Curvature-Constrained Motion Planning and Control for Traffic Cone

Manipulation Robot

Rudolf Krecht

a

and

´

Aron Ballagi

b

Department of Automation and Mechatronics, Sz

´

echenyi Istv

´

an University, Egyetem square, Gy

˝

or, Hungary

Keywords:

Intralogisctics, Automatic Traffic Cone Manipulation, Curvature-Constrained Path Following, GNSS-RTK

Navigation.

Abstract:

This paper presents an integrated system for traffic cone manipulation using a heavy-duty mobile robot

equipped with GNSS-RTK localization, a custom remote supervision and mission control interface, and a

curvature-constrained motion controller. Designed for use in semi-structured outdoor environments, the robot

receives waypoint and speed commands via a tailored extension of Foxglove Studio, which enables intuitive

map-based interaction and real-time trajectory editing. Owning to its high payload capacity, the platform pri-

oritizes stability over maneuverability, thus, it cannot change orientation without longitudinal movement. To

address this, we propose a smooth, curvature-based controller that enforces a minimum turning radius while

following pose and heading goals. The system architecture is built on Robot Operating System 2 (ROS 2),

leveraging modular nodes for map visualization, path planning, motion execution, and action triggering. Our

experiments demonstrate the system’s ability to navigate complex waypoint paths and pause precisely at

mission-dictated locations, more specifically cone placement locations. Our results show that even under

turning constraints, the robot reliably executes full cone manipulation routines with high spatial accuracy and

operational safety. The system highlights the feasibility of pairing high-level operator interfaces with low-level

kinematic-aware planning for constrained robotic platforms.

1 INTRODUCTION

Autonomous transportation technologies are rapidly

reshaping the way people, goods, and infrastructure

interact in both urban and industrial environments.

Although much of the early focus in autonomy has

been directed towards large-scale vehicular automa-

tion, such as autonomous cars and trucks, recent ad-

vances have highlighted the critical importance of

smaller, task-specific systems that operate in con-

strained, semi-structured domains. Two key domains

in this emerging landscape are intralogistics and mi-

cromobility, both of which benefit significantly from

the deployment of compact, autonomous robotic sys-

tems.

Intralogistics refers to the automated management

of material flow within localized facilities such as

warehouses, ports, campuses, and construction sites.

These environments typically require frequent but

repetitive motion of small payloads, precise object

placement, and coordination with human workers or

a

https://orcid.org/0000-0002-8927-8783

b

https://orcid.org/0000-0002-5458-5249

static infrastructure. The ability to automate such

processes has direct implications on operational effi-

ciency, safety, and cost reduction. In this context, au-

tonomous mobile robots (AMRs) equipped with accu-

rate localization, adaptable planning, and simple ma-

nipulation capabilities have become increasingly rel-

evant (Pfrommer et al., 2024).

Parallel to this, the concept of micromobility has

emerged as a framework for understanding small-

scale robotic transportation—both for personal mo-

bility (e.g., scooters, delivery drones) and for au-

tonomous systems tasked with maintaining or re-

configuring urban environments. Examples include

robots that paint road markings, distribute tempo-

rary signage, or manage traffic cones in dynamic

zones such as smart test tracks and urban experiments.

These systems share the need for tight control in con-

strained areas, human-readable behavior, and smooth

integration into existing infrastructure.

Despite growing interest in these domains, rela-

tively little attention has been paid to robotic systems

that perform infrastructure manipulation tasks, such

as placing or removing traffic cones, in coordination

Krecht, R. and Ballagi, Á.

Curvature-Constrained Motion Planning and Control for Traffic Cone Manipulation Robot.

DOI: 10.5220/0013720700003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 2, pages 317-324

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

317

with mobile navigation. These tasks require the com-

bination of precise positioning, safe low-speed con-

trol, and intuitive human–robot interfaces for real-

time supervision. Moreover, the challenge is exac-

erbated when using large or heavy platforms that are

characterized by low maneuverability.

