Semi-Supervised Anomaly Detection in Directed Energy Deposition

Using Thermal Images

Ufuk Ismail Ozdek, Yigit Kaan Tonkaz, Shawqi Mohammed Farea and Mustafa Unel

Faculty of Engineering and Natural Sciences, Sabancı University, Istanbul, Turkey

Keywords:

Additive Manufacturing, Directed Energy Deposition (DED), Anomaly Detection, Semi-Supervised Learning,

One-Class Support Vector Machine (OCSVM), Isolation Forest (iForest).

Abstract:

Directed Energy Deposition (DED) is a crucial additive manufacturing process used in aerospace and health-

care applications, among others. However, ensuring defect-free production remains a challenge due to the

difficulty in detecting defect-related anomalies in real-time. In this study, we address the problem of defect

detection in DED processes through thermal images of melt pools. As an anomaly detection problem, we

adopt a semi-supervised approach based on One-Class Support Vector Machine (OCSVM) and Isolation For-

est (iForest). We analyze the performance of these models across different feature sets. Additionally, this

semi-supervised approach is compared against an unsupervised approach utilizing the same learning algo-

rithms. The results indicate the superiority of the semi-supervised approach for both algorithms. Yet, iForest

outperforms OCSVM with an accuracy of 95% and an F1-score of 0.88, demonstrating its robustness in distin-

guishing defective from non-defective instances. This work provides valuable insights into the applicability of

semi-supervised machine learning techniques for real-time defect detection in DED processes. By leveraging

thermal imaging data and feature-based anomaly detection models, our findings contribute to the development

of efficient, non-destructive quality control mechanisms for additive manufacturing processes.

1 INTRODUCTION

Additive manufacturing (AM) has revolutionized the

production of complex metal components in indus-

tries such as aerospace, healthcare, and defense (Dass

and Moridi, 2019). Among various AM techniques,

Directed Energy Deposition (DED) offers unique

advantages in producing large-scale, high-strength

parts due to its ability to deposit material layer-by-

layer with controlled thermal input (Li et al., 2023).

However, ensuring the structural integrity of DED-

manufactured components remains a significant chal-

lenge due to the formation of in-situ defects such as

porosity, cracking, and lack of fusion. These defects,

if undetected, compromise the mechanical properties

of the final product and necessitate expensive post-

production inspections, increasing both costs and ma-

terial waste (Tang et al., 2022). Traditional de-

fect detection methods, such as X-ray Computed To-

mography (XCT) and destructive testing, are time-

consuming and impractical for real-time monitoring.

While process maps and optimized printing parame-

ters can reduce defects, they do not eliminate them

entirely due to variations in machine settings, mate-

rial properties, and environmental factors. Therefore,

real-time, non-destructive anomaly detection is cru-

cial for improving the quality and reliability of DED-

printed parts (Zamiela et al., 2023b; Herzog et al.,

2024).

Machine learning-based approaches provide a

promising alternative by enabling real-time, non-

destructive defect detection, thereby reducing reliance

on post-production inspections. While machine learn-

ing (ML) techniques have been extensively explored

for defect detection in additive manufacturing, their

application to DED remains comparatively underde-

veloped (Hespeler et al., 2022; Qin et al., 2022),

with most research focusing on Powder Bed Fusion

(PBF) and Selective Laser Melting (SLM). ML-based

anomaly detection in DED is still evolving, with

promising potential for enhancing product quality.

Among ML approaches, supervised methods,

such as support vector machines (SVM) and convo-

lutional neural networks (CNN), achieve high accu-

racy in classifying defects in DED processes using

thermal images. However, they require extensive la-

beled datasets, which are resource-intensive to obtain

(Gaja and Liou, 2018; Khanzadeh et al., 2018). In

Ozdek, U. I., Tonkaz, Y. K., Farea, S. M. and Unel, M.

Semi-Supervised Anomaly Detection in Directed Energy Deposition Using Thermal Images.

DOI: 10.5220/0013729700003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 437-445

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

437

contrast, unsupervised techniques have gained signif-

icant attention for defect detection in DED processes

due to their ability to analyze large amounts of un-

labeled data and identify hidden patterns associated

with defects. Techniques such as K-means clustering,

self-organizing maps (SOM), density-based spatial

clustering of applications with noise (DBSCAN), and

principal component analysis (PCA) are commonly

used to detect anomalies in process data (Taheri et al.,

2019; Garc

´

ıa-Moreno, 2019; Farea et al., 2024). Ad-

ditionally, unsupervised deep learning methods, such

as Variational Autoencoders (VAE), have been ex-

plored for capturing complex, non-linear relation-

ships in DED thermal imaging data. VAE has been

used to encode high-dimensional thermal images into

a latent space, reconstructing input images and iden-

tifying defects by analyzing reconstruction errors

(Zhao et al., 2021). Gaussian mixture model (GMM)

and K-means clustering techniques have been ap-

plied to these latent representations to further refine

anomaly detection in melt pools, allowing models to

separate defective and normal regions effectively.

