detection process, as

can be noticed in Section 3.

Table 1: Hyperparameters of Random Forest and XGBoost.

Random Forest XGBoost

Number of Estimators 100 Number of Estimators 100

Max. Depth 5 Max. Depth 3

Min. Samples per Split 5 L2 Regularization 1

Min. Samples per Leaf 2 L1 Regularization 0.5

Lastly, one of the inherent key strengths of Ran-

dom Forest and XGBoost lies in their transparency

regarding feature importance, allowing practitioners

to directly interpret and understand critical features

impacting anomaly detection outcomes. This inter-

pretability is particularly beneficial for manufacturing

engineers and quality analysts in pinpointing key in-

dicators of defects in real-world DED processes.

2.2.2 Convolutional Neural Network (CNN)

CNNs are a subclass of deep learning models, partic-

ularly effective for spatial data such as images. In this

study, CNNs were utilized in a supervised learning

context to directly classify thermal images as either

defective or non-defective.

After preprocessing, the dataset was split into

training and test sets with an 70%-30% stratified split

to preserve class distribution. To address the highly

imbalanced nature of the dataset, SMOTE was ap-

plied to the training set. Since SMOTE requires 2D

inputs, training images were first flattened, oversam-

pled, and reshaped back to their original shape.

The CNN architecture consisted of the following

layers:

• Conv2D (16 filters) with ReLU activation and

a 3 × 3 kernel, followed by a maximum pooling

layer.

• Conv2D (32 filters) with ReLU activation and

a 3 × 3 kernel, followed by a maximum pooling

layer

• Flatten layer to convert spatial features into a

dense vector.

• Dropout layer (rate = 0.3) to prevent overfitting.

• Dense layer (64 units) with ReLU activation.

• Output layer (1 unit) with sigmoid activation for

binary classification.

The model was compiled with the Adam opti-

mizer (learning rate = 0.001), using the binary cross-

entropy loss. The network was trained for 10 epochs

with a batch size of 16, using 20% of the training data

as a validation set.

2.3 Unsupervised ML Models

2.3.1 Autoencoder

Autoencoders are a class of artificial neural networks

primarily used for unsupervised learning and anomaly

detection. They are designed to learn compressed,

low-dimensional representations of the input data and

subsequently reconstruct the input from this encod-

ing. Deviations between the input and reconstructed

Anomaly Detection in Directed Energy Deposition: A Comparative Study of Supervised and Unsupervised Machine Learning Algorithms

505

output serve as a basis for identifying anomalous in-

stances. Instances with high reconstruction errors are

considered potential anomalies, as they deviate from

the learned patterns of normal data (Zhou and Paf-

fenroth, 2017). Since autoencoders are trained solely

to reproduce their input, they do not require labeled

data, making them inherently suitable for unsuper-

vised anomaly detection.

The model implemented in this study consists of

three primary layers: an input, encoding layer, and

decoding layer. The input layer accepts flattened vec-

tors of the thermal images. The encoding layer con-

tains 64 neurons, strategically selected through empir-

ical testing to ensure sufficient information retention

without overfitting. This layer employs the ReLU ac-

tivation function because of its efficacy in handling

continuous numeric data and mitigating issues such as

vanishing gradients. The decoding layer mirrors the

dimensionality of the input layer and uses a sigmoid

activation function to produce output values within

a normalized range of 0 to 1, ensuring compatibility

with the scaled thermal image data.

The autoencoder was trained using the entire

dataset of preprocessed thermal images, consisting

of 1,564 frames, each normalized to manage pixel

value disparities. The training regime consisted

of 50 epochs with a batch size of 16, determined

through preliminary experimentation to balance train-

ing performance and computational efficiency. Dur-

ing training, input data points were continuously re-

constructed, using the Adam optimizer to minimize

the mean square error (MSE) loss between the origi-

nal and reconstructed frames.