In this paper, we present a complete system for

cone manipulation using a GNSS-guided autonomous

robot, equipped with a curvature-aware controller and

a custom supervision and mission control interface

built on Foxglove Studio (Foxglove, 2024). The sys-

tem enables an operator to define traffic cone place-

ment locations on a live map, and based on the re-

quired traffic cone positions, the integrated motion

planner assigns speed profiles and behavioral seman-

tics, and finally, the controller executes the required

path. The robot tracks these trajectories using a cus-

tom controller that enforces a minimum turning ra-

dius, ensuring feasibility even under physical mo-

tion constraints. The result is a lightweight, adapt-

able solution for localized infrastructure manipula-

tion—applicable to intralogistics scenarios, micromo-

bility deployments, and emerging smart-city test en-

vironments. The setup presented in this paper was

developed and tested at the ZalaZONE Automotive

Proving Ground (ZalaZONE Research and Innova-

tion, 2023).

2 RELATED WORK

The integration of autonomous mobile robots

(AMRs) into intralogistics and micromobility sys-

tems has received significant attention in recent years,

driven by the need for efficient, flexible and safe trans-

portation solutions within structured environments.

AMRs have revolutionized intralogistics by

enabling decentralized problem solving and au-

tonomous navigation in dynamic environments (Fra-

gapane et al., 2021). These robots are increasingly

employed in manufacturing, warehousing, and hos-

pital settings to automate material handling tasks.

The shift from traditional automated guided vehicles

(AGVs) to AMRs is attributed to the latter’s ability to

adapt to dynamic layouts and workflows without the

need for extensive infrastructure modifications.

Micromobility solutions, encompassing

lightweight and compact vehicles, have emerged

as viable alternatives for short-distance transportation

in urban settings. In parallel, the automation of

infrastructure manipulation tasks, such as traffic

cone placement, has been explored to enhance safety

and efficiency. Projects like AutoCone (Hartzer

and Saripalli, 2020) have developed omnidirectional

robots capable of precise cone deployment using

RTK GPS and onboard localization filtering. Instead

of creating a heavy-duty platform for carrying stan-

dard traffic cones, AutoCone approaches the task by

creating mobile, autonomous traffic cones. The Hong

Kong Highways Department introduced RoadBot

1 and RoadBot 2 (Hong Kong Highways Depart-

ment, 2019), intelligent robot systems designed

to autonomously place and collect traffic cones

and warning lanterns on high-speed roads, thereby

reducing the risk to human workers. RoadBot 1 is a

fully integrated robotic arm mounted on a large truck

platform, offering high throughput and operational

safety at the cost of mobility and flexibility.

Our project combines the advantages of these two

approaches while addressing their limitations. It of-

fers a mid-size, heavy-duty robotic platform that can

carry and deploy standard traffic cones autonomously,

achieving a balance between payload capacity and

maneuverability.

Effective trajectory planning and control are criti-

cal for AMRs operating in environments with phys-

ical constraints. Model Predictive Control (MPC)

strategies have been proposed for managing the for-

mation and recovery of traffic cone robots, addressing

challenges related to dynamic coordination and input

limitations. Additionally, curvature-constrained mo-

tion planning has been employed to ensure feasible

paths for robots with limited turning capabilities, en-

hancing their ability to navigate complex terrains.

