Dual-Arm Manipulation of a T-Shirt from a Hanger

for Feeding a Hem Sewing Machine

Filipe Almeida

1 a

, Gonc¸alo Le

˜

ao

1,2 b

, Carlos M. Costa

1,2 c

, Cl

´

audia D. Rocha

1 d

,

Armando Sousa

1,2 e

, Lara Gomes da Silva

3 f

, Lu

´

ıs F. Rocha

1 g

and Germano Veiga

1 h

1

Centre for Robotics in Industry and Intelligent Systems of INESC TEC, Porto, Portugal

2

Faculty of Engineering of the University of Porto, Porto, Portugal

3

ESI Robotics, Esmeriz, Portugal

fi

Keywords:

Dual-Arm Manipulation, Fabrics, Flexible Materials, Robot Handling, Sewing Automation, Textile Industry.

Abstract:

The textile industry is experiencing rapid advancement, reflected in the adoption of innovative and efficient

manufacturing techniques. The automation of clothing sewing systems has the potential to reduce the alloca-

tion of repetitive tasks to operators, freeing them for more value-added operations. There are several machines

on the market that automatically sew the bottom hem of T-shirts, a key component of the garment that fulfills

both functional and aesthetic purposes. However, most of them require the fabric to be positioned manually

by an operator. To address this issue, this work presents a solution to automate the process of feeding a T-

shirt into a SiRUBA sewing machine using a YuMi dual-arm robot. In this scenario, the T-shirt arrives at the

workstation with the main front and back pieces of cloth sewn together, seams facing out, and with no sleeves

yet. This setup starts by turning the garment inside out with the aid of an automated hanger, ensuring that

the seams are facing inward (as the machine requires), and then using the dual-arm robot to feed the garment

into the sewing machine. With our approach, the feeding and hemming process took less than 35 seconds,

with a feeding success rate of 98%. Therefore, this work can serve as a steppingstone towards more efficient

automated sewing systems within the garment production industry.

1 INTRODUCTION

Since the Industrial Revolution in the 18th century,

the textile industry has been one of the most pre-

dominant global industries. In subsequent decades,

the industry continued to grow rapidly in revenue and

employment, but created very low-quality labor stan-

dards. Over time, this inevitably led to most man-

ufacturing being outsourced to factories in develop-

ing countries, allowing lower labor and manufactur-

ing costs. The repetitive and tiring working condi-

tions of this industry remain a concern to this day,

a

https://orcid.org/0009-0000-1129-2916

b

https://orcid.org/0000-0002-9081-9268

c

https://orcid.org/0000-0001-8453-4031

d

https://orcid.org/0000-0001-7254-0346

e

https://orcid.org/0000-0002-0317-4714

f

https://orcid.org/0009-0006-8412-137X

g

https://orcid.org/0000-0002-8680-4290

h

https://orcid.org/0000-0003-3044-6938

and automation could provide a viable answer by al-

leviating some of the workload of factory workers.

The issue is that manipulating flexible objects, such

as textiles, remains a challenge for automation as their

shape changes as they are handled (Sanchez et al.,

2018; Zhu et al., 2022).

The process of manufacturing garments consists

of taking large rolls of fabric, cutting them into

smaller pieces, and sewing them together to obtain the

desired shape (Grishanov, 2011). There are already

several machines in the market that automate parts of

the process. The issue with these types of systems is

that the garment needs to be placed in a specific po-

sition for the machine to function properly. This cre-

ates a production line where several small processes

are automated, but require the operators to transfer the

garments between several machines, creating a very

repetitive and labor-intensive workload.

In the manufacturing of T-shirts, one important

step during assembly is the sewing of the bottom

hem. The bottom hemming step consists of folding

Almeida, F., Leão, G., Costa, C. M., Rocha, C. D., Sousa, A., Gomes da Silva, L., Rocha, L. F. and Veiga, G.

Dual-Arm Manipulation of a T-Shirt from a Hanger for Feeding a Hem Sewing Machine.

DOI: 10.5220/0013718300003982

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 22nd International Conference on Informatics in Control, Automation and Robotics (ICINCO 2025) - Volume 1, pages 93-104

ISBN: 978-989-758-770-2; ISSN: 2184-2809

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

93

up a small margin of the bottom tip of the T-shirt and

stitching it down. This hem is important for both aes-

thetic and functional purposes, namely, for maintain-

ing its shape more easily, preventing the bottom edge

from fraying and tearing, thus increasing durability

and adding a small weight for a smoother drape.

This paper presents a solution to automate the pro-

cess of feeding a T-shirt to a SiRUBA ASC-TBH200

(an automated bottom hem sewing machine). In this

scenario, the T-shirt arrives at the bottom hemming

process with the main front and back pieces of cloth

sewn together, seams facing out, and with no sleeves

yet, which corresponds to the typical state of the gar-

ment in this stage of production. Our approach starts

by turning the T-shirt inside out, so the seams are fac-

ing inward, as the machine requires, and then uses a

dual-arm ABB IRB 14000 YuMi robot to place the T-

shirt in the correct position. This setup was developed

for the EU-funded TexP@ct

1

project, which aims to

study the automation of several garment manufactur-

ing processes.

The paper is structured as follows. Section 2 re-

views related work on the use of robots to automate

sewing systems. Section 3 presents the cloth manip-

ulation system, including the robotic setup and the

grasp planning algorithm. Section 4 presents and dis-

cusses the experimental results of the robotic system.

Section 5 summarizes the findings and presents ideas

for future research.

2 RELATED WORK ON ROBOTIC

AUTOMATED CLOTH SEWING

There is already a body of research, spanning over 35

years (Gershon and Porat, 1988; Tokuda et al., 2024),

on the use of robot arms for automated cloth sewing

and assembly systems. Several approaches involving

feeding a cloth item into a sewing machine have been

developed, using either one or more robotic arms.

2.1 Approaches with One Robot Arm

Most of the related work resorts to a single-arm robot

to perform the sewing task.