After training, anomaly detection was performed

by evaluating the reconstruction error for each ther-

mal frame. The underlying hypothesis is that anoma-

lous frames, characterized by porosity or structural

defects, inherently deviate significantly from normal

thermal patterns, resulting in a higher reconstruction

error. To systematically identify anomalies, two dis-

tinct thresholds based on the percentile distribution of

reconstruction errors were established:

• 95th Percentile Threshold: Frames with MSE

above the 95th percentile were labeled anoma-

lous.

• 99th Percentile Threshold: A more conservative

approach, identifying only the extreme deviations

by setting a threshold at the 99th percentile.

This dual-threshold strategy allowed a nuanced

analysis of detection sensitivity and specificity, pro-

viding insights into the optimal balance for practical

anomaly detection within industrial contexts. Overall,

the autoencoder-based anomaly detection methodol-

ogy outlined provides a robust, unsupervised frame-

work adaptable for monitoring DED processes, offer-

ing a valuable alternative when labeled data is scarce

or expensive to obtain.

2.3.2 DBSCAN

It is a density-based clustering algorithm widely used

in unsupervised anomaly detection tasks. Unlike tra-

ditional clustering algorithms, DBSCAN does not re-

quire a predefined number of clusters; instead, it iden-

tifies clusters based on the density of data points,

classifying points in low-density regions as anoma-

lies (Deng, 2020). Given the high-dimensional na-

ture of the thermal images, dimensionality reduction

was critical for the effective application of DBSCAN.

Principal Component Analysis (PCA) was employed

to reduce the dimensionality of the input thermal im-

ages to 50 principal components (Hemanth, 2020).

This transformation significantly decreased computa-

tional complexity, improved clustering efficiency, and

enhanced the clarity of density-based clusters.

Nonetheless, the optimal parameter selection is

essential for DBSCAN performance. The algorithm

primarily depends on two parameters: the neighbor-

hood radius (ε) and the minimum number of points

required to form a dense region (min samples). To

determine the optimal ε value, a k-distance heuristic

method was utilized, as displayed in Figure 1. Specif-

ically, distances to the 5th nearest neighbor for each

data point were calculated, sorted, and plotted to iden-

tify an elbow point—representing an optimal balance

between overly fragmented clusters (too small ε) and

merged clusters (too large ε). Based on this heuristic,

the ε value was set to 7.7, while the min samples pa-

rameter was set to 5 (see Figure 1). This configuration

provided an effective balance, ensuring that density-

based clustering appropriately distinguished anoma-

lies from typical data patterns. With the optimized

parameters, DBSCAN clusters the PCA-transformed

image data into dense regions, labeling points outside

these clusters as anomalies.

Figure 1: K-Distance graph used for optimal epsilon value

selection. The sharp increase (elbow) around 7.7 suggests

this as the optimal ε value.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

506

3 RESULTS AND DISCUSSION

3.1 Dataset Description

The dataset used in this work (Zamiela et al., 2023)

consists of 1,564 thermal images of the melt pool

recorded during the fabrication of Ti–6Al–4V thin-

walled structures using the OPTOMEC LENS™ 750

system. The thermal images were captured in-process

using a Stratonics dual-wavelength pyrometer, which

records a top-down view of the melt pool during laser

deposition. Each frame consists of a 200×200 pixel

thermal image capturing the relative temperature dis-

tribution of the melt pool. Binary porosity labels

were assigned based on post-process inspection us-

ing Nikon XT H225 X-ray Computed Tomography.

Only 71 images (about 4.5%) contain porosity-related

defects, whilst the remaining 1493 images are defect-

free, leading to a significant class imbalance. This re-

markable class imbalance poses challenges for model

generalization and sensitivity to rare events. Repre-

sentative defect-free and defective images are shown

in Figure 2.

Figure 2: Normal vs defective thermal images.