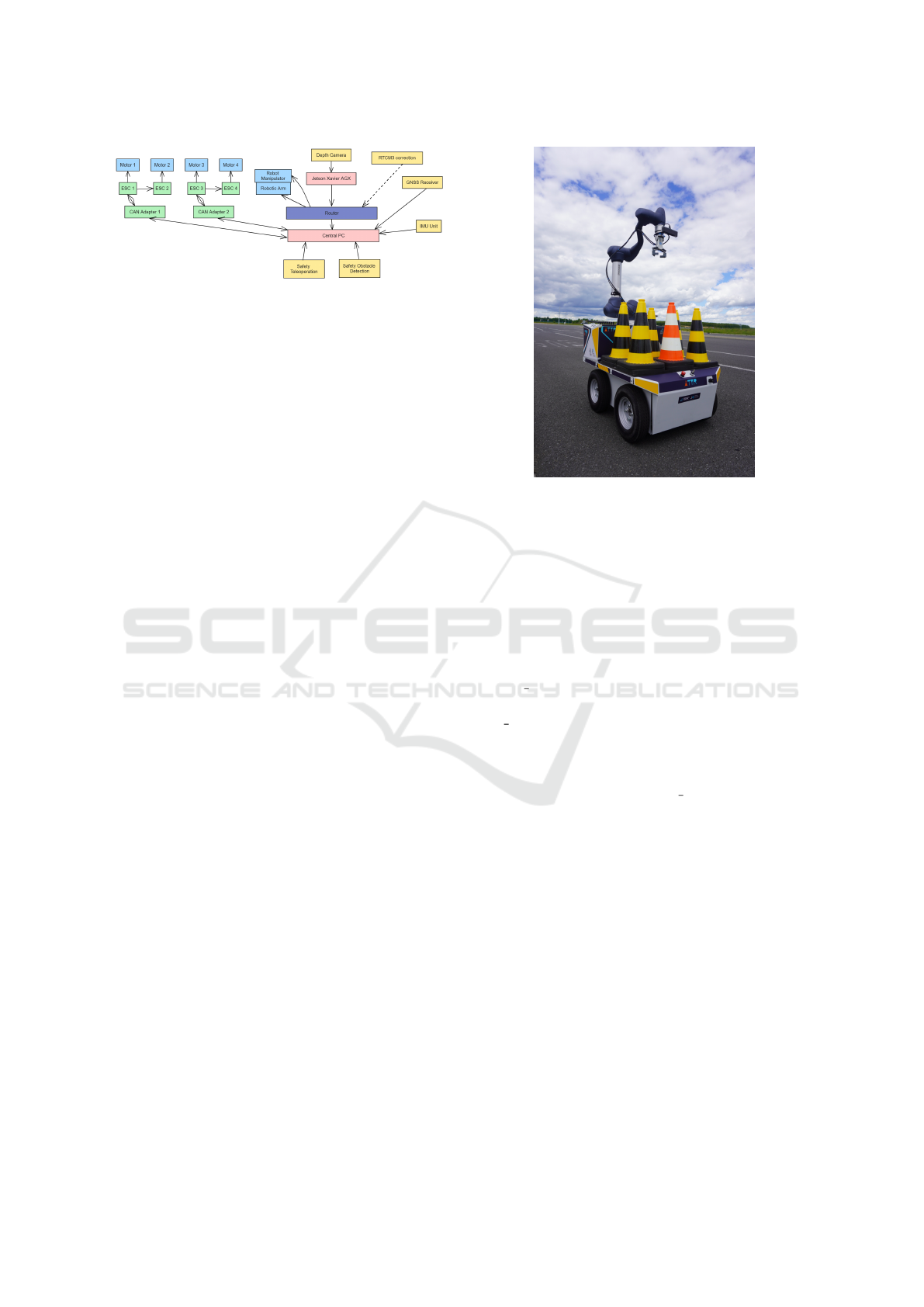

3 SYSTEM OVERVIEW

Our team started the aforementioned project with the

aim of creating a robot platform with a compact form

factor, simple mechanical components, yet a gener-

ous load capacity and an on-board collaborative robot

manipulator. Thus, a compact, four-wheel-drive skid-

steer robot platform has been proposed and proto-

typed (Figure 2). Each of the four brushless drive

motors is individually controlled via a dedicated elec-

tronic speed controller (ESC), and grouped in pairs

under two dedicated Controller Area Network (CAN)

adapters. These adapters communicate with the cen-

tral industrial PC over serial, ensuring real-time con-

trol and fault monitoring. This distributed motor con-

trol setup reduces system complexity while maintain-

ing modularity and serviceability (Krecht and Ballagi,

2022).

The robotic manipulator subsystem consists of

two primary components: a collaborative robotic arm

and its end effector. The arm is physically mounted

on the mobile base and connects to the central PC via

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

318

Figure 1: Block diagram of the robot platform for traffic

cone manipulation.

the 5G router. The end effector, which is affixed to the

arm, interfaces over the same network, allowing uni-

fied control and coordination within the ROS 2 frame-

work.

Inertial data is acquired through an on-board IMU

unit, connected via a direct serial interface to the cen-

tral PC. Alongside, a high-precision GNSS receiver

also communicates via serial and supports Real-Time

Kinematic (RTK) corrections using RTCM3 mes-

sages received through the router using the NTRIP

protocol. As far as our current setup, position is pro-

vided by the GNSS-RTK system, while initial orien-

tation is determined based on the IMU’s integrated

magnetometer.