(Gershon and Porat, 1988; Gershon, 1990) devel-

oped one of the first automated sewing systems within

the FIGARO project, where a PUMA 560 arm with

two spring-loaded, rubber-tipped grippers holds and

moves a cloth panel while it is being sewn in the other

end by a sewing machine. This setup is common to

most other approaches, in which the robot arm holds

1

https://texpact.pt

the cloth by one end while the sewing machine’s nee-

dle sews the cloth on the other end. The main differ-

ences between approaches lie in the hardware used

for the sewing arm, gripper and sensors, alongside

the approach used for motion planning. (Zacharia

et al., 2008; Zacharia, 2010) used fuzzy control to ad-

just the circular motions of a gripper around a nee-

dle. The gripper holds a cloth panel with curved

edges to a worktable during sewing. (Triantafyllou

et al., 2011) use a Selective Compliance Assembly

Robot Arm (SCARA) robot equipped with a pneu-

matic gripper to hold one edge of two plies of fabric

while the other edge is being sewn at an unknown ve-

locity. They use a Proportional–Derivative (PD) fuzzy

controller to move the gripper based on the difference

between the desired and measured force, according

to a force-torque sensor. (Koustoumpardis and As-

pragathos, 2014) improve this later work by adopt-

ing a hierarchical control loop where the force fuzzy

control is performed using an online trained neural

network, which is fed with an estimation of the fab-

ric’s extensibility given by an off-line trained neu-

ral network. (Misios et al., 2019) later further im-

proved on this work with a similar setup by obtaining

the desired tensional force of the robot on the fabric

via a Kelvin-Voigt non-linear model that emulates the

fabric’s physics based on estimations of the fabric’s

type and length. Finally, (Tang et al., 2024) control

a Denso VS-068 arm using a time-scaling model fed

with data from a high-speed camera, and force-torque

impedance control.

One single arm approach that differs from the oth-

ers was developed by (Arai et al., 1989), who instead

mounted a lightweight sewing machine on the robot

arm while the fabric to be sewn was hung in a fix-

ture. A proportional controller based on force feed-

back was used to move each of the robot arm’s joints.

2.2 Approaches with Multiple Robot

Arms

There is also research on the use of two robot arms

for sewing automation. This allows for a finer control

of the cloth but also requires coordinating both arms.

(Kudo et al., 2000) use two different robot arms,

a 4-axis SCARA robot and a 5-axis robot, both with

spring-loaded, rubber-tipped fingers, to hold the fab-

ric and move it while it was sewn by the sewing ma-

chine. (Schrimpf et al., 2012; Schrimpf and Wetter-

wald, 2012) use two UR5 arms to join the four leather

parts of a footstool cover. The use of two robot arms

allows for the parts to be held independently, which is

useful given that they have distinct geometries. They

later incorporated one extra arm in the layout for finer

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

94

material handling and to control the seam when re-

leasing it in front of the sewing machine, given that

the other two robot arms release the part beforehand

to avoid collision with the sewing machine (Schrimpf

and Mathisen, 2016). (Shungo and Hisashi, 2021)

use a horizontal dual-arm manipulator with rollers as

end effectors, which allow for wrinkles in the grasped

cloth to be eliminated more easily. Finally, (Tokuda

et al., 2024) use a DENSO VS-068 dual-arm to sew

two stacked fabric parts together along a desired seam

line printed on the top fabric part. Unlike all the pre-

vious work, rather than feeding the fabric part to the

sewing machine, they hold the fabric on both sides,

and the sewing head is solely used for stitching. This

allows the position and tension of the fabric parts to

be controlled exclusively by the dual-arm manipula-

tor.

Unlike the previous approaches, which use multi-

ple single-arm robots, (Sun et al., 2019) use the same

YuMi dual-arm robot model of this work to place a

cloth piece with holes on a fixture composed of ver-

tical locating pins. The cloth is then sent to a sewing

machine to be sewn, but it is not detailed in their work.

2.3 Comparison with this Work

In comparison with most of the literature, this work

proposes a novel solution as the robot arm does not

have to hold the fabric item during the sewing process,

which is instead inserted around two cylinders of the

sewing machine (similarly to (Sun et al., 2019), who

also rely on fixtures). A dual-arm hardware setup,

along with dual finger grippers, is used to have bet-

ter control over the garment, which is similar to most

of the related research. In addition, the T-shirt being

sewn has larger dimensions than those used in most

related work. As this manuscript corresponds to early

work with a novel robotic setup, no motion control

was performed.

3 CLOTH MANIPULATION

SYSTEM

The cloth manipulation system consists of several

components that work in unison to ensure the suc-

cessful hemming of the T-shirt. The entire system is

displayed in Figure 1. The following subsections pro-

vide details on each component and the final subsec-

tion details the robotic cell’s entire process in detail.

It should be highlighted that the robotic worksta-

tion developed in this work will be integrated into

a larger production cell, which will include another

robot that will pick up the 2 sides of the T-shirt from

a stack for sewing them together, after which the T-

shirt is inserted into a modified version of our T-shirt

holder (to allow it to alternate between a horizontal

configuration alongside the Yumi robot for inserting

the T-shirt and a vertical configuration in front of the

YuMi robot for turning it inside out), after which the

system and processes described in the following sub-

sections will be used to manipulate the T-shirt and

perform the hemming process. Therefore, in the com-

plete system, a human operator will not be required to

place the T-shirt in our workstation, since the entire

production process will be automated.

We developed this prototype to test our T-shirt

feeding approaches, but it will be improved and up-

graded for the integration in the final production cell.

Although it will have several modifications to make it

ready for industrial deployment, the current version is

enough for validating our T-shirt feeding approaches.

3.1 Sewing Machine

As previously stated, the SiRUBA ASC-TBH200

(Figure 2) is an automatic sewing machine that hems

the bottoms of T-shirts or other pieces of clothing

with similar shapes, such as polo shirts and long-

sleeve shirts. The basis for this system is a regu-

lar model of an interlock sewing machine fitted with

guiding wheels and cylinders that move the bottom of

the T-shirt through the machine. There are also sev-

eral sensors and air pressure actuators that shape the

hem throughout the sewing process. Once the T-shirt

is correctly placed, a button can be pressed to start

sewing, and the machine automatically detects when

the hem is finished, completing the cycle by releasing

the T-shirt.