Recent studies have also focused on self-

supervised learning techniques, such as Masked Au-

toencoders (MAE) and Vision Transformers (ViT),

to enhance feature extraction from unlabeled melt

pool data (Era et al., 2024). MAE has been pre-

trained on thermal images, where a portion of the

image was masked and reconstructed, enabling the

model to capture robust spatial dependencies with-

out requiring labeled data. After pretraining, fine-

tuned MAE was successfully integrated with super-

vised classifiers, such as CNN and Multi-Layer Per-

ceptron (MLP) models, to detect melt pool anoma-

lies. These advancements underscore the potential of

self-supervised learning and deep generative models

in enhancing real-time, unsupervised defect detection

in DED, reducing reliance on large labeled datasets,

and improving the scalability of in-situ quality con-

trol frameworks (Era et al., 2024).

However, the formulation of DED defect detec-

tion as a semi-supervised learning problem remains

underexplored. This formulation offers a distinct ad-

vantage over supervised and unsupervised methods,

particularly in handling data imbalance. As with

most anomaly detection tasks, DED defect detection

datasets are imbalanced, with defective instances rep-

resenting only a small fraction of the data. In a semi-

supervised framework, models are trained exclusively

on normal data to learn the underlying distribution

of normal behavior, where significant deviations from

this distribution are classified as anomalies. This ap-

proach enhances robustness against data imbalance

compared to supervised and unsupervised methods.

In this work, we formulate defect detection

in DED processes as a semi-supervised learning

problem, employing two effective semi-supervised

algorithms: One-Class Support Vector Machine

(OCSVM) and Isolation Forest (iForest). To effec-

tively model the normal behavior of defect-free data,

we implement preprocessing steps such as segmenta-

tion and domain knowledge-driven feature engineer-

ing.

The remainder of the paper is organized as fol-

lows: Section 2 details the proposed methodology,

including preprocessing steps and semi-supervised

models. Section 3 presents the experimental results

and discussion, while Section 4 provides the conclud-

ing remarks.

2 METHODOLOGY

The methodological framework, shown in Figure 1,

is structured around two anomaly detection mod-

els—OCSVM and iForest. These models were se-

lected based on their capability to detect anoma-

lies in environments where labeled defect data is

scarce, a common constraint in DED quality con-

trol. OCSVM models the normal class boundary,

while iForest isolates outliers through random splits.

Compared to deep learning-based semi-supervised

models (e.g., semi-supervised VAE), shallow mod-

els such as OCSVM and iForest offer several advan-

tages—especially in structured data settings. These

include greater computational efficiency, easier inte-

gration of domain knowledge via preprocessing and

feature engineering, enhanced interpretability, and

simpler hyperparameter tuning.

2.1 Threshold Segmentation

Threshold segmentation was applied to extract the

melt pool region from the thermal images. A thresh-

old of 1640 °C was used, corresponding to the liq-

uidus temperature of the feedstock material (Ti-6Al-

4V). This segmentation enables the localization of the

melt pool boundary and facilitates the feature extrac-

tion relevant to thermal distribution and shape analy-

sis (Alexopoulou, 2021).

2.2 Feature Extraction

Three comprehensive categories of features were ex-

tracted from the thermal melt pool images:

1) Statistical Features: A set of descriptive statis-

tics was computed from the temperature distribution

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

438

Figure 1: Overview of the proposed methodology.

within each melt pool image, including mean (µ), me-

dian, maximum, minimum, standard deviation (σ),

skewness (1), kurtosis (2), and interquartile range.

These measurements quantify the central tendency,

dispersion, and shape characteristics of the temper-

ature profile.

Skewness =

1

nmσ

3

n

∑

i=1

m

∑

j=1

(T

i j

− µ)

3

(1)

Kurtosis =

1

nmσ

4

n

∑

i=1

m

∑

j=1

(T

i j

− µ)

4

(2)

where T

i j

represents the temperature value at pixel

(i, j) in an n × m thermal image.

2) Gradient Features: The spatial gradients of

temperature were calculated in both x and y direc-

tions to capture thermal transition rates across the

melt pool. From the gradient magnitude distribution,

we derived the gradient mean, standard deviation, and

maximum values, which characterize thermal stabil-

ity during deposition.

3) Geometric Features: From the segmented

melt pool region, we extracted morphological features

including area, perimeter, circularity, aspect ratio, ec-

centricity, and axis measurements. These geomet-

ric attributes capture the melt pool shape character-

istics that have been shown to correlate with porosity

formation. Additionally, peak temperature locations

were identified to enable spatial analysis of thermal

hotspots relative to potential defect formation zones.