For perception, a stereo depth camera is connected

to a dedicated NVIDIA Jetson Xavier AGX computer.

This PC dedicated for the machine’s vision is net-

worked with the central industrial computer via the

5G router, allowing high-bandwidth data transfer and

distributed processing. This setup is intended to de-

tect traffic cones using neural networks assigning a

collaborative robotic arm to approach the traffic cone

(Holl

´

osi et al., 2021).

Altogether, the robot’s system design (Figure 1)

balances modularity and centralization, leveraging

modern industrial and robotics standards to ensure re-

liability, scalability, and ease of integration with col-

laborative automation workflows.

4 HUMAN-MACHINE

INTERFACE

To enable intuitive human-robot interaction for traffic

cone manipulation, we developed a custom user in-

terface panel in Foxglove Studio (Foxglove, 2024), a

modern, browser-based visualization tool for ROS 2.

Unlike traditional approaches, our solution allows op-

erators to interactively define waypoints, assign speed

profiles, and trigger manipulation behaviors in real

time through a map-based graphical interface.

Figure 2: Heavy duty robot platform for traffic cone manip-

ulation.

4.1 Panel Overview

The panel was implemented as a Foxglove Panel

Extension using React and TypeScript. It inte-

grates directly with ROS 2 via the Foxglove Web-

Socket bridge, enabling seamless communication

with the robot using standard ROS 2 message types.

The robot’s trajectory is defined by a /textttge-

ometry msgs/msg/PoseArray message, which speci-

fies the ordered list of waypoints. An associated

std msgs/msg/Float32MultiArray message pro-

vides corresponding speed values for each waypoint.

Operator commands, such as starting or stopping

the robot, and triggering cone placement routines,

are handled via ROS 2 std srvs/srv/Trigger

services.

The panel (Figure 3) presents a live, zoomable

map view centered on a user-specified virtual ori-

gin, overlaid with dynamic visualizations of way-

points, color-coded trajectory lines, and any previ-

ously placed cones. The design ensures real-time

feedback, improves operator awareness, and enables

seamless integration into field deployments.

4.2 Functionality

Through the panel, users can interactively define a

trajectory by clicking directly on the map to specify

waypoints. These waypoints are immediately visual-

ized as traffic cone-shaped markers. Based on traffic

cone locations, a simple trajectory is planned locally.

The placed traffic cones are interconnected and way-

points are defined along these sections at constant dis-

Curvature-Constrained Motion Planning and Control for Traffic Cone Manipulation Robot

319

Figure 3: Custom Foxglove Studio panel for traffic cone

placement and mission control.

Figure 4: Waypoint array including velocity information

generated based on the requested traffic cone placement pat-

tern.

tances. For each waypoint, a speed value can be as-

signed. The discrete longitudinal velocity values are

computed locally using a trapezoidal profile between

traffic cone locations, reaching zero at waypoints des-

ignated for cone placement (Figure 4). After manu-

ally assigning traffic cone locations, the user can fi-

nalize the editing by clicking on a dedicated button,

publishing the waypoint array and speed values to the

robot. The interface includes controls for initiating

and halting robot motion, mapped to /start robot

and /stop robot ROS 2 services. As the user modi-

fies the waypoint list or adjusts speed values, the panel

does not continuously publish updated trajectory data

to avoid unexpected overlays between multiple track

layouts.

4.3 Design Considerations

Foxglove Studio was selected for its modern architec-

ture and flexibility in user interface design. It runs in

any modern web browser without requiring local ROS

installation, making it especially suitable for remote

operation and distributed teams. The support for full

React-based customization enabled us to tailor the in-

terface precisely to the needs of the cone manipulation

task, reducing cognitive load on the operator. Real-

time communication with ROS 2 topics and services

ensures that the panel remains highly responsive, even

when modifying paths during mission execution.

Furthermore, the web-based deployment model

allows the panel to be hosted on a central machine,

enabling access from any network-connected device.

This facilitates supervisory control by multiple users

and aligns well with semi-autonomous or mixed-

initiative mission frameworks.