The process of feeding the T-shirt to the sewing

machine, which is the focus of this paper, has three

main conditions to ensure the hem is properly sewn.

• Since the machine will sew the hem by pulling

the edge under the rest of the cloth, the T-shirt

needs to be inserted with the lateral seams fac-

ing inwards. As the T-shirt arrives at this produc-

tion stage in the opposite orientation, it needs to

be flipped inside-out.

• When feeding the machine, the two main cylin-

ders (in black in Figure 2) and all the parts be-

tween them need to stay inside the T-shirt. The

cloth should fit well around this structure, and al-

though it does not need to be perfectly aligned,

large wrinkles or folds should be avoided.

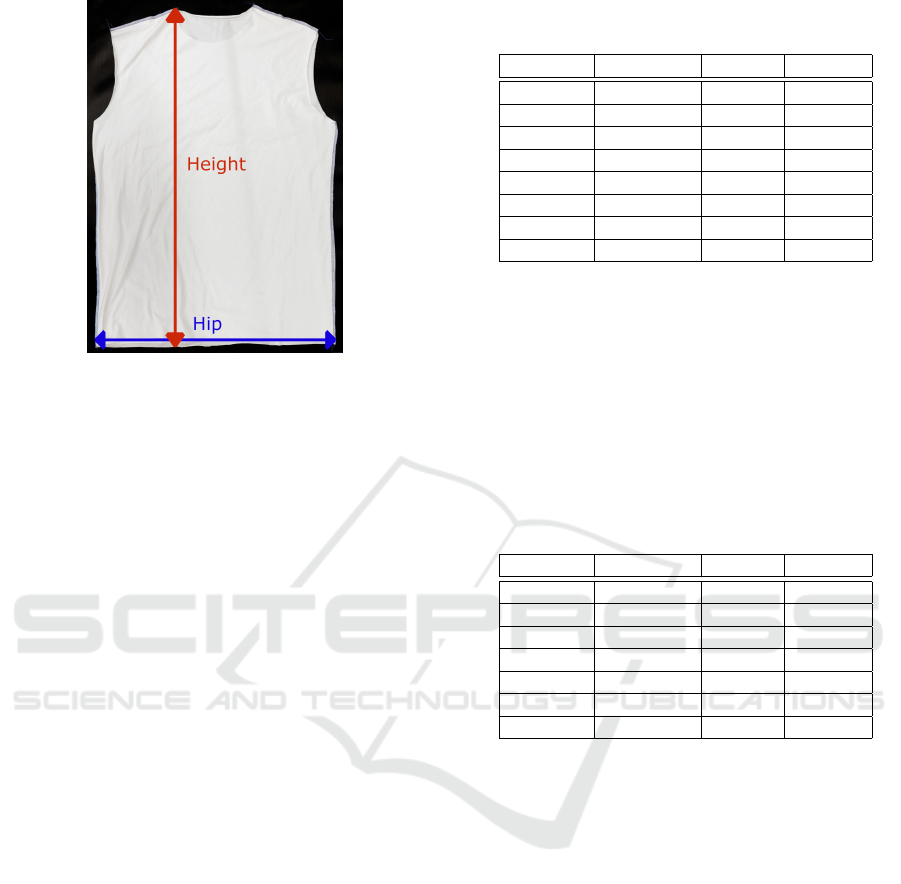

• The T-shirt detection sensor seen in Figure 3

needs to be activated by the bottom edge of the

T-shirt for the sewing to start. Once this sensor is

Dual-Arm Manipulation of a T-Shirt from a Hanger for Feeding a Hem Sewing Machine

95

Figure 1: Cloth manipulation system and all the individual components numbered in blue. Dual-arm ABB YuMi robot (1),

automatic sewing machine (2), hanger structure for initial placement of the T-shirt (3), vertical cylinder to move the hanger

(4), smaller cylinders to hold the T-shirt’s collar in place (5), side supports to open the bottom of the t-shirt.

Figure 2: Automatic sewing machine (SiRUBA ASC-

TBH200). Numbered in blue, the components are: left

cylinder that extends to the left side when a T-shirt is de-

tected (1), right cylinder with guiding wheels to rotate the

T-shirt (2), guiding platform that keeps the T-shirt straight

between the cylinders (3), presser foot and needles of the

sewing machine (4), T-shirt detection sensor (5).

activated, the left cylinder extends to stretch the

T-shirt and begin the hemming process. Ideally, at

this point, the cloth over the left cylinder is mostly

aligned with the one on the right.

If all these conditions are met, the placement of

the T-shirt does not need to be very precise, since the

machine, before starting to sew the fabric, rotates the

T-shirt around the cylinders and uses its sensors and

actuators in an attempt to align as well as possible

the bottom edge, to guarantee the hemming is done

correctly.

3.2 Hanger Structure

The structure that initially holds the T-shirt can be

seen in Figure 1. The basis for this structure functions

essentially as a regular hanger with side profiles for

additional support, ensuring a more predictable start-

ing position. To this structure, two components were

added for improving grasping repeatability.

• Two lateral supports were designed, 3D printed

and installed at the bottom of the vertical pro-

files, for ensuring that the robot had reliable and

fixed grasp zones in the T-shirt, as seen in Fig-

ure 4. Initially, the tests were conducted without

using these 2 supports, and the system was not

capable of having repeatable grasping points, re-

inforcing the importance of the addition of these 2

lateral supports for achieving higher grasping ro-

bustness. The bottom of the supports is larger in

width and depth, where it is in contact with the

bottom edge of the T-shirt, for separating both

sides of the edge of the T-shirt and for straight-

ening the T-shirt side facing the robot, creating a

good grasp point and enough free space for the

gripper to move through. From the bottom to the

top, the piece narrows using smooth surfaces, en-

suring that the T-shirt does not become entangled

or stuck in the structure.

• Two pneumatic cylinders were placed on top of

the hanger, for holding the T-shirt’s collar in place,

while it is being manipulated by the robotic arm.