2.3 Feature Selection

A total of 26 features were initially extracted across

the statistical, gradient-based, and geometric cate-

gories. To reduce dimensionality, minimize redun-

dancy, and enhance model interpretability, a reduced

feature set was selected. Feature selection is based

on the Pearson correlation test where highly corre-

lated features (with correlation coefficients greater

than 0.8 in magnitude) were eliminated to minimize

redundancy. This yielded a reduced feature subset of

16 features that preserved diversity in representation

while minimizing information overlap.

2.4 Normalization

To mitigate the influence of varying feature magni-

tudes and ensure numerical stability in model train-

ing, feature values were standardized using a statisti-

cal transformation based on their mean and standard

deviation, as in (3). This transformation was par-

ticularly important for stabilizing model training, as

differences in feature ranges could have dispropor-

tionately impacted distance-based methods such as

OCSVM. By normalizing the input data, the mod-

els were able to learn more generalizable decision

boundaries, improving their robustness against fluc-

tuations in thermal imaging conditions (Sch

¨

olkopf

et al., 2001).

x

′

=

x − µ

σ

(3)

where µ and σ denote the mean and standard deviation

of the feature, respectively.

2.5 One-Class Support Vector Machine

(OCSVM)

OCSVM operates by learning a decision boundary

that encapsulates the normal data points, treating ob-

servations outside this boundary as anomalies. The al-

gorithm maps input data into a high-dimensional fea-

ture space through a kernel function and constructs a

hyperplane that maximizes the distance between the

origin and the data points.

The OCSVM implementation utilized the Radial

Basis Function (RBF) kernel due to its capability to

model nonlinear thermal distributions, allowing for

accurate detection of porosity-related deviations and

Semi-Supervised Anomaly Detection in Directed Energy Deposition Using Thermal Images

439

defined as in (4).

K(x

i

, x

j

) = exp(−γ||x

i

− x

j

||

2

) (4)

where K(x

i

, x

j

) represents the kernel function applied

to the data instances x

i

and x

j

while γ denotes the ker-

nel coefficient.

In this work, the critical hyperparameters were

optimized through grid search with 5-fold cross-

validation, focusing primarily on:

• Kernel Coefficient γ: It controls the influence ra-

dius of support vectors.

• Outlier Fraction ν: It establishes an upper bound

on the training error rate and a lower bound on the

fraction of support vectors.

The decision function for classifying a new obser-

vation x is formulated as in (5).

f (x) = sign(

n

∑

i=1

α

i

K(x

i

, x)−ρ) (5)

where α

i

represents the Lagrange multipliers, x

i

de-

notes the support vectors, and ρ is the bias term.

The sign function serves as a thresholding mecha-

nism that maps the continuous output of the deci-

sion function into a binary classification. Observa-

tions with f (x) = 1 are considered to conform to the

distribution of normal (non-defective) melt pool im-

ages, whereas those with f (x) = −1 are classified as

anomalies—indicating thermal patterns suggestive of

potential porosity. This function thus constitutes the

final layer of the OCSVM architecture, enabling inter-

pretable defect classification critical to real-time qual-

ity assurance in DED processes.

2.6 Isolation Forest (iForest)

iForest is an ensemble-based anomaly detection algo-

rithm that leverages decision trees to identify anoma-

lies. In contrast to traditional approaches—such as

one-class classification—that aim to model normal

behavior, iForest adopts a different strategy by di-

rectly targeting the isolation of anomalous instances.

This method is built on the premise that anomalies are

infrequent with distinct characteristics, making them

easier to separate from the rest of the data.

iForest offers several notable advantages. It is

computationally efficient and scales effectively to

large and high-dimensional datasets. Additionally, it

requires only minimal and straightforward hyperpa-

rameter tuning. Combined with its fully unsupervised

nature—which removes the need for labeled data—

these characteristics make iForest a highly practical

and versatile choice for anomaly detection tasks.

The iForest algorithm involves repeatedly divid-

ing the data space through random selections of fea-

tures and respective split values. It builds an ensemble

of binary trees, referred to as isolation trees (iTrees),

where each tree is constructed by choosing a feature

at random and then selecting a split value uniformly

between its observed minimum and maximum. This

recursive partitioning proceeds until either each data

point is isolated in its own leaf node or a prespecified

maximum tree depth is attained.

For any data instance, its path length refers to the

number of splits—or edges—encountered as it trav-

els from the root of an isolation tree to the leaf node

where it is ultimately isolated. Because anomalies are

typically rare and possess feature values that set them

apart from the majority of the data, they are more

likely to be separated early in the tree-building pro-

cess. As a result, anomalous instances tend to exhibit

shorter average path lengths across the ensemble of

isolation trees. This average path length serves as

the basis for computing an anomaly score for each

instance, with shorter paths correspnding to higher

anomaly scores and indicating a higher likelihood of

being anomalous.