5 TRAJECTORY PLANNING

The trajectory planning strategy employed in this

system is deliberately operator-driven, focusing on

simplicity, direct control, and real-time feedback.

Rather than relying on automated path planning al-

gorithms, the robot follows a trajectory defined man-

ually through the custom Foxglove panel. This ap-

proach empowers human operators to design and edit

robot paths based on environmental context, task re-

quirements, or safety considerations, while keeping

the planning layer lightweight and adaptable.

5.1 Waypoint-Based Path Specification

The planned trajectory consists of a sequence of spa-

tial waypoints, each representing a desired robot pose

(position and orientation) in two-dimensional space.

In addition to geometric position, each waypoint is

associated with a scalar speed value that modulates

the robot’s linear velocity as it approaches the target.

As mentioned before, these speed values serve

both, as velocity commands and as semantic mark-

ers. In particular, a speed value of zero designates

the waypoint as a logical stop point. When the robot

reaches such a waypoint, it initiates a controlled pause

and triggers a predefined action—typically the place-

ment or retrieval of a traffic cone. After completing

the action and waiting for a configurable duration, the

robot resumes motion toward the next target in the se-

quence.

This combination of spatial and behavioral encod-

ing within the waypoint list enables rich, event-driven

trajectories to be constructed with minimal interface

complexity.

6 MOTION CONTROLLER

The mobile robot used in this system is physically

incapable of performing orientation changes with-

out longitudinal movement due to its size and wheel

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

320

configuration dictated by stability requirements. As

a result, traditional point-turn alignment strategies

commonly used in indoor robotics are infeasible.

To address this limitation, we designed a curvature-

constrained motion controller that enables the robot

to follow arbitrary waypoint sequences using only

smooth, forward-facing movements with bounded an-

gular curvature (Paden et al., 2016). This controller

forms the core of the system’s low-level autonomy,

enabling reliable execution of the trajectories defined

through the user interface.

6.1 Control Architecture

The controller is implemented as a discrete-time,

event-driven finite-state machine (Han

ˇ

zi

ˇ

c et al., 2013)

with three operational states: ALIGN, GOTO, and

PAUSE. These states reflect the primary behaviors

needed to execute a semantically rich waypoint-based

trajectory while respecting the robot’s kinematic con-

straints.

In the ALIGN state, the robot adjusts its heading

toward the current waypoint target. However, unlike

conventional in-place rotation strategies, this align-

ment is performed using a gentle forward arc. The

robot moves slowly while modulating its angular ve-

locity based on the heading error, constrained by a

maximum allowable curvature that reflects the robot’s

minimum turning radius.

In the GOTO state, the robot proceeds toward the

waypoint, continuing to correct its heading dynam-

ically. If the orientation error is too large, forward

velocity is reduced to ensure stability. Otherwise, the

robot follows a curvature-constrained path that blends

translation and heading correction into a single mo-

tion profile.

In the PAUSE state, the robot has reached a way-

point marked with a zero-speed command. It stops

moving, triggers traffic cone placement and remains

stationary for a configurable delay before proceeding

to the next waypoint. During this delay, the robot

can perform application-specific tasks, such as plac-

ing traffic cones, before continuing to the next way-

point.

State transitions are triggered by geometric prox-

imity to the target waypoint (position tolerance),

alignment within an angular threshold (heading toler-

ance), or time-based conditions during pauses. The

robot continues to cycle through these states until

all waypoints have been executed or an external stop

command is received.

6.2 Curvature-Based Control Law

To ensure smooth and kinematically feasible motion,

angular velocity is computed using a curvature-based

control strategy. Let (x, y,θ) denote the current pose

of the robot, and let (x

w

,y

w

) be the position of the tar-

get waypoint. The Euclidean distance to the waypoint

is given by:

d =

q

(x

w

− x)

2

+ (y

w

− y)

2

(1)

The desired heading is computed using the two-

argument arctangent function (Siciliano et al., 2009):

θ

d

= atan2(y

w

− y,x

w

− x) (2)

To compute a smooth angular error, we use the

wrapped angle difference:

∆θ = atan2(sin(θ

d

− θ),cos(θ

d

− θ)) (3)

From the heading error and distance, we compute

an instantaneous curvature κ:

κ =

∆θ

max(d,ε)

(4)

where ε is a small positive constant used to prevent

division by zero at short distances.