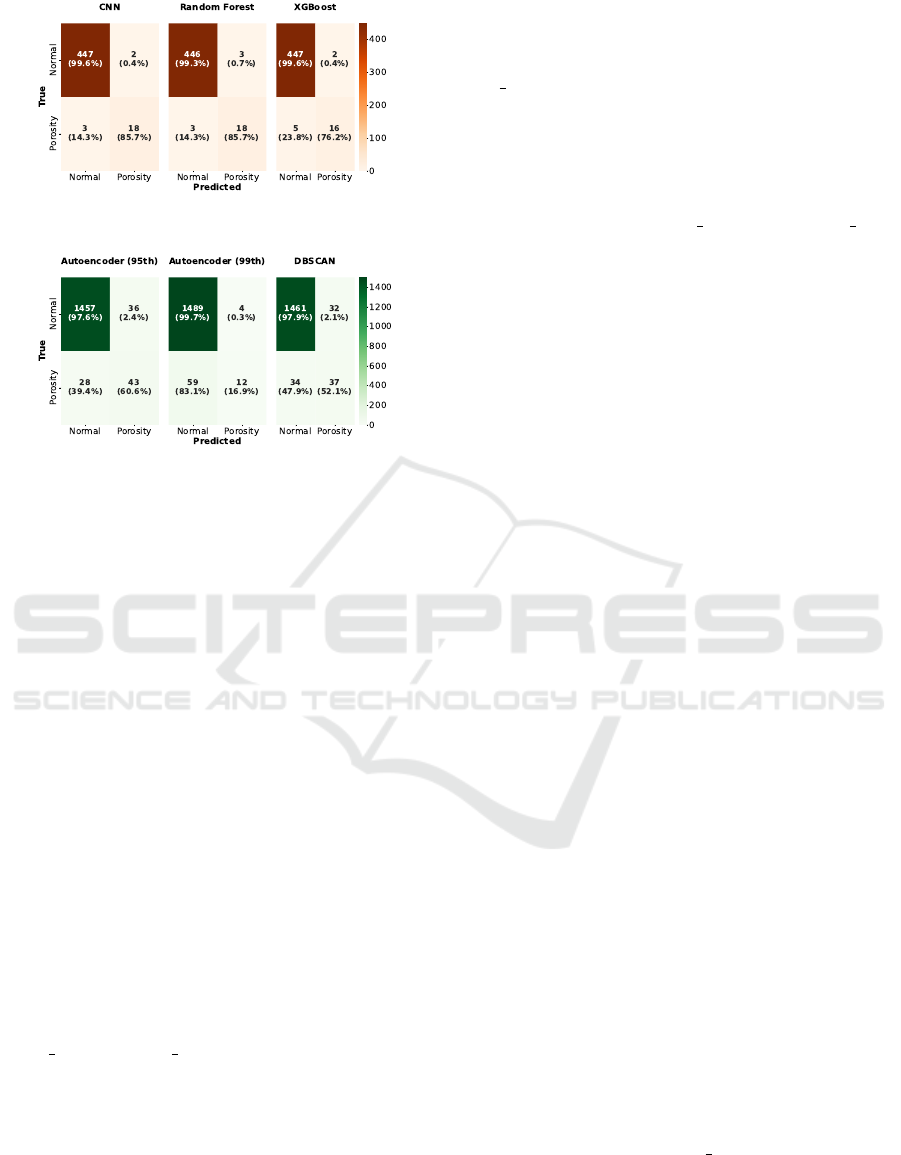

3.2 Defect Detection Results

The comparative evaluation of the models is pre-

sented in Tables 2 and 3, with corresponding confu-

sion matrices shown in Figures 3 and 4. Each model

was assessed based on its ability to identify porosity-

related anomalies from thermal image data, under the

same preprocessing and evaluation.

Among the supervised models, the CNN model

exhibited the most favorable performance profile. It

achieved the most balanced trade-off between preci-

sion and recall, and demonstrated minimal misclas-

sification of both normal and defective instances, as

reflected in its confusion matrix. The direct use of

image-level data, without handcrafted features, likely

contributed to its ability to capture nuanced spatial

patterns indicative of structural defects.

The ensemble tree-based models yielded good re-

sults, although working with low-dimensional input

data compared to CNN. In particular, Random Forest

achieved results comparable to CNN with an F1 score

Table 2: Supervised models results.