As with OCSVM, the critical hyperparameters

were optimized via grid search with 5-fold cross-

validation, and they include:

• Number of Estimators (Trees): It controls the

ensemble size and stability of anomaly score esti-

mates.

• Contamination Parameter: It estimates the pro-

portion of anomalies expected in the data, influ-

encing the decision threshold.

The decision function for classifying a new obser-

vation x is as in (6).

f (x) =

(

anomaly, if s(x) ≥ threshold

normal, otherwise

(6)

where s(x) represents the average anomaly score

across all isolation trees. Higher scores indicate

greater deviation from normal melt pool patterns.

3 RESULTS AND DISCUSSION

3.1 Dataset Description

The dataset used in this study is sourced from Za-

miela et al. (Zamiela et al., 2023a). The dataset com-

prises in-process thermal melt pool images and post-

fabrication porosity labels for Ti-6Al-4V thin-walled

structures, fabricated using the OPTOMEC Laser En-

gineered Net Shaping (LENS™) 750 system. The

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

440

data was collected for nondestructive thermal charac-

terization of laser DED, enabling the development of

predictive models for quality control.

Thermal imaging was captured using a Stra-

tonics dual-wavelength pyrometer, which records a

top-down view of the melt pool and heat-affected

zone, measuring temperatures above 1660 °C. Inter-

nal porosity defects were labeled using Nikon X-Ray

Computed Tomography (XCT) XT H225, providing

reference measurements for lack of fusion defects oc-

curring within the fabricated structure.

The dataset consists of 1,564 cropped pyrometer

melt pool images in CSV format, each with a reso-

lution of 200 × 200 pixels. The dataset includes bi-

nary porosity labels (0 = No Porosity, 1 = Porosity)

with 1,493 non-defective samples and 71 defective

samples, creating a highly imbalanced dataset with

approximately 4.5% defect occurrence rate. Repre-

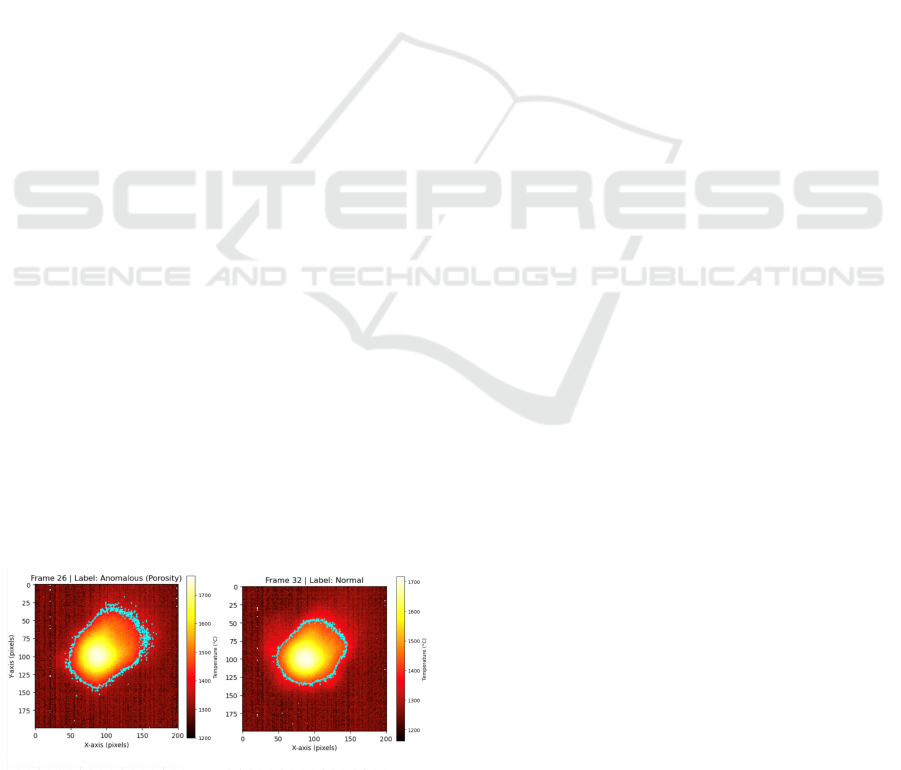

sentative normal and anomalous thermal images are

shown in Figure 2. Each thermal image in the dataset

is accompanied by metadata including frame number,

timestamp, spatial coordinates, melt pool characteris-

tics, and when applicable, porosity size ranging from

0.05 mm to 0.98 mm. The dataset was split into 80%

training and 20% testing. Additionally, the models

were trained using two different settings:

1. Semi-Supervised Setting: The training set con-

tains only normal (i.e., non-anomalous) samples,

consisting of 1,194 normal images, which account

for approximately 80% of the total available nor-

mal data. In this one-class training paradigm, both

models are trained to learn the underlying distri-

bution and characteristic patterns of normal be-

havior. During inference, any test sample that ex-

hibits a substantial deviation from the learned nor-

mal distribution is flagged as anomalous by the

models.