To respect the robot’s physical turning limits, the

curvature is clamped to a maximum value κ

max

=

1

R

min

, where R

min

is the minimum turning radius

(Thrun et al., 2005):

κ ← clip(κ,−κ

max

,κ

max

) (5)

The final angular velocity command ω is com-

puted by scaling curvature with the linear velocity v:

ω = κ · v (6)

This formulation ensures that the robot never ex-

ceeds its curvature constraints while continuously ad-

justing its heading toward the waypoint. It also al-

lows the robot to follow smooth trajectories without

the need for stopping or in-place rotation, which is

particularly important given its limited turning capa-

bilities.

6.3 Behavior at Stop Points

When the controller detects that the robot has reached

a waypoint with an assigned speed of zero, it en-

ters the PAUSE state. Here, it initiates a service call

to trigger a predefined manipulation action—such as

triggering the actuator to place a cone—and begins a

countdown timer. The duration of the pause is config-

ured as a static parameter. Once the pause concludes,

the controller transitions back to the ALIGN state and

proceeds toward the next waypoint.

The controller has been implemented as presented

by (Algorithm 1).

Curvature-Constrained Motion Planning and Control for Traffic Cone Manipulation Robot

321

Data: Current robot pose (x,y,θ), waypoint

(x

w

,y

w

), min. turning radius R

min

Result: Velocity command (v,ω)

Compute dx ← x

w

− x, dy ← y

w

− y;

Compute d ←

p

dx

2

+ dy

2

;

Compute desired heading θ

d

← atan2(dy,dx);

Compute yaw error

∆θ ← atan2(sin(θ

d

− θ),cos(θ

d

− θ));

if state = ALIGN then

if |∆θ| < heading tolerance then

state ← GOTO;

end

else

v ← 0.1;

curv ← ∆θ/ max(d,0.1);

curv ←

clip(curv,−1/R

min

,+1/R

min

);

ω ← curv · v;

return (v,ω);

end

else if state = GOTO then

if d < position tolerance then

if speed = 0.0 then

state ← PAUSE, start timer, stop

robot;

end

else

state ← ALIGN, index ← index

+1;

end

end

else

v ← min(linear speed,speed);

curv ← ∆θ/ max(d,0.1);

curv ←

clip(curv,−1/R

min

,+1/R

min

);

ω ← curv · v;

return (v,ω);

end

else if state = PAUSE then

if not yet triggered then

Call trigger service;

end

if pause duration elapsed then

if more waypoints then

state ← ALIGN, index ← index

+1;

end

else

state ← IDLE, stop robot;

end

end

end

Algorithm 1: Curvature-based motion control.

7 EXPERIMENTS AND

EVALUATION

To validate the proposed curvature-constrained tra-

jectory execution system and assess the effectiveness

of the custom Foxglove-based operator interface, we

conducted two main experiments. The first was car-

ried out in simulation to verify controller behavior un-

der idealized conditions, while the second involved

deploying the system on a physical robot platform

equipped with a traffic cone manipulation mecha-

nism.

7.1 Simulation-Based Validation

The initial evaluation phase was conducted in a

custom-built simulator designed to emulate the mo-

tion dynamics of the real robot. This simulator

subscribed to velocity commands published on the

/cmd vel ROS 2 topic and generated corresponding

tf transformations, effectively mimicking the behav-

ior of the physical platform in a controlled ROS 2

environment. This setup enabled the rapid iterative

development of the controller logic and tuning of key

parameters, including linear speed, angular gain, and

heading and position tolerances, without the risk or

time constraints associated with physical trials.

The simulator confirmed that the curvature-

constrained controller is capable of accurately follow-

ing waypoint sequences with non-zero turning radii.

After several rounds of tuning, the robot success-

fully executed multi-segment paths while complying

with the minimum turning radius constraint. The

ALIGN, GOTO, and PAUSE state transitions behaved

as expected, and the robot consistently stopped and

resumed at designated zero-speed waypoints. This

stage also allowed us to refine speed profiling strate-

gies and verify that orientation interpolation across in-

terpolated poses yielded smooth heading transitions.