Model Precision Recall F1-Score Accuracy

CNN 0.90 0.86 0.88 0.99

Random Forest 0.86 0.86 0.86 0.98

XGBoost 0.89 0.76 0.82 0.98

Table 3: Unsupervised models results.

Model Precision Recall F1-Score Accuracy

Autoencoder (99th) 0.75 0.17 0.28 0.96

Autoencoder (95th) 0.54 0.61 0.57 0.96

DBSCAN 0.54 0.52 0.53 0.96

of 0.86. It yielded consistently high results across all

metrics. The confusion matrix for Random Forest re-

veals only a small number of false positives and false

negatives, underscoring its reliability in practical clas-

sification tasks. XGBoost, while slightly behind the

other two, remained a competitive model with high

precision and moderate recall. Its performance sug-

gests that it is more conservative in detecting anoma-

lies, favoring precision over sensitivity. This behavior

can be useful in industrial settings where minimizing

false alarms is critical, though it may result in some

defective instances being overlooked.

In contrast, the unsupervised models demon-

strated a wider range of performance, with substan-

tial variation depending on threshold sensitivity and

underlying assumptions. The autoencoder’s detection

capability was heavily influenced by the selected per-

centile threshold. At the 95th percentile, it captured

a larger portion of true anomalies but also introduced

more false positives. The 99th percentile threshold,

being more conservative, reduced false positives at

the expense of significantly lower recall. This trade-

off is clearly reflected in the differences between the

two confusion matrices in Figure 4.

DBSCAN, as a clustering-based method, strug-

gled to consistently distinguish defective instances

from the background class (normal class). Its detec-

tion capability was less focused, and it tended to mis-

classify both normal and anomalous samples. Despite

dimensionality reduction via PCA and careful param-

eter tuning, DBSCAN’s density-based assumptions

proved less effective in this context, where anomalies

are subtle and highly variable.

When comparing the two learning paradigms, su-

pervised models consistently outperformed their un-

supervised counterparts across all evaluation metrics.

The availability of labeled data, combined with class

rebalancing techniques such as SMOTE, enabled su-

pervised classifiers to learn more discriminative deci-

sion boundaries. Crucially, these models are explic-

itly trained and optimized to classify thermal images

as either normal or anomalous. In contrast, unsu-

pervised models are typically designed for auxiliary

Anomaly Detection in Directed Energy Deposition: A Comparative Study of Supervised and Unsupervised Machine Learning Algorithms

507

Figure 3: Confusion matrices of the supervised models.

Figure 4: Confusion matrices of the unsupervised models.

tasks, such as input reconstruction or density estima-

tion, that are not directly aligned with classification

objectives. This mismatch limits their sensitivity to

subtle, class-specific patterns, particularly in imbal-

anced datasets. Although autoencoders provided a

flexible and scalable detection framework, their per-

formance was highly dependent on threshold selec-

tion. Similarly, DBSCAN lacked the granularity nec-

essary for fine-grained anomaly identification. Col-

lectively, these findings underscore the advantages of

supervised learning when labeled data is available,

while also highlighting the potential of unsupervised

methods as complementary tools—provided they are

carefully tuned for the task.