2. Unsupervised Setting: The training set com-

prises both normal and anomalous samples, ac-

counting for approximately 80% of the entire

dataset. Specifically, it includes 1,194 normal im-

ages and 57 anomalous images.

Figure 2: Comparison of the thermal images of the melt

pool images in a normal frame and an anomalous (porosity)

frame.

This dual training strategy allowed us to evaluate

the effect of training data composition on model per-

formance. The impact of these training strategies on

model performance is analyzed in the following sec-

tion, considering their effects on classification met-

rics, false positive rates, and overall anomaly detec-

tion accuracy.

3.2 Findings

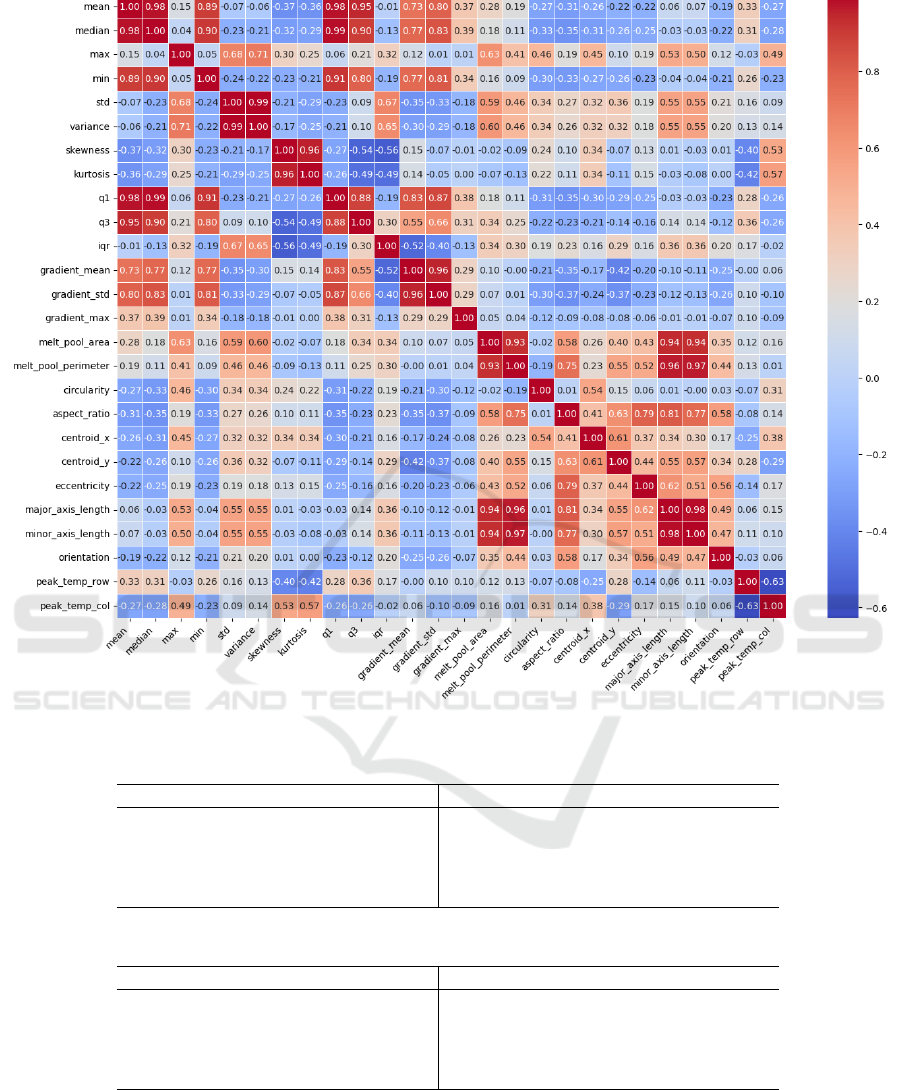

3.2.1 Correlation Matrix Analysis

The correlation matrix in Figure 3 helps us understand

relationships between different features and provides

insights about the dataset, making it easier to choose

the most useful ones for anomaly detection in DED.

A few key takeaways are as follows:

• Feature Redundancy: Some features, like mean,

median, and Q1, are almost identical (correlation

coefficients ≥ 0.98 ). Keeping just one of them

simplifies the model without losing information.

The same applies to features like variance and

standard deviation.

• Effect on Model Performance: Filtering out

redundant features improves model accuracy.

Models trained on the selected features outper-

formed those using all features (see Tables 1 and

2), with iForest handling variability better than

OCSVM, which was more sensitive to training

data changes.