The cylinders are placed along the same plane as

the hanger but are diagonally relative to the top

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

96

(a) Detection sensor not activated. (b) Detection sensor activated.

Figure 3: Sensor to detect the T-shirt’s presence in the sewing machine.

bar, ensuring that the tip of the pneumatic cylin-

ders are in contact with the profile, locking the

T-shirt in place, as seen in Figure 5. Holding the

T-shirt was critical for ensuring that it was turned

inside out correctly and reliably.

3.3 Dual-Arm Robot

The most practical way human beings manipulate

pieces of clothing is by using both hands, with two

grasping points near the extremities of the fabric’s

shape. As the sewing machine was designed for hu-

man usage, the most precise and time-efficient man-

ner to feed it with T-shirts is by using both arms to

guide the T-shirt. This allows the insertion in the left

and right cylinders to happen simultaneously, provid-

ing better coordination between the actions.

Creating a robotic system that can mimic human

behavior in this action requires a dual-arm setup. For

this task, the robot chosen was the ABB IRB 14000

YuMi (Figure 6), along with its parallel electric grip-

pers. This setup presents the following advantages:

• It already possesses a dual-arm setup fully inte-

grated and programmable, with tools to ease com-

munication between both arms. This means there

is no need for a dual robot setup.

• It is a collaborative robot, meaning it was de-

signed to work safely alongside humans. This

is important for textile factories, since they cur-

rently still rely on a lot of people working along-

side robots in their facilities.

• It has a 7-axis configuration on each arm, unlike

the typical 6-axis robots used in this field (Ger-

shon and Porat, 1988; Schrimpf et al., 2012; Tang

et al., 2024; Tokuda et al., 2024). The additional

joint is fairly similar to the elbow rotation in hu-

man arms and helps create movements similar to

humans.

• It is capable of fast and accurate movements with

a high repeatability. Making the process of feed-

ing the machine as fast as possible is crucial since

it is used for mass production. The YuMi robot

allows movements up to 1500 mm/s while main-

taining accuracy and safety guarantees.

Despite these advantages, some drawbacks need

to be considered for the application studied in this pa-

per, mainly related to its physical capabilities. On the

one hand, there is a limited payload capacity of 0.5 kg

per arm. Although that is sufficient to hold a regular

T-shirt, it does not allow a lot of stretching of the fab-

ric, which may be necessary for smaller T-shirt sizes

to fit into the sewing machine. On the other hand, the

robot’s reach is only 559 mm, which often forces it to

be used near its range limits, making reaching certain

poses more difficult.

3.4 Vertical Pneumatic Cylinder

The entire hanger structure presented in Section 3.2 is

supported by a vertical pneumatic cylinder with a 700

mm of course. This allows the T-shirt to be removed

from the hanger in a much more compact working

area, reducing the vertical size of the entire setup. It

also ensures that the hanger does not block the path

for the robot to feed the sewing machine once the T-

shirt is removed from it.

3.5 Sewing Machine Feeding Pipeline

Figure 7 portrays a full cycle performed by the robotic

cell and shows how all the components work together

to feed a T-shirt into the sewing machine.

The T-shirt starts by being manually placed in the

hanger, with the seams facing out and the vertical

cylinder in the highest position (Figure 7(a)). The bot-

tom edge of the T-shirt falls over the wider part of the

2 lateral structures, and the top pneumatic cylinders

are in the retracted position. The workcell then per-

forms the following sequence of steps:

1. The top pneumatic cylinders extend for locking

the top of the T-shirt in place (Figure 5(b)).

Dual-Arm Manipulation of a T-Shirt from a Hanger for Feeding a Hem Sewing Machine

97

(a) Lateral support. (b) Lateral support with T-shirt placed in the struc-

ture.

Figure 4: Lateral support structures added on each side to help find grasping points.

(a) Pneumatic cylinders in the retracted position. (b) Pneumatic cylinders extended for holding the T-

shirt.

Figure 5: Pneumatic cylinders on the hanger to hold the T-shirt in place.

Figure 6: ABB IRB 14000 YuMi dual-arm robot.

2. The robot starts moving its arms towards the pre-

grasp positions, underneath the T-shirt (prepro-

grammed for the T-shirt size).

3. The grippers then move slightly upwards to the

grasp points inside the 2 lateral supports. When

both are in the right position, the gripper closes

their fingers, grabbing the T-shirt (Figure 7(b)).

4. The vertical cylinder starts lowering while the

robot slowly moves the T-shirt upwards (Figures

7(c) and 7(d)). These opposing motions remove

the T-shirt from the hanger and by relying on the

pneumatic cylinders to hold the T-shirt, the robot

is able to turn the T-shirt inside-out reliably.

5. Once the T-shirt is out of the hanger, the robot

pushes it through the guiding cylinders of the

sewing machine with the grippers slightly above

the structure (Figure 7(e)). At this stage, since

the grasp points used in the T-shirt were slightly

shifted towards the robot from each lateral seam,

there should be enough fabric hanging underneath

so that it can pass around the cylinders without

getting stuck.

6. The left arm inserts the left side of the T-shirt all

the way through, releases it and moves out of the

way (Figure 7(f)).

7. The right arm carefully places the right side of the

T-shirt as forward as possible for ensuring that the

sewing machine sensor is activated (Figures 7(g)

and 7(h)). This will cause the left cylinder of the

sewing machine to extend and stretch the T-shirt

(which is why the left arm needs to finish and

move out of the way first, otherwise the sewing

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

98

machine left cylinder would collide with the left

robotic arm). The right arm then releases the T-

short and moves out of the way.

8. The top pneumatic cylinders then retract, releas-

ing the T-shirt from the hanger.

9. The sewing machine can now start the hemming

process.

4 EXPERIMENTAL RESULTS

This section begins by describing the T-shirts used for

the experiments, followed by the three types of tests

performed.

• Machine feeding tests, where the T-shirts are fed

to the machine (but not sewn), focused on mea-

suring the robotic operation’s time.

• Stress tests, where the T-shirts are displaced with

respect to their expected initial state in the hanger,

in order to evaluate the system’s robustness.