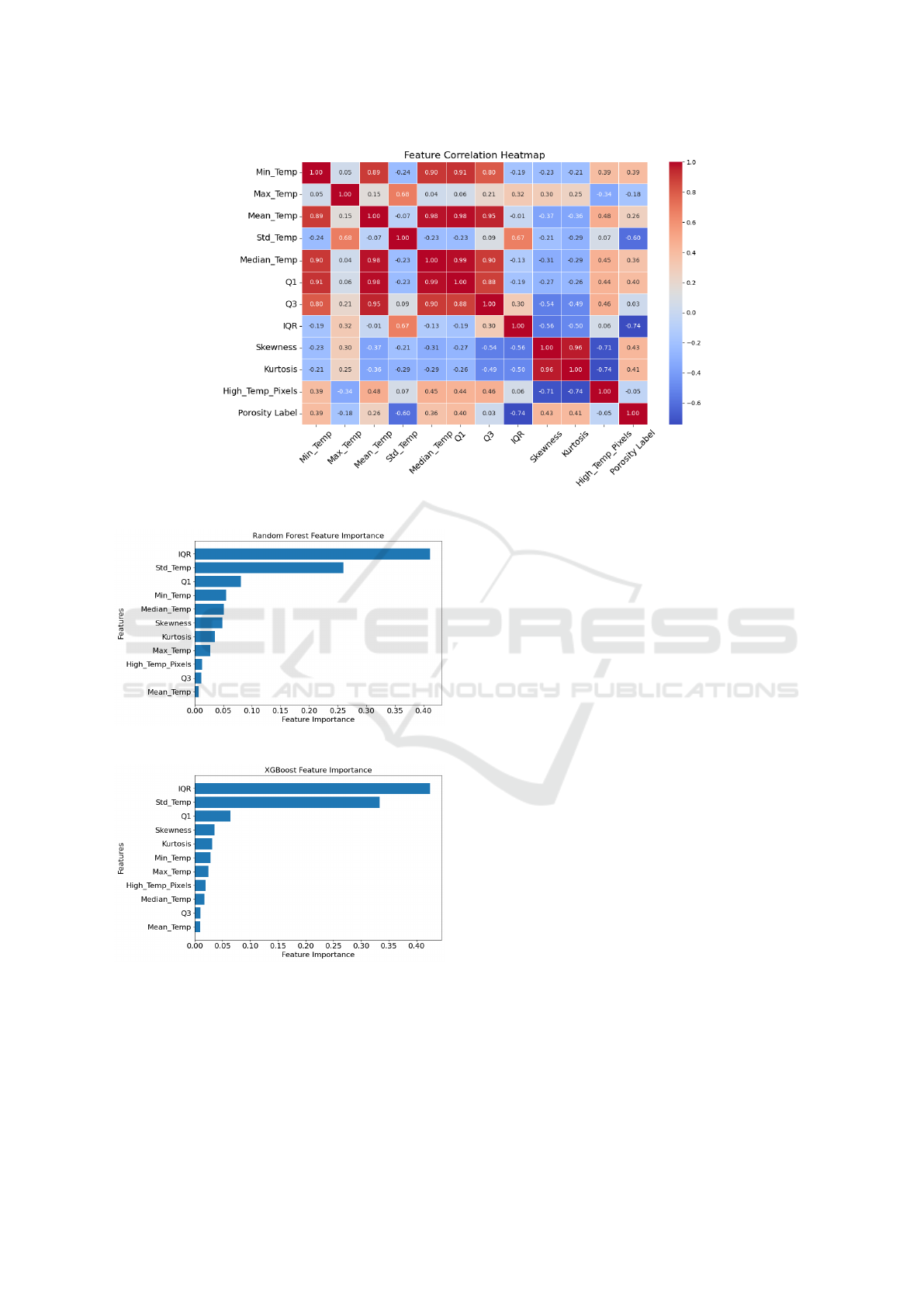

3.3 Feature Analysis

Feature-level analysis revealed several insights into

model behavior and predictive performance. To bet-

ter understand the relationships among input features,

a Pearson correlation test was conducted. The cor-

relation matrix, shown in Figure 5, indicates strong

collinearity among central tendency features such as

Mean Temp, Median Temp, Q1, and Q3, suggesting

redundancy in the thermal distribution representation.

In contrast, features like Skewness, Kurtosis, and IQR

demonstrated lower correlation with others, implying

they provide orthogonal, potentially more informative

cues for anomaly detection.

The feature importance rankings derived from su-

pervised models further validate the relevance of spe-

cific features. The importance plots for Random For-

est and XGBoost are provided in Figure 6a and 6b,

respectively. Both Random Forest and XGBoost

consistently prioritized dispersion metrics—IQR and

Std Temp—as the most influential attributes in distin-

guishing between normal and defective samples. This

aligns with the observation that defective frames of-

ten display abrupt changes in temperature variance,

which are effectively captured by interquartile spread

and standard deviation.