3.2.2 Classification Metrics

Table 1 and Table 2 summarize the performance met-

rics for the OCSVM and iForest models, respectively.

The evaluation was conducted using different feature

sets and training settings.

For OCSVM, the selected feature set yielded

the best results under the semi-supervised scheme,

achieving a precision of 0.76, a recall of 0.97, and

an F1-score of 0.85. However, performance dropped

significantly in the unsupervised scheme, where pre-

cision and F1-score fell to 0.44, and 0.56, respec-

tively. This suggests that OCSVM is highly sensitive

to training data consistency and may not generalize

well under unsupervised settings.

Similarly, iForest performed best with the selected

features under the semi-supervised scheme, proving

that the semi-supervised approach works better at

capturing anomalies for these models. With a preci-

sion of 0.82, a recall of 0.96, and an F1-score of 0.88.

Unlike OCSVM, iForest maintained relatively better

performance under the unsupervised scenario, with an

Semi-Supervised Anomaly Detection in Directed Energy Deposition Using Thermal Images

441

Figure 3: Feature correlation matrix.

Table 1: Results of One-Class SVM (OCSVM).

Feature Set Training Precision Recall F1 Accuracy

All Features

Semi-Supervised 0.75 0.96 0.84 0.93

Unsupervised 0.39 0.67 0.49 0.93

Selected Features

Semi-Supervised 0.76 0.97 0.85 0.93

Unsupervised 0.44 0.77 0.56 0.94

Table 2: Results of Isolation Forest.

Feature Set Training Precision Recall F1 Accuracy

All Features

Semi-Supervised 0.81 0.91 0.86 0.94

Unsupervised 0.62 0.68 0.64 0.96

Selected Features

Semi-Supervised 0.82 0.96 0.88 0.95

Unsupervised 0.74 0.84 0.78 0.98

F1-score of 0.78, indicating its robustness to varying

data distributions.

Overall, using the selected features proved supe-

rior for both models, highlighting their effectiveness

in capturing relevant information. Additionally, iFor-

est demonstrated greater resilience to the unsuper-

vised scheme compared to OCSVM, making it a more

reliable choice in scenarios with data variability.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

442

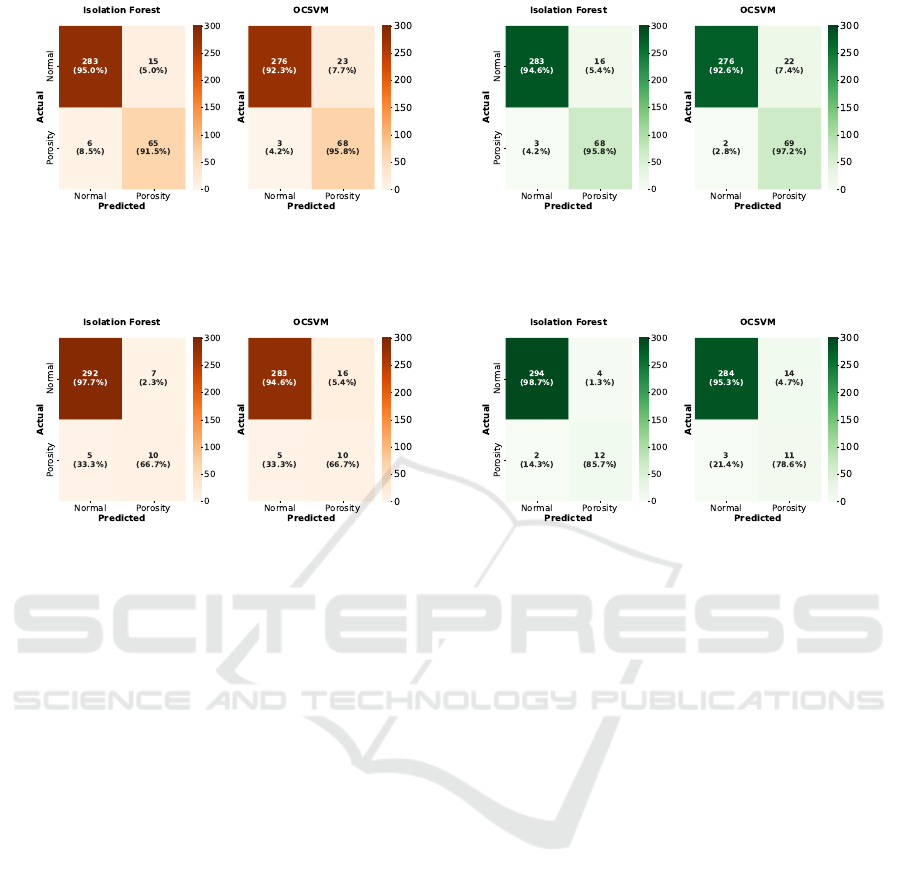

(a) All features (b) Selected features

Figure 4: Confusion matrices for the ML models (semi-supervised setting).