7.2 Deployment on Real Robot

Following successful simulation trials, the complete

system, including the custom Foxglove panel, GNSS-

RTK localization, and the motion controller was de-

ployed on the physical robot. The platform was

equipped with a manipulator capable of placing stan-

dard traffic cones retrieved from predefined onboard

storage locations. Field tests were conducted in out-

door environments with unobstructed GNSS visibility

and a stable RTK base station connection.

In practice, the system demonstrated reliable per-

formance on simple track layouts such as straight

lines and broad arcs. Using the Foxglove panel,

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

322

the operator interactively defined and published cone

placement trajectories, which the robot executed with

minimal supervision. The use of a triangular speed

profile for interpolated segments enabled smooth de-

celeration near stopping points, contributing to con-

sistent placement accuracy.

To assess the overall system accuracy, including

the robot platform and the point-to-point PID con-

troller, the robot’s ability to follow goal points was

evaluated. Figure 5 illustrates three test scenarios: a

straight line of five waypoints spaced 3m apart, a gen-

tle arc defined by five points, and a zig-zag pattern

consisting of four waypoints. In the figure, the red

line represents the executed trajectory, while green

dots denote target waypoints, each surrounded by a

yellow circle with a 0.5m radius for visual clarity.

Figure 5: Test waypoint constellations (straight line, slight

arc, zig-zag pattern).

These constellations were repeated multiple times,

and after reaching 25 waypoints in total, the achieved

accuracy has been evaluated. The results are pre-

sented by Table 1.

Table 1: Waypoint following accuracy metrics.

Metric Value (m)

Mean Absolute Error (MAE) 0.117

Root Mean Square Error (RMSE) 0.146

Standard Deviation 0.089

Maximum Error 0.260

Minimum Error 0.000

Median 0.080

7.3 Limitations and Edge Cases

The described mobile robot for traffic cone placement

defines a number of requirements in order to be oper-

ational. These requirements include good GNSS cov-

erage and the availability of an RTK base. While the

system reliably executes cone placement routines un-

der nominal conditions, certain edge cases pose chal-

lenges. The controller assumes that all waypoints are

reachable via curvature-feasible paths. If the opera-

tor places a cone behind the robot or defines tightly

spaced waypoints that violate the robot’s minimum

turning radius, the robot may be unable to execute

the intended motion. Currently, such scenarios re-

quire trajectory redefinition. Similarly, closely spaced

cones may result in overlapping manipulation zones,

as the dimensions of the robot platform are not taken

into consideration automatically. Solving these edge

cases was out of the scope of this work, and cur-

rently are mitigated by defining policies for traffic

cone placement.

8 CONCLUSION AND FUTURE

WORK

This paper presented a fully integrated robotic sys-

tem designed for automatic traffic cone manipulation

in semi-structured outdoor environments. The plat-

form combines a high-load skid-steer mobile base,

GNSS-RTK localization, a curvature-constrained mo-

tion controller, and a browser-based planning inter-

face to achieve precise waypoint tracking and context-

aware task execution. The system emphasizes modu-

larity and real-world feasibility by leveraging ROS 2,

real-time communication networks, and industrial-

grade components such as CAN-driven ESCs and an

on-board robotic manipulator.

Our experimental results demonstrate that the pro-

posed control and planning architecture is capable of

reliably executing waypoint-defined cone manipula-

tion tasks even under curvature constraints imposed

by the platform’s limited turning capabilities. The

combination of a customized Foxglove Studio panel

and a curvature-aware trajectory controller enables

seamless operator interaction and safe execution of

manipulation routines.