Interestingly, while Min Temp and Median Temp

appeared highly correlated in the correlation matrix,

their respective importances varied between mod-

els—suggesting that although correlated, they do not

necessarily provide equivalent discriminative value.

This underscores the benefit of ensemble-based fea-

ture evaluation, where subtle nonlinear relationships

are accounted for during tree construction.

Altogether, the correlation and feature importance

analyses offer actionable insights for dimensionality

reduction, feature selection, and interpretability. They

confirm that a subset of carefully engineered fea-

tures—particularly those reflecting distribution shape

and spread—can effectively support robust classifica-

tion, even in imbalanced anomaly detection settings.

3.4 Final Remarks

Learning Paradigm: Supervised models clearly

benefited from labeled data and class rebalancing

techniques, enabling them to achieve higher and more

consistent detection accuracy. However, this advan-

tage comes at the cost of increased data annotation

effort and reduced flexibility. In industrial settings

where defect annotation is costly or infeasible at

scale, the reliance of supervised models on labeled

datasets may limit their broader applicability. In con-

trast, unsupervised models offered greater flexibil-

ity by operating without labeled defect data, making

them appealing for anomaly detection in exploratory

or early-stage quality monitoring systems.

Threshold Sensitivity and Stability: While au-

toencoders provided a scalable and adaptable frame-

work capable of learning general thermal patterns,

their effectiveness was tightly coupled to the choice

of reconstruction error threshold. This intro-

duces subjectivity and leads to performance trade-

offs—particularly between recall and false-positive

rates. Similarly, DBSCAN was highly sensitive to pa-

rameter selection (ε and min samples) and struggled

with the subtle and highly variable defect patterns typ-

ical of DED processes.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

508

Figure 5: Feature correlation heatmap among extracted statistical features.

(a) Random Forest

(b) XGBoost

Figure 6: Feature importance plot from the ensemble tree-

based models.

Interpretability and Practical Transparency:

From an interpretability standpoint, the super-

vised tree-based models—Random Forest and

XGBoost—provided clear advantages. Through

feature importance rankings, these models enabled

traceable classification decisions and gave practition-

ers direct insights into which statistical temperature

features were most indicative of porosity-related

anomalies. This level of transparency is particularly

valuable in high-stakes manufacturing environments,

where model trustworthiness is critical. On the

other hand, although unsupervised models are more

adaptable, their decisions are often harder to ex-

plain—especially when based on latent encodings or

density-based assumptions.

Deployment Considerations: While supervised

models deliver stronger performance when sufficient

labeled data is available, their deployment requires

pre-existing defect annotations and careful data bal-

ancing. Unsupervised approaches, however, can be

rapidly deployed in dynamic environments with lim-

ited prior knowledge, making them better suited for

initial system integration or ongoing monitoring. The

optimal deployment strategy may involve a hybrid ap-

proach—utilizing unsupervised methods for continu-

ous monitoring or early anomaly flagging, followed

by supervised refinement when annotated data be-

comes available.

4 CONCLUSION

This study presents a comprehensive comparison

of supervised and unsupervised learning approaches

Anomaly Detection in Directed Energy Deposition: A Comparative Study of Supervised and Unsupervised Machine Learning Algorithms

509

for anomaly detection in DED processes based

on thermal image data, highlighting the respective

strengths and limitations of each paradigm. Super-

vised models—namely, CNN, Random Forest, and

XGBoost—consistently outperformed their unsuper-

vised counterparts, benefiting from labeled data, syn-

thetic oversampling via SMOTE, and, for the tree-

based models, statistically engineered features. While

autoencoders and DBSCAN offered greater flexibility

and did not require labeled data, their performance

was more sensitive to thresholding and parameter se-

lection.