• Full sewing tests, where the full cycle time of

the robotic cell is evaluated, alongside the success

rate of correctly sewing the T-shirt. These metrics

are compared with two human operators.

A video of the robotic cell in operation was made

publicly available at the URL below

2

.

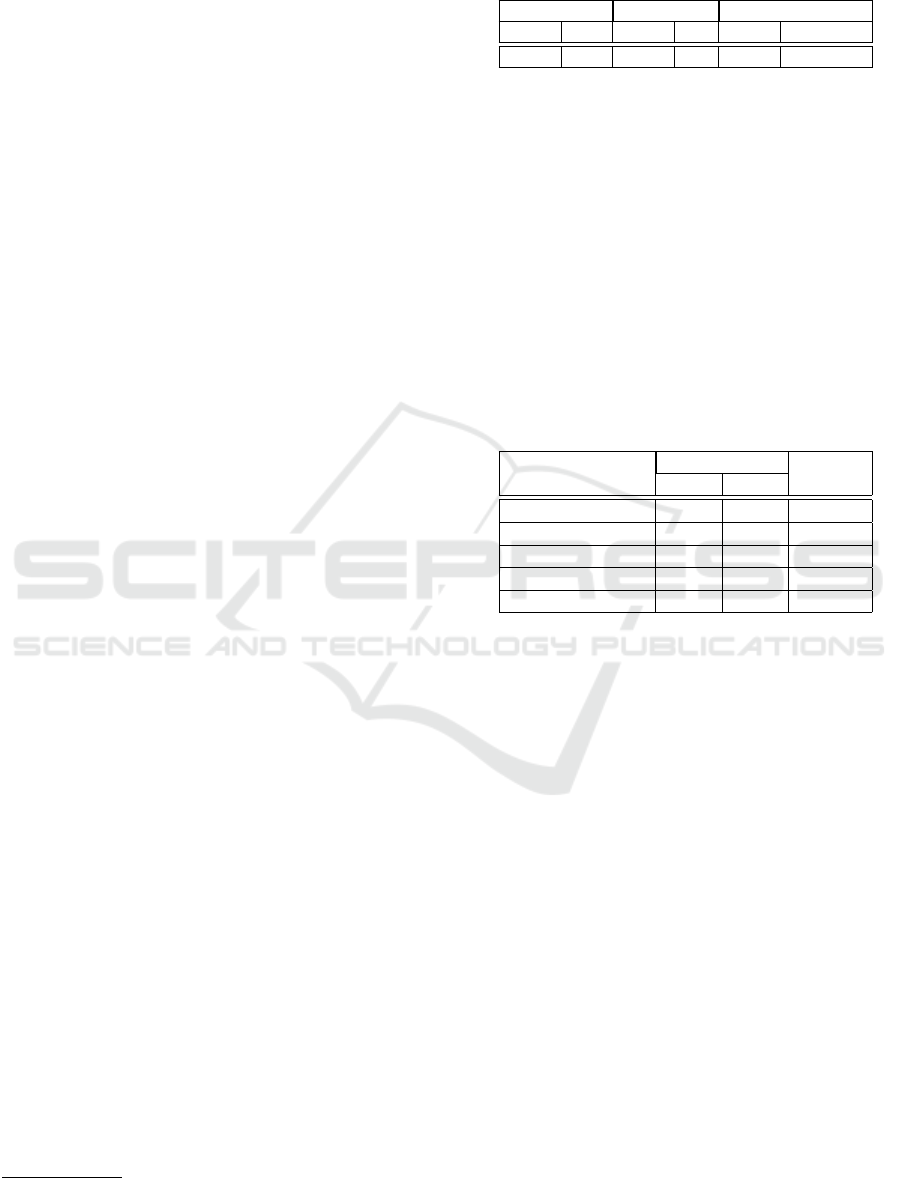

4.1 T-Shirts Testing Samples

All the T-shirts used in the experiments were identical

(depicted in Figure 8) and made of cotton fabric. For

the fabrication addressed studied in this paper, it is as-

sumed that the T-shirts arrive at this production stage

with no sleeves yet, so all the T-shirts used in our tests

were sleeveless. A total of 32 different T-shirts were

used in the tests. The mean and standard deviation for

their height and hip width (Figure 8), and curved edge

score are presented in Table 1. These measures cor-

respond to an XL-sized T-shirt, but results may vary

based on the comparison chart used.

After being handled for some time, the T-shirt fab-

ric starts to curl near the edges, which can introduce

some variance in the T-shirts. To quantify this curl,

a “curved edge score” was subjectively evaluated for

each T-shirt, indicating how rounded the bottom edge

was on a scale from 1 (least rounded) to 5 (most

rounded). As all the 32 T-shirts were never used in

prior experiments, this score tended to be low, as seen

in the last two columns of Table 1.

2

https://github.com/GoncaloLeao/Scientific-Research

Table 1: Mean and standard deviation (SD) for metrics re-

lated to the size and shape of 32 T-shirts.

Height (mm) Hip (mm) Curved edge score

Mean SD Mean SD Mean SD

795 5 577 8 1.56 1.01

4.2 Machine Feeding Tests

The sewing machine is designed for mass production

of garments in an industrial setting, and as such, we

tested our prototype under similar conditions. To sim-

ulate this scenario, the cycle described in Section 3.5

was repeated a total of 86 times. On every itera-

tion the time necessary to complete each stage were

recorded (grasping the T-shirt, pulling it out of the

hanger while flipping, inserting the left side, inserting

the right side, and total time), alongside the success

rates. These results are presented in Table 2.