Future work will focus on several enhancements

aimed at increasing the system’s reliability while ad-

dressing the previously identified edge cases. First,

we plan to integrate dual-antenna GNSS-RTK hard-

ware to obtain accurate heading estimates that are in-

dependent of magnetic disturbances and IMU drift,

even at low speeds or during standstill. Secondly, we

intend to develop a software module to systematically

handle edge cases arising from suboptimal or infeasi-

ble cone placement. By assigning unique indices to

each cone and maintaining an execution queue, the

robot will be able to defer manipulation tasks that

are temporarily unreachable—such as cones located

at sharp backward angles or within physically con-

strained regions—and proceed with constructing the

remainder of the track. Deferred tasks can then be re-

visited once a more favorable pose or configuration is

reached. This approach will explicitly account for the

Curvature-Constrained Motion Planning and Control for Traffic Cone Manipulation Robot

323

physical dimensions and kinematic constraints of the

robot platform. In the longer term, we aim to enhance

the graphical user interface by introducing a mod-

ule that automatically assigns cone positions based on

input parametric drawings and high-level parameters

such as desired inter-cone spacing. We also envision a

dynamic placement strategy that enables the robot to

deploy cones while in motion, thereby eliminating the

need for full stops and improving overall operational

efficiency and task throughput.

ACKNOWLEDGEMENTS

This research was supported by the European Union

within the framework of the National Laboratory for

Autonomous Systems (RRF-2.3.1-21-2022-00002).

REFERENCES

Foxglove (2024). Foxglove studio. Accessed: 2025-06-07.

Fragapane, G., de Koster, R., Sgarbossa, F., and Strandha-

gen, J. O. (2021). Planning and control of autonomous

mobile robots for intralogistics: Literature review and

research agenda. European Journal of Operational

Research, 294(2):405–426.

Han

ˇ

zi

ˇ

c, F., Jezernik, K., and and, S. C. (2013). Mechatronic

control system on a finite-state machine. Automatika,

54(1):126–138.

Hartzer, J. and Saripalli, S. (2020). Autocone: An omni-

directional robot for lane-level cone placement. In

2020 IEEE Intelligent Vehicles Symposium (IV), page

1663–1668. IEEE.

Holl

´

osi, J., Mark

´

o, N., and Ballagi,

´

A. (2021). Forga-

lomtechnikai terel

˝

o b

´

oja

´

eszlel

´

esen alapul

´

o poz

´

ıci

´

o

´

es orient

´

aci

´

o meghat

´

aroz

´

asa [determining the position

and orientation of traffic cones based on detection].

In Digit

´

alis J

´

arm

˝

uipari Kutat

´

asok a Sz

´

echenyi Istv

´

an

Egyetemen - Konferenciakiadv

´

any 2021 [Digital Au-

tomotive Research at Sz

´

echenyi Istv

´

an University -

Conference Proceedings 2021], pages 56–63.

Hong Kong Highways Department (2019). Robot system

for placement and collection of traffic cones and warn-

ing lanterns at high speed roads. Accessed: 2025-05-

28.

Krecht, R. and Ballagi,

´

A. (2022). Tesztp

´

alya kiszolg

´

al

´

as

´

ara

alkalmas auton

´

om robotplatform g

´

ep

´

eszeti tervez

´

ese

[mechanical design of an autonomous robot plat-

form for test track support]. In Mobilit

´

as

´

es

k

¨

ornyezet: J

¨

ov

˝

oform

´

al

´

o j

´

arm

˝

uipari kutat

´

asok konfer-

enciakiadv

´

any [Mobility and Environment: Confer-

ence Proceedings on Future-Shaping Automotive Re-

search], pages 220–232. 2022. novemberi konferen-

cia.

Paden, B.,

ˇ

C

´

ap, M., Yong, S. Z., Yershov, D., and Fraz-

zoli, E. (2016). A survey of motion planning and con-

trol techniques for self-driving urban vehicles. IEEE

Transactions on Intelligent Vehicles, 1(1):33–55.

Pfrommer, J., B

¨

omer, T., Akizhanov, D., and Meyer, A.

(2024). Sorting multibay block stacking storage sys-

tems.

Siciliano, B., Sciavicco, L., Villani, L., and Oriolo, G.

(2009). Robotics: Modelling, Planning and Control.

Springer, London.

Thrun, S., Burgard, W., and Fox, D. (2005). Probabilistic

Robotics. MIT Press, Cambridge, MA.

ZalaZONE Research and Innovation (2023). Innovation

in motion – autonomous systems national laboratory

demonstration day. https://research- and-innovatio

n.zalazone.hu/en/innovation-in-motion-autonomou

s-systems-national-laboratory-demonstration-day/.

Accessed: 2025-05-30.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

324