The results highlight the practicality and reliabil-

ity of supervised learning in quality-critical applica-

tions where labeled datasets are available. However,

unsupervised methods remain valuable for early-

stage deployment and real-time monitoring scenar-

ios. Moving forward, hybrid frameworks that com-

bine the strengths of both paradigms—starting with

unsupervised detection and refining with supervised

feedback—offer a promising direction for scalable,

interpretable, and robust defect detection in metal ad-

ditive manufacturing.

REFERENCES

Chen, T. and Guestrin, C. (2016). XGBoost: A scalable

tree boosting system. In Proceedings of the 22nd

ACM SIGKDD International Conference on Knowl-

edge Discovery and Data Mining, pages 785–794, San

Francisco, CA, USA.

Dass, A. and Moridi, A. (2019). State of the art in directed

energy deposition: From additive manufacturing to

materials design. Coatings, 9(7):418.

Deng, D. (2020). DBSCAN clustering algorithm based

on density. In Proceedings of the 2020 7th Interna-

tional Forum on Electrical Engineering and Automa-

tion (IFEEA), pages 100–103, Zhuhai, China.

Farea, S. M., Unel, M., and Koc, B. (2024). Defect pre-

diction in directed energy deposition using an ensem-

ble of clustering models. In Proceedings of the 2024

IEEE 22nd International Conference on Industrial In-

formatics (INDIN), pages 1–6.

Gaja, H. and Liou, F. (2018). Defect classification of laser

metal deposition using logistic regression and artifi-

cial neural networks for pattern recognition. Interna-

tional Journal of Advanced Manufacturing Technol-

ogy, 94:315–326.

Garc

´

ıa-Moreno, A.-I. (2019). Automatic quantification

of porosity using an intelligent classifier. Interna-

tional Journal of Advanced Manufacturing Technol-

ogy, 105(5):1883–1899.

Hemanth, D. J. (2020). Dimensionality reduction of produc-

tion data using PCA and DBSCAN techniques. Inter-

national Journal of Scientific Research in Engineering

and Development, 3(6):325–329.

Herzog, T., Brandt, M., Trinchi, A., et al. (2024). Defect

detection by multi-axis infrared process monitoring of

laser beam directed energy deposition. Scientific Re-

ports, 14(1):3861.

Khanzadeh, M., Chowdhury, S., Marufuzzaman, M.,

Tschopp, M. A., and Bian, L. (2018). Porosity predic-

tion: Supervised-learning of thermal history for direct

laser deposition. Journal of Manufacturing Systems,

47:69–82.

Li, S. H., Kumar, P., and Chandra, S. (2023). Directed

energy deposition of metals: Processing, microstruc-

tures, and mechanical properties. International Mate-

rials Reviews, 68(1):1–44.

Patil, D. B., Nigam, A., Mohapatra, S., and Nikam, S.

(2023). A deep learning approach to classify and de-

tect defects in the components manufactured by laser

directed energy deposition process. Machines, 11(9).

Rigatti, S. J. (2017). Random forests. Journal of Insurance

Medicine, 47(1):31–39.

Taheri, H., Koester, L. W., Bigelow, T. A., Faierson, E. J.,

and Bond, L. J. (2019). In situ additive manufactur-

ing process monitoring with an acoustic technique:

clustering performance evaluation using k-means al-

gorithm. Journal of Manufacturing Science and Engi-

neering, 141(4).

Tang, D., He, X., Wu, B., Wang, X., Wang, T., and Li, Y.

(2022). The effect of porosity defects on the mid-

cycle fatigue behavior of directed energy deposited

Ti–6Al–4V. Theoretical and Applied Fracture Me-

chanics, 118:103296.

Zamiela, C., Tian, W., Guo, S., and Bian, L. (2023).

Thermal-porosity characterization data of additively

manufactured Ti–6Al–4V thin-walled structure via

laser engineered net shaping. Data in Brief,

51:109722.

Zhou, C. and Paffenroth, R. C. (2017). Anomaly detec-

tion with robust deep autoencoders. In Proceedings of

the 23rd ACM SIGKDD International Conference on

Knowledge Discovery and Data Mining (KDD), pages

665–674.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

510