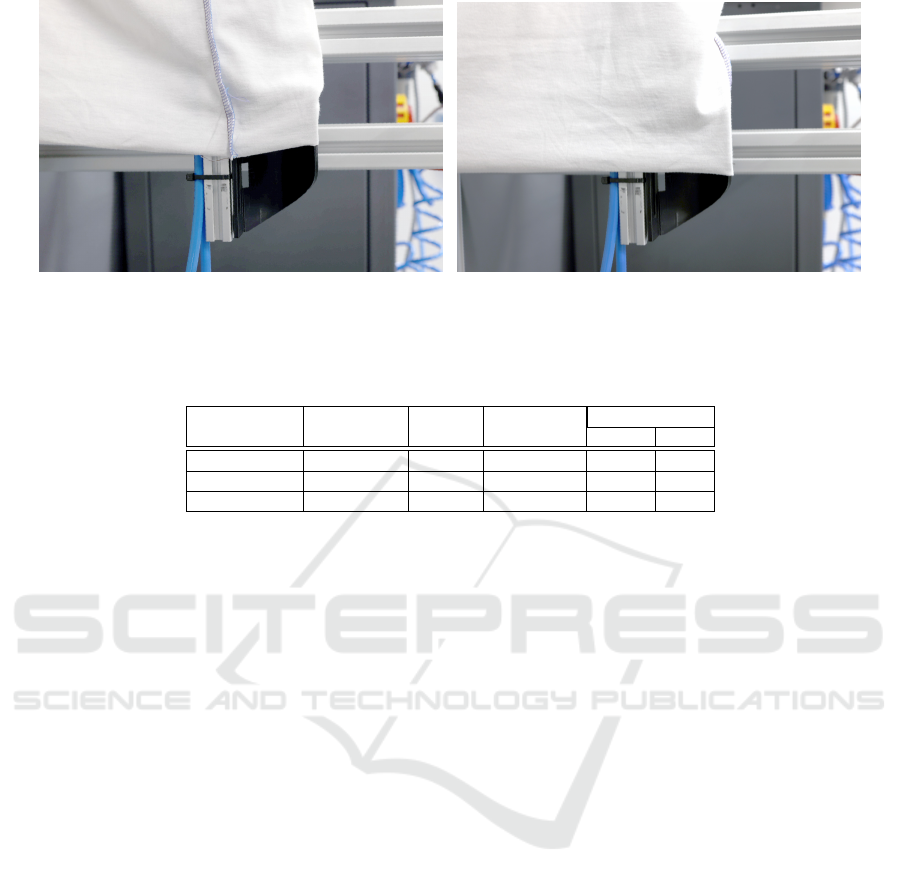

Table 2: Performance metrics for some steps of the T-shirt

feeding process (detailed in subsection 3.5), over 86 runs.

Steps

Time (s)

Success

rate

Mean SD

Grasp (1-3) 2.242 0.013 1

Lower hanger (4) 2.234 0.013 1

Insert left (5-6) 2.798 0.022 0.98

Insert right (7) 2.186 0.015 1

Total (1-8) 9.461 0.031 0.98

From the results, some conclusions can be drawn.

• A total of 84 of the 86 tests were successful, which

shows that the setup can consistently perform the

T-shirt feeding task.

• The only 2 tests that failed had the same issue,

that was excessive force in one of the robotic arm

joints while pushing the T-shirt towards the ma-

chine. The most likely cause for these failures

could be a slight desynchronization between the

start of the motions of the left and right robotic

arms. This stretches the T-shirt, provoking the ex-

cessive force on the joints of the robot.

• All the robotic arm movements were done at the

maximum possible speed, limited either by the

motors’ maximum speed or the payload, except

the ones close to the sewing machine, to guarantee

precision. Moreover, both arms’ tasks were coor-

dinated to be performed simultaneously whenever

it was possible to do so. This allowed the total

cycle time to be lowered to under 10 seconds.

• The robot takes approximately the same time run-

ning the cycle without grabbing the T-shirt, mean-

ing the weight does not affect the motor’s perfor-

mance significantly. This is the most likely expla-

Dual-Arm Manipulation of a T-Shirt from a Hanger for Feeding a Hem Sewing Machine

99

(a) Initial position. (b) Grasping.

(c) Flipping the T-shirt inside out. (d) T-shirt flipped inside out.

(e) Starting insertion into sewing machine. (f) Inserting left arm.

(g) Inserting right arm. (h) Activation of sewing machine sensor.

Figure 7: Sewing machine feeding pipeline.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

100

Figure 8: Example of a T-shirt’s height and hip width.

nation for the low standard deviation values for

the execution time.

• All the 32 T-shirts were used 2 or 3 times, half

of them with the front facing the robot and the

other half facing the sewing machine. Neither the

variations in the T-shirts nor the rotation appeared

to have any effect on the time or success rate.

4.3 Stress Tests

Since the setup is dependent on the starting position

of the T-shirt when it is placed in the hanger, it is im-

portant to know how much margin of error there is

when placing the T-shirt in the initial pose. To retrieve

some data on this metric, some stress tests were per-

formed that increasingly introduced more variation in

the starting state, to try to find possible points of fail-

ure. This section will present those variations and the

results obtained.

The first test consisted of adding a horizontal shift

to the T-shirt. This was achieved by moving the T-

shirt collar on top of the hanger so that the point that

meets the lateral seam of the T-shirt with the bottom

edge is at a certain distance from the lateral supports,

as seen in Figure 9(a). The results of this experiment

are presented in Table 3.

Despite the large shifts, the tests remained suc-

cessful, and the cycle times were unaffected. It is

important to note that the larger the shift, the more

likely it becomes that the top cylinders of the hanger

are no longer capable of holding the T-shirt in place

due to the shape of the collar. This will cause the setup

to lose some control of the T-shirt and can prevent

it from flipping properly, creating a possible point of

failure. Even considering this, the shifts tested were

very significant, so it is possible to say that the system

Table 3: Stress testing the setup by rotating the T-shirt hor-

izontally.

Direction Shift (mm) Result Time (s)

Right 60 Success 9.492

Right 110 Success 9.518

Right 160 Success 9.480

Right 210 Success 9.483

Left 60 Success 9.484

Left 110 Success 9.495

Left 160 Success 9.462

Left 210 Success 9.505

is very resilient to horizontal shifting.

The following experiment was to attempt a verti-

cal shift of the position where the bottom edge of the

T-shirt sits on the lateral supports. This was achieved

by pulling up or pushing down the edge of the T-shirt,

as seen in Figure 9(b), and letting it hold itself in po-

sition with the friction with the hanger, as can happen

accidentally when placing the T-shirt at the start. Ta-

ble 4 shows the results of these tests.