(a) All features (b) Selected features

Figure 5: Confusion matrices for the ML models (unsupervised setting).

3.2.3 Confusion Matrix Analysis

The confusion matrices (see Figures 4 and 5) illustrate

the classification performance of iForest and OCSVM

under different feature sets and training paradigms.

Each confusion matrix represents the average results

obtained over 5-fold cross-validation, ensuring ro-

bustness and mitigating performance fluctuations due

to dataset variability. These matrices allow for a di-

rect comparison of the models in terms of their ability

to correctly identify normal and anomalous samples.

The following key observations are drawn from the

confusion matrices:

Comparison of the Best Results for iForest

and OCSVM: iForest demonstrated a high recall of

95.8%, successfully identifying 68 out of 71 poros-

ity cases (refer to Figure 4b), emphasizing its strong

sensitivity to defects. Additionally, it achieved a pre-

cision of 82%, with 16 normal samples misclassified

as defective. These results lead to an F1-score of

0.88, which reflects a strong balance between detect-

ing defects and limiting false positives. In contrast,

OCSVM exhibited a slightly higher recall of 97.2%,

detecting 69 out of 71 porosity cases, but with a lower

precision of 75.82%, as it misclassified 22 normal

samples as porosity. These results indicate that iFor-

est prioritizes capturing more true defect cases while

maintaining a better balance between false positives

and false negatives, making it more reliable in scenar-

ios where reducing unnecessary false alarms is crit-

ical. On the other hand, OCSVM slightly increases

recall at the expense of more false positives, which

may introduce additional costs in practical DED ap-

plications.

Effect of Feature Selection: Feature selection

played a crucial role in the trade-off between preci-

sion and recall. For iForest, using the selected fea-

tures resulted in a recall of 95.8%. This indicates

that the model correctly detected 68 out of 71 poros-

ity cases, with a false positive rate of approximately

5.4% (refer to Figure 4b). On the other hand, when all

features were used, recall significantly decreased to

91.5%, with a false positive rate of roughly 5%, yield-

ing a lower detection rate for defective instances (re-

fer to Figure 4a). This performance improvement in-

dicates that reducing feature redundancy allowed the

model to better distinguish between normal and de-

fective cases.

Effect of Training Settings: The training scheme

significantly influenced the overall model perfor-

mance, affecting both recall and precision. For

OCSVM, the semi-supervised approach achieved a

precision of 75.8% and a recall of 97.2%, leading to

an F1-score of 85.1%, demonstrating its strong abil-

Semi-Supervised Anomaly Detection in Directed Energy Deposition Using Thermal Images

443

ity to identify defective cases while maintaining a rel-

atively low false positive rate (see Table 1 and Fig-

ure 4b). However, under the unsupervised setting,

performance deteriorated significantly, with precision

dropping to 44% and recall decreasing to 78.6%, re-

sulting in an F1-score of 56.4% (see Table 1 and Fig-

ure 5b). This decline indicates that exposure to mixed

data introduced classification uncertainty, causing the

model to struggle with distinguishing between nor-

mal and defective instances. Similarly, for iForest

(see Table 2 and Figure 4b), training on normal data

(semi-supervised) resulted in a precision of 82%, a

recall of 95.8%, and an F1-score of 87.7%, high-

lighting a strong balance between false positive re-

duction and defect detection sensitivity. In contrast,

when trained under the unsupervised setting, preci-

sion declined to 74%, recall dropped to 85.7%, and

the F1-score decreased to 78% (see Table 2 and Fig-

ure 5b). While iForest demonstrated more robustness

than OCSVM, it still exhibited reduced classification

confidence under the unsupervised scheme, leading to

increased false positives. These findings indicate that

semi-supervised training with exclusively normal data

enhances both recall and precision, ensuring more re-

liable defect detection in DED processes. In contrast,

the unsupervised setting, while more flexible, intro-

duces noise and weakens model performance, partic-

ularly in recall and precision trade-offs.

4 CONCLUSION

This work adopted a semi-supervised anomaly de-

tection approach for defect detection in DED pro-

cesses. It is based on two effective semi-supervised

algorithms: iForest and OCSVM. The results for both

algorithms were compared with an unsupervised set-

ting to highlight the effectiveness of the adopted semi-

supervised approach. The results demonstrate that the

semi-supervised setting, where the training data ex-

clusively includes normal data, significantly enhances

detection performance, as evidenced by higher pre-

cision, recall, and an associated F1-score compared

to the unsupervised setting. Comparing the indi-

vidual algorithms, iForest consistently outperforms

OCSVM in this defect detection task for both set-

tings. In the semi-supervised setting, iForest achieved

an F1-score of 0.88 and a respective accuracy of 95%.