Table 4: Stress testing the setup by shifting the bottom edge

of the T-shirt vertically.

Direction Shift (mm) Result Time (s)

Up 10 Success 9.456

Up 20 Success 9.438

Up 30 Failed -

Down 10 Success 9.426

Down 20 Success 9.438

Down 30 Success 9.426

Down 40 Success 9.436

When pulling the T-shirt up, the problem that first

occurred at 30 mm was that the grip achieved was too

weak, and the robot dropped the T-shirt when pulling

it out of the hanger. Pushing the T-shirt down does not

result in a failure to feed the machine, but it causes

the robot to grab too much fabric. It ends up placing

the T-shirt too close to the sensor, which can lead to

problems with the hemming process. The system is

much more sensitive to vertical shifts. Future itera-

tions of the prototype should include a way to adjust

the height of the grasping points.

4.4 Sewing Tests with Human

Comparison

Although this paper focuses more on the automated

feeding process, it is also necessary to ensure that the

T-shirt’s placement in the hanger is good enough for

a successful hemming. To evaluate this stage, after

being inserted by the robot, a total of 21 T-shirts were

sewn, and the results were observed. To get a base-

Dual-Arm Manipulation of a T-Shirt from a Hanger for Feeding a Hem Sewing Machine

101

(a) Placement with horizontal shift (pulled to the left). (b) Placement with vertical shift (pulled down).

Figure 9: Examples of placements from the stress tests.

Table 5: Performance metrics for a set of sewing tests performed by the prototype and the experienced/unexperienced opera-

tors (using solely the sewing machine).

Operator

Num.

experiments

Success

rate

Perfect hem

rate

Time (s)

Mean SD

Inexperienced 10 0.7 0.6 18.865 3.461

Experienced 10 0.9 0.8 9.573 2.079

Prototype 21 0.76 0.67 9.445 0.024

line of comparison, another 20 tests were done with

a person performing the same procedure of picking

up the T-shirt, flipping it, and inserting it into the ma-

chine. Half of these tests were done by an operator

with more experience with the sewing machine, and

the other half by one with less experience. Table 5

shows the results for this experiment.

From the analysis of these results we can conclude

the following:

• Regarding the time of insertion, there is a signif-

icant difference between an experienced (9.573

seconds) and an inexperienced person (18.865

seconds). As the mean and standard deviation re-

sults show, with more practice, operators can get

faster and achieve better success rate.

• The prototype has a very similar mean time (9.445

seconds) when compared to an experienced opera-

tor (9.573 seconds). The operator can perform the

task faster (fastest time was 8.0 seconds), but it is

very hard to do it consistently, as demonstrated by

the standard deviations. Over time, the average

times seem to even out.

• The sewing machine operation times were also

registered, with the sewing of the hem taking on

average 20.7 seconds. This makes the complete

hem sewing process take around 30 seconds.

• As for the success rate, the prototype performed

better than an inexperienced operator but not as

well as an experienced one.

• Some tests were considered successful even if the

hem had some flaws. Perfect hem rate only con-

sidered the ones where no defects were found,

such as the one in Figure 10.

• Compared to the overall success rate, it decreases

consistently for all operators by around 0.1 sec-

onds, which is probably due to the fine-tuning of

the sewing machine.

• Most of the prototype failures seem to be due to

excess fabric being pushed beyond the sensor on

the sewing machine (5 on 21 tests). This caused

the machine to not properly align the hem fold of

the T-shirt and to sew either with no fold or too

many folds (Figure 11(a)).

• Other defects were incomplete hem in which the

sewing did not catch the inside of the hem (1 on

21 tests) in some sections (Figure 11(b)) and also

misalignment at the end of the hem (1 on 21 tests)

(Figure 11(c)).

5 CONCLUSIONS

The main contribution of this work was a robotic sys-

tem that is able to sew the bottom hem of a T-shirt

using an industrial sewing machine and a dual-arm

robotic arm. Although fabric manipulation is a very

difficult problem which requires precise manipulation

and grasping, our prototype performed this task effi-

ciently and consistently, achieving a T-shirt feeding

success rate of 98%.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

102

(a) Hem. (b) Hem ends overlapping correctly.

Figure 10: Example of a correct hemming done by the sewing machine.

(a) Hem sewing failure due

to excessive folding of the

fabric.

(b) Hemming did not fully catch

the fabric.

(c) Hemming did not have cor-

rect overlap at the end.

Figure 11: Examples of hemming failures.

The experimental results provided some general-

ized insights into fabric manipulation. For indus-

trial applications, focused on speed and repeatability,

robotic manipulation alone can pose some problems

due to the unpredictability of the material. In this pro-

totype, the most successful solution relied on mechan-

ical holding and guiding components. One of them is

the top pneumatic cylinders that hold the T-shirt col-

lar on the hanger, which, in combination with the two

grippers, create a total of four grasping points, well

distributed along the T-shirt. The conclusion is that

the more the T-shirt is constrained, the less loose fab-

ric will exist, leading to more repeatable manipulation

of the T-shirt. Another phenomenon that can be used

is the fact that, when a fabric is stretched, it transitions

from being deformable to having more elastic proper-

ties, creating a much more consistent shape. The 2

lateral supports of our prototype that take advantage

of this effect, which stretch the fabric in the bottom

edge to ensure good grasping points.

This work opens several lines of future work,

where this robotic workcell can be improved. First

of all, our prototype that feeds the sewing machine

will also need to be fed, which is not a trivial prob-

lem. Namely, another workcell will be performing

the sewing of the side of the T-shirt, after which will

feed it to our hanger.

Secondly, grasp and motion planning can be per-

formed, rather than using fixed grasp points and post-

grasp robot motions for both arms. Providing the sys-

tem with perception capabilities is the best solution

as it would both allow the system to work with dif-

ferent T-shirt sizes, and make it more robust against

potential defective initial T-shirt placements, fixing

the problem shown in Section 4.3. This way, the

robot could also have better and more reliable grasp-

ing points, avoiding the problem described in Section

4.4, of too much fabric going over the sensor.

Thirdly, a different robot arm could be used for

manipulation. Although ABB YuMi presented a lot

of advantages, its low payload and limited reach were

the two main issues. There are plenty of alternatives

that could be considered and that could result in im-

provements in reliability and speed. Alternatives in-

clude other dual-arm robot models, but also a pair of

single-arm robots, similar to most of the related work

Dual-Arm Manipulation of a T-Shirt from a Hanger for Feeding a Hem Sewing Machine

103

presented in Section 2.2.

Finally, it could also be interesting to have one

robot operating several sewing machines at the same

time. Namely, while one machine is sewing, the dual-

arm can rotate 180º and feed another sewing machine

or the dual-arm can be mounted on a track and feed

several sewing machines.

ACKNOWLEDGEMENTS

This work is co-financed by Component 5 - Capital-

ization and Business Innovation, integrated in the Re-

silience Dimension of the Recovery and Resilience

Plan within the scope of the Recovery and Resilience

Mechanism (MRR) of the European Union (EU),

framed in the Next Generation EU, for the period

2021 - 2026, within project TEXPACT, with reference

61.

The authors would also like to thank Vitor Tavares

Santos (from INESC TEC) for all the high-quality

photos and the edition of the video showcasing the

robotic cell.

REFERENCES

Arai, T., Nakamura, T., and Sato, M. (1989). Auto-

mated sewing with direct drive manipulator. In

IFAC/IFIP/IFORS/IMACS Symposium on Information

Control Problems in Manufacturing Technology, vol-

ume 23, pages 365–370. Elsevier.

Gershon, D. (1990). Parallel process decomposition of a

dynamic manipulation task: Robotic sewing. IEEE

Transactions on Robotics and Automation, 6:357–

367.

Gershon, D. and Porat, I. (1988). Vision servo control of a

robotic sewing system. In IEEE International Con-

ference on Robotics and Automation (ICRA), pages

1830–1835. IEEE.

Grishanov, S. (2011). Structure and properties of textile

materials, pages 28–63. Elsevier.

Koustoumpardis, P. N. and Aspragathos, N. (2014). In-

telligent hierarchical robot control for sewing fab-

rics. Robotics and Computer-Integrated Manufactur-

ing (RCIM), 30:34–46.

Kudo, M., Nasu, Y., Mitobe, K., and Borovac, B. (2000).

Multi-arm robot control system for manipulation of

flexible materials in sewing operation. Mechatronics,

10:371–402.

Misios, I. H., Koustoumpardis, P. N., and Aspragathos, N.

(2019). Gain scheduled pid force control of a robotic

arm for sewing fabrics. In International Conference

on Robotics in Alpe-Adria Danube Region (RAAD),

volume 980, pages 104–114. Springer.

Sanchez, J., Corrales, J. A., Bouzgarrou, B. C., and

Mezouar, Y. (2018). Robotic manipulation and sens-

ing of deformable objects in domestic and indus-

trial applications: a survey. International Journal of

Robotics Research, 37:688–716.

Schrimpf, J. and Mathisen, G. (2016). Differential feed con-

trol applied to corner matching in automated sewing.

In IEEE International Conference on Robotics and

Automation (ICRA), pages 3894–3900. IEEE.

Schrimpf, J. and Wetterwald, L. E. (2012). Experiments to-

wards automated sewing with a multi-robot system. In

IEEE International Conference on Robotics and Au-

tomation (ICRA), pages 5258–5263. IEEE.

Schrimpf, J., Wetterwald, L. E., and Lind, M. (2012). Real-

time system integration in a multi-robot sewing cell.

In IEEE/RSJ International Conference on Intelligent

Robots and Systems (IROS), pages 2724–2729. IEEE.

Shungo, T. and Hisashi, D. (2021). Development of fab-

ric feed mechanism using horizontal articulated dual

manipulator for automated sewing. In IEEE Interna-

tional Conference on Automation Science and Engi-

neering (CASE), volume 2021-August, pages 1832–

1837. IEEE.

Sun, P., Hu, Z., and Pan, J. (2019). A general robotic frame-

work for automated cloth assembly. In IEEE Interna-

tional Conference on Advanced Robotics and Mecha-

tronics (ICARM), pages 47–52. IEEE.

Tang, K., Tokuda, F., Seino, A., Kobayashi, A., Tien, N. C.,

and Kosuge, K. (2024). Time-scaling modeling and

control of robotic sewing system. IEEE/ASME Trans-

actions on Mechatronics, 29:3166–3174.

Tokuda, F., Murakami, R., Seino, A., Kobayashi, A.,

Hayashibe, M., and Kosuge, K. (2024). Fixture-free

2d sewing using a dual-arm manipulator system. IEEE

Transactions on Automation Science and Engineer-

ing, 22:7927–7940.

Triantafyllou, D., Koustoumpardis, P. N., and Aspragathos,

N. (2011). Model reference fuzzy learning force con-

trol for robotized sewing. In Mediterranean Confer-

ence on Control & Automation (MED), pages 1460–

1465. IEEE.

Zacharia, P., Mariolis, I. G., Aspragathos, N., and Der-

matas, E. (2008). Robot-handling fabrics with curved

edges based on visual servoing and polygonal ap-

proximation. Journal of Engineering Manufacture,

222:1263–1274.

Zacharia, P. T. (2010). An adaptive neuro-fuzzy inference

system for robot handling fabrics with curved edges

towards sewing. Journal of Intelligent and Robotic

Systems, 58:193–209.

Zhu, J., Cherubini, A., Dune, C., Navarro-Alarcon, D.,

Alambeigi, F., Berenson, D., Ficuciello, F., Harada,

K., Kober, J., Li, X., Pan, J., Yuan, W., and Gienger,

M. (2022). Challenges and outlook in robotic manip-

ulation of deformable objects. IEEE Robotics and Au-

tomation Magazine, 29:2–12.

ICINCO 2025 - 22nd International Conference on Informatics in Control, Automation and Robotics

104