Notably, correlation-based feature selection improved

the models’ effectiveness by removing redundancy

and noise. Specifically, it provided the most robust

and stable performance across both normal-only and

mixed-data training conditions. These findings under-

score the robustness of the semi-supervised approach

for anomaly detection with the notorious data imbal-

ance issue. It also emphasizes the critical importance

of feature selection strategies, training data quality,

and algorithm choice in achieving optimal anomaly

detection outcomes. The proposed approach is highly

adaptable and can be seamlessly extended to defect

detection in other additive manufacturing processes,

such as powder bed fusion.

REFERENCES

Alexopoulou, V. E. (2021). Study and modeling of the tran-

sition from conduction to keyhole mode during SLM

process. Master’s thesis, School of Mechanical Engi-

neering, National Technical University of Athens.

Dass, A. and Moridi, A. (2019). State of the art in directed

energy deposition: From additive manufacturing to

materials design. Coatings, 9(7).

Era, I. Z., Zhou, F., Raihan, A. S., Ahmed, I., Abul-Haj,

A., Craig, J., Das, S., and Liu, Z. (2024). In-situ melt

pool characterization via thermal imaging for defect

detection in directed energy deposition using vision

transformers. arXiv preprint arXiv:2411.12028.

Farea, S. M., Unel, M., and Koc, B. (2024). Defect pre-

diction in directed energy deposition using an ensem-

ble of clustering models. In Proceedings of the 2024

IEEE 22nd International Conference on Industrial In-

formatics (INDIN), pages 1–6.

Gaja, H. and Liou, F. (2018). Defect classification of laser

metal deposition using logistic regression and artifi-

cial neural networks for pattern recognition. Interna-

tional Journal of Advanced Manufacturing Technol-

ogy, 94(1-4):315–326.

Garc

´

ıa-Moreno, A.-I. (2019). Automatic quantification

of porosity using an intelligent classifier. Interna-

tional Journal of Advanced Manufacturing Technol-

ogy, 105(5):1883–1899.

Herzog, T., Brandt, M., Trinchi, A., et al. (2024). Defect

detection by multi-axis infrared process monitoring of

laser beam directed energy deposition. Scientific Re-

ports, 14:3861.

Hespeler, S., Dehghan-Niri, E., Juhasz, M., and Luo, K.

(2022). Deep learning for in-situ layer quality mon-

itoring during laser-based directed energy deposition

(LB-DED) additive manufacturing process. Applied

Sciences, 12(18):8974.

Khanzadeh, M., Chowdhury, S., Marufuzzaman, M.,

Tschopp, M. A., and Bian, L. (2018). Porosity predic-

tion: Supervised-learning of thermal history for direct

laser deposition. Journal of Manufacturing Systems,

47:69–82.

Li, S. H., Kumar, P., and Chandra, S. (2023). Directed

energy deposition of metals: Processing, microstruc-

tures, and mechanical properties. International Mate-

rials Reviews, 2023.

Qin, J., Hu, F., Liu, Y., Witherell, P., and Wang, C. C. L.

(2022). Research and application of machine learning

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

444

for additive manufacturing. Additive Manufacturing,

52:102014.

Sch

¨

olkopf, B., Platt, J. C., Shawe-Taylor, J., Smola, A. J.,

and Williamson, R. C. (2001). Estimating the support

of a high-dimensional distribution. Neural Computa-

tion, 13(7):1443–1471.

Taheri, H., Koester, L. W., Bigelow, T. A., Faierson, E. J.,

and Bond, L. J. (2019). In situ additive manufactur-

ing process monitoring with an acoustic technique:

clustering performance evaluation using k-means al-

gorithm. Journal of Manufacturing Science and Engi-

neering, 141(4).

Tang, D., He, X., Wu, B., Wang, X., Wang, T., and Li,

Y. (2022). The effect of porosity defects on the mid-

cycle fatigue behavior of directed energy deposited Ti-

6Al-4V. Theoretical and Applied Fracture Mechan-

ics, 2022.

Zamiela, C., Tian, W., Guo, S., and Bian, L. (2023a).

Thermal-porosity characterization data of additively

manufactured ti–6al–4v thin-walled structure via laser

engineered net shaping. Harvard Dataverse. Available

at: https://doi.org/10.7910/DVN/BWHYEH.

Zamiela, C., Tian, W., Guo, S., and Bian, L. (2023b).

Thermal-porosity characterization data of additively

manufactured Ti–6Al–4V thin-walled structure via

laser engineered net shaping. Data in Brief,

51:109722.

Zhao, X., Imandoust, A., Khanzadeh, M., Imani, F., and

Bian, L. (2021). Automated anomaly detection of

laser-based additive manufacturing using melt pool

sparse representation and unsupervised learning. In

Solid Freeform Fabrication Symposium.

Semi-Supervised Anomaly Detection in Directed Energy Deposition Using Thermal Images

445